Evaluation of Drying Temperature on Bioactive Compounds Retention in Pasta Enriched with Chlorella Luteroviridis Biomass

Isadora Cafruni, Rosane Rech and Roberta Cruz Silveira Thys*

Universidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brazil

Submission: August 28, 2021; Published: October 29, 2021

*Corresponding author: Roberta Cruz Silveira Thys, Instituto de Ciência e Tecnologia de Alimentos, Universidade Federal do Rio Grande do Sul, Porto Alegre, RS, Brazil

How to cite this article: Isadora C, Rosane R, Roberta Cruz S T. Evaluation of Drying Temperature on Bioactive Compounds Retention in Pasta Enriched with Chlorella Luteroviridis Biomass. Nutri Food Sci Int J. 2021. 11(2): 555808. DOI: 10.19080/NFSIJ.2021.11.555808.

Abstract

Microalga incorporation in pasta is an interesting alternative to enrich human diet with important nutrients. However, if present in high amounts, it can weaken the protein network, resulting in a low-quality pasta, with poor texture properties and high cooking loss. This study verified the effect of drying temperature on technological proprieties and carotenoids retention in pasta enriched with 2 % of Chlorella biomass powder. Two drying conditions, high temperature (75-80 °C and 75 % HR), and low temperature (50 °C and 81 % HR) were tested. Pasta samples were analyzed before and after the cooking process and compared to a control sample (not dried). Cooking properties, color, total carotenoids content and carotenoids identification and quantification were evaluated. The high drying temperature resulted in a pasta with lower cooking loss and higher carotenoids content. The drying process increased the nutrients bio-accessibility and promoted a stronger and denser protein network.

Keywords: Pasta; High temperature drying; microalgae; Chlorella; carotenoid

Practical Applications

Microalga incorporation in regularly eaten products as pasta is another viable strategy to increase the intake of healthy compounds. The incorporation of 2 % of Chlorella luteoviridis biomass powder in pasta did not affect cooking quality and the high drying process enhancing the carotenoid bio-accessibility and decreased the carotenoid loss during cooking. After cooked, the high temperature dried pasta with incorporation of Chlorella luteoviridis presented a carotenoid content 3.5 times higher than in the cooked fresh pasta. As microalgae biomass is highly concentrate in bioactive compounds, it can be added in low quantities, without negative effects in technological proprieties of the pasta.

Introduction

Pasta is one of the simplest cereal products and is present in the human diet for millennia. Evidence show that noodles exist in China since at least 3000 BC [1]. It is very versatile: can be served as the main dish or as a side one, and can be produced in different formats, sizes and colors. Pasta has high acceptability, low cost, and it is easy to prepare. Additionally, the technology involved in

its production is also simple [2]. It is a good source of complex carbohydrates and a moderate source of protein and some vitamins. Pasta is a good seller even in bad economic times [3].

Since the second half of the 20th century, great changes in world’s diet have been happening in industrial regions as well in developing countries. Changes in food habits worldwide include higher energy density diets with higher amounts of sugars and fats, mainly saturated fats, and lower intake of complex carbohydrates, dietary fiber, fruits and vegetables. The majority of the world’s population does not consume the daily recommended intake of fruits and vegetables. However, as the increase in urbanization tends to reduce the consumption of primary food, on the other hand, it facilitates the access to a diverse and varied diet [4]. Some studies pointed out that usually people are aware of the benefits of the intake of fruits and vegetables, but, even so, do not eat the recommended amount [5]. Considering this scenario, the incorporation of ingredients with high nutritional value into food with high rates of consumption, such as pasta, is a viable strategy to increase nutrients intake.

Pasta enriched with vitamins and minerals is a cheap way to improve people’s diet [2]. Nevertheless, usually only pasta with small number of vegetables with the purpose of coloring are found in market. Only recently, studies on pasta enrichment with vegetables in amounts that provide the recommended intake, or the recommended dietary allowance has been reported [6]. However, the incorporation of high amounts of vegetables in pasta can weaken the protein network, leading to a product with poor quality, with low texture properties and high cooking loss. The addition of hydrocolloids with high water binding capacity, such as xanthan gum [7] and the use of high temperature drying [8] in pasta production can improve the quality of fortified pasta. Compared to low-temperature drying process, high-temperatures result in better color and firmness, lower cooking loss and less stickiness, bulkiness and adhesiveness [9]. When pasta is dried at high temperatures, the protein network is formed in the raw pasta before starch hydration in boiling water, resulting in a good quality product, because starch is surrounded by the coagulated protein network. The quality of the raw materials is less important in this case. However, at low temperatures drying, both starch gelatinization and protein coagulation happen during boiling. In this case, the quality of proteins in the raw material is very important in order to maintain the final product expected quality [10].

