Sensory Attributes Improvement of Coconut Milk Powder by Employing Mid-Infrared Wave

Umakanthan T1*, Madhu Mathi2 and Umadevi U3

1Veterinary hospital, GokulamAnnadhanamTemple Complex, Plot no.: 1684, Meenavilakku-Meenakshipuram Road, Anaikaraipatty Post, BodinayakanurTaluk, TheniDt, Tamil Nadu, India - 625582

2Veterinary hospital, VadakupudhuPalayam, Erode Dt, Tamil Nadu, India - 638152

3Assistant Professor, Department of Botany, The Standard Fireworks Rajaratnam College for Women, Sivakasi, Virudhunagar (Dt), Tamil Nadu, India

Submission: January 01, 2024; Published: January 18, 2024

*Corresponding author: Umakanthan T, Veterinary hospital, Tamil Nadu, India

How to cite this article:Umakanthan T, Madhu M, Umadevi U. Sensory Attributes Improvement of Coconut Milk Powder by Employing Mid-Infrared Wave. Nutri Food Sci Int J. 2024. 12(5):555846. DOI: 10.19080/NFSIJ.2024.12.555846.

Abstract

Coconut (Cocoa nusefera) is commonly used in cooking and the food industry. Coconut milk powder is dehydrated coconut cream and possesses unique aroma and taste. Enhancing the sensory attributes could greatly impact marketing and pricing. Currently there is no method of enhancement of sensory attributes. In this research, we enhanced the sensory attributes by irradiating the coconut powder with 2-6μm mid-infrared rays emitted by our recently invented 2-6μm mid-infrared generating atomizer – MIRGA. This is a safe and economical process. This method of irradiation resulted in concurrent enhancement of sensory attributes and chemical and structural changes.

Keywords:MIRGA; 2-6μm Mid-IR; Coconut milk powder; Irradiation; Sensory attributes; Enhancement; Safe; Economy

Introduction

Coconut milk is the extraction from grated pulp coconut [1 and is extensively used [2], whereas Coconut milk powder is manufactured through the spray drying of coconut cream. Coconut milk powder is reconstituted with or without water and used in recipes [3] for its peculiar flavour and aroma. It is popular in Southeast Asian, Oceania, South Asian, and East African cuisines, where it is used to produce a variety of beverages such as chilled coconut milk drinks and hot drinks. The consumption of coconut milk products has been associated with health benefits such as lowering blood pressure, cholesterol, improving kidney health, and preventing heart attacks and strokes. The demand for coconut milk products has been increasing, especially in India, where consumers are willing to pay more for products with health benefits. Some leading producers are making organic, vegan, and gluten-free coconut milk to cater to this demand. Coconut milk powder can be used to make mousse, mousse cakes, sliced cakes, Swiss rolls, other sweet treats [4,5,6], and used as a medicine [7]. Coconut milk powder makes cooking easier instead of extracting from the grated coconut pulp. Enhancement of taste and aroma of coconut milk powder are important, because of added value, increase purchase and provide more sense gratification to consumers. Here, we employed the biologically safe 2-6 μm mid-IR [8] to enhance the sensory qualities of coconut milk powder. The results obtained from different laboratory analysis with sensory attribute tests are presented here.

Material

MIRGA (patent no.:401387) utilizes a 20 ml capacity polypropylene plastic atomizer containing inorganic (molar mass 118.44 gm/mole) water-based solution having approximately two sextillion cations and three sextillion anions. The dimension is 86 x 55 x 11 mm, with an orifice diameter 0.375 mm, ejection volume 0.062 + 0.005 ml, ejection time 0.2 sec and average pressure 3900 pascal and cone liquid back pressure 2000 N/m2.During spraying, approximately 1 μg of water lost as mist. The non-volatile material in the sprayed liquid is 153 mg/ml. Every time spraying emits 0.06ml which contains approximately seven quintillion cations and eleven quintillion anions.Depending on pressure (vary with the user) applied to plunger, every spraying isdesigned to generate 2-6µm mid-infrared(estimated by FTIR (retro-reflector) interferometer instrument (Detector type D* [cm HZ1/2 - 1] MCT [2-TE cooled]) at Light wind, Petaluma, California [9-12]. The MIRGA spraying is done from 0.25 to 0.50 meter towards any type of packaged (polythene) coconut powder. The distance is essential for the MIRGA sprayed solution to form ion clouds, oscillation and 2-6µm mid-IR generation (refer Discussion). The 2-6µm mid-IR can penetrate the intervening packaging material and act on the inside coconut milk powder. Close spraying does not generate energy. MIRGA is used like a body spray externally over packaged/ unpackaged coconut milk powder. The inorganic compounds used in the generation of MIR are a perspective for biomedical applications [13,14]. It is also a new synthesis method for preparation of functional material (2-6 µm mid-IR) [15,16]. It is well known that the combination of different compounds, which have excellent electronic properties, leads to new composite materials, which is earning a great technological interest in recent years [17,18]. We used a sensory expert panel (n=6) comprised of condiment industry and consumer panel to examine palatability. Different brands of coconut milk powder purchased from the local market were tested.

