Nutritional Compositions and Sensitivity Analysis of Poultry Feed Mills in Bangladesh through Experimental Economics Approach

Azadul Haque M1, Md Akteruzzaman2, Tofael Ahamed1, Hashem MA3, Sadika Haque2, Mohiuddin M4, Shahnaz Akter5 and Md Monirul Islam1*

1Graduate School of Life and Environment Sciences, University of Tsukuba, Japan

2Department of Agricultural Economics, Bangladesh Agriculture University, Bangladesh

3Department of Animal Science, Bangladesh Agriculture University, Bangladesh

4Department of Animal Nutrition, Bangladesh Agriculture University, Bangladesh

5Department of Economics, Bangladesh Water Development Board (BWDB), Bangladesh

Submission: April 01, 2019; Published: April 23, 2019

*Corresponding author: Md Monirul Islam, Assistant Professor and PhD Student, Graduate School of Life and Environmental Sciences, University of Tsukuba, Tsukuba 305-8572, Japan

How to cite this article: Md Monirul I, Azadul H M, Md Akteruzzaman, Tofael A, Hashem M, et al. Nutritional Compositions and Sensitivity Analysis of Poultry Feed Mills in Bangladesh through Experimental Economics Approach. Agri Res& Tech: Open Access J. 2019; 21(2): 556159. DOI: 10.19080/ARTOAJ.2019.21.556159

Abstract

This research aimed at analyzing of nutritional compositions and resource use efficiency of poultry feeds covering Dhaka, Gazipur, Narsingdi, Kishoreganj and Mymensingh districts in Bangladesh. A total of 30 feed mills which categorized as high, medium and low quality on the basis of feed conversion ratio were selected purposively. The feed sample were collected during March 2013 to March 2014 and analysis by using AOAC, 2000 methods and KII. It is evident that a compound broiler feed of different feed manufacturers has differed between analytical value (AV) means laboratory test result and MV of various nutritional composition of ME value (energy). There is much difference in CP content which was lower than requirements and ME content was higher than requirements. The analytical value of EE (ether extract) was higher than manufacturer value which influence on human health. The results of sensitivity analyses clearly indicate that poultry feed mills were price sensitive.

Keywords: Broiler production; Poultry feeds; Nutritional compositions; Financial profitability; Sensitivity analysis

Abbreviations: AV; Analytical Value; EE: Ether Extract; FCR: Feed Conversion Ratio; BCR: Benefit-Cost Ratio; NPV: Net Present Value; IRR: Internal Rate of Return

Introduction

Livestock is playing an important role in the national economy by contributing significantly to agriculture and to the gross national product of Bangladesh [1-5]. Furthermore, it plays a pivotal role in the rural socioeconomic system as maximum households are directly involved in livestock sub-sector. Poultry industry is one of the major among livestock sub-sectors that committed to supply cheap sources of good quality nutritious animal protein to the nation in terms of meat and eggs [1]. Total investment in poultry industry was Tk. 150 billion with an annual turnover of Tk. 200 to 250 billion [3]. Poultry meat production was 30.21 lac tons and egg production 67542.80 lac in 2013/14 [6]. Poultry plays a pivotal role in bridging the protein gap of animal origin in Bangladesh [7]. The poultry industry in Bangladesh plays a crucial role in economic growth and simultaneously creates numerous employment opportunities for more than 6 million people [3]. Among animal number in Bangladesh, poultry population was the highest in 2011-2012, it was reaches 2329.9 lac in 2005-06 to 2932.4 lac in 2012-13 [8]. Chowdhury [3] pointed out that the per capita consumption of all meat is 14.67kg and egg is 31 numbers as against the requirements of 56kg meat and 365 eggs, respectively. The per capita poultry meat availability is approximately one-fifth of the consumed meat (3kg) which needs to be increased more than double to satisfy the current demand of 7.67kg while that of egg more than three times to meet the per capita minimum requirement of 102 eggs [2,4,9]. The trends of milk, meat and eggs productions were increasing significantly from 2005-06 to 2012-13 [6].

