Cost-Benefit Analysis of Aquaponic and Hydroponic Barley Cultivation: Economic Implications and Yield Performance

Angham Bani Owdeh1, Muayad Salman2* and Mohamed Salah Romdhane1

1National Institute of Agricultural Sciences-University of Carthage, Tunisia

2Research Laboratory of Ecosystems and Aquatic Resources, UR03AGRO; National Agronomic Institute of Tunisia, University of Carthage, 43 Av. Charles Nicolle, Tunis, Tunisia

Submission: October 03, 2024; Published: October 23, 2024

*Corresponding author: Muayad Salman, Research Laboratory of Ecosystems and Aquatic Resources, UR03AGRO; National Agronomic Institute of Tunisia, University of Carthage, 43 Av. Charles Nicolle, Tunis, Tunisia

How to cite this article: Angham Bani O, Muayad S, Mohamed Salah R. Cost-Benefit Analysis of Aquaponic and Hydroponic Barley Cultivation: Economic Implications and Yield Performance. Agri Res& Tech: Open Access J. 2024; 28(5): 556428.DOI: 10.19080/ARTOAJ.2024.28.556428

Abstract

This study evaluates the cost-effectiveness of barley production using aquaponic and hydroponic systems in Nablus Governorate, West Bank, Palestine. Conducted from December 20, 2023, to January 4, 2024, the research compared three systems: an aquaponic system (T1), a hydroponic system with tap water (T2), and a hydroponic system with nutrient solution (T3). The aquaponic system demonstrated a significant increase in tray net weight from 7.94 kg to 11.80 kg over 14 days, with an increase in dry matter from 12% to 16% and a rise in crude protein from 16% to 19%. Hydroponic systems showed lower performance with T2 and T3 achieving net weight increases to 9.27 kg and 9.58 kg, respectively, and a smaller rise in crude protein compared to T1. Cost analysis revealed that the aquaponic system had the highest operational costs at $11,653.35 for six months, while the hydroponic system with nutrient solution was slightly lower at $11,283.98. The hydroponic system with tap water was the lowest operational costs at $10,843.35. Despite higher initial costs, the aquaponic system provided better protein yields, which may justify the investment for higher-value applications.

Keywords: Aquaponic System; Crude Protein; Moisture Content; Dry Matter; Cost Analysis

Abbreviations: CELSS: Controlled Ecological Life Support Systems; AFB: As Fed Basis; NDF: Neutral Detergent Fiber; ADF: Acid Detergent Fiber; ADL: Acid Detergent Lignin; GLM: General Linear Model; T1: Treatment 1, Aquaponic; T2 Treatment 2, hydroponic with tap water; T3: Treatment 3, hydroponic with nutrient solution; NWT: Tray Net WT (kg); MC%: Moisture Content percentage; DM%: Dry Matter percentage; DMW: Tray Dry matter Weigh; CF%: Crude Fiber percentage; CP%: Crude Protein percentage; CPW: Total protein weight per tray.

Introduction

Dairy farmers face numerous challenges in producing green fodder. These challenges include limited land holdings, insufficient space for fodder cultivation, water scarcity or salinity, a lack of high-quality fodder seeds, increased labor demands, and the need for manure and fertilizer. Additionally, fodder crops require a growth period of 45 to 60 days, protection from wild animals through fencing, and are vulnerable to natural disasters. The inconsistent availability of high-quality fodder throughout the year further complicates sustainable dairy farming [1].

Aquaponics offers a comprehensive solution by integrating fish and plant cultivation. In this system, fish waste provides essential nutrients for hydroponic plants, which, in turn, help purify the water, making it suitable for reuse in the fish tank. This method exemplifies the synergy between aquatic life and plant growth, aligning with sustainable agricultural practices as described by the Food and Agriculture Organization [2]. Recent research highlights barley cultivation in aquaponic systems as a promising approach for sustainable agriculture [3]. By combining aquaculture with hydroponics, aquaponics creates a closed-loop system that enhances resource efficiency for barley production.

Hydroponic systems also present a viable option for sustainable crop production, particularly within Controlled Ecological Life Support Systems (CELSS). Studies on wheat production, such as those conducted at the John F. Kennedy Space Center, demonstrate the potential for continuous crop production in hydroponic systems, yielding high amounts of edible biomass [4]. Goddek et al. [5] have emphasized the efficiency of aquaponics in resource utilization, showcasing its potential for high productivity in constrained environments like urban areas or regions with limited arable land. Aquaponics is notable for its nutrient recycling and water conservation capabilities, aligning with sustainable agriculture goals.