Method

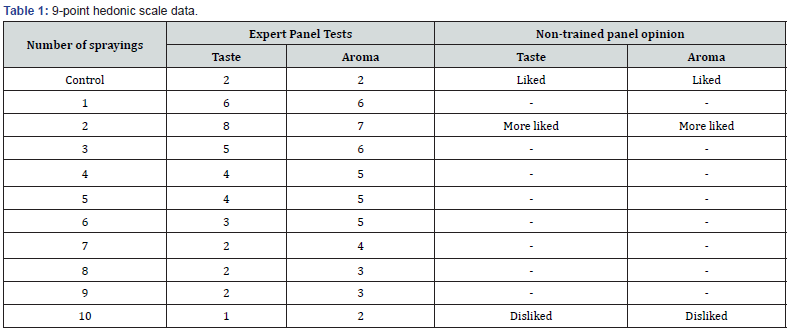

From a bag containing 1000 gm of coconut milk powder,90 gm samples were taken and repackaged into each of 11 polythene bags (>51 micron). The package was sealed with cellophane tape leaving a small vent for sample collection during the trial. A bag marked ‘C’, control bag (non-sprayed), a sample was taken and subjected to sensory evaluation. The remaining 10 packets were numbered from 1 to 10. They were given individually 1-10 sprayings corresponding to the number (1-10) from 0.25-0.50 meter towards the packet. A sample was taken from each packet and individually subjected to sensory evaluation. The acceptability index used was a hedonic scale with a 9-point nominal structure 1 - Dislike extremely, 2 - Dislike very much, 3 - Dislike moderately, 4 - Dislike slightly, 5 - Neither like nor dislike, 6 - Like slightly, 7 - Like moderately, 8 - Like very much, 9 - Like extremely [19,20]. The reason for 10 sprays is that naturally extra energy (mid-IR) input into food should denature it. We irradiated the coconut milk powder’s nature was almost or completely lost. For every trial/ individual brand/ batch used, samples were not mixed. Control, 2 sprayed (sensory attributes enhanced) and 10 sprayed (sensory attributes decreased) samples were used for instrumentations.

i) The instruments used to determine: Chemical compound transformation - Gas chromatography mass spectrometry (GC-MS): Agilent technologies, 7820 GC system, 5977E MSD, Colomn DB-5, Over temp 100-2700C, Detector MS, Flow rate 1.2, Carrier gas Helium Chemical bond changes - Fourier-transform infrared spectroscopy (FTIR): Make: JASCO, Model: FTIR/4200. Resolution: 2 cm-1. Scan: 60 sec. Range: 400-4000 Cm-1. Software: JASCO Spectra Manager for spectra Analysis.

ii) Structural changes - Powder x-ray diffraction (PXRD): Make: Rigaku Model: (Ultimata IV). CuKα anode; λ = 1.541 Ao). Each sample was consolidated in an Quartz glass holder and scanned at 40kV and 30mA from 5 o to 50 2θ values using a scanning period of 2 deg/min and a step size of 0.02. The powder diffraction patterns were analyzed using PXDL software and plotted using OriginPro 7.5.

iii) Nuclear resonances - Proton nuclear magnetic resonance (1H-NMR): The experiments were done on a 600 MHz NMR spectrometer (ECZR Series, JEOL, Japan) using a 3.2mm CPMAS probe at 150MHz frequency. All the samples were run at 18KHz spinning speed at Room Temp and with a delay of 5sec.

iv) Configuration - Transmission electron microscopy (TEM): FEI Technai Spirit G2, HT 120KV, Electron source LaB6, Netherlands.

