- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

The Role of Starter Culture and Enzymes/ Rennet for Fermented Dairy Products Manufacture- A Review

Assefa Bezie* and Hailu Regasa

Milk and Milk Product Research Processing Industry Development, Ethiopian Meat and Dairy Industry Development Institute (EMDIDI), Ethiopia

Submission: June 21, 2019; Published: August 08, 2019

*Corresponding author: Assefa Bezie, Milk and Milk Product Research Processing Industry Development Directorate. Ethiopian Meat and Dairy Industry Development Institute (EMDIDI), P.O.Box: 1573, Debre Zeit,Ethiopia

How to cite this article: Assefa Bezie, Hailu Regasa. The Role of Starter Culture and Enzymes/Rennet for Fermented Dairy Products Manufacture- A Review. Nutri Food Sci Int J. 2019. 9(2): 555756. DOI:10.19080/NFSIJ.2019.09.555756.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Abstract

This review is concerning the role of starter culture and enzymes/rennet for fermented dairy product manufacture, types and sources of enzymes and starter culture, factors affects the activity of both starter cultures and rennet. Fermented milk products are known for their taste, nutritive value and therapeutic properties. Dairy starters are the ‘heart’ of fermented milk products, the most crucial component in the manufacture of high-quality fermented milks. In the dairy industry, some enzymes are required for the production of cheeses, yogurt, and other dairy products, while others are used in a more specialized fashion to improve texture or flavor. Starters are obtained by using traditional and growth media methods. Rennet is an extract from the fourth stomach (abomasum or rennet-bag) of ruminant animals, principally calves and adult cattle, with the capability of clotting milk by enzymic action. Starter cultures can be classified into mesophilic cultures, which grow best at 25-30 ℃, and thermophilic cultures, which grow at higher temperatures (37-45 ℃). Rennet (chymosin and pepsin), Proteases, lactase and catalase are some indigenous enzymes that used for fermented dairy products manufactured. Starter culture changes the milk sugar, lactose, into acid (lactic acid) so that the milk becomes sour (fermented or cultured). Starter cultures of LAB are responsible for the formation of cheese flavor. Main role of starter cultures is to produce acid during manufacture and also contribute to the ripening process. Rennets (rennin, a mixture of chymosin and pepsin obtained mainly from animal and microbial sources) are used for coagulation of milk in the first stage of cheese production. Rennet is an essential clotting agent used during the manufacture of many cheeses. Its main function is to coagulate milk proteins such as casein. Rennet is mainly used in hard cheese making and little is used in the manufacture of soft cottage cheese or fromage frais. heat treatment, Quantity of additives / sanitizing chemicals, culture, saltwater, rennet and Quantity of additives /culture, salt, water, rennet/ are the main factors which affects the activity of starter cultures and enzaymes/rennet.

Keywords: Dairy products; Enzymes; Fermented products; Rennet; Role; Starter cultures

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Introduction

Raw milk for processing generally comes from cows, but occasionally from other mammals such as goats, sheep, and water buffalo [2]. Milk is processed into different dairy products. So that, several dairy products such as cream, butter, yogurt, kefir, and cheese have been produced and consumed worldwide for millennia [2]. Dairy products are generally defined as food products that are produced from milk. They are rich sources of energy [3]. The inclusion of dairy products adds diversity to plant-based diets. However, the role of milk and dairy products in human nutrition has been increasingly debated in recent years, both in the scientific literature and in popular science literature [4]. Consequently, the quantity and types of dairy products manufacture in the world becomes increased (Figure 1).

The main dairy product is fresh milk (32.3 million tons/year), followed by cheese (4.1 million tons/year), yogurt and other fermented milks (2.8 million tons/year), small quantities of butter (0.8 million tons/year) and cream (0.5 million tons/year) [5]. Yoghurt and fermented milks havereceived considerable attention as carriers of live probiotic cultures [6]. Besides, so many kinds of fermented milk and milk products are manufactured by using starter cultures in the dairy industry with their known properties.

Fermented milk products are known for their taste, nutritive value and therapeutic properties. Fermented milks are products prepared from milks, entire, mostly or completely skimmed, concentrated or milk substituted from partially or fully skimmed dried milk, somewhat or completely skimmed pasteurized or sterilized and fermented by means of specific microorganisms [7,8]. Milk products also serve as the important delivery vehicles for probiotic bacteria. The probiotic bacteria have a long history of association with dairy products [9]. Now a day, milk processors used dairy starter and enzymes/rennet for dairy product production/manufacture.