Microalgae incorporation is a viable possibility to increase food nutritional value without compromising technological and sensory properties. These organisms are rich in nutrients such as carotenoids, vitamins and polyunsaturated fatty acids and small quantities applied in food are enough to bring good benefits [11]. The genus Chlorella, for example, is associated with several health benefits because of its high content of bioactive compounds, such as antioxidant compounds: β-carotene, chlorophyll, α-carotene, α-tocopherol, ascorbic acid, lycopene, lutein, zeaxanthin, trace elements such as zinc, copper, and magnesium [12]. Chlorella luteroviridis biomass was reported to be rich in carotenoids, mainly lutein, zeaxanthin, β-carotene and α-carotene; and its lipids possess a high proportion of omega 3 fatty acids. Depending on the culture conditions, the omega 6 to omega 3 (ω6:ω3) ratio in C. luteoviridis lipids can be as lower as 1.37, and the protein mass fraction ranges between 10 % and 30 % of the dry biomass [13]. There are several biological benefits associated to ω3 fatty acids consumption, as prevention of chronic inflammatory diseases, rheumatoid arthritis, inflammatory bowel diseases, cardiovascular disease, Alzheimer’s disease, and decreasing the risk of depression, among others [14]. A review on several studies pointed that lutein and zeaxanthin play critical roles in delaying the onset and reducing the risk of cataract and age-related macular degeneration, both of which are responsible for 56 % of all cases of blindness globally [15].

However, in order to achieve the nutritional recommendation of certain nutrients in pasta, components losses must be considered. For example, hydrophilic vitamins and phytochemicals are very likely to be leached to the cooking water and drying can cause degradation of heat sensitive bioactive compounds. A strong gluten network, however, can minimize these losses [6].

This study investigated the effect of drying temperature on carotenoid retention in pasta enriched with Chlorella luteoviridis biomass. Low temperature (LT) drying (50 °C) and high temperature (HT) drying (75-80 °C) were tested. The cooking quality, the color and the carotenoid content were evaluated, and the main carotenoids were identified.

Materials and Methods

Chlorella luteoviridis biomass powder

The microalga Chlorella luteoviridis was cultured in 2.4-L flat-plate airlift photobioreactors at 28 °C, using modified f/2 medium (600 mg/L NaNO3) as described elsewhere [16,17]. At the end of the culture, the whole content of the photobioreactor was centrifuged to separate the microalga biomass from the culture medium, and the biomass was lyophilized to obtain the Chlorella luteoviridis biomass powder (Chl-powder)

Pasta manufacture

The pasta was made by mixing 500 g of bread wheat flour (protein 11.5 %, ash 0.61 %, moisture 14.1 %), 170 mL of water and 10 g of Chl-powder for 10 min using an industrial mixer (G.Paniz, Mod 90334, Brazil) to obtain an homogeneous dough. The dough was extruded in the same equipment (40 ± 2 °C) through a die to obtain the fettuccini shaped pasta.

At the extruder exit, the pasta was manually cut into 100 mm length, hanged in a pasta rack and allowed to dry for 20 min. The product was then packed in plastic bags and stored under refrigeration (4 °C). To define the drying conditions, two pre-tests were performed. In the first one, the pasta was pre-dried at 40 °C for 1 h, allowed to rest for 30 min (27 °C and 85 % RH), and then dried at 75-80 °C for 35 min. In the other trial, the whole drying (1 h 35 min) was held at 75-80 °C with 30 min resting stage at 27 °C and 85 % RH in the middle of the drying process. The cooking loss was measured for both trials and, as there was no difference in this aspect, it was defined that no pre-drying would take place for the purpose of this study. Thus, the real effect of each temperature tested could be observed. Thereby, pasta samples were dried at two drying conditions, HT (high temperature, 75-80 °C and 75 % HR) or LT (low temperature, 50 °C and 81 % HR).

Pasta samples (fettuccini about 2.0 mm thickness, 100 mm length) were dried in a tray batch dryer until the moisture of pasta reached about 12 g per 100 g, wet basis. Both of them had a resting stage of 30 min at 27 °C and 85 % HR at the middle of the drying process. In addition, the drier was cooled to 30 °C before the pasta was removed to avoid a “thermal chock” and consequent pasta cracking.

