Prospecting the Physical, Chemical and Nutritional Characteristics of Commercial Fruit Flours

Caroline Giane de Carli, Vanderlei Aparecido de Lima and Ornella Maria Porcu*

Department of Chemical Processes and Biochemistry, Federal Technological University of Paraná, Brazil

Submission: December 13, 2017;Published: December 20, 2017

*Corresponding author: Ornella Maria Porcu, Department of Chemical Processes and Biochemistry, Federal Technological University of Paraná, Brazil, Tel: +55 [46} 3220-2511; Fax: +55 (46) 3220-2500; Email: ornellamporcu@gmail.com

How to cite this article: Caroline G d C, Vanderlei A d L, Ornella M P. Prospecting the Physical, Chemical and Nutritional Characteristics of Commercial Fruit Flours. Nutri Food Sci Int J. 2016; 2(1): 555577. DOI:10.19080/NFSIJ.2016.02.555577

Abstract

The diversity of fruits produced in Brazil is an alternative of consumption when industrialized in the form of flour and becoming a source of nutrients, dietary fiber and minerals. They may also have its use added as an ingredient in the development of new food products making them healthier. The objective of this study was to characterize physical, chemical, and nutritional status of 10 different commercial fruit flours (afaf (A£), plum (AM), green banana (BV), coconut (CO), orange (LA), lemon (LI), Apple (MA), papaya (MM), passion fruit (MR) and grape (UV)) and for each type of flour three separate lots were evaluated. Measures were taken in triplicate for parameters of humidity, water activity, mineral fixed residue, protein, dietary fiber, pH, minerals (Cu(copper), Fe(Iron), Zn(zinc), Mn(Manganese), Na(sodium), K(potassium), Ca(Calcium), Mg (Manganese), P (phosphorus), Co (Cobalt), Cd (cadmium), Cr (chromium), Pb (lead), vitamin C content and instrumental color in the color space (CIE L*, a*, b*, Cab, Hab).

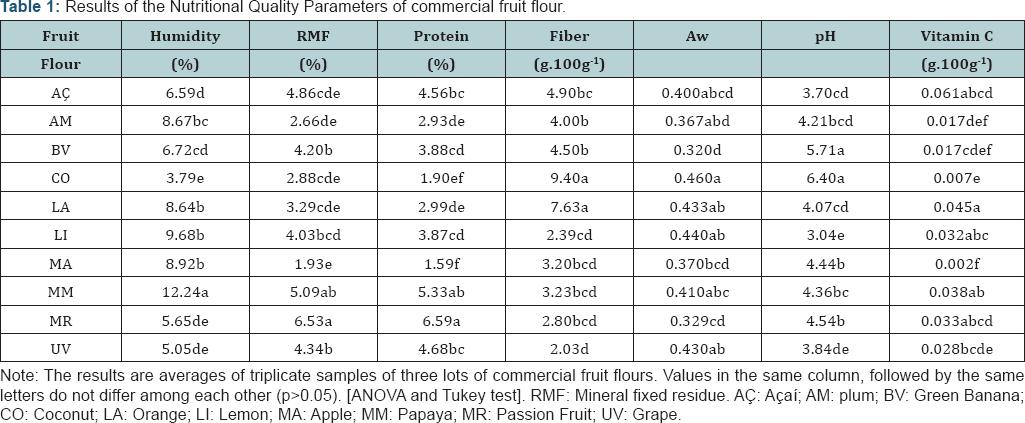

The moisture content for all commercial fruit flours studied was below 13% and the water activity (Aw) was less than 0.5000 which is of utmost importance to hygienic and sanitary conservation. The pH was variable according to characteristics from the fruit. For the ash content, there was a variation of 1.93 % ± 0.8 (MA) to 6.53 % ± 0.14 (MR). The content of proteins ranged from 1.59 % ± 0.09 (MA) and 6.59 % ± 0.86 (MR). The higher content of dietary fiber was significantly higher for (CO). For the analysis of vitamin C the lowest value was observed for MA and the greater for A£. The color characteristics resulting from the color channels (L*, a*, b*; and X, Y, Z) for each flour were shown as an intrinsic property of fruit that originates the flour, establishing a system of color that indicated uniformity of sample into several individual lots of flour.All flour has nutritional quality and potential use for the enrichment of foods.