Poultry feed mill industry as an agribusiness enterprise is comparatively new in Bangladesh [9-12]. Total feed business, especially, the business of concentrates was controlled by some feed traders. Bangladesh is a feed deficit country [13]. At present there are about 250 registered feed mills in Bangladesh. These feed mills are not produced sufficient amounts of feed [4]. There is a general agreement that low poultry production in Bangladesh is mainly due to lack of nutritious feed and high price of poultry staffs. The major feed additives are: toxin binder, mold inhibitor, enzymes, synthetic amino acids and vitamins, feed premixes, vitamin-mineral premixes, trace minerals, organic acids, probiotics, salmonella killer, antibiotic for therapeutic use through feeds (antibiotic as growth promoter is strictly prohibited to use in the feed according to Feed Act 2010). Most of the feed additives have been imported by the health companies and feed millers. The major feed ingredients have been imported by the commercial feed millers. The major feed ingredients are: meat and bone meal, fish meal, protein concentrates, fish meal, soybean meal where around 50% is locally produced [4].

Though, due to the government’s initiatives, supply situation of feed has improved slightly, but still supply is very much inadequate in relation to high increasing demand. The expansion of commercial feed industry in Bangladesh can possible to fulfill more than 80% of the total compound feed requirements. Considering the existing growth rate of poultry, cattle and aquaculture, the estimated annual compound feed requirement would be 10.60 million MT in 2020-21 [4]. Therefore, according to the estimation of their existing production capacity, it is revealed that compound feed production will meet only 26.11% of the total requirement in 2020-21 [13]. Hence, it indicates the potential of compound feed production in the country in future.

Moreover, the poultry farmers are suffering severely from the lack of security of their farms and investment of Bangladesh [14]. Every year, thousands of farms are collapsing due to bird flu outbreak and many for their incapability to buy high priced poultry ingredients and absorb losses from market price fall [14]. In addition, feed intake accounts for approximately 65-70 percent of the total cost of a farm. The poultry feed consumption was around 18.36 lac MT in 2015 [5]. The most significant constraint in the development of livestock sub-sector is the acute shortage of balanced feed, which has been discussed earlier. In recent past, many small-scale dairy and poultry farms were established in the country, but 20 to 25 percent of dairy farms and 25 to 30 per of poultry farms dropped out in their infant stage. Thus, by ensuring the supply of quality feed for livestock sub-sector, the feed mill industry is enhancing the whole economy significantly through its forward linkage effect.

As the quality of feed is one of the determinant factors in successful poultry farming, the present research was taken to evaluate the quality of compound broiler feeds manufactured by different feed manufacturers. This quality assessment of feeds had been focused on several tests from initial observation on receipt, quantitative analysis. This study is a modest effort undertaken to examine the cost-effective supply chain of raw materials and supply of poultry feed. The overall goal of this research is to analysis the nutritional compositions of poultry feeds and return over investment considering sensitivity analysis of broiler production in Bangladesh and policy implications for the future research. The specific objectives are as follows:

a. The nutritional composition determined by using the method of AOAC [15].

b. The nutritional value obtained from AOAC was compared with written in company supplying over the bags.

c. The objective function = Nutrient requirement was maximized, and cost of the raw ingredient was minimized.