At the end of the pasta preparation, six pasta samples were analyzed: uncooked fresh pasta (UF), cooked fresh pasta (CF), uncooked low temperature dry pasta (ULT), cooked low temperature dry pasta (CLT), uncooked high temperature dry pasta (UHT), cooked high temperature dry pasta (CHT).

Moisture and pasta cooking properties

Fresh and dry pasta moisture were determined drying 5 g of fresh pasta at 110 °C until constant weight [18]. Optimum cooking time (OCT), cooking loss, water absorption and volume gain were determined using the methodologies of the American Association of Cereal Chemists, Official Methods 16-50 and 16-51 [19]. The cooking proprieties were determined using 10 g of pasta sample broken into 5-cm pieces and cooked in 170 mL of boiling distilled water. The time when the inner white core of the pasta disappeared was identified as the OCT (al dente point). The cooking loss, the water absorption and the volume gain were determined at the optimum cooking time and expressed as a percentage of the raw pasta. All the tests were carried in triplicate.

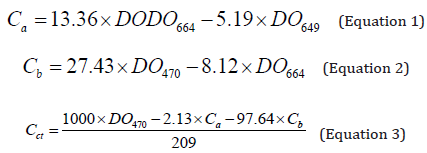

Total carotenoids

The total carotenoids were extracted using ethanol 95 % and analyzed spectrophotometrically [20]. The pasta samples (CF, UF, CHT, UHT, CLT and ULT) were lyophilized and grinded using gral and pistil. An aliquot of 10 mL of 95 % ethanol was added to 0.5 g of pasta sample, mixed in a vortex agitator and stored overnight in dark (4 °C). The next day, all tubes were centrifuged (Sigma Laboratory Centrifuge 4K15) for 20 min and the supernatant was read in a spectrophotometer (Amersham Biosciences, Ultrospec 3100 Pro) at 664 nm (DO664), 649 nm (DO649) and 470 nm (DO470). The following equations were used to determine chlorophyll a (C_a, mg L-1), chlorophyll b (C_b, mg L-1) and total carotenoids (C_Ct, mg L-1). The final results were expressed in micrograms of carotenoids per gram of dry pasta (µg g-1).

Carotenoid’s identification and quantification

The carotenoid extracts were prepared according to the method described by Mercadante and Rodrigues-Amaya [21]. The carotenoids were extracted from the lyophilized CHT sample using acetone and saponificated with 10 % KOH in methanol. The extract was concentrated in rota-evaporator under vacuum (T < 35 °C), dried in nitrogen flux and stored (-18 °C) for posterior analysis by high-efficiency liquid chromatography - HPLC.

The samples were analyzed by HPLC (Waters Alliance® E2695) using a reversed phase column C30 (250 mm × 4.6 mm ID, 3 µm, YMC, model CT99SO3-2546WT) [22]. Previous to injection, the samples were diluted in methyl tert-butyl-ether (MTBE) and methanol, put in the ultrasound (Unique, USC 1400) and filtered (Millex LCR 0.45, 13 mm). The injection volume was 20 µL. The mobile phase was water/methanol/MTBE with a flow rate of 1 mL min-1 in a total running time of 67 min. Carotenoids were detected at a wavelength of 450 nm and identified based on retention time compared with reference materials.

Color

Color analyses were performed with a Hunter Lab Colorimeter (MiniScan XE Plus, Reston, VA). Color was expressed in L*, a*, b* Hunter scale parameter. Results were expressed as color differential (∆E) between fresh and cooked pasta (Equations 4-8). Results are the means of independent duplicate determinations.

Results and Discussion

Table 1: Moisture and cooking properties for uncooked fresh pasta (UF), uncooked low temperature dry pasta (ULT) and uncooked high temperature dry pasta (UHT).

|

|

Moisture (%) |

OCT |

Cooking loss (g/100 g pasta) |

Water absorption (g/100 g pasta) |

Volume gain (g/100 g pasta) |

|

UF |

29.35 ± 0.07 |

5.0 ± 0.1a |

11.7 ± 1.4a |

198 ± 12a |

107.0 ± 0.5a |

|

ULT |

13.23 ± 0.13 |

8.0 ± 0.2b |

9.86 ± 0.05a,b |

225 ± 02a |

106.5 ± 1.0a |

|

UHT |

11.16 ± 0.03 |

7.5 ± 0.5b |

6.73 ± 0.34b |

212 ± 08a |

107.1 ± 0.5a |

Results indicate mean values ± SD. Means with the same letter in the same column are not significantly different (Tukey test, p≤ 0.05).