Results

From Table 1, it is observed that control had regular taste and aroma; 2 sprayed sample had acquired a sweetness and an enhanced taste and aroma; and 10 sprayed had lost taste and aroma. These sensory attribute changes were perceived in 1-5 minutes after spraying.

Instrumentation results (raw data in Supplementary file Data D1)

The control, 2 sprayed and 10 sprayed samples used for instrumentation were from the same source, the difference among them is only in the number of sprayings given.

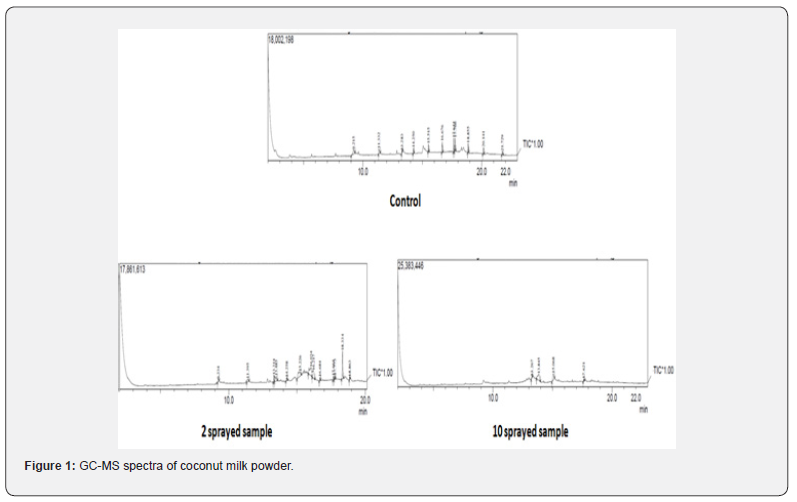

GC-MS

In 2 sprayed samples, relative to the control, there are additional peaks at ~16 min, ~16.2 min, ~17.77 min, and ~18.3 min, and here are peaks missing at ~20.1 min and ~21.7 min. These additional peaks in the 2 sprayed sample are attributed to sugar molecules and the compounds above giving the sample a sweeter and nutter flavor. In 10 sprayed samples, compared to control, there are high intensity additional peaks at 13.845 min and 15.068 min. The relative area ratio of the peaks at 13.267 min and 17.621 min is 0.78, whereas the peak area ratio of control is 0.21. There are many peaks missing when compared to the control and this indicates most of the sugar and flavor compounds have been removed after 10 spraying (Figure 1) (detailed GCMS interpretation in Supplementary file Text T1).

