Influence of Bacterial Adaptation on Copper Bioleaching from Printed Circuit Boards

Yamanea LH*, Moraesa VT, Tenórioa JAS and Espinosaa DCR

Department of Metallurgical and Materials Engineering, University of São Paulo, Brazil

Submission: March 10, 2018; Published: May 21, 2018

*Corresponding author: Yamanea LH, Department of Metallurgical and Materials Engineering, University of São Paulo, Brazil.

How to cite this article: Yamanea LH, Moraesa VT, Tenórioa JAS, Espinosaa DCR. Influence of Bacterial Adaptation on Copper Bioleaching from Printed Circuit Boards. Adv Biotech & Micro. 2018; 9(3): 555761. DOI: 10.19080/AIBM.2018.09.555761

Abstract

The use of microorganisms in the recovery of metals, a process called bioleaching, using secondary sources, can be regarded as an alternative process to the traditional processes that are used for the recycling of printed circuit boards, and the microorganism adaptation has been reported as being worthwhile, since it increases the metabolic capacity and as a consequence the solubilisation of the metals.

The aim of this study was to carry out the adaptation of the A. ferrooxidans-LR bacteria to the presence of comminute printed circuit boards from old printers and computers, and to compare the final extraction of copper and the influence of the types of boards on the adaptation and bioleaching process. The bacterial adaptation process was conducted by means of sequential subcultures, with a gradual increase in the pulp density. The bioleaching trials were carried out under the same conditions as the adaptation trials with monitoring of the pH and determination of the final extraction of copper. The results showed that in the case of bacterial adaptation, the final pulp density reached after 3months was one of 28.5gL-1, which represented a 90% increase. No differences were observed in relation to the origin of the printed circuit boards, suggesting that the toxicity that the printed circuit boards confer upon the bacterial activity is related to the materials that make up the boards rather than the concentration of the said materials, given that printers and computers have different concentrations of metals, polymers and ceramic materials. The extraction of copper at the final pulp density (of 28.5gL-1) was 64% for printers and 52% for computers, but at pulp densities below 25gL-1 the extraction of copper was above 85% for both of the types of printed circuit boards studied.

Keywords: Epigenetics; Environment; Metals; Methylationl; Acetylation; Double strand break

Introduction

Bioleaching, which exploits the use of microorganisms to recover metallic ions, is one of the most promising biotechnologies [1] and can be used in combination with chemical processes to recycle electronic scrap [2]. Studies [3-5], involving bacterial adaptation at a stage prior to bioleaching, reported an increase in the extraction percentages of the metals studied, however, although this fact has already been accepted, it is still not absolutely clear what the reasons are for this increase in extraction capacity which is achieved with adapted bacteria.

The microorganisms’ need to adapt could be due to different factors, such as temperature [6], different substrates [3] and different metallic concentrations [4]. Studies suggest that morphological and biochemical changes, such as alterations in the cell membrane, proposed by Oger & Cario [7] and by Xia et al. (2008), occur during the adaptation process.

Xia et al. (2008) suggest that there are significant differences in the bacterial attack and in the tolerance to the stress of rupture of adapted and non-adapted bacterial cells due to the changes in the components and in the structure of the cell wall. In addition, Oger & Cario [7] explain that modifications in the composition of the lipidic membrane, in a strategy which is known as adaptation by homeoviscosity, occur in response to the changes in the environmental conditions. The membrane plays an important role in regulating the flow into and out of the cells.

The difficulty entailed in determining the factors involved in the adaptation process, is probably in connection with managing to isolate these factors, because, since we’re talking about a biological system, there is a complex interactions between the conditions of the environment, the type of microorganism and the method used. The fact that the adaptation process is not yet clearly defined also raises the question as to whether we should call it the adaptation or the natural selection process, as discussed by Creager [8] in a review of old and new debates regarding bacterial capacity to acquire resistance to medicines.

Lastly, it is worth remembering that the adaptation mechanism can be manipulated in order to improve the microorganism’s capacity to develop some activity that is of economic interest, but that it can also occur in a way that is contrary to human interest, such as in the case of adaptation by pathogens to medicines [8], antiseptics [9] and antibiotics [10] in other words, adaptation is a natural process of living beings.

The study has sought to evaluate the influence of bacterial adaptation on copper extraction and of the use of different types of printed circuit boards (PCB-P and PCB-C) on bacterial adaptation.

