Physico-Chemical and Microbiological Analyses of A Smoke-Dried Meat Product (Kamsa) During Six Months Storage Period

Hauwa L Yusuf1*, Amin O Igwegbe2, Paul Y Idakwo2, Gambo Ahmad1 and Abashe Sani3

1Department of Food Science and Technology, Bayero University Kano, Nigeria

2Department of Food Science and Technology, University of Maiduguri, Nigeria

3Department of Food Science and Technology, Kano State University of Science and Technology, Nigeria

Submission: April 10, 2020; Published: April 20, 2020

*Corresponding author: Hauwa L Yusuf, Department of Food Science and Technology, Faculty of Agriculture, Bayero University Kano, Nigeria

How to cite this article: Hauwa L Y, Amin O I, Paul Y I, Gambo A, Abashe S. Physico-Chemical and Microbiological Analyses of A Smoke-Dried Meat Product (Kamsa) During Six Months Storage Period. Agri Res & Tech: Open Access J. 2020; 24(2): 556261. DOI: 10.19080/ARTOAJ.2020.24.556261

Abstract

Fresh beef with low moisture content from skeletal muscle was used to produce the sample based on a standardized method. The sample produced was sterilized, packaged, and stored as the sample stock for further analyses over a period of six months. Data was generated from the proximate, chemical, and microbiological analyses of the packaged smoked-dried product. The proximate and chemical analyses showed a gradual and significant (P ≤ 0.05) decrease in moisture content from the fourth month, while the ash and protein contents showed a continuous significant (P≤0.05) increase as the storage period progressed. The fat content also decreased significantly (P≤0.05) during the third month, and then stabilized from fourth to sixth months. The Thiobarbituric Acid (TBA) content increased significantly (P≤0.05) from month 4, indicating the occurrence of oxidation reactions. The results of the microbial analyses, expressed in cfu/g indicate the presence of both bacteria and fungi, but in numbers that did not exceed the microbiological limits for ready- to- eat foods of 102 to ˂ 104 cfu/g, leading to the conclusion that kamsa could be stored at ambient temperatures for up to six months without significant deteriorative effects if properly packaged.

Keywords: Kamsa; Proximate analysis; Microbiological analysis; Storage period; TBA

Introduction

Meat had been known for its rich nutritive value, which should explain why it is very important in most diets. The protein profile of meat consists of all amino acids that have been described as essential and required by the body for protein synthesis. A large proportion of the world’s population relies on meat as a source of essential nutrients [1-6]. The meat supply situation in Nigeria remains critical in spite of the relatively large animal population of 38.5 million sheep and 19.2 million cattle. An average Nigerian consumes 3.89g/h/d of animal protein, which is less than the 34g/h/d recommended by FAO [7,8]. Meat products, when not consumed immediately, are often processed using a range of traditional techniques involving salting, drying, cooking, smoking and marinating, or a combination of these operations to lengthen their shelf life [9-11]. Drying is probably one of the oldest methods of food preservation which helps to conserve meat by reducing the water activity [11-13]. In the Northern parts of Nigeria, drying, salting, spicing, and smoking are the common traditional methods widely used in meat preservation, usually in combination with the higher temperatures prevailing in those parts of the country, or with direct heat application. The intention is to cook or partially cook, reduce moisture content, or impart a flavour to the meat product. However, a combination of these purposes is often the target when preserving meat locally. For instance, hot smoking method is adopted in meat products such as Balangu [14], Tsire, and Dambun nama, while intense drying for expulsion of moisture is often necessary to preserve the product for a longer period of time as applied to Kilishi [15], or in kamsa [7,16], or in dambun nama [17], or in Jirga [18]. Poor and inadequate means of transportation create difficulties in the distribution of meats to different parts of Nigeria. Thus, effective supply to demand areas in shelf stable forms with reduced bulk requires processing, preservation, packaging and storage of meat products.

Kamsa is a low moisture, smoke-dried local meat product indigenous to the North Eastern Nigeria, and is usually stored for a minimum period of six months. It serves as a convenient source of animal protein to its consumers. The study on the storage stability of kamsa requires fundamental data that includes a microbiological and moisture profile of the product. This study was therefore, designed to assess the physico-chemical and the microbiological profile of the product during a storage period of six months.