While aquaponic systems generally involve higher initial setup costs due to the need for fish tanks, biofilters, and plumbing, hydroponic systems may have lower initial costs as they do not include components for fish cultivation. Both systems, however, require investments in infrastructure, grow lights, and climate control [6]. Operational expenditures for both systems include electricity, labor, nutrient supply (for hydroponics), and fish feed (for aquaponics) [7]. Although aquaponics may incur additional costs related to fish health and water quality, the dual production of fish and plants can offset some of these expenses. Both systems are capable of high yield efficiency through controlled environment agriculture, with hydroponics offering precise nutrient management for faster plant growth and aquaponics providing high-quality crops while minimizing chemical fertilizers [8].

Aquaponics is particularly resource-efficient, using 90% less water compared to traditional soil-based agriculture. Hydroponics also conserves water better than soil cultivation but does not recycle nutrients as effectively as aquaponics. The reuse of water in aquaponics significantly reduces waste and conserves resources [9]. Both systems offer sustainable alternatives to traditional farming by reducing the need for arable land and minimizing water usage. Aquaponics also benefits from reduced fertilizer runoff and lower environmental contamination, supporting sustainable agriculture goals through efficient resource use and reduced ecological footprints [5]. Economic analyses often indicate that despite significant upfront investments, the long-term benefits of sustainable production can be profitable. The integrated nature of aquaponics provides dual income streams from fish and plant sales, potentially enhancing economic viability [10]. The primary aim of this study was to conduct a comprehensive cost-benefit analysis of barley production in aquaponic and hydroponic systems, evaluating the economic viability, resource efficiency, and productivity of each system.

Materials and Methods

The research was conducted in Nablus Governorate, West Bank, Palestine (32.2211° N, 35.2544° E) between December 20, 2023, and January 4, 2024. The experimental aquaponic system was housed in a 77-square-meter structure (7m x 7m) with a plastic roof and shaded sides, supported by steel beams (80mm x 40mm). It included a 1000-liter polyethylene IBC tank, encased in a galvanized iron frame, and transparent plastic hydroponic trays (90cm x 25cm x 7cm) supported by galvanized metal stands. Each 2m x 2m x 0.25m tray was divided into four sections with five holes per section, equipped with flow stoppers. Water circulation was maintained using 220-volt, 20-25-watt pumps with a flow rate of 1500-2000 liters per hour. The recirculating aquaponic system, designed to optimize barley sprout growth, could hold 490 trays and produce 70 trays daily. Local barley seeds were prepared by washing, cleaning, and soaking them for 24 hours before being placed on trays for two days of moist germination. Afterward, 1 kg of seeds per tray was transferred to aquaponic and hydroponic systems. The experiment involved three treatment groups: T1 (aquaponic system), T2 (hydroponic system with tap water), and T3 (hydroponic system with tap water and commercial nutrient solution), conducted over 7- and 14-day periods during which growth measurements were taken (Table 1).

Initial Investment

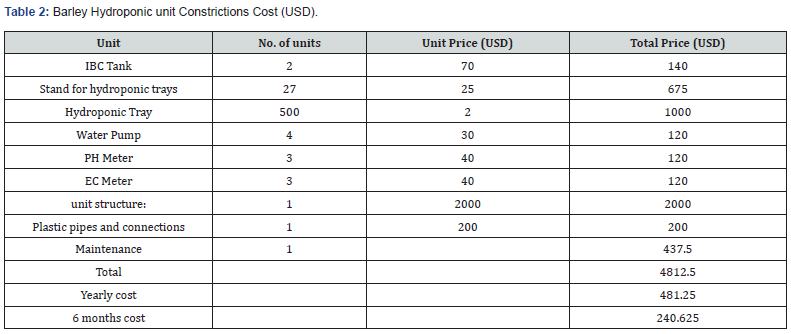

Table 2 details the costs involved in setting up a barley hydroponic unit. The initial investment totals $4,812.50, which covers the costs of tanks, trays, pumps, meters, structure, pipes, and maintenance. It also outlines recurring expenses, including an annual cost of $481.25 and a semi-annual cost of $240.63. This breakdown helps in financial planning for the agricultural setup, providing a comprehensive view of both the initial and ongoing costs associated with hydroponic farming.