Materials and Methods

Printed circuit boards

Two types of printed circuit boards were used for this study; those from computers and those from printers. The printed circuit boards from computers (PCB-C) were removed from old computers from the Polytechnic School of the University of São Paulo and weighed a total of 45kg, while the circuit boards from printers (PCB-P), consisting of a single lot of 146 printed circuit boards from printers, weighing a total of 6.65kg. The PCB-Ps were selected manually, with the broken boards being removed, so that only boards that were in one piece, which weighed a total of 6.18kg, went forward to the mechanical processing stage. In the case of the PCB-Cs, roughly 2.8kg of the boards were used, from the total number collected for this study.

Mechanical processing of the printed circuit boards

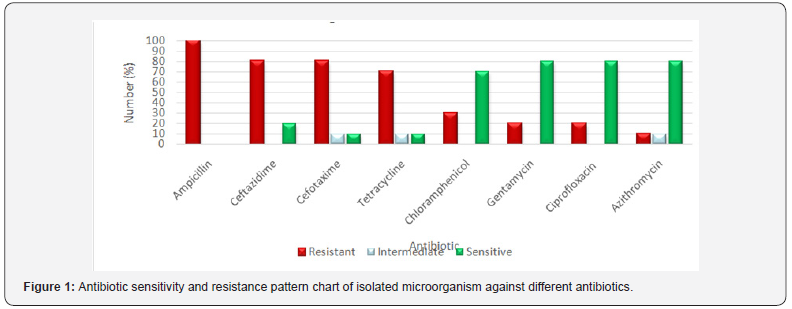

Figure 1 shows a block diagram illustrating the stages and processes carried out under this study. The processes of each stage shown in Figure 1 are set out below.

Legend: PCB-P: Printed Circuit Boards from Printers;

PCB-C: Printed Circuit Boards from Computers; AAS: Atomic Absorption Spectroscopy.

Reduction and comminution of the printed circuit boards: The printed circuit boards taken from printers (PCBPs) were first ground up in a cutting mill using a 9mm blade, followed by a 6mm blade, with the aim of reducing losses and facilitating comminution in a hammer mill using a 1mm blade. The printed circuit boards taken from computers (PCB-Cs) were only comminuted in a hammer mill, initially using a 6mm blade, followed by a 2mm blade, given that the previous reduction in size in order to make it suitable for the mill’s apertures was carried out using a manual guillotine.

Different routes were adopted in the comminution process for each type of board (PCB-P and PCB-C) to make adjustments to take into account the differences in size, thickness and type of base of the printed circuit boards (dual-layer and multilayer) using different kinds of mills in order to obtain similarly comminuted material.

Magnetic separation of the comminuted printed circuit boards: The comminuted PCB-C was magnetically separated using a dry cross belt magnetic separator with a 6.5A electromagnet, thus dividing it into two materials, one magnetic and the other non-magnetic. The non-magnetic material was used in the bacterial adaptation and characterization trials, while the magnetic material was used in calculating the final mass balance and in the characterization stage.

For the comminuted PCB-Ps, an HFP-RE 15x12 model Inbrás dry-drum magnetic separator was used, and the magnetic and non-magnetic material obtained following the separation was submitted to the same trials as were used in the case of the PCBCs.

Characterization of the fractions obtained as a result of the mechanical processing of the printed circuit boards

Pyrolysis: In the pyrolysis, aliquots of approximately 5-10g from each printed circuit board (PCB-P and PCB-C) after comminution were placed in ceramic navicules. These navicules were left for one hour in the muffle kiln at a temperature of 800 °C in an inert argon atmosphere. The determination of the fractions: the organic fraction (composed of polymers) which vaporizes, and the inorganic fraction (composed of metals and ceramic materials) which remains in solid form in the bottom of the navicules, is calculated by the difference between the final and the initial mass.

Leaching in aqua-regia: The inorganic fraction remaining in the ceramic navicules from each one of the samples of PCB-P and PCB-C, was solubilized with aqua-regia in a ratio of 1:20 [11]. The period of contact between the sample and the aqua-regia was one of 24hours, followed by simple filtration with quantitative filter paper. As a result, 2 fractions were obtained, a leached fraction containing aqua-regia and the solubilized metals, and an insoluble fraction, which corresponds to the insoluble materials retained in the filter paper, this is the material which indicates the ceramic fraction.

