Chemical, Photochemical Composition, Physical and Sensory Qualities of acha-Guava Flour Blends and Biscuits

Ayo JA* and Johnson RG

Department of Food Science and Technology, Federal University Wukari, Nigeria

Submission: October 03, 2018; Published: December 05, 2018

*Corresponding author: Ayo JA, Department of Food Science and Technology, Federal University Wukari, Wukari, Nigeria.

How to cite this article: Ayo J, Johnson R. Chemical, Photochemical Composition, Physical and Sensory Qualities of acha-Guava Flour Blends and Biscuits. Nutri Food Sci Int J. 2018; 8(1): 555727. DOI: 10.19080/NFSIJ.2018.08.555727.

Abstract

The study investigated the chemical, phytochemical composition, physical and sensory qualities of acha-guava flour blends and biscuit the work was aimed at ameliorating the quality of acha-based biscuits with the addition of guava flour. Flour blends were produced by substituting guava flour into acha flour at 5, 10, 15, 20, and 25%. Proximate composition, pasting properties, functional properties, phytochemical composition, vitamins and mineral of the flour blends were determined. Biscuits were produced from the flour blends and the physical properties and sensory qualities of the biscuits were analyzed. The carbohydrate and protein decreased from 81.60to 77.30 and 8.32to 7.70%, respectively. The moisture content, fat content, fibre and ash content increased from 8.08to 8.44, 1.28 to 2.63, and 0.21to 2.5and 0.20 to 1.62% respectively, with increase in the added guava flour (5-25%). Water absorption, foaming, and swelling capacity of acha flour increased from 2.35to 2.83ml/g, 4.13to 7.65ml/g and 5.75to 7.74ml/g, respectively. Bulk density and oil absorption capacity decreased from .89to .85/cm3 and 2.10 to 1.81ml/g respectively, with increase in the added guava flour (5-25%). The peak viscosity, trough viscosity, breakdown, final viscosity, and setback decreased from 2336.83 to 1107, 1535 to 935, 801 to 172, 3719.8 to 1863, and 2186.0 to 928RVS, respectively, with increase in the percentage guava flour. Iron, carotenoid, vitamin C and total phenol increased from 4.0 to 25.0ppm, 5.36 to 14.17mg/100g, 1.94 to 7.96mg/100g, and 0.22 to 0.86mg/100g respectively, while phosphorus decreased from 1110.10 to 814.3ppm with increase in percentage of added guava flour. There was an increase in break strength and spread ratio ranging from 1.35 to 2.64kg and 4.53 to 5.15 respectively, as a result of the increase in level of guava-flour substitution. The reverse was observed for the thickness, diameter, volume and weight of the biscuit which ranges from .88 to .60cm, 4.34 to 4.13cm, 13.05 to 8.00cm3, and 11.50 to 10.70g respectively. Sensory qualities evaluated were colour, texture, taste, odour, crispiness, and general acceptability with an average mean score ranging from 4.60 to 7.65, 5.50 to 6.85, 6.10 to 7.45, 5.80 to 6.85, 5.55 to 6.85and 6.20 to 7.95. The sample, 95:5% acha-guava blends is the most preferred and acceptable with average mean score of 7.95 and corresponding increment of 0.28, 2.22, 79.38, and 1.3% of ash content, protein, fat and crude fibre respectively.

Keywords: Water absorption; Foaming; acha flour; Peak viscosity; Trough viscosity; Breakdown; Final viscosity

Introduction

Biscuit and Cookies are usually produced from wheat flour and they are the same product since the British call them biscuit while the Americans call them cookies [1,2] identified an increasing tendency among children and adults to move away from traditional eating pattern of three meals a day to eating snacks instead of meal. Biscuits enriched with carrot generally have been found to be rich in carbohydrate and protein; they contain fat (14.10 ± 0.08%), carbohydrate (69.31 ± 0.12%), ash (2.32 ± 0.03%), and protein (8.10 ± 0.01%), fibre (0.93 ± 0.01) and moisture (6.17 ± 0.02) as reported by [3].

