Training Systems for Cape Gooseberry Production in South of Brazil Cultivated in Latosol

Isabela Leticia Pessenti1, Ricardo Antonio Ayub2*, Lygia Werlang Momoli3, Evaldo Leandro Potma da Silva4 and Pedro Reque Kouba4

1PhD Student in Agronomy, State University of Ponta Grossa (UEPG), Brazil

2PhD Professor in Plant Health Department, State University of Ponta Grossa (UEPG), Brazil

3Master in Agronomy, State University of Ponta Grossa (UEPG), Brazil

4Graduate in Agronomy, State University of Ponta Grossa (UEPG), Brazil

Submission:July 18, 2019; Published: August 09, 2019

*Corresponding author: Ricardo Antonio Ayub, Departamento de Fitotecnia e Fitossanidade, Universidade Estadual de Ponta Grossa - UEPG, Av. Carlos Cavalcanti, 4748, 84030-900, Ponta Grossa - PR, Brazil

How to cite this article: Isabela Leticia Pessenti, Ricardo Antonio Ayub, Lygia Werlang Momoli, Evaldo Leandro Potma da Silva Teresa. Training Systems for Cape Gooseberry Production in South of Brazil Cultivated in Latosol. Agri Res& Tech: Open Access J. 2019; 22(2): 556193. DOI: 10.19080/ARTOAJ.2019.22.556193

Abstract

The objective of this paper was to measure four Physalis peruviana training system under the Latosol soil and climate conditions in the South Region of Brazil. The trial design was composed by randomized groups, with 4 training systems, which were the free system (witness), espalier system, X system and V system, with 5 plants for each treatment and 3 replications. For the fruit harvest, it was standardized at stage 4. The measurement of the height and the diameter of the main branches, number, diameter and fresh mass of the fruit (without calyx) and estimated productivity (kg ha-1) was made. For the qualitative analysis, the soluble solids content (ºBrix) (SS), titratable acidity (% citric acid) (TA), pH and SS/TA ratio were evaluated. Color attributes of fruit (without calyx), L, a*, b* and angle hue were evaluated as well. The espalier system showed higher productivity and number of fruits. Cape-gooseberry plants growth with the V system had bigger diameter and height on the main branches, as well as bigger mass and diameter of the fruit. The chemical analysis like soluble solids, total titratable acidity, pH, ratio and color attributes of fruit did not differ statistically when undergone to the four training systems.

Keywords:Physalis peruviana; Crop management; Fruit quality; High productivity; Sustainable cultivation

Introduction

Cape gooseberry (Physalis peruviana L.) is a perennial plant that belongs to the Solanaceae family. In Brazil, its growing is still new and has become a great alternative of growing, especially because the fruit trading is for the “natural” market as well as for the production of jelly, candies, juice and ice cream [1]. With the developing market, studies are necessary to develop new and more viable technology for cultivation, as well as for characterizing the growing and development of the plants under specific climate, soil and management conditions of this crop [2]. Cape gooseberry cultivation is a bush with very thick branches, and it has decumbent branches, a support system is necessary for the plants during growth, which makes it easier for the crop handling and increasing the productivity [3]. The type of training and tying required depend on the density of the seeds, the land topography, availability of the materials and its costs. Several training systems |may be used on the growing of cape gooseberry, including the ones described on other kinds of plant production or, yet, the ones used on solanaceous plants, such as on the tomato. As commercial crops, the training of cape gooseberry plants is mandatory and the plant spacing may depend on the training system used. A distance of 0.8 to 1.5 between plants and 2 3 meters between the rows is recommended [2,4].

In Brazil, the plant distance ranges from 0,5 to 1,5 meters, according to the tutor. Distances of 3 X 1 meters or 3 to 0,5 meters between grooves and plants, respectively, are recommended [1]. The number of plants per hectare determines the cultivation density and the amount of harvest costs [5]. For those reasons, the knowledge of tutoring becomes an important information to have better productive and qualitative results. The objective of this paper was to evaluate four types of training system more adequate for the growing and production of P. peruviana fruit under the soil and climate conditions of Ponta Grossa, Campos Gerais, Parana, Brazil.