Determination of the concentration of metals: The leached fraction of the non-magnetic material from each one of the printed circuit boards (PCB-Ps and PCB-Cs) was sent for chemical analysis to determine the elements present using the atomic absorption spectrometry (AAS) technique. The metals analyzed were: Cu, Fe, Sn, Pb, Zn, Al, Ag and Au. The results in the metals analysis were used to calculate the final extraction of copper and in the characterization of the non-magnetic material.

Bacterial adaptation

The process of bacterial adaptation was carried out with the LR strain of the A. ferrooxidans bacteria. The Acidithiobacillus ferrooxidans was isolated from acidic leaching liquor from uranium ore (Garcia Jr, 1989) and kindly conceded by the professors Oswaldo Garcia Jr and Denise Bevilaqua (UNESPAraraquara).

A. The T&K [12] culture medium, which is made up of two solutions (A and B) acidified with H2SO4 5M up to a pH of 1.8, was used for microbial inoculum growth:

B. Solution A: (NH4)2SO4: 0.625gL-1; MgSO4.7H2O: 0.625gL- 1 and K2HPO4: 0.625gL-1, Sterilized in autoclave, at 120 °C, for a period of 30minutes and 1atm.

C. Solution B: 166.5 gL-1 FeSO4.7H2O, Sterilized by filtration in Millipore membrane (0.45μm).

The preparation of the T&K culture medium consisted of the mixture of the A and B in a ratio of 4:1, respectively. The LR strain of A. ferrooxidans was cultivated in 200mL of the T&K culture medium, at a temperature of 30 °C in a rotary shaker with a rotation speed of 170rpm, using 10mL of inoculum, which represents 5%v/v. The bacterial adaptation process was conducted by means of sequential subcultures, with a gradual increase in the quantity of PCB-P and PCB-C starting from a pulp density of 15gL-1, at which the bacteria was already adapted. Increasing additions in the quantity of non-magnetic material from printed circuit boards (1-2.5gL-1) after each cycle were added during the replication process. Each replication cycle is characterized by the bacterial tolerance acquired by means of natural selection to the pulp density evaluated, followed by a repetition of the same conditions and an increase in the bacterial population.

The bacterial response, considered as positive, during the adaptation process is visual, with a change in the solution’s color from greenish to reddish in the space of a few days (from 2 to 5), compared to the abiotic control solution (without bacterial innoculation). The comparison is based on the fact that, with the bacterial innoculation, the ferrous ion contained in the culture medium, which gives the solution its greenish color, is oxidized by the ferric ion (which gives the solution its reddish color), by means of the bacterial metabolic activity, causing a change in the solution’s color within a few days, while the color of the control solution remains unaltered, bearing in mind that the natural oxidization of the ferrous ion in acid pH occurs more slowly (between 15 to 20 days).

If there is no change in the solution’s color, after a period of up to 5 days, it is believed that there was no bacterial adaptation due to the death or inhibition of the bacteria at the pulp density studied. It is also stressed that the oxidized culture solution obtained from the previous successful bacterial adaptation after repetition of the same conditions is used as inoculum.

Bioleaching experiments

After the bacterial adaptation period, the bioleaching trial was assembled, repeating the conditions determined experimentally, with the addition of the quantity of substrate to which the bacteria is adapted (pulp density), of the culture medium (T&K medium) and of the inoculum containing the adapted bacteria. When it was necessary, the pH was corrected using a sterile sulfuric acid solution 5M. Aliquots of 10mL were removed at the end of the trials (on the 15th day) for analysis of copper by AAS in order to calculate the percentage extraction of copper.

Result and Discussion

Characterization of the fractions obtained in the pretreatment of the printed circuit boards

Pyrolysis and leaching in aqua-regia: The composition of

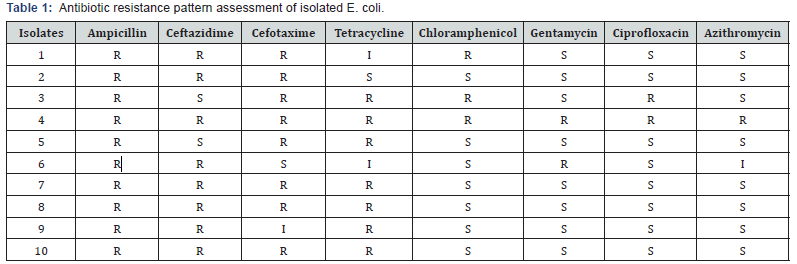

Determination of the concentration of metals: The determination of the concentration of metals in the non-magnetic material from the PCB-Ps and PCB-Cs is presented in Table 1 & 2, respectively. It can be observed that the concentration of the metals present in the PCB-Ps and PCB-Cs, as shown in Table 1 & 2, respectively, varies and that copper, as was expected, is the metal that exhibits the highest concentration in the samples studied. The discussion about the concentration of the fractions that make up the printed circuit boards was carried out in an earlier study [13].