Dairy starters are the ‘heart’ of fermented milk products, the most crucial component in the manufacture of high-quality fermented milks. The cultures are harmless food-grade microorganisms, such as active bacteria, that are intentionally grown in milk or whey or other formulated media to impart desirable and predictable flavor and texture to fermented milk products. The microorganisms employed in milk fermentation are single-strain or multiple-strain cultures of lactic acid bacteria, producing different types of fermented milk products [10,11].

The leading factors in the cheese-making process are the lactic bacteria. They are necessary for the lactic fermentation: they transform lactose (the milk sugar) into lactic acid; this acidification process helps the rennet’s work, the draining of the whey after the curd has been broken and the cheese maturation.

In the dairy industry, some enzymes are required for the production of cheeses, yogurt, and other dairy products, while others are used in a more specialized fashion to improve texture or flavor [12]. Therefore; the objective of this paper is to identify The Role of Starter Culture and Enzymes/Rennet for the Manufacture of Dairy Products, determine the types of starter culture and Enzymes that used for fermented dairy product production and to differentiate sources of Starter Culture and Enzymes/Rennet.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Definition

Starter culture

It can bed efined as one or more strains of one or more species of desirable bacteria used to inoculate a raw or pasteurized product to start a fermentation to produce a fermented food by accelerating and steering its fermentation process.

Starter cultures are also those microorganisms (bacteria, yeasts, and molds or their combinations) that initiate and carry out the desired fermentation essential in manufacturing cheese and fermented dairy products [7].

Rennet

Rennet and rennin are general terms for any enzyme used to coagulate milk. Technically rennet is also the term for the lining of a calf's fourth stomach. Animal rennet is a milk clotting enzyme isolated from calf stomachs. The major components of rennet are Chymosin (EC3.4.23.4) but in commercial preparations of rennet other proteases, typically bovine pepsin, are found in various concentrations [12,13]. In addition, the terminology, knowing the sources of starter cultures and enzymes/rennet are relevant for sustainable fermented dairy products manufacture.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Sources of Starter Cultures and Enzymes /Rennet

Milk is the usual growth medium for bulk starters, but other media may also be used. These may contain nonfat milk powder, phosphate salts, sodium citrate, dextrose, dextrin, pancreatin, dried autolyzed yeast, lactose, and sucrose. Starter cultures for fermented milk manufacture are also available in freeze-dried or frozen concentrated form, and either as directvat- set (DVS) type or as cultures for bulk starter production. The popularity of DVS type cultures is increasing. Application of DVS cultures eliminates the risk of phage contamination during starter preparation in the plant and ensures appropriate strain balance [10]. Starters are obtained by using traditional and growth media methods.

Traditionally, a starter is obtained via growth of lactic acid bacteria in milk at a suitable temperature. The starter is subsequently maintained by propagating and growing it in a fresh portion of milk. Currently, special growth media other than milk are also utilized to avoid multiplication of bacteriophages during starter manufacture [14].

Rennet is an extract from the fourth stomach (abomasum or rennet-bag) of ruminant animals, principally calves and adult cattle, with the capability of clotting milk by enzymic action [15]. A study by Moschpoulou [16] showed that Rennet is the enzymatic preparation of two main acid proteolytic enzymes (chymosin and pepsin) secreted in the fourth stomach (abomasum) of unweaned ruminants (calves, lambs or kids). Chymosin can also be obtained from several other animals, microbial or vegetable sources, but indigenous microbial chymosin (from fungi or bacteria) is ineffective for making cheddar and other hard cheeses [12].

Milk contains scores of enzymes. The native or indigenous enzymes are those known to be excreted by the mammary gland. Most of these are synthesized by the secretory cells, others derive from blood, for example, plasmin. Moreover, several enzymes are present in the leukocytes, e.g., catalase. Moreover, the native enzymes can be present at different locations in the milk. Many of them are associated with the fat globule membrane [14].