Materials and Methods

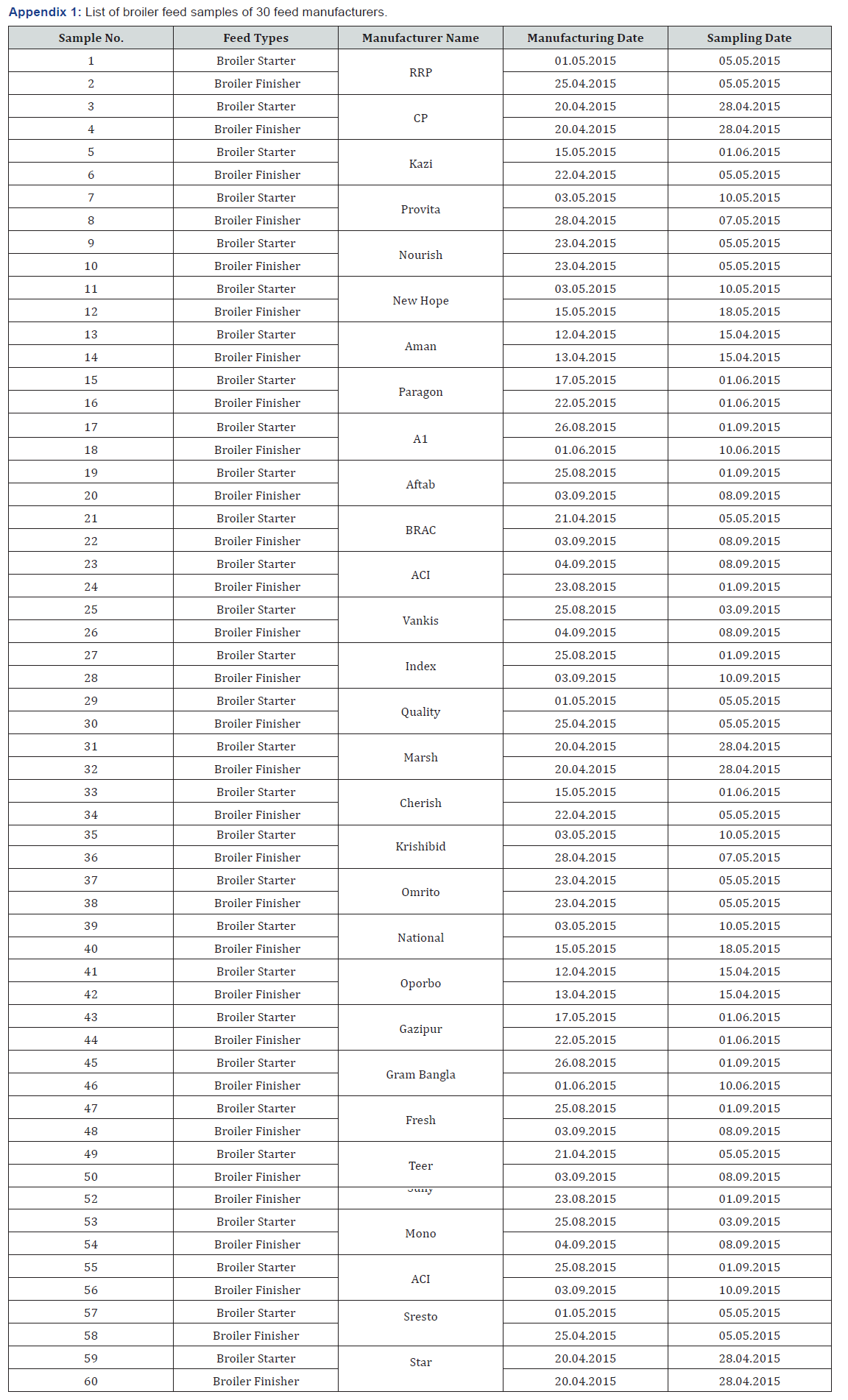

Sixty compound feed samples (30 broiler starter feeds and 30 broiler finisher feeds) of 30 different feed manufacturers were collected proportionately from different locations of Dhaka, Gazipur, Narsingdi, Mymensingh and Kishoreganj districts. The field work conducted with feed miller, dealer, different sizes of poultry farm owners and farmers. Table 1 showed that a multistage stratified sampling was applied in this study. The feed mills categorized on the basis of feed conversion ratio (FCR) that is high quality feed mills (FCR; below 1.5 to below 1.6), medium quality feed mills (FCR: 1.6 up to below 1.7) and low-quality feed mills (FCR: 1.7 up). The selected commercial farms were categorized by flock size small scale: < 1000 birds, medium scale: 1001-2000 birds and large scale: above 2000 birds. In conformity with the objectives of the study, a structured questionnaire developed for collecting relevant primary data from the poultry feed miller, dealer and sub-dealer and farmers. The present study covered approximately from March 2013 to December 2014. It has been found that CP (crude protein) and energy level written over the bag but some time industries people are exploiting to farmers by using unknown growth stimulating substances to increase for FCR value:

a. The nutritional composition determined by using the method of AOAC [15].

b. The nutritional value obtained from AOAC was compared with written in company supplying over the bags.

c. The objective function = Nutrient requirement was maximized, and cost of the raw ingredient was minimized.

The quality of compound feeds depends on the storage time also. The broiler feed samples were collected within 10-15 days after manufacturing of feeds at feed mills from broiler farmers. After collection, feed samples were stored in refrigerator during chemical analysis at animal nutrition laboratory. During the collection of samples, feed bags and nutrient specification, expired date on bags of different feed sample were carefully observed and recorded.

Chemical analysis (proximate analysis)

The proximate components and energy content of the collected feed samples were tested at Animal Nutrition Laboratory, Bangladesh Agricultural University, Mymensingh (Appendix 1). The chemical composition (dry matter, crude protein, crude fibre, ether extract and ash) was determined by the procedure of AOAC [15]. The ME content of the feed samples was determined by using the values of crude fiber (CF), ether extract (EE), and ash according to the method of Wiseman [16].