FTIR

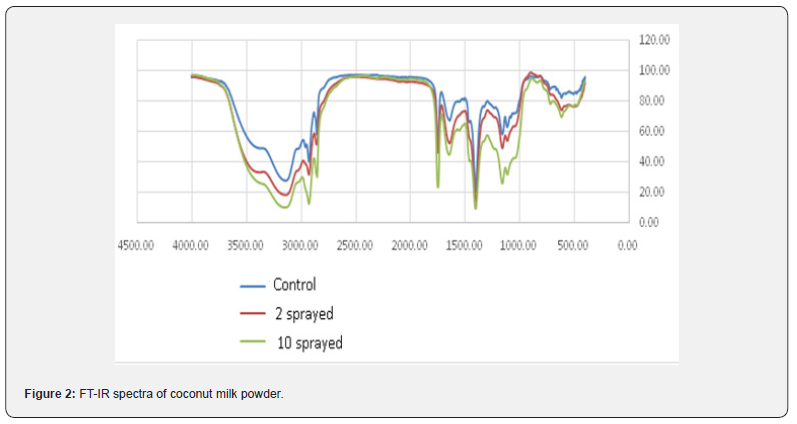

Peak 3384 cm-1 is responsible for the presence of the O-H here we can determine it as part of water peak. Compared to control, in 2 sprayed sample square of this peak is bigger by 59%. In 10 sprayed sample square of this peak is bigger by 85%. Peak 3146 cm-1 is responsible for the presence of the O-H, here we can determine it as characteristic peak of carbohydrates. Compared to control, in 2 sprayed sample square of this peak is bigger by 39%. In 10 sprayed sample square of this peak is bigger by 90%. Peak 2926 cm-1 is responsible for the presence of the C-H and is characteristic of carbon chain. Compared to control, in 2 sprayed sample square of this peak is bigger by 42%. In 10 sprayed sample square of this peak is bigger by 142%. Peak 2854 cm-1 is responsible for the presence of the C-H and is characteristic of carbon chain. Compared to control, in 2 sprayed sample square of this peak is bigger by 57%. In 10 sprayed sample square of this peak is bigger by 171%. Peak 1746 cm-1 is responsible for the presence of the C=0 here we can determine it as part of lipids. Compared to control, in 2 sprayed sample square of this peak is bigger by 15%. In 10 sprayed sample square of this peak is bigger by 148%. Peak 1645 cm-1 is responsible for the presence of the N-H here we can determine it as part of proteins.

Compared to control, in 2 sprayed sample square of this peak is bigger by 68%. In 10 sprayed sample square of this peak is bigger by 82%. Peak 1403 cm-1 is responsible for the presence of the CH2 group near C=O group here we can determine it as part of lipids. Compared to control, in 2 sprayed sample square of this peak is bigger by 42%. In 10 sprayed sample square of this peak is bigger by 73%. Peak 1156 cm-1 is responsible for the presence of the C-O group here we can determine it as part of carbohydrates. Compared to control, in 2 sprayed sample square of this peak is smaller by 37%. In 10 sprayed sample square of this peak is bigger by 170%. Peak 1109 cm-1 is responsible for the presence of the C-O group here we can determine it as part of carbohydrates. Compared to control, in 2 sprayed sample square of this peak is bigger by 48%. In 10 sprayed sample square of this peak is bigger by 74%, (Figure 2). Area of the peaks increases in 2 sprayed and 10 sprayed samples. 2 sprays caused an increase in protein and fat, while 10 sprays reduced the number of proteins and OH groups.

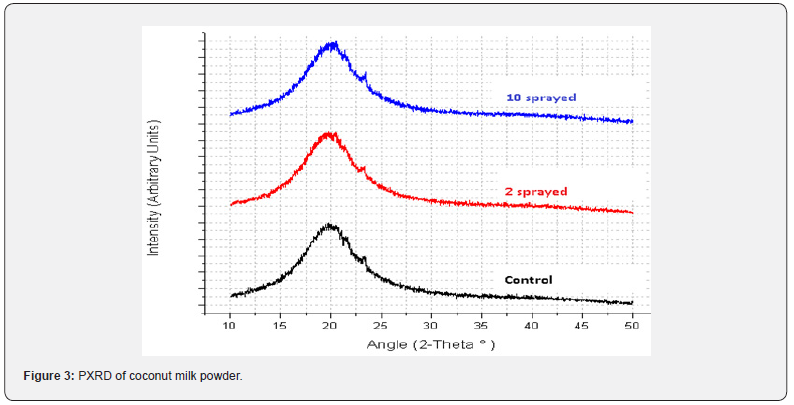

PXRD

Control: One broad peak is observed between 10.0o and 30.0o, with noticeable minor peak observed at 2q= 23.32o. Broad diffraction peak implies that X-rays were scattered in many directions.2 sprayed sample:One broad peak is observed between 10.0o and 30.0o, with noticeable minor peak observed at 2q= 23.32o. Broad diffraction peak implies that X-rays were scattered in many directions.10 sprayed sample: One broad peak is observed between 10.0o and 30.0o, with noticeable minor peak observed at 2q= 23.42o. Broad diffraction peak implies that X-rays were scattered in many directions (Figure 3). The XRD signals of the samples contain a large amount of noise. This behavior indicates amorphous phase. As discussed in Rosa et al., [21], this characteristic is attributed to the high lignin content of coconut. The XRD patterns of the control and the sprayed samples are relatively like each other. With this, it can be inferred that the sprayings retained the initial amorphous state of the coconut powder samples. Intensity of the XRD spectrum increases as spraying increases. Generally, peak intensity variations can be accounted for on crystallite sizes and non-random crystallite orientations.