Keywords: Food fortification; Functional ingredients; Chemical composition

Introduction

The style of life of the Brazilian population need changing in dietary habits, because the lack of physical activity, decreasing of the time allocated to leisure, have been associated with increased incidence of chronic diseases [1]. It is also noted, that in addition to the NTCDs there is also high prevalence of nutritional deficiencies. The low scale consumption of fruits, vegetables and legumes can be considered one of the risk factors associated with high morbidity and mortality in developing countries [2-4]. Brazil is a major producer of fruits; it is possible to find various types of fruit during the different seasons of the year. Much of what is produced is converted into other products, generating some residues such as bark, olive and seeds which can be used for the manufacture of fruit flour, because many important nutrients are present in such parts of the fruit, offering the consumer a great choice of consumption, both by their nutritional characteristics and sensory characteristics.

The Brazilian legislation in accordance with the Resolution- RDC No. 263, September 22th, 2005, describes flour as the products obtained from edible parts of one or more species of cereals, legumes, fruits, seeds, tubers and rhizomes by milling and/or other technological processes are considered safe for food production [1]. Among the many types of flours that are in trade there is the flour from fruits such as flour of acai berry, plum, green banana, coconut, orange, lemon, apple, papaya, passion fruit and grapes. The composition of such flour can vary according to the season of the year, soil characteristics, conditions of storage of fruits and processing conditions for the obtaining of flour. The objective of this study was to characterize physical, chemical and quality nutritional of commercial fruit flours.

Materials and Methods

Samples

The samples were obtained in the town of Francisco Beltrao, Paraná State, Brazil. We selected 10 commercial fruit flour: acai (AQ, plum (AM), green banana (BV), coconut (CO), orange (LA), lemon (LI), apple (MA), papaya (MM), passion fruit (MR) and grape (UV). We analyzed three different lots in different periods of the year 2014 and each batch consisted of 100g each. The commercial fruit flour from coconut and passion fruit were analyzed only lots 1 and 3 because there was no commercial availability of samples for lot 2.

Chemical and mineral composition

Determining the chemical composition ofthe fruit commercial flour the whole quantity was used, being determined for the ten different types. All analyzes were performed in triplicate. Through analytical determinations it was possible to quantify the humidity [5], content of lipids [6], protein by Kjeldahl technique [6] with factor of correspondence nitrogen-protein of 5.75 (vegetable proteins) [7] and fixed mineral residue [5], pH determined by potentiometry [6] and Vitamin C [8].

The dietary fiber was determined following the methodology described on manual Total dietary fiber assay Kit (Sigma- Aldrich-Cod TDF-100A e TDF-C10). The analyzed mineral profile for the ten varieties of fruit commercial fleur comprised the following macro minerals: P(phosphorus), K(potassium), Na(sodium), Ca (calcium), Mg(magnesium), and micro minerals as Cu(copper), Fe(iron), Zn(zinc), Mn(manganese), Co (cobalt), and the highly toxic Cd(cadmium), Cr(chromium), Pb(lead) by Atomic absorption spectrometer Using air-acetylene flame with the exception of calcium for which it was used a mixture of acetylene-nitrous oxide (Analytik Jena AG; Model Nova A 300) [7].

Color parameters

The color analyses were determined in quadruplicate directly in colorimeter Minolta Chroma Meter CR-300b/USA, (illuminant D 65) [5]. The equipment was calibrated following the manufacturer's instruction manual [9]. We used a sample of approximately 100.0 g sample previously homogenized for measurement of spatial coordinates of color by the CIELAB AS L*, a*, b*, X, Y, Z and Cab, h0ab. The appliance is composed of a light-projection tube which in contact with the sample passes the reading through reflectance to a data processor.

Water activity and pH evaluation

The reading of water activity (Aw) happened in the Aqua Lab brand4TE model, version 4 device. For the determination of the pH of the samples, it was used a potentiometric device [6,10].

Results and Discussion

The quality of flour is measured by physical, chemical and rheological tests that intend to predict the behavior of the flour in the manufacturing processes of food products and if correctly interpreted, offer a high hit probability. Through them, it is also possible to test effects of changes in the formulation and use of additives [10]. The commercial fruit flours were evaluated as to the content of moisture, mineral fixed residue (RMF), proteins, dietary fiber, water activity (Aw), potential of hydrogen (pH) and vitamin C and the results are presented in Table 1. Regarding the content of mineral fixed residue (ashes) evidenced in this study it was observed that the lowest value occurred for the flour of apple (1.93%±0.8) and the maximum value of 6.53%±0.14 resulted for commercial flour of passion fruit. This variation derives from the difference between the commercial fruit flour, or of any interaction between the constituents of the sample whose composition depends on the original fruit (Table 1).