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Types of Culture

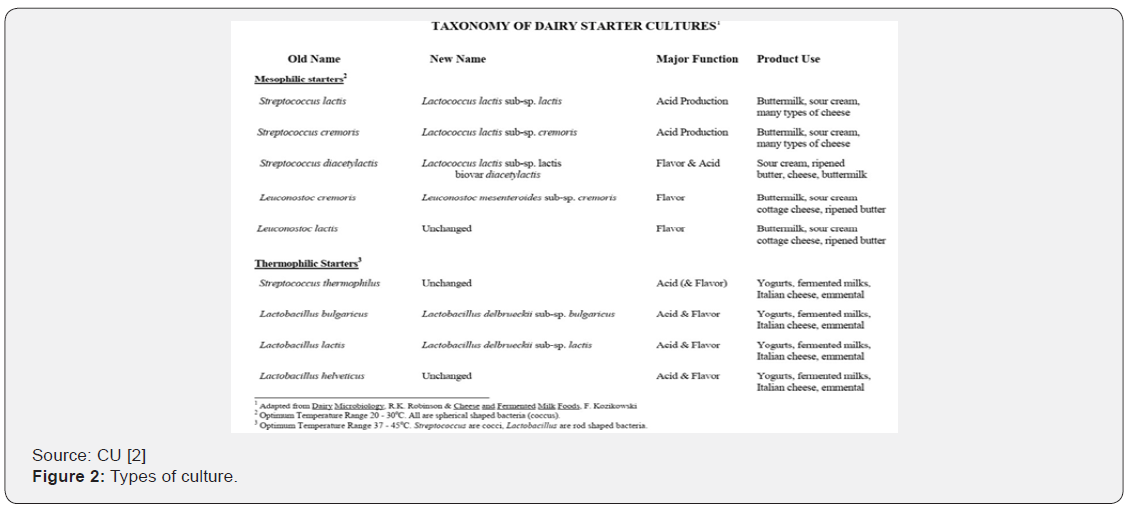

Diverse lactic starter cultures are used in the manufacture of commercial fermented milk products in the world. They can be classified into mesophilic cultures, which grow best at 25-30 ℃, and thermophilic cultures, which grow at higher temperatures (37-45 ℃) [10] (Figure 2).

Mesophilic starters

Mesophilic cultures are widely used in the fermented milk industry in the manufacture of products such as ‘filmjo¨lk’ and ‘lactofil’ (in Sweden) and ‘ymer’ (in Denmark). Mesophilic starters will almost certainly contain Lactococcus lactis subsp. cremoris, but rarely will this species be used alone. Buttermilk, ‘la˚ngfil’, and ‘viili’, which are popular in Norway, Sweden, and Finland,combine Lc. lactis subsp. cremoris with Leuconostoc species. Other fermented milk products made with mesophilic starters include sour cream, cultured butter milk,and kefir [10]. In addition, mesophilic cultures are used for the production of stirred types of yoghurt.

Thermophilic culture

Thermophilic starter cultures are used for the manufacture of yogurt, Bulgarian buttermilk, and the whole range of products made with intestinal bacteria, primarily lactobacilli and bifidobacteria [10]. Currently, thermophilic starter cultures are used for the production of so many types of dairy products such as set yoghurt and different variety cheese (mozzarella cheese, provolone, feta, gauda e.t.c).In addition to starter cultures, Different types of enzymes are applicable for different purposes .

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Types of enzymes

Proteases

Are used to produce hydrolyzed whey protein, which is whey protein broken down into shorter polypeptide sequences. Hydrolyzed whey is less likely to cause allergic reactions and is used to prepare supplements for infant formulas and medical uses [12].

Lactase

Lactase (-galactosidase, EC 3.2.1.23) is used to hydrolyze lactose to glucose and galactose as a digestive aid and to improve the solubility and sweetness in various dairy products. Many people do not have sufficient lactase to digest milk sugar. Lactose hydrolysis helps these lactose-intolerant people to drink milk and eat various dairy products [19]. It is also used in the preparation of ice cream, to make a creamier and sweeter tasting product. Lactase is usually prepared from Kluyveromyces sp. of yeast and Aspergillus sp. of fungi [12].

Catalase

The enzyme Catalase has found limited use in one particular area of cheese production. Hydrogen peroxide is a potent oxidizer and toxic to cells. It is used instead of pasteurization, when making certain cheeses such as Swiss, in order to preserve natural milk enzymes that are beneficial to the end product and flavor development of the cheese. These enzymes would be destroyed by the high heat of pasteurization. However, residues of hydrogen peroxide in the milk will inhibit the bacterial cultures that are required for the actual cheese production, so all traces of it must be removed. Catalase enzymes are typically obtained from bovine livers or microbial sources and are added to convert the hydrogen peroxide to water and molecular oxygen [12].