The formula is ME (Kcal / kg ) = 3951 + 54.4EE − 88.7CF − 40.8Ash

Where, CP is the crude protein (in percentage), EE is the ether extract (in percentage) and Ash is the Ash (in percentage).

Return over investment analysis

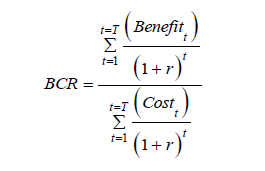

To estimate the profitability of the feed mills and poultry farms, project appraisal techniques such as BCR, NPV and IRR were used. The financial analysis in this study was conducted from the view point of owner of feed mill. Discounted measures of project were used for financial analysis since undiscounted measures of project worth is quite unable to take into consideration the timing of benefits and costs through the project life. The discounted measures are commonly used in agricultural project analysis. These are:

a. Benefit-Cost Ratio (BCR).

b. Net Present Value (NPV).

c. Internal Rate of Return (IRR)

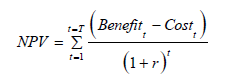

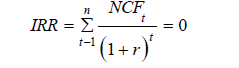

The BCR is a relative measure which is used to compare benefits per unit of cost. The NPV, on the other hand, is an absolute measure which estimates the projects net present worth. The IRR is also a relative measure which may be defined as the average earning power of the money invested in a project over the project life [17,18]. The formal mathematical statements of the discounted measures of project worth suggested by Gittinger [19] are as follows:

Benefit cost ratio (BCR): The benefit cost ratio (BCR) is a relative measure which was used to compare benefit per unit of cost. BCR estimated as a ratio gross returns and gross costs. The formula of calculating BCR (undiscounted) is shown as below.

Net present value (NPV): NPV is the current value of all net benefits associated with a project. NPV calculated by the following equation:

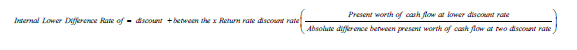

Internal rate of return (IRRI): IRR is the maximum interest rate that could be paid for the project resources that would leave enough money to cover investment costs and still allow society to break even. IRR will be calculated by the following equation.

Where, B is the benefit in each year; Ct is the cost in each year; NCFt is the net cash flow in each year f = 1,2…..n; n is the number of years; i is the interest (discount) rate; and t for time.

For calculating the IRR, interpolation method is usually used. The rule for interpolating the value of the internal rate of return lying between discount rates at too high on the one side and at too low on the other side. Thus,

Sensitivity analysis of poultry feeds production

Output and prices vary over time and subject to feed millers and farmers’ risk. In the production cycle, certain prices, quantities and costs may be highly variable resulting in a large effect on net returns. At the same time, good output prices make poultry feed millers and farmer’s profitable and less prices make looser. In case of poultry feed raw materials price, output price is more sensitive. So, sensitivity analyses have been done by assuming some scenarios with varying input and output prices. By doing this, it is possible to study the impact of changing feed raw materials and feed price. Effects of sensitivity analysis of different quality poultry feed mills considering followings situation.

a. Considering 5 percent decrease of feed price in market.

b. Considering 10 percent decrease of feed price in market.

c. Considering 5 percent increase of raw materials price in market.

d. Considering 10 percent increase of raw materials price in market.