Material and Methods

The experiment was carried out between August 2016 and June 2017, in South Region of Brazil with latitude 25º05’49’’ S and longitude 0°03’’11” W, elevation of 969 meters. According to Alvares et al. [6] in the Köppen classification, the climate is Cbf, humid temperate climate with temperate summer, with well-defined winter and summer seasons, precipitation well distributed throughout the year and soil with Dystrophic Red-Yellow Latosol. The average temperature is 17.5ºC and the average annual rainfall is 1495 millimeters. The trial design was composed by randomized groups, with 4 training systems, which were the free system (witness), espalier system, X system and V system, with 5 plants for each treatment and 3 replications. The experimental plots were formed by 3 rows of 20 plants with spacing at 3 meters between rows and 1 meter between plants. To produce the seedlings, seeds of Physalis peruviana L. were used. The extraction was performed in a low power crusher of fruit. Afterwards, they were filtered and placed to dry in the shade. After dried, they were sown in polysterene trays of 200 cells with dimensions of 680 X 344 X 53 millimeters and the Lupa™ substrate.

After 40 days, the seedlings were transferred 2 liters plastic bags with 40X40X40 centimeters, fertilized with 16 ton ha-1 of cow manure, where they stayed for 34 days for acclimatization until they reached 15 to 20 centimeters and had 3 to 4 leaves, containing substrate with a mixture of soil, sand and organic compound (2:1:1). The seedlings were hanged to planting. The top-dressing fertilization was made 23 days after planted and on the 131th day of the transfer (DAT), the first dose was 11,7g of KCl per plant (39kg ha-1) and 45g of ammonium sulphate per plant (150 kg. ha- 1) and the second one, 22g of KCl per plant (73,33kg ha-1).

The espalier plants were trained with 4 branches and with 2 per level. For the X system, 4 branches were trained with 2 branches per level. For the V system, only 2 branches were kept, with one branch per level and on the “witness” (free system), there was no use of any type of training, the plants were allowed to grow naturally. The harvest was standardized to stage 4 according to ICONTEC [7]. The measurement of the height and diameter of the main branches and the counting of the number of fruit was made. After harvest, the productivity (kg ha-1), physical analysis of the fruit, such as diameter and fresh mass of the fruit (without calyx) were evaluated. For the qualitative analysis, the soluble solids content (ºBrix) (SS), titratable acidity (% citric acid) (TA), pH and SS/TA ratio were evaluated. The color attributes of fruit (without calyx), L (black (L=0), white (L=100)), a* (that ranges from green (-a) and red (+a), b* (that ranges from blue (-b) and yellow (+b) and angle hue (0º=red 90º=yellow, 180º=green and 360º=blue) were evaluated as well. The data were submitted to Shapiro Wilk’s test for normality, followed by analysis of variance, and, if signifi cant, submitted to the average test through Tukey test, under 5% of probability using SISVAR 5.6 computer program [8].