Cereal grains like wheat, corn, rice, barley, sorghum, etc. provide 68% of the total world food supplies. Wheat is mainly used as a dietary staple, averaging two-thirds of total consumption [4]. Owing to shortage of wheat, several developing countries have devised programs to assess the feasibility of alternative sources for substituting or blending of wheat flour with other cereals [5].

acha (D. exilis) is of considerable importance in Nigeria where it is commonly eaten, often in preference to other cereals, as many as three times a day as a porridge, couscous or non-alcoholic beverage, valued as a weaning food because of its low bulk and high caloric density with minimal processing requirement, it grows even where rainfall and soil fertility are poor and can be stored in closed containers for many years without need of preservatives [6].

acha contains high water absorption capacity that gives it capacity to be utilized in baked foods. It also contains pentosans which gives it the ability to form gel in the presence of oxidizing agents at room temperature with high residual protein coupled with high levels of Sulphur and hydrophobic amino acid residues which makes it useful in baking [7]. The recent finding of the unique properties of acha flour, particularly in relatively lowering the blood glucose level and which could subsequently reduce the diabetic populace have make researchers to focus on D.exilis [8].

Guava (Psidium guajava) is usually consumed as fresh fruit, being a flavorful and healthy alternative for a snack. It is also served with cream and sugar for dessert or combined with other fruits in cocktails and salads [9]. Guava juice is also very popular, being an excellent juice alternative for infant feeding or may be eaten with salt, pepper, vinegar, soy sauce or may be preserved into jam, butter, marmalades, relishes, and chutneys (Glaucia et al. 2012). Few studies have been conducted on the phytochemistry and total antioxidant capacity of guava, especially processed guava juice or puree. However, it is well documented that guava contains a very high amount of vitamin C, anthocyanin, lycopene, and carotenoids, [10].

The leaves of guava are used traditionally by many people to overcome a wide range of diseases, while the guava fruits are believed to overcome several of problems and a source of antioxidants [11]. Red guava fruit is also believed to help cure dengue hemorrhagic fever (DHF). Guava fruit contains vitamin C, two times higher than other fruits such as orange which makes it an important compound that has an antioxidant activity [12]. Other compounds in guava fruit are carotenoids such as betacarotene, lycopene, and beta-cryptoxanthin, and polyphenols [13]. Lycopene is associated with the prevention of cardiovascular damage due the LDL oxidationas the impact of dyslipidemia [14]. Antioxidant content in guava fruit can be used as a source of natural antioxidants; these include vitamins A, C, and E as well as numerous non-nutritive compounds such as polyphenolics, flavonoids, carotenoids, and thiol-containing compounds. Lycopene content in guava fruit is proven to prevent or delay the oxidative damage of lipids, proteins and nucleic acids caused by reactive oxygen species (ROS) [12].

Resent investigations in relation to the unrealized ability of acha to ameliorate the crises of diabetes and its deficiencies in some nutrient, have called for its fortification to bridge the existing gap. The abundance and perishability of guava with its high nutrient content calls for processing to reduce wastage and could be used as a fortifier or enriched food product with relatively low nutrient.

Fortification of acha biscuits with guava could improve the antioxidant, minerals, vitamin content and add value to the sensory qualities of food products. Also, the use of guava could reduce post-harvest losses, create more market for the raw material and increase the quest for production of nutritious food by food industries. The objective was to determine the chemical, phytochemical composition, physical, and sensory qualities of acha-guava flour blend biscuits.

Materials and Methods

Materials

Cream colored acha grains (D. exilis) purchased from Jos central market in Plateau state, Nigeria while the fresh guava (Psidium guajava (red colored) was obtained from Bayesa, Ussa Local Government, Taraba State, Nigeria. Other ingredients such as baking fat (Simas), baking powder (Omega), and salt (Dangote table salt) were purchased from Wukari New market, Taraba state, Nigeria.

Methods

Preparation of acha flour

acha flour was produced using the method described by Ayo et al. [8]. acha grains were winnowed to remove chaff and dust. Adhering dust and stones were removed by washing in water (sedimentation) using local calabashes and floating foreign materials by decanting. The washed and de-stoned grains were drained and dried in a cabinet drier (Model: CD0005, FT3) at 40°C to a moisture content of about 12%. The dried grains were milled using Attrition milling machine (Inch15HP Super 150-180 Kilogram Tw-HM-1016) and sieved (0.3μm aperture size). The flour was packaged inpolyethylene bag and stored at 5oC as acha flour for later use.