Results and Discussion

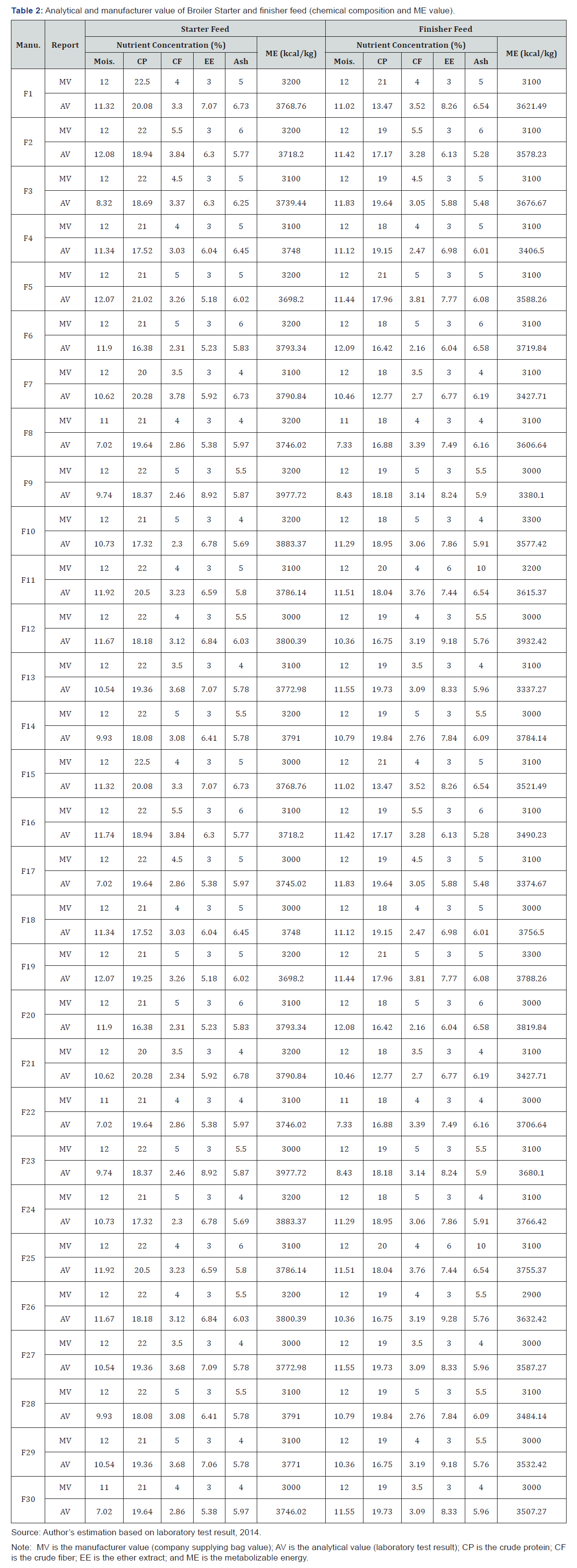

Analytical and manufacturer value of broiler starter and finisher feed

The results of analytical value (laboratory test result) and the manufacturer value (different company supply feed bags labeling there gives statement of the percentage of different components) differed. The nutritional components of analytical value and manufacturer value (the statement of feed company supplying bag) of broiler starter feed samples differed except the moisture, CF, and Ash content of feeds. The analytical value of broiler starter feed of F1 manufacturer of moisture, CP, CF, Ash and EE were 11.32%, 20.08%, 3.30% 7.07% and 6.73% whereas manufacturer values were 12%, 22.50%, 4.00%, 3.00% and 5.00%, respectively. But ME value of this manufacturer MV and AV were 3200.00 and 3768.76 kcal per kg which indicates that analytical value more than manufacturer values (Table 2). The analytical value of broiler starter feed of F2 manufacturer of moisture, CP, CF, Ash and EE were 12.08%, 18.94%, 3.84% 6.30% and 5.77% whereas manufacturer values were 12%, 22.00%, 5.50%, 3.00% and 6.00%, respectively. But ME value of this manufacturer MV and AV were 3200.00 and 3718.20 kcal per kg which indicates that analytical value more than manufacturer values. The moisture content of F2 manufacturer is the height of these manufacturers. The analytical value of broiler starter feed of F3 manufacturer of moisture, CP, CF, Ash and EE were 8.32%, 18.69%, 3.37% 6.30% and 6.25% whereas manufacturer values were 12%, 22.50%, 4.00%, 3.00% and 5.00%, respectively. But ME value of this manufacturer MV and AV were 3100.00 and 3739.44 kcal per kg which indicates that analytical value more than manufacturer values. The similar results also found for broiler starter feed of F5, F7, F21, F23 and F27 manufacturer (Table 2).

In case of broiler finisher feed of F1 manufacturer of moisture, CP, CF, Ash and EE were 11.02%, 13.47%, 3.52% 8.26% and 6.54% whereas manufacture values were 12.00%, 21.00%, 4.00%, 3.00% and 5.00%, respectively. But ME value of this manufacturer MV and AV were 3100.00 and 3621.49 kcal per kg which indicates that analytical value more than manufacturer values. The analytical value of broiler finisher feed of F6 manufacturer of moisture were 12.09% whereas manufacture values were 12.00% which is the height value of these manufacturers. The analytical value of broiler finisher feed of F14 manufacturer of crude protein was 19.84% whereas manufacture values was 19.00% which is the height value of these manufacturers. The analytical value of broiler finisher feed of F26 manufacturer of ether extract was 9.28% whereas manufacture values was 9.00% which is the height value of these manufacturers. The analytical value of broiler finisher feed of F20 manufacturer of ME was 3819.84% whereas manufacture values was 3000.00% which is the height value of these manufacturers (Table 2).