The content of dietary fiber was observed in greater relevance for CO, which does not statistically differ from the contents observed for LA. The lowest content of dietary fiber was observed in commercial flour of lemon (2.39±0.1 g.100g-1). The flour of green banana is rich in insoluble dietary fiber and resistant starch [11] vegetable origin compound resistant to enzymatic hydrolysis, to digestion and the absorption in the small intestine. This way, this fraction shares many of the characteristics and benefits attributed to dietary fiber in the human body. Literature sources presented research potential of green banana due to its high content of dietary fiber to health [11,12]. We found in this study a number of fibers that ranged from 2.03% (UV) to 9.40% (CO), whose contents were all higher than those found in green banana cv. Silver (1.01g.100g-1) [13] and in flour of potato peel (1.62g.100g'1) [14]. They are still above the content of fiber in tapioca flour (0.31 g.100g-1) and in average content (1.85g. 100g-1) found for several analyzed flour of cassava [15].

Mineral Content

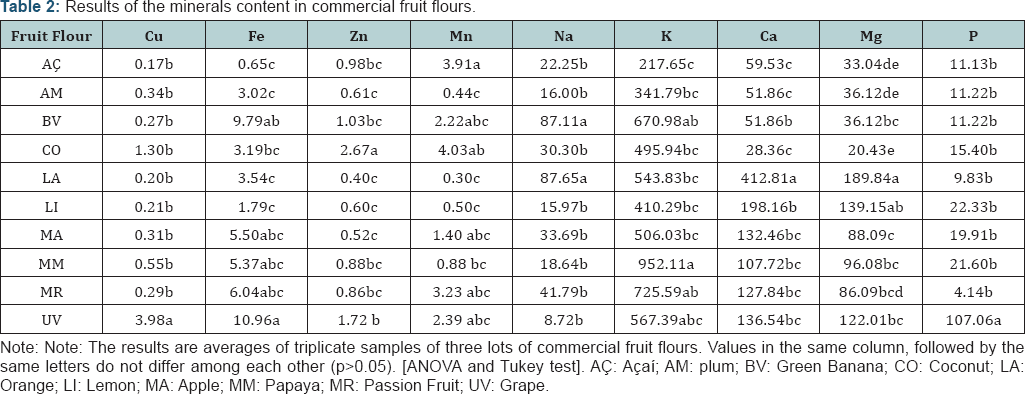

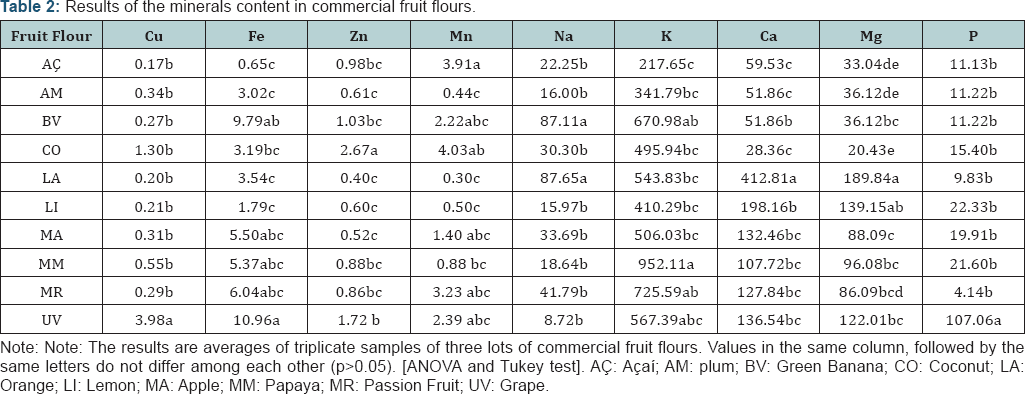

Table 2 presents the results obtained by atomic absorption spectroscopy for the determination of individual mineral elements in samples of commercial fruit flour trade. This analysis confirms that the nutritional value, prevents or corrects deficiencies of one or more nutrients [1] for the commercial fruit flour. In this study,, the highly toxic elements such as Cd(cadmium), Cr(chromium) and Pb(Lead) were found with concentration limit below the detection limit of the method (0.005mg.100g-1). The commercial flour of grape showed higher copper content (3.98mg.100g-1), followed by the CO (1.30mg.100g-1) and MM (0.55mg.100g-1). These values are higher than those reported for ripe dry banana (0.39 to 0.66 mg.100g-1) [15]. And it is even higher, when comparing the contents of copper for UV and the flour of banana cv. Silver (1.65mg.100g-1) [16]. According to the Food Composition Table [17] flours made from rye, wheat, corn, thread featured quantities of copper less than 0.60mg.100g-1 but there are no results for commercial fruit flour. On the other hand, it should be noted that elevated levels of copper are toxic and can compromise health.