Preparation of guava flour

The procedure as described by Sanjinez-Argandona et al. [15] was modified and used in the preparation of guava flour. Fresh Matured and ripe guava fruit were obtained. Washed, sorted, peeled, sliced and steam blanched (Hughes Blancher Model #:02- 1471) for 3min. The sliced guava fruit were dried at 40°C in oven (San-Del Model 50) and milled using attrition mill (Inch15HP Super 150-180 Kilogram Tw-HM-1016) and sieved (0.3μm aperture size). Packaged in a polyethylene bag and stored (at temperature 5oC).

Formulation of flour blend

The guava flour was mixed with acha flour separately at different proportions (5:95, 10:90, 15:85, 20:80 and 25:75) while one hundred percent (100%) acha flour and wheat was used as the control. The flours were thoroughly mixed using a Kenwood blender to a uniform blend by Ayo & Gidado [3].

Production of acha-gauava composite biscuit

The recipe adopted for the work is shown in Table 1 as described by Ayo & Gidado [3]. The guava powder was substituted into acha flour at 5, 10, 15, 20 and 25% respectively. The sweet potato powder was beaten into the fat until fluffy and acha-guava composite flour and other ingredients were added, while mixing at a medium speed of Kenwood blender. The method described by Ayo & Gidado [3] was used to produce the biscuits.

* Average mean score with the same letter(s) on the same column are not significantly different, p=0.05.

Proximate composition determination

The proximate analysis of samples for moisture content, crude protein, ash, Crude fat, Carbohydrate and crude fiber was carried out on the flour as described by AOAC [16].

Determination of minerals and vitamin

The phosphorous, iron and Vitamin B1 of the acha-guava flour blends were determined as described by AOAC [16] methods while the Vitamin C content was determined by direct calorimetric method as described by Kalia [17].

Determination of phytochemicals

Carotenoids content of the acha-guava flour blends was determined as described by Krishnaiah et al. [18] method, while the total polyphenol was determined by Folin-Ciocalteu’s method using gallic acid as standard as described by Priyanka [19].

Functional properties determination

The functional properties: - bulk density, water absorption capacity, oil absorption capacity, foam capacity and swelling power of the acha–guava flour blends were determined as described by Onwuka [20].

Determination of pasting properties

Pasting properties of the acha-guava composite flour were determined using the Rapid Visco Analyzer (RVA-4, Newport Scientific, Australia and Thermocline for Windows programme).

Determination of physical properties

The breaking weight, volume, break strength and spread ration of acha-guava composite biscuit were determined using the method described by Ayo et al. [8].

Sensory Evaluation

The sensory quality of the acha-guava biscuits was evaluated using twenty untrained panelists, randomly selected from Department of Food Science and Technology Federal University Wukari, Nigeria based on their familiarity with the biscuit. The biscuits, appropriately coded (ACH, RJG, EYM, and AMD) and of the same size and temperature (29 ± 3oC) were placed in white plastic plates separated by compartment and placed in sensory laboratory. The panelists rinsed their mouths with bottled water after tasting each sample and were not allowed to make comment during evaluation to prevent influencing other panelist. A nine-point Hedonic scale with one (1) representing “extremely dislike” and nine (9) “extremely like” was used, presented as a questionnaire. The qualities assessed were color, texture, taste, flavor, crispness and general acceptability as described by Ayo & Gidado [3].

Statistical Analysis

All the analyses were conducted in duplicates in completely randomized design. The data were subjected to analysis of variance using Statistical Package for Social Science (SPSS) software version 23, 2017. Means where significantly different were separated by the least significant difference (LSD) test. Significance was accepted at p<0.05

Results and Discussion

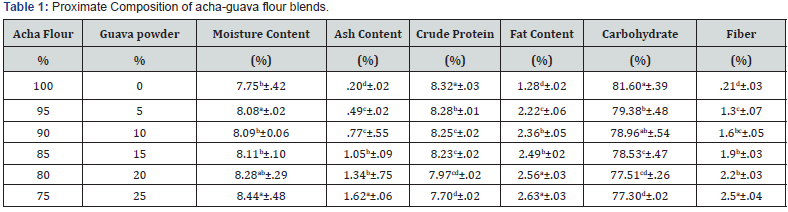

Proximate Composition of acha-guava flour blends

Flours and flour blends were produced from acha and guava flour blend and proximate composition is presented in Table 1. The carbohydrate and protein decreased from 81.60±.39 to 77.30±.02 and 8.32±.03 to 7.70±.02%, respectively. The decrease could be due to poor protein content level in guava flour. The moisture content, fat content, fibre and ash content increased from 8.08±.02 to 8.44±.48, 1.28±.02 to 2.63±.03, and .21±.03 to 2.5±.043 and .20±.02 to 1.62±.06% respectively, with increase (0- 25%). The effect of adding guava to acha are significant, p>0.05. The 75:25% acha-guava samples had the highest value for moisture content, crude fibre, fat and ash, while the 100:0% achaguava samples had the highest value for protein and carbohydrate