Lipases

Lipases are used to break down milk fats and give characteristic flavors to cheeses. The flavor comes from the free fatty acids produced when milk fats are hydrolyzed. Animal lipases are obtained from kid, calf, and lamb, while microbial lipase is derived by fermentation with the fungal species Mucor meihei [12]. the result agrees with the finding of [19] who indicated that Lipases are used mainly in cheese ripening for development of lipolytic flavors.

Chymosin

known also as rennin, is a proteolytic enzyme related to pepsin that synthesized by chief cells in the stomach of some animals. Its role in digestion is to curdle or coagulate milk in the stomach.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

Role of Starter cultures

There are several types of fermented milk products and each product is made with different lactic starter bacteria [20]. Dairy starter cultures are prepared cultures of microorganism employed in the manufacture of a variety of dairy products including butter, cheese, yoghurt and cultured milk. All dairy starter cultures produce acids; the most important group of microorganisms are the lactic acid bacteria which are included in almost all dairy starter cultures [21].

Starter culture changes the milk sugar, lactose, into acid (lactic acid) so that the milk becomes sour (fermented or cultured). Lactic acid bacteria have much to offer within food preservation and flavour generation [19]. A finding by Walstra et al. [13] revealed that Lactic acid bacteria are the prime agents in producing soured (fermented) milk and dairy products. A great majority of the flavour compounds produced in yogurt result from the activity of microorganisms in starter cultures. The predominant organisms in these starter cultures are lactic acid bacteria (LAB), for example, Lactococcus lactis, Lactobacillus species, Streptococcus thermophilus, Bifidobacterium species, and Leuconostoc species [22].

Starter cultures of LAB are responsible for the formation of cheese flavor. Several LAB are widely used and their role can be divided into starters, and non-starters, including adjunct, cultures. Main role of starter cultures is to produce acid during manufacture and also contribute to the ripening process. Nonstarter cultures do not responsible to the production of acid, but they contribute more during ripening process [23,24]. Moreover, Starter cultures are important to produced different milk/dairy products such as many cheeses, butter, and yoghurt and to controlled preservation and fermentation processes.

According to Panesar [8] during fermentation, certain physical and chemical changes occur in the milk due to the growth and fermentative activities of lactic acid bacteria used as starter cultures. The main role of lactic acid bacteria used as starter during cheese production is the production of lactic acid through metabolism of lactose. This action improves the milk coagulation process, makes the curd stronger and protects the final product against contamination [25]. Berry [26] reported that Lactic acid bacteria ferment milk’s inherent lactose to lactic acid, providing desirable sour notes. By lowering the product’s pH, shelf life is also extended, as the acidic environment controls the growth of spoilage microorganisms.

Natural cheese making uses lactic acid produced by the fermentation of lactic acid bacteria (LAB) to control the pH. Lactic acid bacteria are Gram-positive, non-motile, and nonspore forming [27]. Yogurt taste is mainly characterized by an acid character due to the presence of lactic acid in the product. Yogurt aroma is characterized by about hundred volatile compounds that consist of carbonyl compounds (mainly acids and esters), alcohols, and heterocyclic and sulfurcontaining compounds. Among them, acetaldehyde is the major flavor compound of yogurt, where it confers a pleasant fresh and fruity aroma. It is produced by the lactic acid bacteria [28]. The acid produced during fermentation helps to form curds, also called a gel, and contributes to syneresis of the curd, removal of water held within the milk proteins [29].

In the meantime, many enzymes are responsible for dairy products manufacture.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Role of Enzymes/rennet for dairy products Manufacture

Rennets (rennin, a mixture of chymosin and pepsin obtained mainly from animal and microbial sources) are used for coagulation of milk in the first stage of cheese production [17]. Milk coagulation properties (MCP) are an important aspect in assessing cheese making ability [30]. The production process of cheese coagulation of milk proteins to ‘curds’ is achieved by the proteolytic activity of rennet added to milk [31]. This confirms the study of Kevany et al. [32] who obtained that the concentration of residual rennet in the cheese can be used to indicate the potential proteolytic activity during ripening. Rennet is an essential clotting agent used during the manufacture of many cheeses. Its main function is to coagulate milk proteins such as casein. Rennet is mainly used in hard cheese making and little is used in the manufacture of soft cottage cheese or fromage frais [15].