Results and Discussion

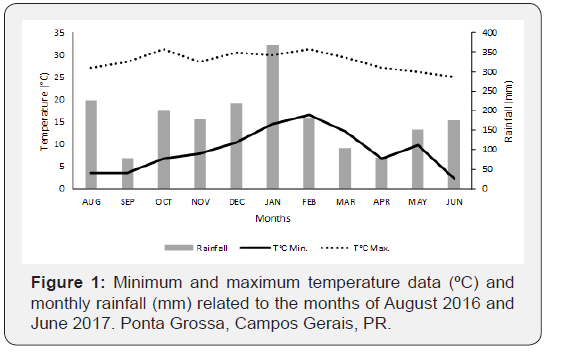

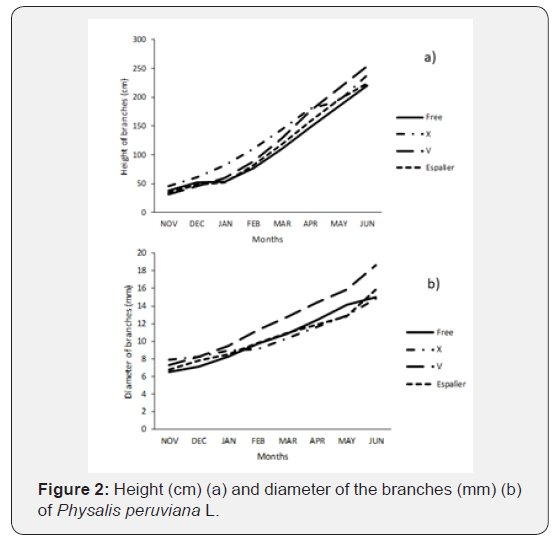

In Figure 1, it was possible to observe the minimum and maximum monthly temperature and the monthly rainfall (mm) during the development cycle of the crop from August 2016 to June 2017. Figure 1. Minimum and maximum temperature data (ºC) and monthly rainfall (mm) related to the months of August 2016 and June 2017. Ponta Grossa, Campos Gerais, PR. Figure 2A, showed that the V system resulted in the highest plants at 253cm. García et al. [4] also observed average values of 253 and 259cm for the V system at 3 X 0,5m spacing and 3 X 1m in the harvest of 2008/2009. This improvement on the height of the branches may be related to the higher incidence of direct radiation, leading to a higher leaf area index, higher production of photo-assimilated, causing more accumulation of fresh mass of the fruit. However, the V training system provided smaller production when compared to the others Melo et al. [9].

Figure 2. Height (cm) (a) and diameter of the branches (mm) (b) of Physalis peruviana L. during the cycle of 2016/2017 related to the four types of training system. Averages followed by the same letter do not differ between each other on the Turkey test (p≤0,05). Vertical lines show the standard deviation. In Figure 2B, it was possible to observed that initially all the systems had similarities on the diameter of the branches until January; however, the V system was better if compared to the others. About the height, the solar radiation provided a better growing of the branches on the height as well García et al. [3]. Observed a bigger diameter of branches on the V inverted system, on the three types of thickness evaluated. Muniz et al. [2], verified the plants conducted on the V system (3,00 X 1,00m), showed bigger diameter of the branches than the plants trained on the other systems and spacing in the harvests. It was stated that as the plant grown and developed itself, the diameter of the branches is likely to increase, however, on a more gradual way than the plant’s height. The trunk diameter reflected photo-assimilated accumulation that was translocated to the top. The bigger trunk diameter reduced plant lodging, favored by the spacing and training system.