Chemical Analysis

Sprouts from each group were weighed on the 7th and 14th days. Representative samples from each group were oven-dried at 60°C, ground through a 1-mm mesh sieve, and stored for chemical analysis. Chemical analysis was carried out at the National Agricultural Research Center Laboratory. Moisture content was determined by drying samples at 60°C for 48 hours. Nitrogen content was assessed using the Kjeldahl method, with crude protein calculated by multiplying nitrogen content by 6.25, as per AOAC [11] guidelines. Ash content was measured by igniting samples in a muffle furnace at 550°C for 4 hours. Neutral detergent fiber (NDF), acid detergent fiber (ADF), and acid detergent lignin (ADL) were analyzed using the methods outlined by Van Soest et al. [12] and the ANKOM 200 Fiber Analyzer [13].

Statistical Analysis

The statistical analysis of the data was conducted using the general linear model (GLM) procedure of SPSS 22. The analysis followed a completely randomized model with three treatments and three replications within both the 7-day and 14-day periods. The model can be represented by the equation:

Yij = μ + Ti + Dj + eij

In this equation, Yij represents the observation, μ represents the overall mean, Ti represents the effect of treatment (T1, T2, T3), Dj represents the effect of days in planting (7 days, 14 days), and eij represents the residual error. To determine significance, a threshold of P < 0.05 was used, while a trend was considered for 0.05 < P < 0.10.

Results

Table 3 displays the average measurements of Tray Net Weight (NWT), Moisture Content (MC%), Dry Matter (DM%), Tray Dry Matter Weight (DMW), Ash Percentage, Crude Fiber Percentage (CF%), Crude Protein Percentage (CP%), and Total Protein Weight per Tray (CPW) at 7 and 14 days across different treatments. For Treatment 1 (T1), which uses an aquaponic system, the tray net weight increased from 7.94 kg on day 7 to 11.80 kg on day 14. The moisture content decreased from 87% to 83%, and dry matter increased from 12% to 16%. Tray dry matter weight also increased significantly from 0.990 kg to 1.963 kg. The ash percentage remained constant at around 9%, while crude fiber percentage increased from 17% to 22%. Crude protein percentage rose from 16% to 19%, and total protein weight per tray increased from 0.163 kg to 0.387 kg. In Treatment 2 (T2), which uses a hydroponic system with tap water, the tray net weight increased from 6.82 kg on day 7 to 9.27 kg on day 14. Moisture content decreased from 88% to 86%, with dry matter decreasing from 13% to 11%. Tray dry matter weight increased from 0.773 kg to 1.320 kg. The ash percentage was around 9%, crude fiber remained at 17%, and crude protein percentage was 17% at both time points. Total protein weight per tray increased from 0.135 kg to 0.227 kg. Treatment 3 (T3), which uses a hydroponic system with a nutrient solution, showed a tray net weight increase from 6.63 kg on day 7 to 9.58 kg on day 14. Moisture content decreased from 88% on day 7 to 86% on day 14. Dry matter was 13% at both time points, with tray dry matter weight increasing from 0.756 kg to 1.263 kg. The ash percentage decreased slightly from 9.3% to 8.9%, while crude fiber percentage rose from 18% to 21%. Crude protein percentage increased from 13% to 18%, and total protein weight per tray increased from 0.102 kg to 0.232 kg.

Table 4 details the breakdown of costs associated with running an aquaponic system over a six-month period. The costs are categorized by unit, with each having a specified quantity, unit price, and total cost. The cost for electricity amounts to $150, based on 750 kilowatt-hours at $0.20 per kilowatt-hour. The water expense totals $27 for 18 cubic meters at $1.50 per cubic meter. Labor costs are significant, with a total of $3,850 for 770 hours of work, charged at $5 per hour. The dry barley seeds cost $6,300, derived from 12,600 kilograms priced at $0.50 per kilogram. For fish fingerlings, the expense is $180 for 600 units, each costing $0.30. Fish feed amounts to $630 for 420 kilograms at a rate of $1.50 per kilogram. There is also a lump sum of $516.35 allocated for other miscellaneous costs. The total costs for these items come to $11,653.35. When considering the overall six-month period and including additional expenses, the total cost is $11,893.975. This calculation is based on managing 70 trays per day.