The increase in moisture content could be due to the relative increase in the fibre content of the added guava as it is hygroscopic. Fibers have the ability of absorbing moisture. The crude fibre increased with increase in added guava powder. This could be due to the presence of high dietary fibre content in fruits and vegetables [21]. Accurately measuring the fibre content of foods is critical to making a sound benefit claim, whether it is a nutrient claim, structure-function claim, or health claim [22].

Ash content indicates the presence of mineral matter in food. Increase in ash content indicates that samples with high percentage of ash will be good sources of minerals. The carbohydrate decreased with increase in guava powder addition. The results obtained in this study are within the ranges earlier reported for acha [23]. Ayo & Gidado [3] reported similar range for biscuits from acha and carrot flour. Olapade et al. [24] also reported a similar range for biscuits from acha and cowpea flour. The carbohydrate contents of these samples are an indication that the products are good sources of energy.

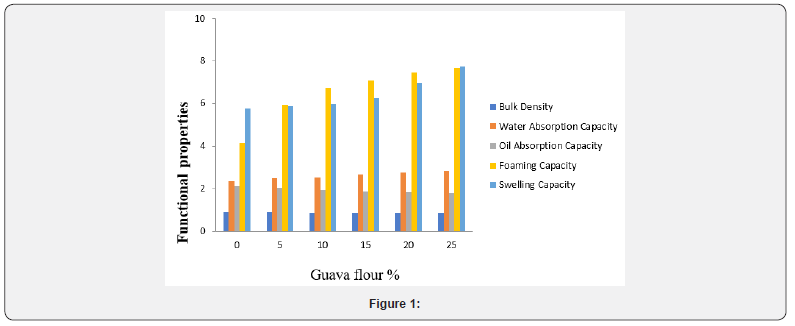

Functional properties of acha-guava flour blends

The result of the functional properties of acha-guava flour blends are shown in Table 2. The effect of added guava flour (0- 25%) on water absorption, foaming, and swelling capacity of acha flour increased from 2.35±.07 to 2.83±.11ml/g, 4.13±.70 to 7.65±.16ml/g and 5.75±.02 to 7.74±.08ml/g, respectively. Bulk density and oil absorption capacity decreased from .89±.01 to .85±.014g/cm3 and 2.10±.141 to 1.81±.01ml/g, respectively (Figure 1). The 75:25% acha-guava samples had the highest value for water absorption, swelling and foaming capacities and lowest value for bulk density and oil absorption capacity. The increase in the WAC could be due to molecular structure of the guava flour [25]. The effect is significant different, p>0.05. Functional properties are the intrinsic physico-chemical properties that reflect complex interaction between the composition, structure, confirmation and physic-chemical properties of protein and other food components and the nature of the environment in which these are associated and measured.

* Average mean score with the same letter(s) on the same column are not significantly different, p=0.05.

High WAC of composite flour suggests the potential of the flours in the formulation of foods such as sausage, dough and bakery products where hydration to improve dough handling is a preferred characteristic. The observed variation could be due to different protein concentration, their degree of interaction with water and conformational characteristics [26]. The increased swelling capacity of flours depends on the particle size, variety and type of processing methods. The results agreed with the reported quality attributes of biscuit from acha (digitariaexilis) flour supplemented with cowpea (vignaunguiculata) flour by Olapade et al. [24].

The decreased OAC of the flour blends upon addition of guava flour might be attributed to the molecular structure of starch which is loosely linked, allowing for more penetration of liquid materials. The blends could also be used in formulations for products such as ground meat, doughnuts and pancakes, where oil absorption is not of paramount importance [27]. The bulk density of flour is measured without the influence of any compression. This revealed that bulk density depends on the particle size and moisture content of flours. The high bulk density of flour could suggest their suitability for use in food preparations. However, low bulk density would be great significance in the preparation of complementary foods [28].