Rennet plays significant role in the sensory characteristics of the produced cheese, because it contains also lipolytic enzymes that release free fatty acids (FFA) during ripening. Consequently, several cheeses have special sensory characteristics that are attributed to the rennet used and this is mainly the case of the cheeses made with rennet from small ruminants although, commercial lipase preparations from small ruminants are frequently used to enhance lipolysis in cheese. Chymosin, pepsin A and gastriscin (or pepsin B or pepsin C), which are secreted in the abomasum of young ruminants, belong to the group of aspartic proteinases having two residues of Asp in their active centre. These gastric aspartic proteinases are secreted in the mucus of abomasum in the form of zymogens and their action is to clot and digest the milk [16].

Commercial rennet extracts used for the manufacture of most cheese varieties are free from lipase activity. However, rennet pastes used in the manufacture of certain hard Italian cheese varieties, such as Provolone and the various Pecorino cheeses, and often in traditional Greek feta, contain much lipase activity [33]. On the other hand, several factors inhibit /affect the functionality or activity of starter cultures as well as enzymes during fermented milk and dairy products manufacturing.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Factors affecting cultures and enzymes activity

A number of factors may adversely affect the activity of starters, leading to poor quality of fermented milks and financial losses to the manufacturer. When lactic acid is not produced by a starter culture at the desired rate, the culture is called ‘slow’. The slowness can be due to either the genetic makeup of the strains or extrinsic factors. The latter include, among others, (1) bacteriophage, (2) residues of antibiotics and sanitizing agents, (3) inhibitory compounds naturally found in milk, (4) variations in milk composition due to mastitis or seasonal factors, and (5) metabolites of spoilage bacteria. A lower rate of acid production can also be caused by irregular culture transfers, by fluctuations in incubation temperature, and by over acidification [10].

Heat treatment

Heat treatment is the most widely used processing technology in the dairy industry. Its main purpose is to destroy microorganisms, both pathogenic and spoilage, to ensure the milk is safe and has a reasonable shelf-life [3,34,35]. Each microorganism has a specific temperature for optimal growth and production rates (g/L/h) [36]. Temperature in the range of 65-72 °C destroys 60-80 % of bacteria. The delay of growth of the additional heat-treated culture is positive from the perspective of rennet cheese production, as the additional biomass of bacterial culture - though incapable of growth at the initial stages of cheese making but possessing active peptidolytic enzymes - may accelerate the ripening process of cheese and prevent the accumulation of bitter peptides in the cheese bulk that may be synthesized at the first stage of ripening under the influence of rennin or proteinases bound with a cell wall [37]. A study by Simsek et al. [38] showed that high temperature led to reduction of bacterial content, this reduction has been effective in reducing the content of the enzymes. Microbial enzymes derived from Rhizomucor miehei, for example, are less heat-sensitive than other enzymes and may be preferred for cheese operations with higher cooking temperatures [27].

Time duration

The time needed for fermentation may be as short as 2.5 h for the classic yogurt starter culture [39]. As could be expected on the basis of the chemical acidification reaction that underlies the fermentation process, pH dropped during the 3-5 hr to values 4.6. Moreover, it was observed that samples produced by strains with low proteolytc activity had sigmoidal pH decrease but starter cultures with high proteolytic activity showed different acidification profiles and fermentation times had been longer [40]. The time required for the gel with low rennet concentration to reach a medium firmness, as determined by an experienced cheese maker, was found to be 50 min [32].

Increased the ratio of rennet in addition to the recommendation with little amount is positively affects the activity of rennet i.e. it speeds up the formation of curd/ coagulation during cheese manufactured). Depending on the manufactured date and quantity of rennet, curd will be formed from 30-45 minutes.

Quantity of additives / sanitizing chemicals, culture, saltwater, rennet

Many sanitizing chemicals, such as quaternary ammonium compounds, iodine and chlorine compounds, retard acid development by starter cultures. Colostrum and late lactation milk contain non-specific agglutinins, which clump and precipitate sensitive strains of the starter. The agglutinins may possibly retard the rate of acid production by interfering with the transport of lactose and other nutrients. Seasonal variation of the solids-not-fat fraction of milk affects the growth and the balance of strains in culture. Another cause of slow starters may be attributed to antibiotics in milk. Concentrations as low as 0.005-0.05 international units (IU) of antibiotics per mL of milk, used in mastitis therapy, are high enough to impact partial or full inhibition of the culture. Proper use of sanitizers includes verification of sanitizer concentration as well as removal of residual sanitizers from the pipes and vessels prior to the use of equipment for processing of fermented dairy products [41].