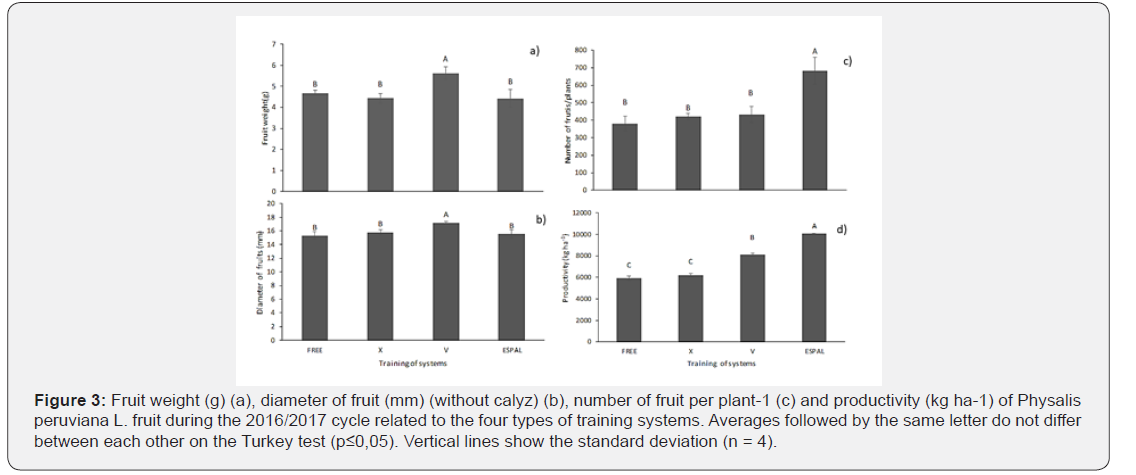

For the fresh mass of the fruit (Figure 3A), the highest value was from the V system, with average of 5,61g. The other values from the training systems were lower. Lima et al. [5] found average values of 10,05g for the cape gooseberry crop in RS, on the other hand, Rodrigues et al. [10] obtained the average of approximately 3g for the cape gooseberry crop in stage 4 (yellow) in Minas Gerais. García et al. [3] obtained average values of 4,95g in Colombia, similar results of this paper. The fresh mass of the fruit was considered an important characteristic, since it was related linearly to the development and/or ripening, except when the fruit are in advanced stage of maturation. The mass was correlated with the size of the fruit and was a characteristic of cultivar. When they reached the complete development, the fruit must present variable mass between the typical limits of the cultivar, which are very variable [5,10].

Figure 3. Fruit weight (g) (a), diameter of fruit (mm) (without calyz) (b), number of fruit per plant-1 (c) and productivity (kg ha- 1) of Physalis peruviana L. fruit during the 2016/2017 cycle related to the four types of training systems. Averages followed by the same letter do not differ between each other on the Turkey test (p≤0,05). Vertical lines show the standard deviation (n = 4).

The physical evaluation of the fruit was important, since the fruit with good appearance and measures considered high are the main attraction for the consumer. In the cape gooseberry fruit studied by Silva et al. [11], it was verified the average size of the ripe fruit was around 18,4mm of transverse diameter. On the evaluation of the diameter of the fruit (Figure 3b), the highest values were obtained with the V training system, with average of 17,2 mm, which differed significantly from the other training systems, and these last ones did not differ between themselves (Figure 3). Similar values were found by Rodrigues et al. [10], of 17,45mm for cape gooseberry fruit. The incidence of the solar radiation could have favored a higher production of photo-assimilated, causing more accumulation of fresh mass of the fruit. The espalier training system was better when it comes to the total number of fruit (682) (Figure 3C), differing from the free training, X and V systems, with values of 380, 422 and 432 fruits per plant, respectively. García et al. [3] observed that the amount of fruit was bigger to the espalier system, obtaining the best results density 2x2m and 3X2m with total amount of 300 and 436 fruits per plant, respectively.

Castro et al. [12] state the vegetative growth of cape gooseberry is favored by an increase of the temperature and longer days. Therefore, when grown in places or seasons with higher temperature the growing period was shortened and the production begins earlier [13]. According to Ramírez et al. [14], it is common to observe simultaneously floral buds, completely open flowers, unripe fruit and ripe ones on the same plant, which present undetermined growing habit. Related to the productivity (Figure 3D), the espalier system was better than the others (10 ton ha-1), differing in high values of the free, X and V systems, which did not differ between themselves, these productivity values are found in countries like South Africa, Colombia and Ecuador. In Brazil, Muniz et al. [2] observed values between 3,93 and 3,60 kg ton ha-1 for both agricultural harvest in the espalier system, respectively. García et al. [3] observed in Colombia higher values than this project for the espalier training system, which were approximately 12 and 13 t ha-1 with the spacing of 2X2 and 3X2, respectively. On the other hand, Moura et al. [15] observed values between 10,91 and 5,97 t ha-1 in the espalier system on the two thickness values evaluated in Minas Gerais, Brazil. These authors reported the influence of radiation on the vegetative growth of the plant, leading to a higher productivity. The espalier training system had greater production due to the higher number of fruits per plant, where this variable was significant. The harvest period of the 2016/2017 crop lasted approximately seven months, which was the same length observed by Muniz et al. [4], while in the producer regions of Colombia, the harvest was made over the course of two consecutive years. This high productivity may be explained due to the favorable conditions during the cycle, where there were high temperatures (Figure 1) and solar radiation in an atypical winter, extending the development of the crop.