Materials and Methods

Fresh beef from skeletal muscle with an average moisture content of 70% was used to produce the kamsa samples used in this study; the meat was purchased directly from a central abattoir in Kano State. The handling of the fresh meet and the processing (smoke-drying) into kamsa, were carried out following the procedures outlined by Yusuf [19] and Yusuf et al. [16]. The proximate and chemical analyses were conducted monthly and for a period of six months. The quantification of percent moisture, protein, fat, and ash as well as the TBA was carried out as described in AOAC [20], Nielsen [21], and Igwegbe et al. [8]. The TBA analysis was carried out using a spectrophotometer (SpectrumLab 22 PC) at a wavelength of 532 nanometers, after standardizing the instrument with a TBA reagent. The TBA value was obtained using the following equation:

TBA value = Optical Density (OD) × 1.44

On the other the hand, the microbial analysis of the kamsa samples was conducted as prescribed by Quinn et al. [22], Vipul et al. [23] and Igwegbe et al. [24]. All the glassware (petri-dishes, test tubes, pipettes, flasks and bottles) used in the analysis were sterilized in a hot oven at 170 ± 5°C for at least two hours, while the media and distilled water were sterilized by autoclaving at 121°C for 15 min and at 15 psi. The media, which included potato dextrose agar (PDA) nutrient agar (NA) for total aerobic platecount, Eosine methylene blue agar (EMBA) and deoxycholate citrate agar (DCA) were used for the enumeration of the organisms (bacteria, yeast, mould and Coliforms). The media were prepared following their respective manufacturer’s instructions. Serial dilutions were made using 1g of thoroughly grind processed meat sample shaken in 9ml of distilled water. Plating was carried out in duplicates and the pour plate method was used to make the viable counts [22,23]. The incubation was carried out at 33°C for 48 hours for bacterial counts (including mesophilic and thermophilic spore formers) and at 25°C for 5 days for yeast and mold counts, while the coliform count (MPN/ml) were determined using 3-tube MPN techniques [22,24,25-27]. For each dilution, the viable colonies in the three plates were counted and the means were calculated.