The commercial flour of coconut also presented zinc in greater quantity (2.67mg.100g-1) and the lowest quantity was found in the commercial flour of orange (0.40mg.100g-1). Zinc is important in biochemical functions where it participates as a cofactor of several enzymes. The literature indicates a ratio between the concentration of iron and zinc at about 4:1 (Fe:Zn) as opposed to the use of zinc, indicating therefore that the iron can impair the bioavailability of zinc in the human organism [9,18,19] as evidenced by a chemical similarity between them [20]. In this study, the proportion found in all samples of commercial fruit flour is it possible to establish the flours of A£, CO, LI and MM as favorable to the usage of zinc.

The mineral manganese in the analyzed samples of commercial fruit flour showed greater quantity in A£ (3.91mg.100g-1) and did not statistically differ from commercial flours of CO, MA, MR, and UV. The lowest content of this mineral has been observed in commercial flour of plum (0.44mg.100g-1). For zinc and manganese the values recommended by the IDR are smaller, 7 and 2.3mg/day, respectively [1]. The content of sodium was observed with higher prevalence in the flour in LA (87.65mg.100g-1) and BV (87.11mg.100g-1), and the lowest content was observed for LI (15.97mg.100g-1). Regarding phosphorus contents, the flour of grapes has showed the highest value (107.06mg.100g-1) followed by LI, MM, MA and CO and these did not statistically differ from the others (A£, AM, BV, LA and MR) whose levels were lower than 12mg.100g-1. The daily recommendation for phosphorus is 700mg/day [1]. The mineral element calcium was found in larger quantities in the LA (412.81mg.100g-1) and in smaller quantities in CO (28.36mg.100g'1). A medium content of calcium was detected for green banana cv. Silver 130 mg.100g-1 [16] whose values were higher than those recorded in this work for BV. Thus, we consider it a rich source of calcium in descending order of concentration of calcium the flours LA, LI, UV, MA, MR and MM and due to the high values of calcium found we indicate its use in foods enrichment of this element.

In accordance with the RDC n° 269 of ANVISA [1] the daily intakes recommended (IDR) for calcium is 1000 mg/day for an adult person, 700 mg for children aged 1 to 10 years and 1200 mg for pregnant women. The commercial flour of LA, LI, UV, MA, MR e MM, represents 41.28, 19.82, 12.01, 13.25, 12.78 and 10.77% of the IDR, respectively. The amount of magnesium found in this work for BV (36.12mg.100g-1) was close to the registered to ripe banana 25 to 35mg.100g-1 [15]. For the magnesium the IDR is 260 mg/day [1]. All samples of commercial fruit flour are also a rich source of potassium (217.65mg.100g-1 < K< 952.11mg.100g-1). The mineral potassium was found in greater quantity in the MM (952.11mg.100g-1) and in smaller quantities in A£ (217.65mg.100g-1). This behavior agrees with the suggested by [21] when evidenced to fruit residue flour from fruit such as red guava, white guava, mango, cashew and caja an increased potassium concentration with emphasis to the red guava with 488.92 mg.100g-1 corresponding to 32% of the IDR [1] and it is four times greater than that of the white guava (112.63mg.100g-1). In another study, in powder of guava residues contained 555.36±1.02mg of K.100g-1 [22].

The content of minerals (Fe, Zn, Cu and Mn) in residues obtained from the production of pulp from guava, caja, cashew and mango was quantified and the content of Fe (8.97mg.100g-1) was highlighted in the residual pulp of white guava, still, it was evaluated that the influence of sequential extraction of Cu, Fe, Mn, Mg and Zn in flour of fruit and vegetable residue in two separate lots, there was a significant difference between the lots [23]. The most important metals that characterize commercial fruit flours were Cu, Mg, Na, Mn and Fe. The other metals, K, Zn and Ca contributed in a smaller scale to determine the pattern of this type of food matrix.

The commercial flour of grape was differentiated from the others, because it possesses the greater contents of the minerals copper, iron and phosphorus. Commercial orange and banana flours have higher amounts of calcium and sodium minerals (Figure 1).