Some research findings showed that there are several factors can contribute to the variation in nutrient content including genetic background of the plant, agricultural conditions where the plant is grown (e.g. fertilization rates), stressors (e.g. drought, extreme heat early frosts and diseases) and processing conditions (e.g. mechanical extraction or chemical extraction). Other factors like sampling and laboratory analysis could add up to the nutrient variability [20,21].

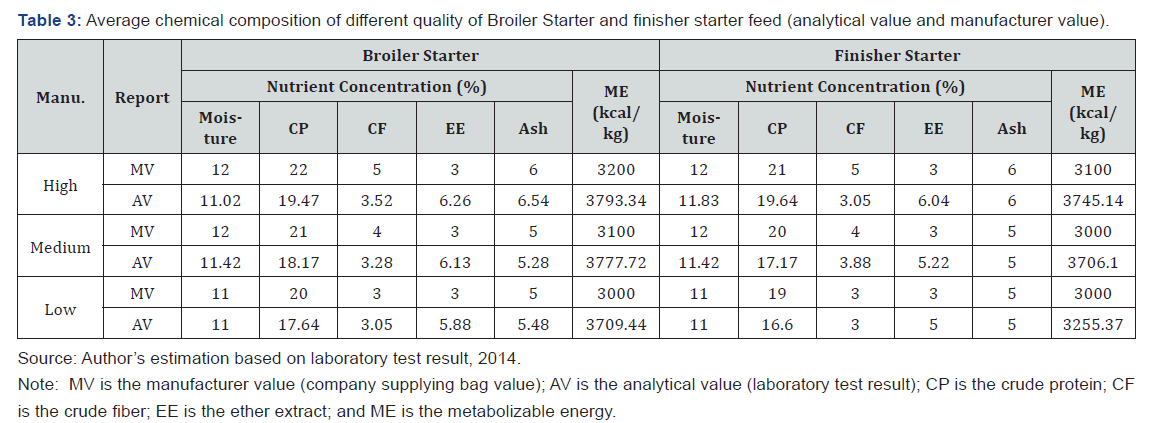

Average chemical composition (analytical value and manufacturer value)

Average chemical composition of nutritional components and ME value of the broiler feed samples of 30 different feed manufacturers which were collected from feed company bags and analyzed in the laboratory (Table 3). Table 3 shows that the average analytical value of broiler starter feed of high-quality manufacturer of moisture, CP, CF, Ash and EE were 11.32%, 19.47%, 3.52%, 6.26% and 6.54% whereas manufacturer values were 12%, 22 %, 5.00%, 3.00% and 6.00%, respectively. But high quality of manufacturer’s average ME value of MV and AV was 3200.00 and 3793.34 kcal per kg which indicates that analytical value of ME is more than manufacturer values. The medium quality manufacturer of their nutrient concentration of average analytical values were 11.42%, 18.17%, 3.28%, 6.13% and 5.28% whereas manufacturer values were 12%, 21 %, 4.00%, 3.00% and 5.00%, respectively. But medium quality of manufacturer’s average ME value of MV and AV was 3100.00 and 3777.72 kcal per kg which indicates that analytical value of ME is more than manufacturer values (Table 3). The low-quality manufacturer of their nutrient concentration of average analytical values were 11.00%, 17.64%, 3.05%, 5.88% and 5.48% whereas manufacturer values were 11.00%, 20.00%, 3.00%, 3.00% and 5.00%, respectively. The low quality of manufacturer’s average ME value of MV and AV were 3000.00 and 3709.44kcal per kg which indicates that analytical value of ME value is more than manufacturer values.