Results and Discussion

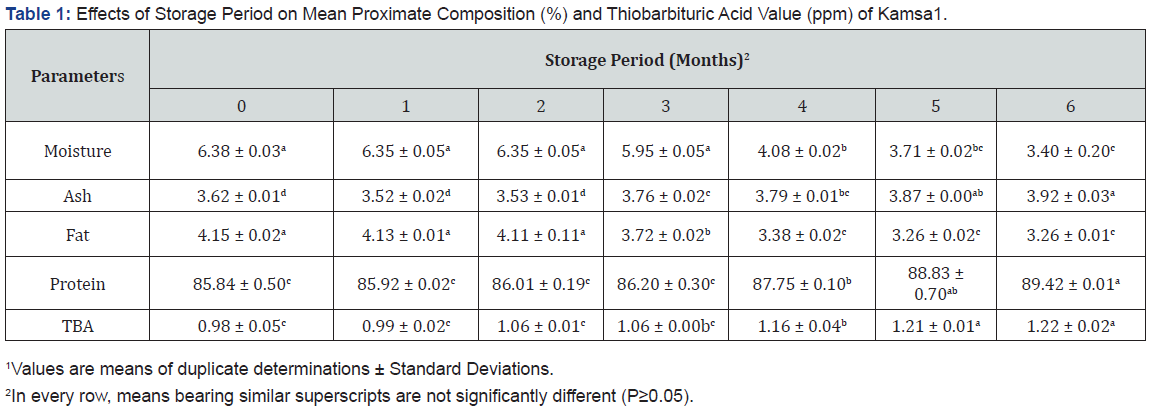

The results of proximate analysis of kamsa samples recorded during the six months of the storage period of this study are presented in Table 1. There were significant differences (P≤0.05) between the proximate composition of the product in the first three months and the last three months of the storage period. The moisture value at fourth month (4.08 ± 0.02%) differed significantly (P≤0.05) from that of the sixth month (3.40 ± 0.20%). However, no significant differences (P≥0.05) were observed between the moisture contents recorded during the fifth and sixth months, 3.71 ± 0.02 and 3.40 ± 0.20%, respectively (Table 1). The decrease in moisture content of the packaged product may be attributed to polymer permeability properties as suggested by Robertson [28]. From the same Table 1 also, the ash and protein contents were generally observed to increase as the storage period progressed. This could be due to the decrease in moisture content, which caused an increase in the total solid contents including the protein and ash. The increase in the mean protein contents from the first to third months, 85.92 ± 0.02, 86.01 ± 0.19 and 86.20 ± 0.30%, respectively, was however, not significant (P≥0.05); but there was a significant increase in the protein contents during the fourth and fifth months, (87.7 5 ± 0.10 and 88.83 ± 0.70%) that also differed significantly (P≤0.05) from the mean value (89.42 ± 0.01%) recorded in the sixth month (Table 1). In general, a significant increase was observed after every two months of the storage, with the highest values obtained during the fifth and sixth months.

Similarly, the fat content showed a gradual decrease as the storage period progressed; however, the decrease in the average fat contents recorded was not significantly different (P≥0.05) from the fourth to the sixth months, 3.38 ± 0.02, 3.26 ± 0.02 and 3.26 ± 0.01%, respectively (Table 1). The same trend in fat content was observed between the first and second months. However, the reduction in the values of the fat contents were significantly different (P≤0.05) between the first two months and the third month, and between the third month and the last three months (Table 1). The significant reduction in the fat content observed during that period could be attributed to either the leeching out of oils that may had been caused by the smoke-drying process, or by the storage conditions, or by both of them. Ali et.al. [29], reported that the storage of fat containing foods over temperatures above 30oC caused fat migration. They attributed it to the leakage of liquid glycerides from the center to the surface of the product. Also, the thiobarbituric acid (TBA) values (expressed in ppm) of kamsa recorded during the six months period of this study are shown in Table 1. The values increased as the storage period progressed, with the highest values, 1.21 and 1.22ppm, recorded in the fifth and sixth months, respectively. These two values differed significantly (P≤0.05) with those of the second, third and fourth months, which are 1.06, 1.06, and 1.16ppm, respectively (Table 1). The lack of significant rise in TBA values (0.99, 1.06, and 1.06ppm) during the first three months of the storage period could be interpreted as absence or presence of very low oxidative reactions in the packaged products. Moreover, the significant increase (P≤0.05) from the fourth months may be because of gradual buildup of breakdown products of fats or oxidation by products, which was sustained through the fifth and sixth months. Furthermore, the lack of sustained increase from the first three months could mean that the high initial values recorded at that period might be because of interferences from additional absorption of other TBA reactive substances (TBARS) as observed by Fisher et al. [30] and Zaazaa [31]. The TBA test is useful as a measure of lipid oxidation during the initial stages [32,33], and because TBARS may undergo extensive modifications at advanced stages of oxidation [34]. Foods, which contain high concentrations of unsaturated lipids, are particularly susceptible to lipid oxidation. Lipid oxidation is an extremely complex process involving numerous reactions that give rise to a variety of chemical and physical changes in the lipid components of any food. Without the application of preservatives and stabilizers, the fats in meat may also begin to rapidly decompose after cooking or processing, leading to an objectionable taste known as warmed over flavor [8,31,32,35].