Pasta cooking quality parameters and moisture evaluated in this study are reported in Table 1. There was statistically significance difference in optimum cooking time for UF and the dried samples. The higher moisture of UF (~30%) decreases the cooking time of the pasta. The drying conditions had no influence on the cooking time of UHT and ULT.

The moisture content for uncooked fresh pasta (UF) and uncooked high temperature dry pasta (UHT) pasta were within the range stablished by ANVISA [23] for fresh (≤ 35.0 %) and dry (≤ 13 %) pasta, respectively. Uncooked low-temperature dry pasta (ULT) moisture content was slightly higher than the maximum of 13 % for dry pasta, probably due water adsorption after drying, either before packaging or during samples preparation for analysis.

High-temperature drying lead to a decrease in cooking loss compared to fresh pasta. This effect is a consequence of the stronger protein network that is formed in the uncooked pasta when HT drying is applied [24] and was also observed in other studies: Padalino et al [25] reported an average cooking loss of 4.25 % for pasta dried at very high temperature (90 °C) and 5.09 % for pasta dried at low temperature (50 °C); Dexter et al. [26] experienced decrease in solid losses in all three semolina samples studied when higher temperatures were used, especially in the final drying stage. D`Amico et al. [27] reported lower cooking loss in gluten-free pasta when higher drying temperatures were used. Overall, cooking loss was lower than 12 % for all samples, indicating that the amount of flour substituted was not enough to damage the gluten network and resulting in a good quality pasta [28]. These results were similar to those reported by Léon et al. [29] for pasta with incorporation of 20% of spirulina in dried bread wheat pasta and for Del Bem et al. (2012) [30] for pasta with substitution of 35 % of wheat semolina by peas and chickpeas flours.

No significant difference was noticed between the three samples regarding water absorption and volume gain. The expected water absorption and volume gains are about 200 % and 300 %, respectively [31]. Léon et al. [29] reported a smaller water absorption (~150 g/100 g pasta) of pastas with incorporation of 5 % of spirulina. Increase in volume, however, was low considering this reference and some other studies on pasta [30-32]. The use of bread wheat flour in pasta formulation can explain this result, as well as for Léon et al. [29] that reported lower water absorption for bread wheat pastas with incorporation of spirulina. If a higher protein content flour had been used, as durum wheat semolina for example, a stronger gluten network would be formed and, consequently, more water would be retained, leading to higher increase in weight and volume.

The fresh, dried and cooked samples were also analyzed by their total carotenoids content (Table 2). For uncooked samples, UF and UHT pasta had no significant difference, while ULT showed higher total carotenoid content. While thermal treatment can degrade some nutrients, heat can also increase their bioaccessibility [33]. Thus, it can be assumed that in ULT, the moderate thermal treatment was enough to increase carotenoids bioaccessibility without high losses. However, it is important to consider the results for the cooked samples, once this is how people consume pasta. The CHT pasta showed the lower carotenoid loss, i.e., difference between the uncooked and cooked samples, resulting in a final product with higher carotenoids content than the cooked fresh pasta (CF) and without significant difference to the cooked low-temperature pasta (CLT) sample. Overall, the drying process increased total carotenoids bioaccessibility [33], however the high temperature drying led to the formation of a more compact, dense and strong protein network [24], reducing carotenoid losses during cooking.

Table 2: Total carotenoids, carotenoid loss and color variation (DE) in uncooked fresh pasta (UF), cooked fresh pasta (CF), uncooked low temperature dry pasta (ULT), cooked low temperature dry pasta (CLT), uncooked high temperature dry pasta (UHT), cooked high temperature dry pasta (CHT) incorporated with 2 % of Chlorella luteoviridis biomass powder.

|

|

Total Carotenoids (µg g-1) |

Carotenoid Loss (µg g-1 and %) |

∆Ε |

|

UF |

13.6 ± 0.7b |

11.6 ± 1.0 |

11.4 ± 1.5a |

|

CF |

2.0 ± 0.3d |

-85.30% |

|

|

ULT |

17.4 ± 0.2a |

12.0 ± 0.7 |

13.0 ± 1.0a |

|

CLT |

5.4 ± 0.5c |

(69.0 %) |

|

|

UHT |

13.2 ± 0.6b |

6.2 ± 1.4 |

17.4 ± 4.7a |

|

CHT |

7.0 ± 0.8c |

(47.0 %) |

Results indicate mean values ± SD. Means with the same letter in the same column are not significantly different (Tukey test, p≤ 0.05).