Abbreviations: T1: Treatment 1, Aquaponic; T2 Treatment 2, hydroponic with tap water; T3: Treatment 3, hydroponic with nutrient solution; NWT: Tray Net WT (kg); MC%: Moisture Content percentage; DM%: Dry Matter percentage; DMW: Tray Dry matter Weigh; CF%: Crude Fiber percentage; CP%: Crude Protein percentage; CPW: Total protein weight per tray.

*Based on 70 tray per day.

Table 5 provides a detailed breakdown of the six-month operating costs for a hydroponic system using nutrient solutions. The cost of electricity for the period totals $150, based on 750 kilowatts at $0.20 per kilowatt. Water costs amount to $27 for 18 cubic meters at a rate of $1.50 per cubic meter. The cost of labor is $3,850, calculated from 770 worker hours at $5 per hour. The expense for dry barley seeds is $6,300, with 12,600 kilograms priced at $0.50 per kilogram. Fertilizer costs are $200, billed as a lump sum. Additional miscellaneous expenses are $516.35. Summing up all these costs, the total operating expense comes to $11,043.35, with the total cost over six months being $11,283.98, based on operating 70 trays per day.

*Based on 70 tray per day.

The six-month operating costs for the hydroponic system are detailed in (Table 6). The total expenses amount to $10,843.35, which includes the costs for electricity, water, labor, and dry barley seeds. An additional lump sum of $516.35 brings the overall total to $11,083.975. This table provides a comprehensive breakdown of financial requirements, highlighting the key cost elements necessary for effective management of the hydroponic system. The detailed expense overview allows for accurate budgeting and financial planning for the operation of the system over the six-month period.

Table 7 provides an overview of the six-month production metrics per unit for different treatments, focusing on As Fed Basis (AFB), Dry Matter (DM), and Crude Protein (CP) content. In Treatment 1 (Aquaponic), the production metrics were substantial: on day 7, the As Fed Basis was 100,044 kg, with a Dry Matter of 12,474 kg and a Crude Protein content of 2,057.706 kg. By day 14, these figures increased significantly to 148,680 kg AFB, 24,733.8 kg DM, and 4,881.744 kg CP. For Treatment 2 (Hydroponic with Tap Water), the metrics were somewhat lower compared to Treatment 1. On day 7, the As Fed Basis was 85,932 kg, with a Dry Matter of 9,739.8 kg and a Crude Protein content of 1,698.858 kg. By day 14, the production metrics were 116,802 kg AFB, 16,632 kg DM, and 2,862.468 kg CP. Treatment 3 (Hydroponic with Nutrient Solution) showed a different pattern. On day 7, the As Fed Basis was 83,538 kg, Dry Matter was 9,525.6 kg, and Crude Protein was 1,280.79 kg. On day 14, the metrics improved to 120,708 kg AFB, 15,913.8 kg DM, and 2,925.09 kg CP. Additionally, the dry seed baseline figures provided were 12,600 kg AFB, 10,962 kg DM, and 1,096.2 kg CP. These figures illustrate the variations in production efficiency and output across the different treatments over the six-month period.

Abbreviations: T1: Treatment 1, Aquaponic; T2 Treatment 2, hydroponic with tap water; T3: Treatment 3, hydroponic with nutrient solution; AFB: As Fed Base; DM: Dry Matter; CP: Crude Protein; *Based on 70 tray per day.

Abbreviations: T1: Treatment 1, Aquaponic; T2 Treatment 2, hydroponic with tap water; T3: Treatment 3, hydroponic with nutrient solution; AFB: As Fed Base; DM: Dry Matter; CP: Crude Protein; *Based on 70 tray per day.

The cost per kilogram for As Fed Basis (AFB), Dry Matter (DM), and Crude Protein (CP) as shown in Table 8. Cost per Kilogram of As Fed Basis, Dry Matter, and Crude Protein for Different Treatments varies based on the type of treatment applied. In Treatment 1 (Aquaponic), the cost per kilogram of AFB on day 7 was US$ 0.119, with corresponding costs of US$ 0.953 for DM and US$ 5.780 for CP. Treatment 2 (Hydroponic with tap water) showed AFB costs of US$ 0.129, DM costs of US$ 1.138, and CP costs of US$ 6.524. Treatment 3 (Hydroponic with nutrient solution) recorded the highest costs on day 7, with US$ 0.135 for AFB, US$ 1.184 for DM, and US$ 8.810 for CP. On day 14, the costs decreased across all treatments. In Treatment 1, the cost for AFB was US$ 0.079, DM cost US$ 0.480, and CP was US$ 2.436. Treatment 2 recorded costs of US$ 0.094 for AFB, US$ 0.666 for DM, and US$ 3.872 for CP, while Treatment 3 had costs of US$ 0.093 for AFB, US$ 0.709 for DM, and US$ 3.857 for CP. Additionally, for dry seeds, the costs were US$ 0.50 for AFB, US$ 0.574 for DM, and US$ 5.747 for CP.