Effects of the Storage Period on Microbial Stability of Kamsa

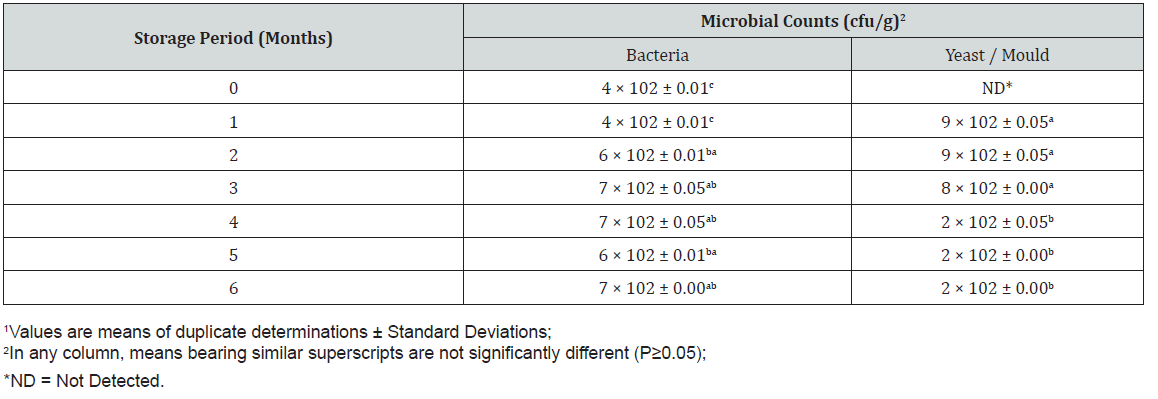

Generally, to maximize the shelf life of meat or its products, it is very important to begin with high quality fresh meat having a low bacterial count [24]. Processing, handling, and storage procedures, on the other hand, must be such that contamination will not occur and conditions unfavorable to the growth of microorganisms will be maintained. Several processes are designed to destroy microorganisms in order to prevent the transmission of disease and to increase storage stability of the products. The traditional method of examining microbiological safety, storage stability, and sanitary quality of foods is to test representative samples of the final product for the presence of pathogens or spoilage organisms. Different microbial groups (e.g., aerobic plate counts and yeast and moulds); indicator bacteria such as Coliforms are used as indicators of sanitation per gram or milliliter of a product. The results of the microbial analyses obtained during the six months storage period of this study are presented in Table 2 inclusive of their standard deviations, and are expressed as colony forming unit per gram (cfu/g). The total bacterial plate count, as well as the yeast and mould counts recorded from kamsa during the period did not exceed the limits for ready to eat foods of 102 to ˂ 104 cfu/g, recommended by the Food Standards [36], and Centre for Food Safety [37]. This low microbial load according to Adam and Moss [38] could be due to the low water activity (aw) value of dehydrated foods, which is usually below 0.6. This, the authors observed, is the limiting value for the active growth of any microorganism (even though survival may still occur). Moreover, at low aw, the spoilage of foods is not microbiological, but due to insect damage or chemical reactions such as oxidation. In this study, however, a significantly (P ≤ 0.05) increasing trend in the mean bacteria counts of 4.0 ×102, 6.0 ×102 and 7.0 ×102 cfu/g was recorded during the first, second and third months, respectively. This increase could be due to the higher moisture content of the product in the first three months. As indicated earlier, the presence of moisture is directly related to water activity and the higher the water activity, the more susceptible the food will be to microbial spoilage and unfavourable chemical reactions [11,13]. Furthermore, no significant changes (P≥0.05) were observed in the mean microbial counts of the product from the third up to the sixth months of the storage period (Table 2). This could possibly be because of the stabilization of the moisture content in those months. The processing and storage conditions employed for kamsa in the present study were meant to prevent or minimize the activity of microorganisms during the storage period; and this has proven to be effective as indicated by the low microbial counts recorded. In addition, these low microbial counts obtained during the storage period, might not be as a result of inadequate processing, but they might have been picked up during the course of handling.

On the other hand, no significant differences (P≥0.05) were recorded on the fungal (yeast and/or mould) loads of kamsa from the first to the third months. The average number recorded during the period was 9.0×102, 9.0×102 and 8.0×102 cfu/g, respectively; these figures dropped to 2×102cfu/g and remained constant from the fourth to the sixth months, and the highest counts was observed in the first and second months (Table 2). The decrease in the mean fungal counts as the storage period progressed might not be unconnected to the decreasing moisture content of the product. Incidentally, no Coliform group was detected in the products through the six months storage period. In general, the spoilage of meat occurs if the meat is not treated in a matter of hours or days after slaughter, and that would result in the meat becoming unappetizing, poisonous or even infectious. Spoilage may be caused by practically unavoidable infection and subsequent decomposition of the meat by bacteria, mould and yeast, which are borne by the animal itself, by the meat handlers themselves, and by the implements that come in contact with the meat during meat handling [6,8,10,39]. The results obtained in this study have shown that meat could be kept edible for a much longer time, though not indefinitely, if proper hygienic measures are observed during slaughtering and processing, and if appropriate safety, good manufacturing practices and proper storage procedures are applied.

Conclusion

All foods undergo varying degrees of deterioration during storage. Processed foods may change in color, texture, flavor, or any quality attributes depending on the method of processing, condition and length of storage. This study concludes that, with proper packaging, the traditionally smoke-dried meat, kamsa, could be stored at ambient temperatures for up to six months without significant deteriorative activities or oxidation reactions, and that the level of fat oxidation reactions will depend on the part and amount of fat in the fresh meat used in the preparation.