Evaluation of commercial fruit flour composition: other analytical parameters

In food analysis, it is of utmost importance to determine a specific component of the food as the case of the determination of pH. The potential of hydrogen (pH) is an important measure for the determination of food deterioration such as microorganisms growth, activity of the enzymes, retention of taste and smell in the products, and choice of packaging [24]. Such information may serve for different purposes, such as: nutritional assessment of a product; food quality control; development of new products and monitoring of legislation.

The potential of hydrogen (pH) is also one of the ways to determine the acidity, which is directly related to the fruit that gave origin to the flours. The lowest pH value was observed in the commercial flour of lemon (3.84±0.07), while the highest value observed was in the flour of coconut (6.4±0.14).It was reported to green banana cv apple and silver pH equal to 6.11 and 6.24, respectively [25], higher than our study (pH=5.71).For flour of pumpkin seed pH equal to 6.22 [26].For flour of cashew stem and peel of passion fruit found pH of 4.15 and 3.77, respectively [27] and, in this case, it was lower than that obtained for MR in this study.

In the present work, it was found that the pH was in the range of 3.5 to 6.5, demonstrating that these flours were in the range of pH (2.0 and 8.5) in which molds and yeasts easily multiply. Lower pH values may indicate a concentration of acids during a drying process, as the case of obtaining fruit flour [28]. In this study we also observed a large variability in chemical composition, but it comes from different types of commercial fruit flour. On the other hand, when comparing certain constituents we observed that there is difference. The percentage of proteins soluble (Albumins and globulins) or insoluble (gliadin and glutenins) in commercial fruit flour resulting, in this study varied in the range of 1.59%± 0.09 (MA) to 6.59%±0.86 (MR).

Larger levels of proteins were characterized for flour of green banana peel developed from cultivars apples and silver obtaining 9.97 and 7.10%, respectively [26]. In flour of passion fruit peel, the proximate composition and the content of proteins was equal to 11.76 % ±1.17 [23]. In general the wheat flour has protein content between 8 to 16 % [29] and these parameters are higher when compared to the levels obtained in this study, indicating that different quantities affect the final nutritional quality. On the other hand, it is still great the applicability of these flours in the research and development of new products, for example being used as ingredients or agents of fortification in the baking area. And, it comes as a proposal to implement an alternative diet focusing on health and nutrition [30-33].

Vitamin C content

Regarding the vitamin C content, the lowest value was observed for the flour of apple (0.002±0.01mg.100g-1) and the highest value was observed for a^ai fruit (0.061±0.01 mg.100g-1). The results obtained for that content are inferior to the residue flour of orange [34] residue of green banana [16], flour or peel of passion fruit plant [35] among other studies [36,37]. The low vitamin C content observed in commercial flour fruit can be caused by processing and heat treatment to which the fruit undergone in order to obtaining the flour.

Another reason that can justify these results are packaging and storage conditions of flour in commercial points of sale, since these are not protected from the action of light, but in containers or transparent plastic packaging exposed to light and to handling of the seller.