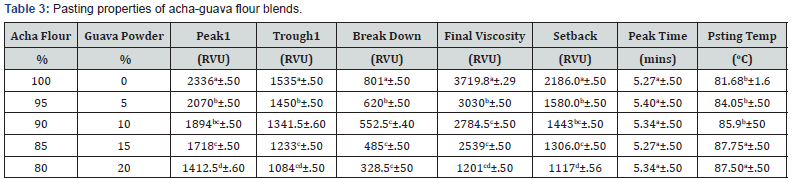

Pasting Properties of acha-guava flour blends

The results of the pasting properties are shown in Table 3. The peak viscosity, trough viscosity, breakdown, final viscosity, and setback decreased from 16.83±.50 to 1107±.50, 1535±.50 to 935±.50, 801±.50 to 172.±.50, 3719.8±.29 to 1863±.50, and 2186.0±.50 to 928.0±.50RVS, respectively, with increase in the percentage guava flour. The effect of adding guava powder are significant, p>0.05, for all the parameters except for peak time. The 100:0% acha-guava Sample had the highest values for all the properties. Pasting properties are dependent on the rigidity of starch granules, with consequent effect on the granule swelling potential and the amount of amylose leaching out in the solution [29]. The high content of starch in the 100:0% acha-guava (control) sample, compared to other samples may contribute to some extent, to the higher pasting viscosity observed which could be the resultant effect of decrease in viscosities with decrease in the acha flour proportion.

* Average mean score with the same letter(s) on the same column are not significantly different, p=0.05.

High values of breakdown associated with high peak viscosities could be related to the degree of swelling of the starch granules during heat treatment. The peak viscosity often correlates with the quality of end-product and also provides an indication of the viscous load likely to be encountered by a mixing cooker (Sanaa and El-Sayed, 2004). The lower setback viscosities of acha starches could make the suitable for preparing gels with tendencies to synereses [30].

Pasting time of fonio grains (acha) reported by Jideani et al. [31] was significantly higher than that obtained in this study which could be due to climatic and soil factors. A higher pasting temperature indicates high water-binding capacity, higher gelatinization tendency and lower swelling property of starchbased flour due to high degree of associative forces between starch granules [32]. Pasting temperature is one of the properties which provide an indication of the minimum temperature required for sample cooking, energy costs involved and another components stability. Therefore, from the results obtained, 100% acha samples could be said to be more sensitive to heat treatment with less energy consumption, thereby saving time and cost. Ayo & Gidado [3] reported a similar range for pasting properties of acha-carrot biscuits.

Minerals, vitamins and phytochemical composition of acha-guava flour blends

The results minerals, vitamins and phytochemical composition of acha-guava flour blends shown are shown in Table 4. Iron, carotenoid, vitamin C and total phenol increased from 4.0±.50 to 25.0±.50ppm, 5.36±.04 to 14.17±.06mg/100g, 1.94±.05 to 7.96±.02mg/100g, and .22±.03 to .86±.02mg/100g respectively, while phosphorus decreased from 1110.10±.50 to 814.3±.50ppm with increase in percentage of added guava flour. The effect of adding guava to acha flour are significant, p>0.05 on the vitamin C and phosphorous content. The 75:25% acha-guava samples had the highest value for iron, carotenoid, vitamin C and total phenol. Iron and vitamins (vitamin C and B1) increased as the levels of substitution of guava flour with acha increased (5-25%). The findings agreed with that of Ayo et al. (2010) and Igbabul et al. (2014). Carotenoids are abundant in the red, yellow, orange, and green colored vegetables and fruits. They are, after chlorophyll, the second most widely occurring plant pigment found in nature (MacDougall 2002). The high degree of hydration and long carbon chain length of these molecules makes them hydrophobic and therefore fat-soluble molecules. The major purpose of carotenoids in the human diet is to serve as precursors to pro-vitamin A, a required nutrient for humans (MacDougall 2002).

* Average mean score with the same letter(s) on the same column are not significantly different, P=0.05.

The vitamin C is one of the most abundant antioxidants consumed, with fruits being the main source of the nutrient. Because L-ascorbic acid is an excellent reducing agent and is abundant in nature, it may help stabilize phenolics and other antioxidants during processing by the donation of hydrogen atoms. These compounds could also impart color, astringency, and bitterness and possible nutritional properties [33].