.

Bacterial adaptation

Using a pulp density of 30gL-1 no bacterial response was observed after one week, despite the fact that success was obtained using a pulp density of 25gL-1, and for this reason the pulp density was reduced to 28.5gL-1, which was final pulp density achieved. Three further subcultures were carried out using the same final pulp density in order to confirm the result and another attempt was made to increase the pulp density, but without any bacterial response.

Different authors [6-15] suggest a reason as to why the bacterial adaptation causes an increase in the solubilization of metals from the microbiological point of view. According to Xia et al. (2008), the adapted bacteria may adhere more easily to the surface of the substrate due to more of the cell surface’s proteins having acquired a specific interaction with the substrate. Haghshenas et al. [3] also suggest changes on a biochemical level.

It should be stressed that there is no defined protocol for the bacterial adaptation process, which hinders the debate of information and the comparison of data, given that the bio hydrometallurgical studies report the use of different microorganisms, methods, pulp densities and substrates [14- 20] for example, Chiang et al. [16], used fungi to extract metals from a different substrate, while Faramarzi et al. [19] used a cyanogenic bacteria to mobilize gold. The use of different microorganisms may imply different morphological and biochemical modifications, as well as the different methods adopted [20-23].

Li & Ke [5] promoted bacterial adaptation using synthetic solutions of the ions of the metals present on a printed circuit board, based on the average concentration reported in the literature. This method did not evaluate the joint influence of the concentration of metals with the boards’ other components, such as glass fiber and resin. Since there is no defined method, there are also no restrictions in relation to exploring the capacity of some microorganisms to change the substrate, one example of this is that Haghshenas et al. [3] studied bacterial adaptation using different concentrations of ores, while Lewis et al. [23] did this by means of gradually increasing vehicle scrap.

The common point in all the studies is that bacterial adaptation does indeed increase the microorganism’s capacity to tolerate the presence of different elements foreign to its medium of origin, and for this reason the addition of comminuted printed circuit boards to the system inoculated with the bacteria without prior bacterial adaptation causes the death of the bacterial population due to the toxicity that the comminuted material produces in the bacterial environment.

It is still not yet clearly defined which of the materials (metals, glass fiber, resin and ceramic materials among others) that make up the printed circuit boards cause this toxicity or even whether it is the combination of a few of them, however, no differences were observed in the bacterial adaptation process using different types of printed circuit boards (PCB-Ps and PCBCs), which suggests that the different compositions observed in the characterization (Table 1 & 2) did not influence the process.

It should also be stressed that the pulp density of 15gL-1 at which the bacteria was already adapted was obtained by means of the adaptation process with PCB-Cs. The continuation of the process, starting off at this pulp density that had previously been studied, is what introduced PCB-Ps in parallel for comparison purposes.

The results obtained from the bacterial adaptation process allow us to assume that although the composition did not have any influence, there is a maximum pulp density that can be achieved with the bacterial adaptation process, with it not having been possible to increase this by maintaining the same study conditions (rotation, temperature, pH, culture medium, inoculum volume, type of culture), making the bioleaching environment become saturated by solubilized metals.

Bioleaching trials

Initially, it was planned to carry out a bioleaching trial each time that the pulp density increased by 10gL-1, starting off from 15gL-1, so that bioleaching trials would evaluate the pulp densities of 15gL-1, 25gL-1, 35gL-1 and so on, however, the adaptation process only went up to a pulp density of 28.5gL-1, therefore, the results presented in Table 3 in relation to final copper extraction are from the trials that were carried out with pulp densities of 15gL-1, 25gL-1 and 28.5gL-1.

Legend: PCB-P: Printed Circuit Board from Printers; PCB-C: Printed Circuit Boards from Computers.

As can be observed in Table 3, the copper extraction obtained at the pulp density of 15gL-1, as expected, achieved the same percentage extraction result as was obtained in a previous study carried out, and which served as a basis for this study, including using the PCB-Ps, with which the bacteria had not come in contact before, as a substrate. Both types of printed circuit boards evaluated achieved 99% copper extraction after a 15-day trial. This fact corroborates the fact that the difference in the composition of the two types of printed circuit boards did not have any influence over the extraction of copper, and that, once adapted to a type of substrate, the bacteria can support variations without any negative impact on its metabolic activity, provided that the variations are related to the concentration and not to the composition [24].