The color differential (∆E) between uncooked and cooked pasta samples (Table 2) showed no statistic difference. Fradique et al. [34] not found color losses in pasta with addition of 2 % of Chlorella vulgares incorporation. They attributed this decrease in color to pigment diffusion into cooking water and oxidation caused by thermal treatment.

The carotenoid identification in the cooked high temperature pasta (CHT) showed that the most relevant carotenoids present in the pasta enriched with C. luteoviridis biomass powder were lutein, zeaxanthin, α-carotene and β-carotene (Table 3). These are the same main carotenoids identified in C. luteoviridis biomass in previous studies [13,17]. Pasta made with bread flour without eggs do not have detectable amounts of these carotenoids [35].

Table 3: Main carotenoids identified in cooked high temperature dry pasta (CHT) incorporated with 2 % of Chlorella luteoviridis biomass powder.

|

Carotenoid |

Content (µg g-1) |

|

all-trans-lutein |

2.60 ± 0.26 |

|

all-trans-zeaxanthin |

0.46 ± 0.07 |

|

all-trans-α-carotene |

0.95 ± 0.06 |

|

all-trans-β-carotene |

1.02 ± 0.06 |

Results indicate mean values ± SD.

Conclusion

The incorporation of 2 % of Chlorella luteoviridis biomass powder in bread wheat pasta did not affect cooking quality, indicating that the protein network was not damaged by adding this small amount of biomass. The drying process increased carotenoid bioaccessibility and decreased the carotenoid loss during cooking, so as the carotenoid content in the cooked dried pasta was 3.5 times higher than in the cooked fresh pasta.

The use of microalga to increase the nutritional value of pasta is a viable technology. As microalgae biomass is highly concentrate in bioactive compounds, it can be added in low quantities, without negative effects in technological proprieties of the pasta. Additional studies are now necessary to evaluate consumer´s acceptance.

References

- Brockway BE (2001) Pasta. In Gaithersburg M (Ed.), Cereals and cereal products : chemistry and technology, Aspen Publishers, pp. 254-262).

- Reis TA (2013) Caracterização de macarrão massa seca enriquecido com farinha de polpa de pescado, PP: 0-82.

- Marchylo BA, Dexter JE (2001) Pasta production. Cereals Processing Technology 109-130.

- FAO (2002) Background.

- Silva CL da (2011) Consumo de frutas e hortaliças e conceito de alimentação saudável em adultos de Brasília.

- Oliviero T, Fogliano V (2016) Food design strategies to increase vegetable intake: The case of vegetable enriched pasta. Trends in Food Science and Technology 51: 58-64.

- Silva E, Sagis LMC, Van Der Linden E, Scholten E (2013) Effect of matrix and particle type on rheological, textural and structural properties of broccoli pasta and noodles. Journal of Food Engineering 119(1): 94-103.

- Petitot M, Boyer L, Minier C, Micard V (2010) Fortification of pasta with split pea and faba bean flours: Pasta processing and quality evaluation. Food Research International 43(2): 634-641.

- Roda A (2016) Innovation in drying process of pasta - Italian Food Tech.

- Resmini P, Pagani MA (1983) Ultrastructure Studies of Pasta A Review. Journal of Food Structure 2(2): 98.

- Lira R de A (2011) Estudo do rendimento de biomassa da microalga nativa Chlorella sp. visando a obtenção de biocombustíveis. Universidade Federal de Viç

- Panahi Y, Darvishi B, Jowzi N, Beiraghdar F, Sahebkar A (2016) Chlorella vulgaris: a multifunctional dietary supplement with diverse medicinal properties. Current Pharmaceutical Design 22(2): 164-173.

- Diprat AB, Menegol T, Boelter, J. F., Zmozinski, A., Rodrigues Vale, M. G., Rodrigues, E., & Rech, R. (2017). Chemical composition of microalgae Heterochlorella luteoviridis and Dunaliella tertiolecta with emphasis on carotenoids. Journal of the Science of Food and Agriculture 97(10): 3463-3468.

- Puri M, Thyagarajan T, Gupta A, Barrow CJ (2015) Omega-3 fatty acids produced from microalgae. In Kim SK (Ed), Springer Handbook of Marine Biotechnology. Berlin, Heidelberg: Springer Berlin Heidelberg, pp. 1043-1057.