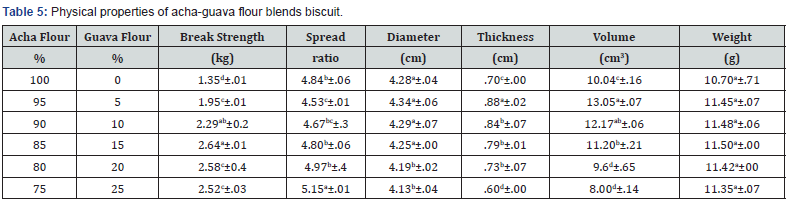

Physical composition of acha-guava blend biscuits

The physical properties of the acha-guava flour blend biscuits are shown in Table 5. There was an increase in break strength and spread ratio ranging from 1.35±.01 to 2.64±.01kg and 4.53±.01 to 5.15±.01, respectively, as a result of the increase in level of guavaflour substitution. The reverse was observed for the thickness, diameter, volume and weight of a piece of biscuit which ranges from .88±.02-.60±.00cm, 4.34±.0-4.13±.04cm, 13.05a±.07-8.00±.14cm3, and 11.50±.00 - 10.70±.71g respectively. The 85:15% acha-guava samples had the highest breaking strength and weight, 75:25% had lower values in volume, thickness and diameter, and 95:5% samples had the highest in diameter, thickness and volume respectively. The effect of adding guava powder are significant, p>0.05, for weight. The increased spread ratio observed in guavaflour substituted biscuit samples could be due to the difference in the particle sizes and characteristics of the constituent flours of guava and acha (Agu et al, 2007). Joel et al. [34]and Olapade et al. [24] reported similar trend in biscuits from wheat and full fat soya and biscuit from acha flour supplemented with cowpea flour. The spread ratio could be an indicator of biscuit quality.

* Average mean score with the same letter(s) on the same column are not significantly different, p=0.05.

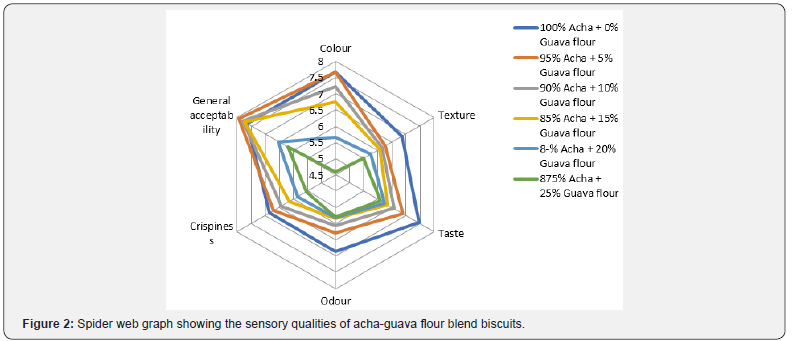

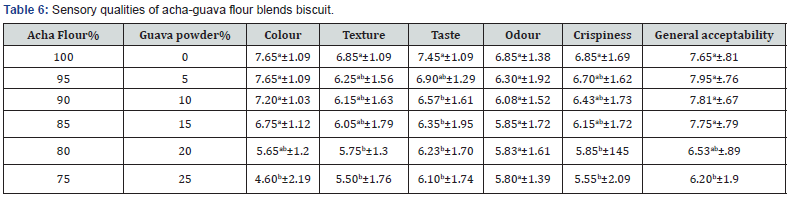

Sensory evaluation of acha-guava flour blend biscuits

The sensory qualities evaluated are presented in Table 6 The result showed that the average mean score for colour, texture, taste, odour, crispiness, and general acceptability ranged from 4.60±2.19-7.65±1.09, 5.50±1.76-6.85±1.09, 6.10±1.74- 7.45±1.09,5.80±1.39-6.85±1.38, 5.55±2.09-6.85±1.69 and 6.20±1.9-7.95a±.76. The effect of guava was significant, p>0.05, for colour, texture, taste, crispiness and general acceptability. The relative increase in the average mean scores for texture could be due to the increasing fibre content of the guava with effect on the crispiness of the biscuit. The value for odour of the biscuits was not significantly different (p˂0.05) from each other. The sample, 95:5 % acha-guava blends is the most preferred and acceptable with average mean score of 7.95±.76. This effect on the sensory could be due to inherent flavor compounds in guava. Ayo & Gidado [3] reported a similar range for sensory qualities of acha-carrot biscuits and Dabels et al. [35] also reported similar range of wheat, acha and mung bean composite biscuit (Figure 2).