Discussion

In discussing the findings, it becomes evident that Treatment 1 (aquaponic system) demonstrated superior performance in terms of growth and nutritional content over the two-week period compared to both hydroponic systems (T2 and T3). This advantage is clear in parameters such as net weight, dry matter weight, and crude protein percentage, with T1 showing greater increases across the board. For instance, while all treatments displayed increased tray net weight over time, T1 had a significantly higher final weight, driven by a combination of higher dry matter and crude protein percentages. Moisture content trends varied slightly, with T1 showing a more significant reduction from day 7 to day 14 compared to T2 and T3. This could suggest better water utilization or efficiency in the aquaponic system. Both hydroponic treatments, T2 (tap water) and T3 (nutrient solution), maintained relatively high moisture contents over time, which may have limited their overall dry matter production.

When considering dry matter and protein yields, T1 outperformed the other treatments significantly. By day 14, T1’s crude protein weight per tray had nearly doubled, reflecting its ability to sustain higher protein production. Meanwhile, T2 and T3 demonstrated more moderate gains, with T3 slightly surpassing T2 in crude protein by the end of the study, likely due to the nutrient solution’s supplementation in T3. Crude fiber increased in all treatments, but T1 again had the highest increase, which may contribute to better forage quality for livestock. Ash content remained fairly consistent across all treatments, indicating stability in mineral content, though T3 showed a slight reduction.

On the cost side, the aquaponic system (T1) incurred the highest overall operational costs compared to the hydroponic systems. However, the enhanced yield, especially in crude protein, contributed to a more favorable cost-per-kilogram outcome in T1. The hydroponic system with tap water (T2) and nutrient solution (T3) both required less capital investment, but their respective cost per kilogram of crude protein was notably higher than T1, highlighting the efficiency of the aquaponic system in protein production despite its higher operating costs.

In terms of production metrics, the aquaponic system delivered the highest As Fed Basis, Dry Matter, and Crude Protein outputs on both day 7 and day 14. This supports the conclusion that the aquaponic system is the most productive and efficient in terms of both biomass and nutrient content, despite its higher initial costs. The nutrient solution hydroponic system (T3) offered slightly better results than the tap water hydroponic system (T2) but still lagged behind T1 in key production parameters.

The study’s findings align well with existing literature on aquaponic and hydroponic systems. The superior productivity observed in the aquaponic system mirrors the results of Lennard and Lennard [14], who found that aquaponics often provides higher yields due to the nutrient-rich fish waste that benefits plant growth. This supports the study’s results showing greater increases in tray net weight, dry matter, and protein content in the aquaponic system compared to the hydroponic treatments.

These observations are further validated by Ayipio et al. [15], who highlighted that aquaponics tends to enhance crop yield through the use of nutrient-rich fish effluents. The increased production metrics, such as higher dry matter and protein content in the aquaponic treatment, reflect this benefit and corroborate the meta-analysis findings that suggest aquaponics offers substantial advantages over hydroponics. The economic analysis in the study also aligns with findings from Love et al. [6] and Suhl and Dannehl [16], who discussed the profitability potential of aquaponics. Despite the variable outcomes influenced by scale and market conditions, the lower cost per kilogram observed in the aquaponic system suggests cost-effectiveness. This is consistent with Rakocy et al. [17], who emphasized the efficient nutrient cycling and water use in aquaponic systems, contributing to reduced production costs.

Moreover, the study’s results echo the resource efficiency and sustainability benefits noted by Xu et al. [18] and Wasko et al. [19]. The aquaponic system’s lower resource inputs and higher yields align with these researchers’ findings on the environmental benefits and efficient use of resources inherent in aquaponics. Overall, these comparisons highlight the practical advantages of aquaponic systems in terms of productivity, economic feasibility, and resource efficiency. In a recent study by Jones et al. [20], aquaponic systems were found to offer a competitive edge in terms of cost-effectiveness due to reduced operational costs and efficient resource use. Their research indicated that the initial setup costs of aquaponic systems could be higher, but the long-term savings on water and fertilizers, along with higher crop yields, resulted in lower overall production costs. This finding supports the study’s observation of lower costs per kilogram of green fodder and dry matter in aquaponic treatments compared to hydroponic methods.