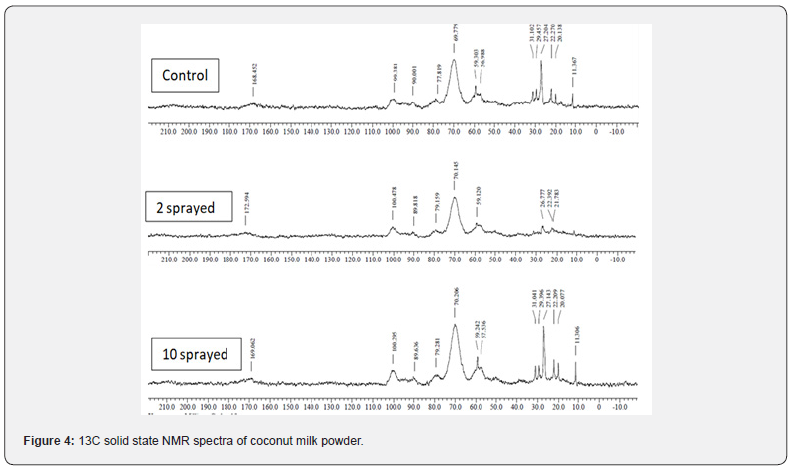

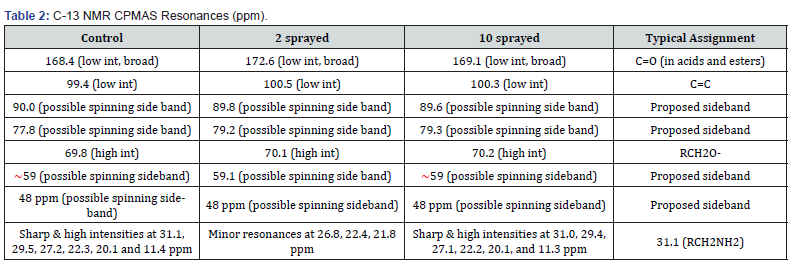

13C solid state NMR

The NMR spectrum of control samples shows resonances that suggest the presence of C=O, C=C, RCH2O-, RCH2NH2, R3CH, and RCH3 functional groups which is generally consistent with the reported chemical composition of flavors in coconut. Whereas 2 sprayed samples is lacking resonances at 31.1 ppm, 29.5 ppm, 27.2 ppm, 20.1 ppm and 11.4 ppm, and there are additional resonances at 26.2 ppm and 21.8 ppm. These differences are due to the change in the lactone, pyrazine, furan, and pyrrole content which give rise to a sweet and nutty flavor in 2 sprayed samples. But 10 sprayed samples show resonances at ~100 ppm and ~59 ppm which appear to be of slightly higher intensity relative to the control and these apparent differences are related to the tastelessness of this sample (Figure 4) (Table 2).