The printed circuit boards are constructed from layers of glass fiber interwoven with layers of copper, on top of which are inserted the electronic components, which add ceramic, polymeric and metallic materials to the boards’ composition, [25], and although the concentrations vary in accordance with the type of board, the age and origin of the boards, other types of materials are not normally used [22]. In the trial using the pulp density of 25gL-1 after the bacterial adaptation showed tolerance to this pulp density, the extraction of copper after a 15-day trial was 87% for the PCB-Ps and 85% for the PCB-Cs [26].

In a study carried out previously, without the continuation of the bacterial adaptation process starting off at 15gL-1, different pulp densities were studied for the purpose of evaluating the influence of the increase in the pulp density on the bioleaching of metals. This study noted that the increase in the pulp density reduced the solubilization of the metals present in the printed circuit boards, extracting roughly 70% of the copper when the pulp density of 30gL-1 of PCB-C was studied. This shows that the bacterial adaptation is an important process which is capable of increasing the extraction of copper under the same conditions [27].

When increasing the pulp density to 28.5gL-1, a significant decrease was observed in the extraction of copper from both types of printed circuit boards, despite the bacteria having shown tolerance at this pulp density during the bacterial adaptation process. This may have occurred due to the bacterial metabolic capacity being under a borderline stress condition, given that at a higher pulp density (30gL-1), the bacteria did not exhibit tolerance.

The time that elapsed between the study that was carried out with bacteria adapted to 15gL-1 and the continuation of the adaptation process was one of roughly 11months. During this period, various subcultures were carried out, merely in order to keep the adapted bacteria alive. It can be inferred that the natural selection process to which the bacteria are subjected with each subculture, makes them increasingly resistant, and therefore, the longer that subcultures are made with the same pulp density the greater the subsequent populations’ tolerance acquired by natural selection.

When the adaptation process was resumed, the time between new subcultures with greater pulp densities was one of roughly 2weeks and despite the fact that the bacterial population having shown itself resistant to pulp densities of up to 28.5gL-1, little time elapsed so that new more adapted bacterial populations were naturally selected through further subcultures.

Conclusion

The continuation of the adaptation process of the LR strain of the A. ferrooxidans bacteria to the presence of two types of printed circuit boards (outdated printers and computers), starting off from 15gL-1, increased the bacterial tolerance and consequently the extraction percentage of copper after a 15- day trial. The results showed that the types of printed circuit boards studied had no significant influence over the bacterial adaptation process and the bioleaching of the copper [28].

The results suggest that bacterial adaptation should be a continuous process and that various subcultures may be carried out after each adaptation cycle, with the aim that the new bacterial populations are selected naturally resulting in an increase in the extraction percentage of copper.

Acknowledgement

The authors wish to thank the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Brazil for granting a postdoctoral scholarship.

References

- Anjum F, Shahid M, Akcil A (2012) Biohydrometallurgy techniques of low grade ores: A review on black shale. Hydrometallurgy 117-118: 1-12.

- Pant D, Joshi D, Upreti M, Kotnala R (2012) Chemical and biological extraction of metals present in E-waste: A hybrid technology (Review). Waste Manag 32(5): 979-990.

- Hagshenas D, Alamdari E, Torkmahalleh MA, Bonakdarpour B, Nasernejad B (2009) Adaptation of Acidithiobacillus ferrooxidans to high grade sphalerite concentrate. Minerals Engineering 22(15): 1299-1306.

- Ilyas S, Anwar MA, Nianzi SB, Ghauri MA (2007) Bioleaching of metals from electronic scrap by moderately thermophilic acidophilic bacteria. Hydrometallurgy 88(1-4): 180-188.

- Li HM, Ke JJ (2001) Influence of Ni+2 and Mg+2 on the growth and activity of Cu+2-adapted Thiobacillus ferrooxidans. Hydrometallurgy 61(3): 151-156.

- Birgander J, Reischke S, Jones DL, Rousk J (2013) Temperature adaptation of bacterial growth and 14C-glucose mineralisation in a laboratory study. Soil Biology and Biochemistry 65: 294-303.