Acknowledgement

The authors remain highly grateful to the Managements of Department of Food Science and Technology, Faculty of Agriculture, Bayero University of Kano, Kano State; the Department of Food Science and Technology, Faculty of Engineering, University of Maiduguri, Borno State, Nigeria; and the Department of Food Science and Technology, Faculty of Agriculture and Agricultural Technology, Kano State University of Science and Technology, Kano, Nigeria, for providing the resources and enabling environments for the conduct of this study.

References

- Nuru H, Buvanendran J (1984) A review of Protein Intake in Third world societies. World Food Supply: Protein Intake Third World Quarterly 2(3).

- Monson F, Sanudo C, Sierra I (2005) Influence of breed and ageing time on the sensory meat quality and consumer acceptability in intensive reared beef. Meat Science 71(3): 471-479.

- Thippareddi H, Sanchez M (2006) Thermal processing of meat products. In: Sun DW Thermal Food Processing: New Technologies and Quality Issues. (Ed.), Taylor and Group CRC Press, New York, pp. 156-192.

- Nohr D, Biesalski HK (2007) Mealthy food: meat as a healthy and valuable source of micronutrients. Animal 1(2): 309-316.

- Biesalski HK, Nohr D (2009) The nutritional quality of meat. In: Kerry JP, Ledward D (Eds.), Improving the Sensory and Nutritional Quality of Fresh Meat. (1st) Woodhead Publishing Ltd, Cambridge, England.

- Olaoye OA (2011) Meat: an overview of its composition, biochemical changes and associated microbial agents. International Food Research Journal 18(3): 877-885.

- Yusuf HL, Abubakar UM (2011) A Study of the Moisture sorption characteristics of Kamsa (a smoke dried meat product). Biological and Environmental Sciences Journal for the Tropics 8(4).

- Igwegbe AO, Idakwo PY, Yusuf HL, Agbara GI, Maijalo AI, et al. (2019a) Effects of sodium citrate and garlic on organoleptic properties, proximate composition, free fatty acid and thiobarbituric acid levels of treated smoke-died meat stored at ambient temperature. CPQ Medicine 5(5): 2-14.

- Heinz G, Hautzinger P (2007) Meat Processing Technology for Small-to-Medium-Scale Producers. Food and Agriculture Organization (FAO) of the United Nations. Regional office for Asia and the pacific, Bangkok.

- Norrung B, Anderson JK, Buncie S (2009) Main concerns of Pathogenic Microorganism in Meat. Safety and Processed Meats. In: Toldra F (Ed.), Springer New York, pp. 3-29.

- Zukal E, Incze K (2010) Drying. In: Handbook of Food Processing/ Chapter 11. In: Fidel T. (Ed.). Wiley-Blackwell: A John Wilaey and Sons, Inc. Publication, Iowa, USA pp. 219 -229.

- Lawrie RA, Ledward DA (2006) Lawrie’s meat science (7th), Cambridge: Woodhead Publishing Limited.

- Shafiur RM, Perera CO (2007) Drying and Food Preservation. In: Shafiur MR, Handbook of Food Preservation, (2nd), CRC Press, New York, pp. 403-432.

- Abdullahi FS, Igwegbe AO, Bello AB, Abashe S, Adam IK, et al. (2019) Assessment of Microbial Quality of Balangu-Dipping Water from Six Outlets in Wudil Town in Kano State, Nigeria. International Journal of Food Science and Technology 9(2): 1-12.

- Igene JO, Abulu EO (1984) Nutritional and bacteriological characteristics of tsire type suya, a popular Nigerian meat product. Journal of Food Protection 47(3): 193-196.

- Yusuf HL, Igwegbe AO, Idakwo PY, Ismail BB (2019) Process Standardization using Sensory Evaluation of Kamsa: A Smoked-dried Meat. In Proceedings of the 43rd Conference of the Nigerian Institute of Food Science and Technology. Awka Anambra State, Nigeria pp. 3-4.

- Eke MO, Ariahu CC, Okonkwo TM (2012) Production and Quality Evaluation of Dambu-Nama, a Nigerian Dried Meat Product. Nigerian Food Journal 30(2): 66-72.