Instrumental Colorimetry Analysis

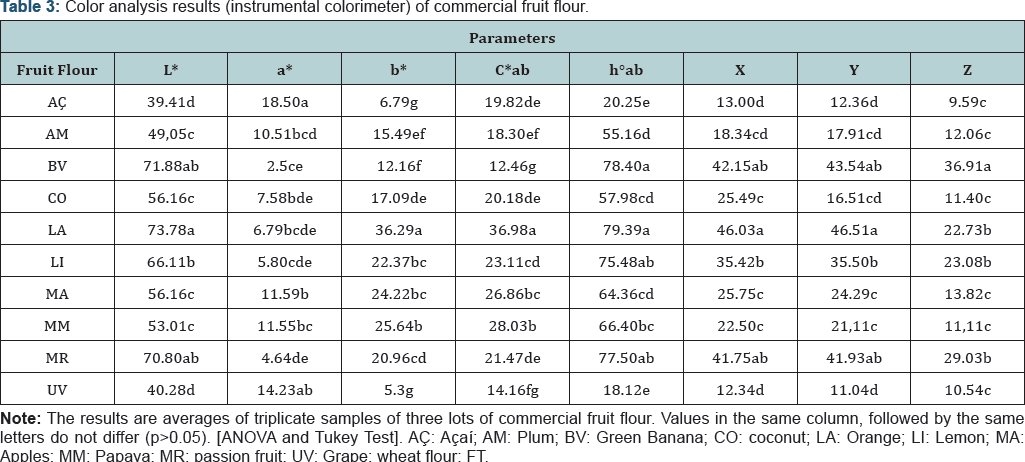

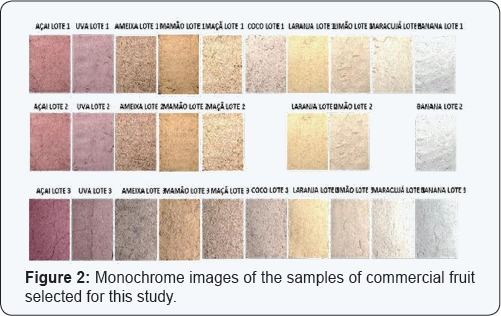

Table 3 shows the average values of the colorimetric parameters (L*, a*, b*, C*, ho, X, Y, Z) for the color of the commercial fruit flour assessed by instrumental colorimeter of the fruit flours selected for this study (Figure 2). The color of a flour will depend on its level of natural pigments, proteins, fibers and the presence of impurities. The color attribute (Table 3) is very important for the consumer, however, in the case of the samples selected for this study it was detected a well-defined visual difference for each type of fruit. The higher values of L* correspond in ascending order to LI, MR, BV, and LA. As this parameter measures brightness, the greater this value the clearer is the sample. All samples of fruit flour showed a significant difference for L* except for BV, LA and MR. The results of the chromaticity a* responsible for the colors of (-) green to (+) red, were all positive, with the greatest values found in ascending order to MM, MA, UV, and Af. Thus, the commercial fruit flour of a^af has a color of greater intensity of red in its composition.

For the values of b* the colors vary from (-) blue to (+) yellow, the higher the value of b* the greater the tendency of color to yellow. Thus, the commercial flour of orange (36.29+1.36) with higher value of b* tends to appear with pale yellow intense and the lowest value found in flour of grape (5.3+1.07) and (6.79+2.23), which showed no significant difference between them (p<0.05) therefore do not tend to yellow color. The Chroma C* index (chroma or saturation) showed that LA has high saturation or strong color (36.98+1.29) while BV has the lowest oxygen saturation (12.46+1.01) or more opacities. Among the samples it was observed that the Hue angle (h°ab = tint) resulted in higher for LA, consequently indicating tonality closest to the yellow, agreeing with the parameter chroma b*.The literature presents a few studies on the measurement of color in commercial fruit flour; however, there are many studies with different fruits and industrial wastes from these fruits, as well as development of bakery products with the addition of flour processed in the laboratory [32,38-41].

Conclusion

The study of the physicochemical parameters determined in the present study were efficient in the analysis of technical quality and the nutritional profile of commercial fruit flour showing that its use is possible as an alternative to enhance the supply of the population making it more healthy and balanced. Thus, we can indicate them as excellent alternative for enrichment of bakery products, adding not only economic value but also nutritional value, to the quality of the formulation of a food product.

References

- BRASIL (2005) Ministério da Saúde. Agencia Nacional deVigilància Sanitària. Regulamento técnico para produtos de cereais, amidos, farinhas e farelos. Resolufao RDC no. 263, de 22 de setembro de 2005. Diàrio Oficial da Uniao, 23 de setembro de 2005, Sefao 1, pp. 368.

- Ministério da Saúde (2006) Guia Alimentar da Populafao Brasileira: Promovendo a Alimentalo Saudàvel. Brasilia.

- Organizado Mundial da Saúde (OMS) (2004) Global Strategy on Diet, Physical Activity and Health. Fifty-Seventh World Health Assembly Wha 57.17. Genebra: OMS, maio.

- Informe Sobre Saúde no Mundo (2002) Reduzir os Riscos e Promover Uma Vida Saudàvel. Genebra: OMS.

- (AACC) American Association of Cereal Chemists (2000) (10th edn), St. Paul, Turkey.

- (AOAC) Association of Official Analytical Chemistry (1997) Official methods of analysis of AOAC: (16th edn). Gaithersburg: AOAC, pp. 1141.

- BRASIL (2003) Resolufao RDC ANVISA/MS RDC no 360, de 23 de dezembro de 2003. Regulamento Técnico sobre Rotulagem Nutricional de Alimentos Embalados, Diário Oficial da Uniao, Brasilia, DF, 26 dez.

- Instituto Adolfo Lutz (2008) Normas Analíticas do Instituto Adolfo Lutz: Métodos Químicos e Físicos para Análise de Alimentos. (3rd edn), Sao Paulo: IAL, Turkey.

- Decagon Devices (2007), Inc. Manual de Instrufoes Aqualab Lite.