Conclusion

The study demonstrates that the aquaponic system offers superior overall performance compared to hydroponic systems. Despite higher operational costs, the aquaponic system provides better growth and nutrient content, indicating its effectiveness in integrating fish and plant production. This efficiency in nutrient utilization and biomass production makes aquaponics a promising approach for sustainable agriculture. While the hydroponic systems show potential with lower initial costs, they fall short in comparison to the enhanced productivity and nutrient density of the aquaponic setup. Thus, for maximizing output and nutrient quality, investing in aquaponics could be more advantageous in the long run.

References

- Naik PK, Swain BK, Singh NP (2015) Production and Utilisation of Hydroponics Fodder. Indian J Anim Nutr 32(1): 1-9.

- FAO (2013) Statistical year book 2013 World Food and Agriculture. Food and Agriculture Organization of the United Nations. Rome pp. 180.

- Fussy Andre, Papenbrock Jutta (2022) An Overview of Soil and Soilless Cultivation Techniques-Chances, Challenges and the Neglected Question of Sustainability. Plants (Basel) 11(9): 1153.

- Hinkle CR, Mackowiak CL, Owens LP, Prince RP (1989) Continuous hydroponic wheat production using a recirculating system. NASA Technical Memorandum TM 102784.

- Goddek S, Delaide B, Mankasingh U, Ragnarsdottir KV, Jijakli H, et al. (2015) Challenges of sustainable and commercial aquaponics. Sustainabil 7(4): 4199-4224.

- Love DC, Jillian PF, Ximin Li, Elizabeth SH, Laura G, et al. (2015) Commercial aquaponics production and profitability: Findings from an international survey. Aquaculture 435: 67-74.

- Tokunaga K, Tamaru C, Ako H, Leung P (2015) Economics of small-scale commercial aquaponics in Hawaii. J World Aquac Soc 46(1): 20-32.

- Pantanella E, Cardarelli M, Colla Giuseppe, Marcucci E (2012) Aquaponics vs. Hydroponics: Production and Quality of Lettuce Crop. Acta Horticult 927: 887-894.

- Somerville C, Cohen M, Pantanella E, Stankus A, Lovatelli A (2014) Small-scale aquaponic food production: Integrated fish and plant farming. FAO Fisheries and Aquaculture Technical Paper No. 589.

- Bailey DS, Ferrarezi RS, Lieth JH (2016) Economic analysis of commercial hydroponic greenhouse lettuce production in the U.S. HortTechnol 26(6): 858-865.

- AOAC (1990) Association of Official Analytical Chemists. Official Methods of Analysis (15th edn). Arlington, VA, USA.

- Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and non-starch polysaccharides in relation to animal nutrition. J Dairy Sci 74(10): 3583-3597.

- ANKOM (2005) ANKOM Technology. ANKOM 200 Fiber Analyzer Operator's Manual. ANKOM Technology Corporation, Fairport, NY, USA.

- Lennard W, Ward J (2019) A Comparison of Plant Growth Rates between an NFT Hydroponic System and an NFT Aquaponic System. Horticulturae 5(2): 27.

- Ayipio Emmanuel, Daniel E Wells, Alyssa McQuilling, Alan EW (2019) Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis. Sustainabil 11(22): 6511.

- Suhl J, Dannehl D (2010) Economic analysis of aquaponic systems: A review. Water Sci Technol 61(3): 635-642.

- Rakocy JE, Masser MP, Losordo TM (2006) Recirculating aquaculture tank production systems: Aquaponics-integrating fish and plant culture. SRAC Publication 454: 1-16.

- Xu Y, Sandoval Solis S, Tang Y, Fitzsimmons K (2015) Quantifying water and nutrient budgets in aquaponic systems. Aquac Engineer 66: 35-42.

- Wasko A, Wooten J, Summerfelt S, Waldrip H (2018) Economic feasibility of aquaponic systems: The case of Texas. Journal of the World Aquacul Soc 49(3): 450-461.

- Jones S (2002) Evolution of aquaponics. Aquaponics J 24: 14-17.