The formation of the coagulum depends upon on the quantity and type of rennet selected. Coagulation may be inhibited by residual chlorine in the cheese vat; as little as 2 ppm of residual chlorine will destroy 40% of rennet activity in 3 minutes. Typically, hard water (pH> 7.0) also decreases rennet activity [27].

Storage place, time and temperature

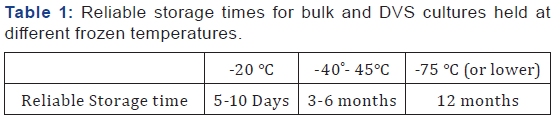

Starter cultures are perishable and have a finite shelf-life! Freeze-dried cultures can be stored at 4ºC for longer than 12 months. Successful cheese making depends on healthy, active starter bacteria which produce acid consistently from day to day. To ensure that starter bacteria perform predictably; it is important to handle and stores them correctly [42](Table 1).

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Conclusion

Dairy products are generally defined as food products that are produced from milk. The quantity and types of dairy products manufacture in the world becomes increased. The leading factors in the cheese-making process are the lactic bacteria. They are necessary for the lactic fermentation: they transform lactose (the milk sugar) into lactic acid; this acidification process helps the rennet’s work, the draining of the whey after the curd has been broken and the cheese maturation.

In the dairy industry, some enzymes are required for the production of cheeses, yogurt, and other dairy products, while others are used in a more specialized fashion to improve texture or flavor. The production process of cheese coagulation of milk proteins to ‘curds’ is achieved by the proteolytic activity of rennet added to milk.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Conflict of Interest

Author declares no conflict of interest.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

Acknowledgement

The author would like to thank Ms Betelhem Tarkegn for her valuable support during writing this paper. Our glory also going to Ethiopian Meat and Dairy Industry Development Institute staff as a whole, particularly dairy sub-sector professionals for their comments.

- Review Article

- Abstract

- Introduction

- Definition

- Sources of Starter Cultures and Enzymes /Rennet

- Types of Culture

- Types of enzymes

- Role of Starter cultures and Enzymes/ rennet for fermented dairy products Manufacture

- Role of Enzymes/rennet for dairy products Manufacture

- Factors affecting cultures and enzymes activity

- Conclusion

- Conflict of Interest

- Acknowledgement

- References

References

- Grosch Werner (2008) Milk and dairy products, Germany Research Center for Food and Chemistry.

- MYVMC (Virtual Medical Centre) (2018) Milk and Milk Products (Dairy Products).

- Assefa Bezie (2019) The Effect of Different Heat Treatment on the Nutritional Value of Milk and Milk Products and Shelf-Life of Milk Products. A Review. Dairy and Vet Sci J 11(5): 2196-2573.

- FAO (FOOD AND AGRICULTURE ORGANIZATION OF THE UNITED NATIONS) (2013) Milk and dairy products in human nutrition.

- RAC/CP (Regional Activity Centre for Cleaner Production) (2002) Prevention of pollution in the Dairy Industry.

- Kotze AD (2003) The Survival of yeasts and Probiotics as Adjunct Starters in Cheese.

- Abdel SM (2017) Microbial starter cultures.

- Yerlikaya Oktay (2014) Starter cultures used in probiotic dairy product preparation and popular probiotic dairy drinks. Food Sci Technol 34(2): 221-229.

- Panesar SP (2011) Fermented Dairy Products: Starter Cultures and Potential Nutritional Benefits. Food and Nutrition Sciences 2(1): 47-51.

- Surono S and Hosono A (2011) Fermented Milks | Starter Cultures. In: Fuquay JW, et al. (Eds.), Encyclopedia of Dairy Sciences, (2nd edn), San Diego: Academic Press, 2: 477-482.

- Ebing P, Rutgers K (2006) Preparation of dairy products. Agromisa Foundation and CTA, Wageningen.

- Phillips Theresa (2019) Enzymes Used in the Dairy Industry.

- Hullmuth K,Van den Brink MJ (2013) microbial production of enzymes used in food applications .