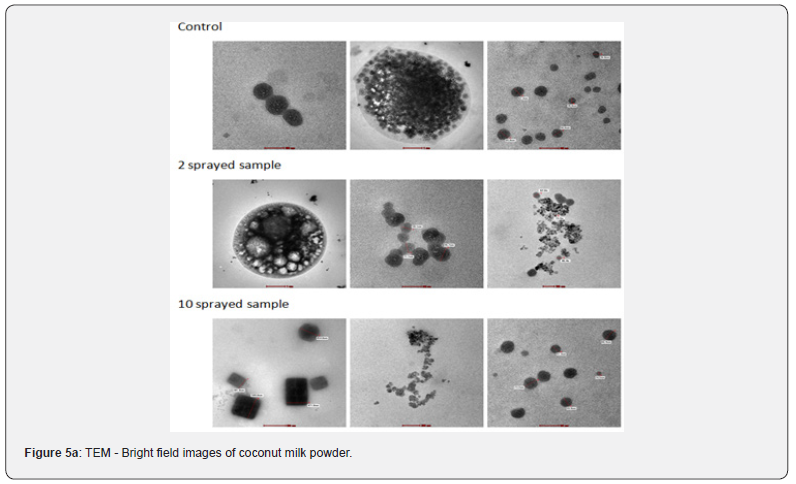

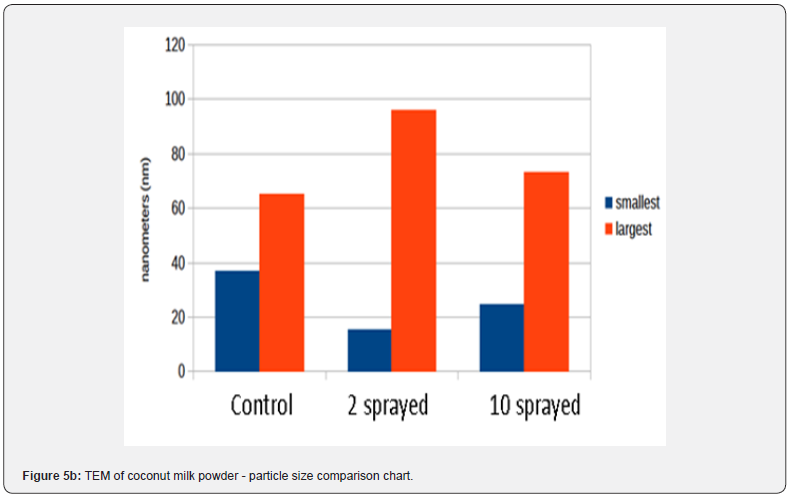

TEM of coconut milk powder samples

Control sample shows spherical particles within a larger circular morphology of about 3 microns in diameter. The smallest apparent spherical particle is about 37 nm and the largest about 65 nm. 2 sprayed samples reveal a morphology of about 3 microns in diameter containing smaller particles of varying sizes. The smallest apparent size is about 15 nm while the largest is about 96 nm. These changes in particle size imply changes to the sample that result in the enhanced taste and aroma compared to the control. In 10 sprayed samples, the TEM images are distinct from the control. There are rectangular particles whose sizes range from about 300 nm to 590 nm (0.3 microns to 0.59 microns). The smaller spherical particle sizes range from about 24 nm to 73 nm. The distinct changes in the larger particles (rectangular vs spherical) may indicate a change associated with the reduced taste and aroma of 10 sprayed sample (Figure 5a & 5b).

Discussion

The sensory attribute research on coconut milk powder is yet to be developed. The tempering process also affects the sensory characteristic of the milk powder, making the consumer’s acceptance questionable [22]. From reviewed literature, it seems that malliard reaction/ caramelization process were not tried to increase the flavor of coconut milk powder. Until an invention is made, MIRGA is placed in literature as an economical, rapid, easy and eco-friendly technology. The presented interpretations demonstrated the various changes occurred in molecular level caused by MIRGA generated 2-6µm mid-IR. Invention background, definition, technique of mid-IR generation from MIRGA, toxicological study on MIRGA, safety of the MIRGA sprayed usables and primeval and future scope of MIRGA have been described by Umakanthan et al., [19] and Umakanthan et al., [20] (detailed discussion on MIRGA available in supplementary text).

Action of MIRGA emitted 2-6 µm mid IR on the target substances.

While spraying MIRGA, most of the mid-IR energy scatters through the air and gets absorbed by receptors (edibles or usables) molecules. Virtually all organic compounds absorb mid-IR radiation which causes a change in molecule’s vibrational state to move from the lower ground state to excited higher energy state [23]. This leads to changes in chemical bonds [24,25] and these bond parameter changes led to consequent changes in target’s physical and chemical characters, configuration, compound transformation depending on the dose of energy applied [26-29]. Nanostructured water layers can be triggered upon application of mid-IR radiation, since water molecules absorb in this region [30]. Coconut milk powder constituents are carbohydrates, protein, lipids, water, etc. The applied mid-IR is absorbed by the nano-structured water molecules [30,31], which cause a change in the vibrational modes viz., chemical bonds and new molecule occurrence [24,32,33], including changes in configuration. The stereochemical configuration changes directly influence the taste [34]. Moreover, chemical bond changes always alter the physical and chemical characters [28,29] in terms of improved taste, aroma, protein and lipid of coconut milk powder. Depending on the number of MIRGA spraying (energy given), a receptor’s chemical bond configurations and subsequent physical and chemical characters can be altered to our desire. As displayed in the results, 2-6 µm MIR generated from the MIRGA equipment caused chemical and molecular level changes in the coconut milk powder components. Similar favorable results were obtained by spraying MIRGA in coffee, tea, cocoa, edible salts and terminaliaby Umakanthan et al. [9]; Umakanthan et al., [10]; Umakanthan et al., [11]; Umakanthan et al., [12].