- Zimmermann LOG, Sedor J, Noreto, LM, Santiago, WE, Ferreira, DTL (2009) Avaliafao Físico-Quimica e Reológica das Principais Farinhas de Trigo Comercializadas em Padarias do Município de Cascavel. Anais do I Seminário Internacional de Ciencia, Tecnologia e Ambiente. UNIOESTE, Cascavel - Paraná.

- Freitas, MCJ (2000) Dietas Ricas em Amido Resistente de Bananas Verdes (Musa AAA-Nanicao e Musa AAB-Terra) Promovem Alterafoes na Funfao Intestinal, no Metabolismo Lipídico e Glicídico e na Microbiota Intestinal. Dissertafao (Mestrado) Faculdade de Engenharia de Alimentos, Universidade Estadual de Campinas, Campinas, Sao Paulo, pp.112.

- Machado, NCR, Sampaio RC, Lima JCR (2013) Efeito do Amido Resistente da Biomassa de Banana Verde. In: V Seminário De Pesquisa e TCC da Faculdade de Uniao De GOYAZES. Anais. Goiás. V Seminário de Pesquisa e TCC da FUG- Disponível em.

- Borges AM, Pereira Joelm, Lucena EMP de (2009) Caracterizafao da Farinha de Banana Verde. Cienc Tecnol Aliment 29(2): 333-339.

- Fernandes AF, Pereira J, Germani R, Oiano Neto J (2008) Effect of the Parcial Replacement of Wheat Flour for Potato Skin Flour (Solano Tuberosum L.). Cien Tecnol Aliment 28: 56-65.

- Dias, LT, Leonel, M (2006) Caracterizafao Físico-Química de Farinhas de Mandioca de Diferentes Localidades do Brasil. Cienc Agrotecnol 30(4): 692-700.

- Ministério da Saúde. Agencia Nacional de Vigilancia Sanitária (2005). Resolufao RDC n° 269, de 22 de setembro de 2005. O "Regulamento Técnico Sobre a Ingestao Diária Recomendada (IDR) de Proteína, Vitaminas e Minerais”. ANVISA -Agencia Nacional de Vigilancia Sanitária, de 23 de setembro de 2005.

- Medina JC, Bleinroth EG, Martin-Quintal Z, Travaglini D, Okada M, et al. (1985) Banana: Cultura, Materia-Prima, Processamento e Aspectos Económicos. ITAL, Campinas, Brazil pp. 302.

- Tabela Brasileira de, Composifao de Alimentos (2011) - 4a Edifao- Banco de dados Tabela Brasileira de Composifao de Alimentos.

- Pedrosa, LFC, Cozzolino, SMF (1993) Efeito da Suplementafao com Ferro na Biodisponibilidade de Zinco em Uma Dieta Regional do Nordeste do Brasil. Sao Paulo Rev Saúde Pública 27(4): 266-270.

- Lobo AS, Tramonte VLC (2004) Efeitos da Suplementafao e da Fortificafao de Alimentos sobre a Biodisponibilidade de Minerais. Rev Nutr 17(1): 107-113.

- Solomons TW (2009) Livros Química Orgánica - Vol. 2 - Solomons, T.W. Graham/ Fryhle, Craig B. (8521616783) 1(9).

- Sena DN, Oliveira AFR, Sousa MMA, Almeida MMB, Sousa PHM (2014) Farinha de Resíduos de Processamento de Frutas Tropicais: Determinafao dos seus Potenciais Antioxidantes. Congresso Brasileiro De Engenharia Química 1(2).

- Reis LS (2013) Influencia do Armazenamento na Extrafao Sequencial de Micronutrientes e Elementos Trafo em Farinha de Resíduo de Frutas e Hortalifas. Dissertafao (Mestrado em Alimentos e Nutrifao) - Universidade Federal do Estado do Rio de Janeiro, Rio de Janeiro pp. 71.

- Cecchi HM (1999) Fundamentos Teóricos e Práticos em Análises de Alimentos. Campinas SP, Editora da Unicamp pp. 211.

- Castilho LG, Alcantara BM, Clemente, E (2014) Desenvolvimento e Análise Físico-Química da Farinha de Banana Verde das Cultivares Mafä e Prata. Rev e-exata 7(2): 107-114.

- Amorim, AG, Souza, TA, Souza, AO (2012) Determinalo do pH e Acidez Titulável da Farinha de Semente de Abóbora (Cucurbita máxima). VII Congresso Norte Nordeste de Pesquisa e Inovafäo (CONNEPI). Palmas, Tocantins.