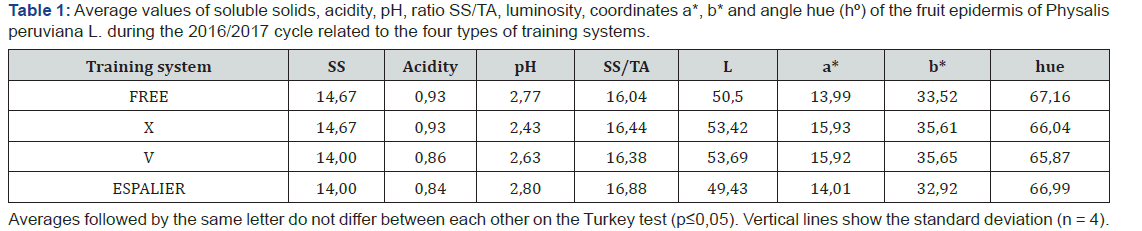

As shown on Table 1, there was no significant difference on the level of soluble solids (SS) (ºBrix), titratable acidity (TA) (% citric acid), pH and SS/TA ratio according to the free, X, V and espalier training systems. About the total soluble solids, Codex Stan [16] states that the fruit must present at least 14 ºBrix to be commercialized. In this experiment, the treatments did not differ statistically between each other, with average of 14,33 ºBrix, exceeding the values obtained in Lages, SC, with average of 13,34 ºBrix [4], however they were similar to the ones obtained in Lavras, MG, with 14,21 ºBrix [10], just as with Lima et al. [18], García et al. [3] and Melo et al. [9].

Table 1 Average values of soluble solids, acidity, pH, ratio SS/ TA, luminosity, coordinates a*, b* and angle hue (hº) of the fruit epidermis of Physalis peruviana L. during the 2016/2017 cycle related to the four types of training systems.

Total titratable acidity was an important quality characteristic, it tended to vary due to environmental and genetic factor. The organic acids present in food influence the taste, smell, color, stability and quality management. The titratable acidity ranged from 0,84 to 0,93 between the training systems. According to Fischer et al. [17], the type of training does not have direct influence on the percentage of citric acid. The pH was variable according to environmental factors and factors of the same plant, but it was an important tool for the evaluation of the fruit acidity. With the pH values, acidity criteria may be set in a comparative manner between the fruits. On this experience, the average values were 2,43 to 2,80. These values were lower to the ones found by Melo et al. [9], in which the average ranged from 3,94 to 3,89 for training systems for two and three stems, respectively. In the relation of total soluble solids/titratable acidity (TSS/TA, which represents the balance between sugars and acids), all treatments were similar between each other. According to a rule of Instituto Colombiano de Normas Técnicas e Certificação [7], in order to commercialize cape gooseberry, this relation must be 6,0 or higher. In the current paper, in all studied treatments the value was above 16,0, which demonstrates a determinant factor in the physical-chemical quality of the fruit. Lima et al. [5] found average values of 18,73 and 16,26 to the inverted V training system and the triangular one, respectively.

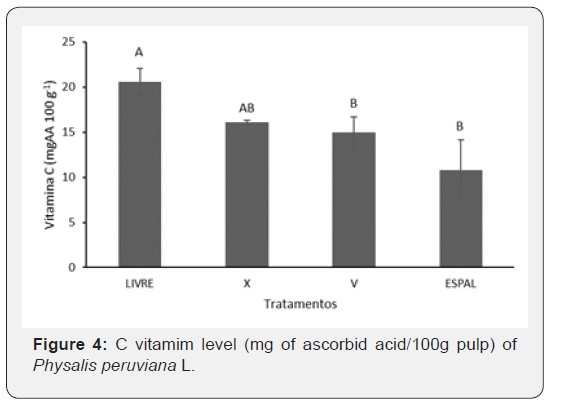

For the luminosity (L*), a* (variation between red and green), b* (variation between blue and yellow) and hº (hue angle), significant differences were not found according to the training system used. For the C vitamin level (Figure 4), it was possible to observe the free system obtained better results when compared to the others (20,5mg 100g-1), but did not differ from the X system (16,1mg 100g-1). Melo et al. [9] found significant difference for the training system with two stems, with average between 18,42mg and 100g- 1 a 24,04mg 100g-1.