Safety of MIRGA sprayed usables

In our nearly two-decades of research, we observed MIRGA induced bond altered target substances had not shown any adverse reaction upon consumption/use. As a comparison, to assure the safety of the bond altered targets’ millennium long consumption by human/ living kinds; we submit that in nature, (A) Stereochemical configuration has great influence on taste [34] e.g. variety of mango, grapes, rice, etc., (B) Cooking and digestive enzymes break chemical bonds thereby soften our edibles. And, as an example; raw rice on water-boiling to boiled rice; rice on raw heat to puffed rice; rice on boiling and drying to flat rice; rice on pressure to rice flour [35,36], each by-product has its unique aroma, taste, texture and shelf life but with same molecular formula C6H10O5), (C) In food industry, sensory attributes and shelf-life are enhanced by altering the food’s chemical bonds using various irradiation processes like, radappertization, radicidation, raduriaztion [37], (D) On heating, ice to water to steam and vice versa manifestations are due to changes in the hydrogen bonding, where steam has negligible hydrogen bonding [38] but the chemical composition (H2O) remains the same [39]. Field studies also showed that, MIRGA spray is eco-friendly, non-toxic, non-irritant to soft tissues such as cornea, safe to infants even if sprayed directly, needs no skill but easy to handle (like perfume body spray), and highly economical (USD 0.30 per MIRGA unit which emits 300 sprayings).

Conclusion

In this research we irradiated the coconut milk powder with 2-6µm mid-infrared. The irradiation has enhanced the nutritive value and the taste and aroma. This research can be applied to other edible powders to enhance their inherent attributes.

Competing interest

In accordance with the journal’s policy and our ethical obligation as researchers, we submit that the authors Dr. Umakanthan and Dr. Madhu Mathi are the inventors and patentee of Indian patent for MIRGA (under-patent no.: 401387) which is a major material employed in this study.

Data and materials availability

All data is available in the manuscript and supplementary materials.

Funding

The authors received no specific funding for this research.

References

- Philippines Coconut Authority (2014) Coconut Processing Technologies: Coconut Milk. FPDD guide No.2 - Services of 2014. Department of Agriculture Republic of the Philippines.

- Yusof N, Ramli RAA, Ali F (2007) Chemical, sensory and microbiological changes of gamma irradiated coconut cream powder. Radiation Phys Chem 76(11-12): 1882-1884.

- Tangsuphoom N, Coupland JN (2005) Effect of heating and homogenization on stability of coconut milk emulsion. J Food Sci 70(8): 466-470.

- Sanuki A, Takatoya Haruki, Ori Kensuke (2020) Coconut milk powder, method for producing same, and food product.

- Habeych N, Edwin A, Galaffu N, Chuat J, Gaddipati S (2020) Coconut milk powder.

- Poornima Singh S, Dubey RK (2022) Coconut Milk Benefit Human Body. International journal of advances in agricultural science and technology.

- Amarasiri WA, Dissanayake AS (2006) Coconut fats. Ceylon Med J 51(2): 47-51.

- Pereira MF, Shulika O (2011) Terahertz and Mid Infrared Radiation: Generation, Detection and Applications. Springer Science + Business Media BV, The Netherlands.

- Umakanthan, Mathi M (2022a) Decaffeination and improvement of taste, flavor and health safety of coffee and tea using mid-infrared wavelength rays. Heliyon 8(11): e11318.

- Umakanthan T, Mathi M (2022b) Quantitative reduction of heavy metals and caffeine in cocoa using mid-infrared spectrum irradiation. J Indian Chem Society 100(1): 100861.

- Umakanthan T, Mathi M (2023c) Increasing saltiness of salts (NaCl) using mid-infrared radiation to reduce the health hazards. Food Sci Nutr 11(6): 3535-3549.

- Umakanthan, Madhu Mathi (2023d) Potentiation of Siddha medicine using Muppu (Universal Potentiator). Int J Pharm Res Appl 8(4): 2070-2084.

- Tishkevich DI, Korolkov IV, Kozlovskiy AL, Anisovich M, Vinnik DA, et al. (2019) Immobilization of boron-rich compound on Fe3O4 nanoparticles: Stability and cytotoxicity. J Alloys Compd 797: 573-581.

- Dukenbayev K, Korolkov IV, Tishkevich DI, Kozlovskiy AL, Trukhanov SV, et al. (2019) Fe3O4 nanoparticles for complex targeted delivery and boron neutron capture therapy, Nanomaterials 494.