* Average mean score with the same letter(s) on the same column are not significantly different, p=0.05.

Conclusion

In conclusion, enriched biscuit with guava-flour substitutions were found to be nutritionally superior in fat content, fibre, iron, carotenoid total phenol, vitamin C and B1 respectively. The sample with 5% guava flour was most preferred corresponding relatively high improvement in the ash, fat, fibre, iron, carotenoid, vitamin C, total phenol and vitamin B1 content of the acha based biscuits. The appearance and crispiness of the acha-guava biscuit were greatly improved and acceptable.

The use of acha-guava flour blends in biscuits will go a long way in enhancing nutrition, health and wellbeing of the consumers and reduce the dependence on wheat flour. The properties of acha-guava could also make it a good candidate for use as edible blend and as raw material for several domestic and industrial purposes and in medical sector, acha could recommended as a dietary supplement for diabetic patients due to its high fibre content minerals and vitamins as result of added guava flour.

References

- Ishinwu CN (2005) Qualities of cookies produced by partial replacement of wheat with plaintain (Musa paradisca) flour. Nigerian Journal of Nutritional Science 26(2): 23-25.

- Anyika JU, Uwaegbute AC (2005) Frequency of consumption and nutrient content of some snacks eaten by adolescent female secondary and university students in Abiastate. Nigerian Journal of Nutritional Science 26(2): 10-15.

- Ayo JA, Gidado FE (2018). Physicochemical, Phytochemical and Sensory Evaluation of acha-Carrot Blend Biscuit. Current Journal of Applied Science 25(5): 1-15.

- Anjum FM, Butt MS, Ahmad N, Ahmad I (2002) Phytate and mineral content indifferent milling fractions of some Pakistani spring wheats. Int J Food Sci Technol 37(1): 13-17.

- Abder Kader ZM (2000). Enrichment of Egyptian “Balady” bread. part 1 Baking Studies, physical and sensory evaluation of enrichment with decorticated crackedbroadbean flour (Viciafaba L.). Nahrung 44 (6): 418-421.

- Chukwu O, Abdul kadir AJ (2008) Proximate Chemical Composition of acha (Digitaria exilis and Digitaria iburua) Grains. Journal of Food Technology 6(5): 214-216.

- Ayo JA, Andrew E (2016) Effect of added Bambara groundnut on the quality of acha-date palm based biscuit. International Journal of Biotechnology and Food Science 4(3): 34-38.

- Ayo JA, Ayo VA, Nkama I, Adewori R (2007) Physicochemical, invitro digestibility and organoleptic evaluation of acha-wheat biscuit supplemented with soybean flour. Nigerian Food Journal 25(1): 77-79.

- Azzolini M, Jacomino PA, Bron IU (2004) Indices to evaluate postharvest quality of guavas under different maturation stages. Pesquisa Agropecuaria Bras 39(2): 139-145.

- Jimenez-Escrig A, Rincon M, Pulido R, Saura-Calixto F (2001) Guava fruit (Psidium guajava L.) as a new source of antioxidant dietary fiber. J Agric Food Chem 49(11): 5489-5493.

- Barbalho SM, Farinazzi-Machado FMV, de Alvares Goulart R, Brunnati ACS, Ottoboni AMMB et al. (2012) Psidium guajava (Guava): A Plant of Multipurpose Medicinal Applications. Journal of Med Aromat Plants 1(4): 1-6.

- Lim Yau Yana , Lim Theng Teng, Tee Jing Jhi (2006) Antioxidant Properties of Guava Fruit: Comparison with Some Local Fruits. Sunway Academic Journal 3: 9-20.

- Nascimento RJ, Araújo CR, Melo EA (2010) Antioxidant from agriindustrial wastes of the guava fruits (Psidium guajava L). Alim Nutr 21(2): 209-216.

- Sesso HD, Wang L, Ridker PM, Buring JE (2012) Tomato-based food products are related to clinically modest improvements in selected coronary biomarkers in women. J Nutr 142(2): 326-333.