Conclusion

The training systems influence on the growth and development of the cape gooseberry under the Latosol soil and climate conditions in South Region of Brazil, and the espalier system showed higher productivity and number of fruits. Cape gooseberry plants trained on the V system have bigger diameter and height of the main branches and bigger mass in the diameter of the fruit under the Latosol soil and climate conditions in South Region of Brazil. The chemical analysis and color attributes in cape gooseberry crop did not differ statistically among the four training systems, except for the free system that had higher values for C vitamin.

Acknowledgment

To Ponta Grossa State University and Coordination of Improvement of Higher Level Personnel - CAPES for the financial support

References

- Muniz J (2014) General aspects of physalis cultivation. Ciência Rural 44(6): 964-970.

- Muniz J (2015) Vegetative growth and productive potential of cape gooseberry. Revista de Ciências Agroveterinárias 14(1): 15-23.

- García EQ, García OS, Sandoval CEV (2015) Efecto del tutorado y distancias de siembra sobre el rendimiento de Physalis peruviana L. Actualidad & Divulgación Científica 18(1): 91-99.

- Muniz J (2011) Conduction systems for physalis production in Southern Brazil. Revista Brasileira de Fruticultura 33(3): 830- 838.

- Lima CSM (2009) Chemical characteristics of cape-gooseberry fruits in different sepal colors and training systems. Revista Brasileira de Fruticultura 31(4): 1060-1068.

- Alvares CA, Stape José Luiz, Sentelhas Paulo Cesar, de Moraes Gonçalves José Leonardo, Sparovek Gerd (2013) Köppen’s climate classification map for Brazil. Meteorologische Zeitschrift 22(6): 711-728.

- Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC) (1999) Norma Técnina Colombiana Uchuva – NTC 4580. (Bogotá: ICONTEC) p. 17.

- Ferreira DF (2011) Sisvar: a computer statistic analysis system. Ciência e Agrotecnologia 35(6): 1039-1042.

- Melo RDC (2016) Avaliação de acessos de fisális sob duas formas de condução de plantas em sistema agroecológico nas condições do Cerrado. Embrapa Hortaliças-Boletim de Pesquisa e Desenvolvimento (INFOTECA-E). 140: 30.

- Rodrigues FA (2012) Characterization of the harvest point of Physalis peruviana L. in the region of Lavras, MG. Bioscience Journal 28(6): 862-867.

- Silva DF (2013) Postharvest and fruit production of cape gooseberry in Minas Gerais State, Brazil. Revista Ceres 60(6): 826-832.

- Castro PR, Kluge RA, Sestari I (2008) Manual de fisiologia vegetal: fisiologia de cultivos. Piracicaba: Ceres pp. 864.

- Betemps DL (2014) Time of sowing, phenology and growth of cape gooseberry plants in southern Brazil. Revista Brasileira de Fruticultura 36(1): 179-185.

- Ramírez F (2013) Cape gooseberry (Physalis peruviana L.) phenology according to the BBCH phenological scale. Scientia horticulturae 162: 39-42.

- Moura PHA (2016) Plastic covering, planting density, and prunning in the production of cape gooseberry (Physalis peruviana) in subtropical region. Revista Caatinga 29(2): 367-374.

- Codex (2005) Norma del codex para uchuva. Mé (Codex Stan, 226) p. 14.

- Fischer G (2005) Avances en cultivo, poscosecha y exportación de la uchuva Physalis peruviana L. en Colombia. (Bogotá: Universidad Nacional de Colômbia, Facultad de Agronomía) p. 221.

- Lima CSM (2010) Periods replanting and training systems of cape-gooseberry. Ciência Rural 40: 2472-2479.