- Kozlovskiy AL, Alina A, Zdorovets MV (2021) Study of the effect of ion irradiation on increasing the photocatalytic activity of WO3 microparticles. J Mater Sci Mater Electron 32: 3863-3877.

- El-Shater RE, Shimy HE, Saafan SA, Darwish MA, Zhou D, et al. (2022) Synthesis characterization, and magnetic properties of Mn nanoferrites. J Alloys Compd 928: 166954.

- Kozlovskiy AL, Zdorovets MV (2021) Effect of doping of Ce4+/3+ on optical, strength and shielding properties of (0.5-x)TeO2-0.25MoO-0.25Bi2O3-xCeO2 glasses. Mater Chem Phys 263: 124444.

- Almessiere MA, Algarou NA, Slimani Y, Sadaqat A, Baykal A, et al. (2022) Investigation of exchange coupling and microwave properties of hard/soft (SrNi0.02Zr0.01Fe11.96O19)/(CoFe2O4)x nanocomposites, Mat. Today Nano 100186.

- Everitt M (2009) Consumer-Targeted Sensory Quality. Glob Issue Food Sci Tech pp. 117-128.

- Wichchukit S, O’Mahony M (2014) The 9-point hedonic scale and hedonic ranking in food science: some reappraisals and alternatives. J Sci Food Agri 95(11): 2167-2178.

- Rosa MDF, Medeiros ES, Malmonge JA, Wood D (2010) Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydrates Polymers 81(1): 83-92.

- Wattanapahu S, Suwonsichon T, Jirapakkul W, Kasermsumran S (2012) Categorization of Coconut Milk Products by Their Sensory Characteristics. J Nat Sci 46: 944-954.

- Girard JE (2014) Principles of Environmental Chemistry, 3rd edition, Jones & Bartlett Learning, USA, p. 99

- Shankar DR (2017) Remote Sensing of Soils. Germany: Springer-Verlag GmbH, p. 268.

- Mohan J (2004) Organic Spectroscopy: Principles and Applications, (2nd edn), Alpha science international Ltd., Harrow, UK, p. 19.

- Yi G (2012) Semiconductor Nanostructures for Optoelectronic Devices: Processing, Characterization and Applications. Berlin, Heidelberg: Springer-Verlag, p. 198.

- Esmaeili K (2015) Viremedy, Homeopathic Remedies, and Energy Healing Remedies as Information – including Remedies; A Synopsis p. 43

- Atkins P, Paula J (2011) Physical Chemistry for the Life Sciences, Oxford university press, Oxford, p. 365

- Datta S N, O’Trindle C, Illas F (2014) Theoretical and Computational Aspects of Magnetic Organic Molecules. Imperial College Press, London, pp. 224

- Sommer A, Caron A, Fecht HJ (2008) Tuning Nanoscopic Water Layers on Hydrophobic and Hydrophilic Surfaces with Laser Light. Langmuir 24(3): 635-636.

- Pollack GH (2015) Cell Electrical Properties: Reconsidering the Origin of the Electrical Potential. Cell Biol Int 39(3): 237-242.

- Tsai SR, Hamblin MR (2017) Biological effects and medical applications of infrared radiation. J Photochem Photobiol B 170: 197-207.

- Xu R, Xu Y (2017) Modern Inorganic Synthetic Chemistry, (2nd edn) Elsevier BV, Netherlands, UK, USA, p. 124.

- Williamson KL, Masters KM (2011) Macroscale and Microscale Organic Experiments, 6th edition, Brooks/ Cole C engage learning, CA, p. 720.

- Scanlan N (2011) Complementary Medicine for Veterinary Technicians and Nurses, Wiley-Blackwell publishing, USA.

- Kowtaluk H (2006) Food for today 9E, 9th edition. Tata McGraw-Hill Publishing Company Limited, New Delhi, India p. 456.

- Sivasankar B (2014) Food Processing and preservation, PHI Learning Private Limited, Delhi, India, p. 246.

- Day (1999) Ecosystems: Oceans. Routledge Taylor & Francis Group, London and New York p 44.

- Raymond KW (2010) General Organic and Biological Chemistry, (3rd edn) John Wiley & Sons, Inc, USA, p176.