- Nwachukwu ID, Udenigwe CC, Aluko RE (2016) Lutein and zeaxanthin: Production technology, bioavailability, mechanisms of action, visual function, and health claim status. Trends in Food Science and Technology 49: 74-84.

- Kochem LH, Da Fré NC, Redaelli C, Rech R, Marcílio NR (2014) Characterization of a novel flat-panel airlift photobioreactor with an internal heat exchanger. Chemical Engineering and Technology 37(1): 59-64.

- Menegol T, Diprat AB, Rodrigues E, Rech R (2017) Effect of temperature and nitrogen concentration on biomass composition of Heterochlorella luteoviridis. Food Science and Technology, 37(Special Issue).

- AOAC (1990) Official Methods of Analysis of the Association of Official Analytical Chemists. (P. Cunniff, Ed.), Official Methods of Analysis of the Association of Official Analytical Chemists (15th). Arlington VA: Association of Official Analytical Chemists.

- AACC (2000) American Association of Cereal Chemists. Approved Methods Committee. (10th ed.). St. Paul Minn: AACC.

- Lichtenthaler HK, Buschmann C (2001) Chlorophylls and carotenoids: measurement and characterization by UV-VIS spectroscopy. In Current Protocols in Food Analytical Chemistry. John Wiley & Sons, Inc.

- Mercadante AZ, Rodriguez-Amaya DB (1998) Effects of ripening, cultivar differences, and processing on the carotenoid composition of mango. J Agric Food Chem 46(1): 128-130.

- Rodrigues DB, Flores ÉMM, Barin JS, Mercadante AZ, Jacob-Lopes E (2014) Production of carotenoids from microalgae cultivated using agroindustrial wastes. Food Research International 65(Part B): 144-148.

- ANVISA (2000) Resolução - RDC no 93, de 31 de outubro de 2000.

- Zweifel C, Handschin S, Escher F, Conde-Petit B (2003) Influence of high temperature drying on structural and textural properties of durum wheat pasta. Cereal Chemistry 80(2): 159-167.

- Padalino L, Caliandro R, Chita G, Conte A, Del Nobile MA (2016) Study of drying process on starch structural properties and their effect on semolina pasta sensory quality. Carbohydrate Polymers, 153: 229-235.

- Dexter JE, Matsuo RR, Morgan BC (1981) High temperature drying: effect on spaghetti properties. Journal of Food Science 46(6): 1741-1746.

- D’Amico S, Mäschle J, Jekle M, Tömösközi S, Langó B, et al. (2015) Effect of high temperature drying on gluten-free pasta properties. LWT - Food Science and Technology 63(1): 391-399.

- Hummel C (1966) Macaroni products: manufacture, processing and packing (2nd ed). London: Food Trade Press.

- León AE, De Marco ER, Steffolani ME, Martínez C (2014) Effects os spirulina biomass on the technological and nutritional quality os bread wheat pasta. LWT - Food Science and Technology 58: 102-108.

- Del Bem MS, Polesi LF, Sarmento SBS, Anjos CBP. Dos. (2012) Propriedades físico-químicas e sensoriais de massas alimentícias elaboradas com farinhas de leguminosas tratadas hidrotermicamente. Alimentos e Nutrientes 23(1): 101-110.

- Casagrandi DA, Canniatti-Brazaca SG, Salgado JM, Pizzinato A, Novaes NJ (1999) Análise tecnológica, nutricional e sensorial de macarrão elaborado com farinha de trigo adicionada de farinha de feijão-guandu. Revista de Nutrição 12(2): 137-143.

- Menegassi B, Leonal M (2006) Análises de qualidade de uma massa alimentícia mista de mandioquinha-salsa. Revista Raízes e Amidos Tropicais 2: 27-36.

- van Boekel M, Fogliano V, Pellegrini N, Stanton C, Scholz G, et al. (2010) A review on the beneficial aspects of food processing. Molecular Nutrition & Food Research 54(9): 1215-1247.

- Fradique MM, Batista AP, Nunes MC, Gouveia LL, Bandarra NM, et al. (2010) Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products. Part 1: Preparation and evaluation. Journal of the Science of Food and Agriculture 90(10): 1656-1664.

- Dalla Costa AP, Thys RCS, Rios AO, Flôres SH (2016) Carrot flour from minimally processed residue as substitute of β-carotene commercial in dry pasta prepared with common wheat (Triticum aestivum). Journal of Food Quality 39(6): 590-598.