- Oger P, Cario A (2013) Adaptation of the membrane in Archaea. Biophysical Chemistry 183: 42-56.

- Creager AN (2007) Adaptation or selection? Old issues and new stakes in the postwar debates over bacterial drug resistance. Studies in history and philosophy of science Part C Studies in History and Philosophy of Biological and Biomedical Sciences 38(1): 159-190.

- Russel A (2004) Bacterial adaptation and resistance to antiseptics, disinfectants and preservatives is not a new phenomenon. J Hosp Infect 57(2): 97-104.

- Fuente Núñez C, Reffuveille F, Fernández L, Hancock R (2013) Bacterial biofilm development as a multicellular adaptation: antibiotic resistance and new therapeutic strategies. Current Opinion in Microbiology.

- Park YJ, Fray DJ (2009) Recovery of high purity precious metals from printed circuit boards. Journal of Hazardous Materials 164(2-3): 1152- 1158.

- Tuovinen OH, Kelly DP (1973) Studies on the growth of thiobacillus ferrooxidans-use of membrane filters and ferrous iron agar to determine viable number and comparison CO2 fixation and iron oxidation as measures of growth. Arch Microbiol 88(4): 285-298.

- Yamane LH, Moraes VT, Espinosa DC, Tenório JA (2011) Recycling of WEEE: Characterization of spent printed circuit boards from mobile phones and computers. Waste Manag 31(12): 2553-2558.

- Brandl H, Faramarzi MA (2006) Microbe-metal-interactions for the Biotechnological Treatment of Metal-containing Solid Waste. China Particuology 4(2): 93-97.

- Brandl HB, Wegmann M (2001) Computer-munching microbes: Metal leaching from electronic scrap by bacteria and fungi. Hydrometallurgy 59(2001): 319-326.

- Chiang Y, Santos R, Monballiu A, Ghyselbrecht K, Martens J, et al. (2013) Effects of bioleaching on the chemical, mineralogical and morphological properties of natural and waste-derived alkaline materials. Minerals Engineering 48(2013): 116-125.

- Cui J, Zhang L (2008) Metallurgical recovery of metals from electronic waste: A Review. Journal of Hazardous Materials 158(2-3): 228-256.

- Das N (2010) Recovery of precious metals through biosorption-A review. Hydrometallurgy 103 (1-4): 180-189.

- Faramarzi MA, Stagars M, Pensini E, Krebs W, Brandl H (2004) Metal solubilization from metal-containing solid materials by cyanogenic chromobacterium violaceum. J Biotechnol 113(1-3): 321-326.

- Fu KB, Lin H, Cheng H, Mo XI, Dong WB (2013) Bioleaching of djurleite using Acidithiobacillus ferrooxidans (Technical note). Minerals Engineering 40: 38-41.

- Garcia O (1989) Estudos da Biolixiviação de Minérios de Urânio por Thiobacillus ferrooxidans (Doctoral thesis). Instituto de Biologia da Universidade Estadual de Campinas, Brazil, p. 261.

- Kelley EJ (2008) Introduction to base materials. (6th edn), CF Coombs (Eds.), McGraw-Hill Handbooks, New York, USA,

- Lewis G, Gaydardzhiev S, Bastin D, Barrel P (2011) Bio hydrometallurgical Recovery of Metals from fine shredder residues. Minerals Engineering 24(11): 1166-1171.

- Liang G, Tang J, Liu W, Zhou Q (2013) Optimizing mixed culture of two acidophiles to improve copper recovery from printed circuit boards (PCBs). Journal of Hazardous Materials 250-251: 234-245.

- Nakahara H (2008) Types of printed wiring boards. In: Coombs CF (Ed.), Printed Circuits Handbook. (6th edn), McGraw-Hill Handbook, New York, USA, pp. 5.3-5.14.

- Shou peng L, Ning G, Hai yan W, Guan zhou Q, Xin xing L (2011) High efficient mixed culture screening and selected microbial community shift for bioleaching process. Transactions of Nonferrous Metals Society of China 21(6): 1383-1387.

- Yang Y, Diao M, Liu K, Qian L, Nguyen A, Qiu G (2013).

- Zhang S, Forssberg E (1999) Intelligent Liberation Column bioleaching of low-grade copper ore by Acidithiobacillus ferrooxidans in pure and mixed cultures with a heterotrophic acidophile Acidiphilium sp. Hydrometallurgy 131-132: 93-98 and Classification of Electronic Scrap. Powder Technology 105: 295-301.