- Argandona EJS, Cunha RL, Menegalli FC, Hubinger MD (2005) Evaluation of total carotenoids and ascorbic acid in osmotic pretreated guavas during convective drying. Italian Journal of Food Science 17(3): 305-314.

- AOAC (2012) Official Method of Analysis of the AOAC. In: Horwitc W (ed.), Association of Offical Analytical Chemists. (16th Edn), Washington DC, USA.

- Kalia M (2002) Food Analysis and Quality Control. Kalyani Publications, New Delhi, India, p.167

- Krishnaiah D, Devi T, Bono A, Sarbatly R (2009) Studies on phytochemical constituents of six Malaysian medicinal plants. Journal of Medicinal Plant resources 3(2): 67-72.

- Priyanka Patel, Kayla Ellis, Rajitha Sunkara, Loius Shackelford, Simon Ogutu, et al. (2016) Development of a Functional Food Product Using Guavas. Journal of Food and Nutrition Sciences 7(10): 927-937

- Onwuka GI (2005) Food Analysis and Instrumentation: Theory and Practice. Naphathali Prints, Nigeria, pp. 95-96.

- Villanueva-Suárez MJ, Redondo-Cuenca A, Rodríguez-Sevilla MD, de las Heras Martínez M (2003) Charaterisation of non-starch polysaccharides content from different edible organs of some vegetables, determined by GC and HPLC: Comparative study. J Agric Food Chem 51(20): 5990-5995.

- Mermelstein NH (2009) Laboratory: Analyzing for resistant starch. Journal of Food Technology 63(4): 80-84.

- McWatters KH, Phillips RD, Walker SL, Mccullongh SE, Mensa-Wilmot Y, et al. (2004) Baking performance and consumer acceptability of rew and extruded cowpea flour breads. Journal of Food Quality 27(5): 337- 351.

- Olapade AA, Akingbala JO, Oguntunde AO, Falade KO (2011) Effect of processing method on the quality of cowpea (Vigna unguiculata) flour for akara preparation. Plant Food for Human Nutrition 58(3): 1-10.

- Kaushal P, Kumar V, Sharma HK (2012) Comparative study of physicochemical, functional, anti-nutritional and pasting properties of taro (Colocasia esculenta), rice (oryza sativa), pegeon pea (cajanus cajan) flour and their blends. LWT- Food Science and Technology, p. 10.

- Butt MS, Batool R (2010) Nutritonal and Functional properties ofsome proising legumes proteins isolate. Pakistan J Nutr 9(4): 373-379

- Abulude FO (2005) Distribution of selected minerals in some Nigerian white bread. Nig Food Journal 23: 139-147.

- Akpata MI, Akubor PI (1999) Chemical composition and selected functional properties of sweet Orange (citrus sinensis) seed flour. Plant Foods Hum Nutr 54(4): 353-362.

- Morris VJ (1990) Starch gelation and retrogradation. Trends in Food Science and Technology 1: 2-6.

- Jideani IA, Akingbala JO (1993) Some physiochemical properies of acha (Digitaria exilis Staph) and iburu (Digitaria iburua Staph) grains. Journal of Sciences and Food Agriculture 63(3): 369-371.

- Jideani IA, Takeda Y, Hizukuri S (1996) Structures and physicochemical properties of starches from acha (Digitaria exilis), Iburu (Digitaria iburua), and Tamba (Eleusine coracana). Cereal Chemistry 73: 677-685.

- Adebowale AA, Sanni SA,Oladapo FO (2008) Chemical, functional and sensory properties of instant yam-Breadfruit flour. Nigerian Food Journal 26(1): 2-12.

- Uddin MS, Hawlader MNA, Luo D, Mujumdar AS (2002) Degradation of ascorbic acid in dried guava during storage. J Food Engineering 51(1): 21-26.

- Joel Ndife, Fatima Kida, Stephen Fagbemi (2014) Production and quality assessment of enriched cookies from whole wheat and full fat soya European Journal of Food Science and Technology 2(1): 19-28.

- Nanyen D, Dooshima IB, Julius A, Benbella I (2016) Nutritional Composition, Physical and Sensory Properties of Cookies from Wheat, acha and Mung Bean Composite Flours. International Journal of Nutrition and Food Sciences 5(6): 401-406.