- Food and Agriculture Organization FAO (1990) Animal Production and Health paper 79. Manual on Simple Methods of Meat Preservation. Food and Agriculture Organization of the United Nations, Rome, Italy.

- Yusuf HL (2017) Process Standardization and Storage Studies of Kamsa and Dambun Nama: Traditional Nigerian Dried Meat Products from Beef. A Ph.D Thesis Submitted to School of Postgraduate Studies, from the Department of Food Science and Technology, Faculty of Engineering, University of Maiduguri, Borno State, Nigeria, pp. 178.

- AOAC (2000) Official Methods of Analysis. Association of official Analytical Chemists. Washington DC. USA.

- Nielsen SS (2010) Introduction to the Chemical Analyses of Foods. CBS Publishers, and Distributors, India.

- Quinn PJ, Carter ME, Markey B, Carter GR (2002) Clinical Veterinary Microbiology. Mosby International Ltd., London. pp. 42-49.

- Vipul V, Singh R, Tiwari RK, Srivastava N, Verma A (2012) Antibacterial activity of extracts of Citrus, Allium & Punica against food borne spoilage. Asian Journal of Plant Science and Research 2(4): 503-509.

- Igwegbe AO, Kassum AL, Maina FJ, Bristone C, Abubakar F, et al. (2019b) Effects of sodium citrate and garlic on pH and microbial stability of smoke-dried meat stored at ambient temperatures. In: Opara JA (Eds.), Health, Environment and Sustainable Development: A Book of Readings in Honour of Professor Ibrahim Njodi, Chapter 23. University of Maiduguri Press, pp. 226-240.

- American Public Health Association (APHA) (1995) Standard Methods for Examination of Water and Wastewater. (19th Ed), APHA Washington DC.

- Townsend DE, Irving RL, Naqui A (1998) Comparison of the Sim Plate Coliform and Escherichia coli test with Petri-film, three tube MPN, and VRBA+ MUG methods for enumerating Coliforms and E. coli in food. J Food Protect 61(4): 444-449.

- Cheesbrough M (2006) District laboratory practice in tropical countries. (2nd Edn), Cambridge University Press. Cambrigde, UK, pp. 47-54.

- Robertson GL (2006) Food Packaging Principles and Practice. (2nd), CRC Press, New York,

- Ali A, Selamat J, Che Man YB, Suria AM (2001) Effect of Storage Temperature on Texture, Polymorphic structure, Bloom Formation, and Sensory Attributes of Filled Dark Chocolate. Food Chemistry 72(4): 491-497.

- Fisher AV, Enser M, Richardson RL, Wood JD, Nute GR, et al. (2000) Fatty acid composition and eating quality of lamb types derived from four diverse breed production systems. Meat Science 55(2): 141-147.

- Zaazaa A (2015) The effects of dietary supplementation and product formulation on the oxidative stability of lipids and proteins in meat and meat products. Proceedings of the Giornata del Dottorato - Curriculum in Scienze e Biotecnologiedegli Alimenti , Cesena, Italy. pp. 41-43.

- Calkins CR, Hodgen JM (2007) A fresh look at meat flavour. Meat Science 77(1): 63-80.

- Zaazaa A (2014a) Bioactive compounds in food products from animal origin, as related to food quality and stability. Proceedings of the Giornata del Dottorato - Curriculum in Scienze e BiotecnologiedegliAlimenti , Cesena, Italy. pp. 15-16.

- Pomeranz Y, Meloan CE (2004) Food Analysis, Theory and Practice. (3rd), CBS Publishers and distributors, India.

- Wood JD, Richardson RI, Nute GR, Fisher AV, Campo MM, et al. (2003) Effects of fatty acids on meat quality: A review. Meat Science 66(1): 21-32.

- Food Standards, Australia New Zealand (2002) Food Standards Code, Canberra: Information Australia.

- Center for Food Safety (2007) Microbiological Guidelines for Ready-to-eat Foods. Centre for Food Safety and Environmental Hygiene Department, 66 Queensway, Hong Kong.

- Adam MR, Moss MO (2007) Food Microbiology. New Age International Publishers, New Delhi.

- Jay JM, Loessner MJ, Golden DA(2005) Modern Food Microbiology, (7th), Springer Science + Business Media Inc New York, USA.