- Walstra P, Wouters J, Geurts, T (2006) Dairy Science and Technology Second Edition, Wageningen, The Netherlands.

- TSE/BSE (2002) Report on: The safety of Animal Rennet in Regard to Risks from Animal Tse or Bse in particular.

- Moschpoulou E (2011) Characteristics of rennet and other enzymes from small ruminants used in cheese production.

- CU (2008) Dairy Starter Cultures -- General Characteristics.

- Qureshi MA, Khare AK, Pervez, Uprit S (2015) Enzymes used in dairy industries. International Journal of Applied Research. 1(10): 523-527.

- Rajiv ID (1998) Factors Affecting Viability of Yoghurt and Probiotic bacteria in Commercial Starter cultures.

- EMEA (2000) Note for Guidance for the Assessment of the effect of antimicrobial substances on Dairy Starter cultures.

- Hansen EB (2002) Commercial bacterial starter cultures for fermented foods of the future. International Journal of Food Microbiology, pp. 119-131.

- Gerrit S, Bart AS, Wim JME (2005) Flavour formation by lactic acid bacteria and biochemical flavour profiling of cheese products. FEMS Microbiology Reviews 29: 591-610.

- Widyastuti Y, Rohmatussolihat, Andi Febrisiantosa (2014) The Role of Lactic Acid Bacteria in Milk Fermentation. Food and Nutrition Sciences 5: 435- 442.

- Kongo MJ (2013) Lactic Acid Bacteria as Starter- Cultures for Cheese Processing: Past, Present and Future Developments.

- Fox PF, Law J, Mc Sweeney PLH, Wallace J (1993) Biochemistry of Cheese Ripening. In, Fox PF (Ed): Cheese: Chemistry, Physics and Microbiology. Vol 1, General Aspects, pp. 389-438, Chapman & Hall, London.

- Berry Donna (2013) The short- and long-term benefits of cultures and enzymes.

- Beard Gale M (2009) The Impact of Intrinsic and Extrinsic Factors on the Safety and Quality of Hard and Semi-soft Natural Cheese.

- Corrieu G and Béal C (2016) Yogurt: The Product and its Manufacture. In: Caballero B, et al. (Eds.) the Encyclopedia of Food and Health, Oxford: Academic Press, vol 5: 617-624.

- ASM American Society for Microbiology (2014) Microbes Make the Cheese.

- Mamo A and Balasubramanian N (2018) Calf rennet production and its performance optimization. Journal of Applied and Natural Science 10(1): 247 - 252.

- Van Dijck PWM (1999) Chymosin and Phytase, Journal of Biotechnology 67: 77-80.

- Kevany Soodam, Lydia Ong, Ian B Powell, Sandra E Kentish, Sally L Gras (2015) Effect of rennet on the composition, proteolysis and microstructure of reduced-fat Cheddar cheese during ripening. Dairy Science Technology, EDP sciences/Springer 95(5): 665-686.

- McSweeney LHP (2004) Biochemistry of cheese ripening. Society of Dairy Technology, Vol 57, No 2/3. International Journal of Dairy Technology.

- IDF (2018) Heat Treatment of Milk - Overview.

- CEPMSA (Consumer Education Project of milk SA) (2016) The effect of heat treatment on the nutritional value of milk and milk products.

- Demirci A, Izmirlioglu G, Ercan D (2014) Fermentation and Enzyme Technologies in Food Processing.

- Garbowska M, Pluta A, Berthold A (2014) Dipeptidase Activity and Growth of Heat-Treated Commercial Dairy Starter Culture. Appl Biochem Biotechnol 175: 2602-2615.

- Simsek B, Sagdic O (2012) Effects of Starter Culture Types and Different Temperatures Treatments on Physicochemical, Microbiological and Sensory Characteristics, and Fattty Acid Compositions of Cokelek Chee. Kafkas Univ Vet Fak Derg, 18(2): 177-183.

- Knut JH (2001) Probiotic bacteria in fermented foods: product characteristics and starter organisms.

- Elahe A, Mohammad HE, Shahram S (2016) The effect of proteolytc actvity of starter cultures on technologically important propertes of yogurt. Food sciences and nutrition.

- Chandan, RC (2013) Dairy-Fermented Products.

- Randall KT (1996) Frozen Culture Handling and Storage. Vol 8 No. 4. A Technical Resource for Dairy Manufacturers, Wisconsin Center for Dairy Research.