- Uchóa AMA, Costa JMC, Maia GA, Silva EMC, Carvalho AFU, et al. (2008) Parámetros Físico-Químicos, Teor de Fibra Bruta e Alimentar de Pós Alimenticios obtidos de Resíduos de Frutas Tropicais. Seguranza Alimentar e Nutricional, Campinas, 15(2): 58-65.

- Alcántara SR, Almeida FAC, Silva FLH (2007) Emprego do Bagafo Seco do Pedúnculo do Caju para Posterior Utilizafäo em um Processo de Fermenta o Semi-Sólida. Rev Bras de Produtos Agroindustriais 9(2): 137-142.

- Sousa MSB, Vieira LM, Silva MJMD, Lima A (2011) Caracterizafäo Nutricional e Compostos Antioxidantes em Resíduos de Polpas de Frutas Tropicais. Ciénc agrotec 35(3): 554-559.

- Scheuer PM, Francisco A, Miranda MZ, Limberger VM (2011) Trigo: Características e Utilizafäo na Panificafäo. Rev Bras de Produtos Agroindustriais 13(2): 211-222.

- Vernaza GV, Márcia Arocha Gularte, Yoon Kil Chang (2011) Addition of Green Banana Flour to Instant Noodles: Rheological and Technological Properties. Cienc Agrotecnol 35(6): 1157-1165.

- Gonfalves CR, Leäo MF (2013) Produfäo de Iogurte com Adifäo de Farinhas Mistas a partir dos Resíduos de Mafä, Maracujá e Uva. Enciclopédia Biosfera -Centro Científico Conhecer Goiania 9(17): 3618.

- Azevedo et al., (2015) Avaliafäo Física, Físico Química e Sensorial de Cookies Enriquecidos com Farinha de Afaí. Rev. Verde de Agroecol. e Desenvolvimento Sustentável 10(4): 49-54.

- Pires, VCF, Silva, FLH, Souza, RMS Parametros da Secagem da Banana Pacovan e Caracterizafäo Físico Química da Farinha de Banana Verde. Rev. Verde de Agroecol. e Desenvolvimento Sustentável 9(1): 197-209.

- Clemente E, Flores AC, Rosa CILF, Oliveira DM (2012) Características da Farinha de Resíduos do Processamento de Laranja Characteristics of Flour Residues from the Orange Processing. Rev. Cienc. Exatas e Naturais 14(2): 257-269.

- Pita J da SL (2012) Caracterizafäo Físico-Química e Nutricional da Polpa e Farinha da Casca de Maracujazeiros do Mato e Amarelo. Dissertafäo de mestrado. Universidade Estadual do Sudoeste da Bahia, Itapetinga. p. 77.

- Pereira, GIS, Pereira, RGFA, Barcelos, MdeFP, Morais, ARde (2003) Avaliafäo Química da Folha de Cenoura Visando ao seu Aproveitamento na Alimenta fäo Humana. Lavras, Cienc Agrotecnol 27(4): 852-857.

- Moreno, JdeS (2016) Dissertafäo (Mestrado) Obtenfäo, Caracterizafäo e Aplica fäo de Farinha de Resíduos de Frutas em Cookies - Itapetinga: UESB, p.86.

- Xavier D (2013) Desenvolvimento de Produto Alimentício à Base de Farinha de Trigo Integral e Ingredientes Funcionais Dissertafäo (Mestrado) - Universidade Tecnológica Federal do Paraná. Programa de Pós-Graduafäo em Tecnologia de Processos Químicos e Bioquímcos. Pato Branco/PR, pp.185.

- Mews L, Carminatti R, Porcu OM, Oviedo MSVP (2014) Coordenadas de Cor e Carotenoides Totais em Polpa de Goiaba Microencapsulada Obtida Por Spray Dryer. In: COBEQ Florianopolis/SC.

- Pessoa TRB (2009) Avaliafào do Processo de Obtenfào de Farinha de Casca de Banana Verde (Musa sapientum) das Variedades Prata,Pacovan e Mafà. Dissertalo (Mestrado em Ciencia e Tecnologia de Alimentos)- Universidade Federal de Paraiba, Joao Pessoa, pp.123.

- Lopes LD (2013) Desenvolvimento e Avaliafào De Subprodutos de Uva e Sua Utilizalo Como Ingrediente Alimenticio. Dissertalo (Mestrado em Tecnologia de Alimentos)-Universidade Tecnològica Federal do Paraná, Londrina, p. 72.