In case of finisher feed the average analytical value of highquality manufacturer of moisture, CP, CF, Ash and EE were 11.83%, 19.64%, 3.05%, 6.04% and 6.00% whereas manufacturer values were 12.00%, 21.00 %, 5.00%, 3.00% and 6.00%, respectively. But high quality of manufacturers’ average ME value of MV and AV were 3100.00 and 3745.14kcal per kg which indicates that analytical value of ME is more than manufacturer values. The medium quality manufacturer of their nutrient concentration of average analytical values were 11.42%, 17.17%, 3.08%, 5.22% and 5.00% whereas manufacturer values were 12.00%, 21.00%, 4.00%, 3.00% and 5.00%, respectively. But medium quality of manufacturer’s average ME value of MV and AV were 3000.00 and 3706.10kcal per kg which indicates that analytical value of ME is more than manufacturer values. The low-quality manufacturer of their nutrient concentration of average analytical values were 11.00%, 16.60%, 3.00%, 5.00% and 5.00% whereas manufacturer values were 11.00%, 19.00%, 3.00%, 3.00% and 5.00%, respectively. The low quality of manufacturers’ average ME value of MV and AV were 3000.00 and 3255.37kcal per kg which indicates that analytical value of ME value is more than manufacturer values (Table 3).

Profitability analysis of broiler production

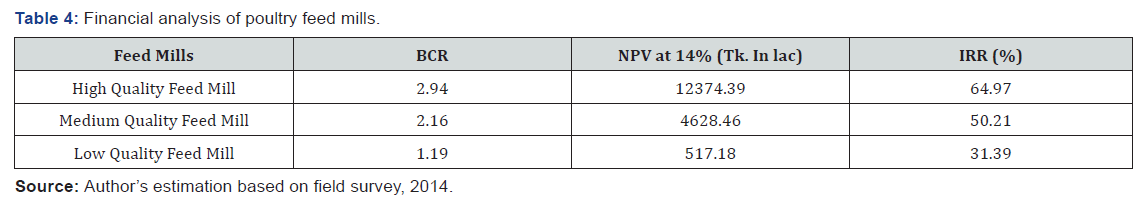

After estimation all cost and returns it was easy to find out financial returns of poultry feed mill. The result of benefit-cost analysis is highly sensitive to the discount rate; the choice of an appropriate discount rate, therefore, plays a vital role in the appraisal of projects. The difficulties in estimating the opportunity cost of capital are reflected by the study. The case becomes more difficult in developing countries, because of various kinds of imperfection and high distortion in the capital market. However, the available literature suggests that in most developing countries, the opportunity cost of capital varies between 8 to 15 percent. According to the manager of the Sonali Bank of Mymensingh branch, the lending rate of agriculture (production) loan is 14 percent. Thus, a 14 percent discount rate has been chosen for the appraisal poultry feed mill.

Before proceeding to the final results, it is worthwhile to recapitulate some salient features of the selected discounting measures i.e., Benefit Cost Ratio (BCR), Net Present Value (NPV) and Internal Rate of Return (IRR). The BCR is a relative measure which is used to compare benefits per unit of cost. The NPV criterion, on the other hand, is an absolute, not a relative measure may have a smaller NPV than a large marginally acceptable project. As long as both have a positive NPV, this is not really a problem for the selection of a project. The IRR is not affected by the rate of discount, while the NPV may change as a result of using a different discount rate [22,23]. It is argued [24] that the ranking of projects under the IRR criterion may also differ in the case where net benefits vary overtime, even though all projects may have the same life time. Nonetheless, all projects having IRR above the opportunity cost of capital can be accepted. The summary results of financial analysis of thirty poultry feed mill are presented in Table 4 shows that BCR was 2.94, 2.16 and 1.9, respectively a high, medium and low-quality feed mill which indicates the benefit cost ratio of high-quality feed was better than medium and lowquality feed. Considering 20 years’ time period and 14 percent discount rate, the NPVs from poultry feed mill were also positive. The average NPV of high, medium and low-quality feed mill was also positive. The NPV of high, medium and low-quality feed mill were Tk. 12374.39 lack, Tk. 4628.46 lack and Tk. 517.18 lack, respectively which indicates the net present values of high-quality feed mill was more than medium and low-quality feed (Table 4).

The positive NPVs indicate that poultry feed mill are considered to be financially sound and the project said financially viable because average IRR of high quality feed mill and low quality feed mill. And IRR of high, medium and low-quality feed mills were 64.97%, 50.21% and 31.39%, respectively which greater than the normal bank rate also indicates the internal rate of return of highquality feed mill was better than medium and low quality feed. That means it support that investment on high quality poultry feed mill is highly profitable and economically viable. In view of these circumstances, the financial analyses showed that poultry feed mills were highly profitable from the view point of individual investments. This research is also supported by some research like feed costs typically represent the highest cost item in smallholder production systems, implying that both quantity and quality of feed have a significant effect in determining profitability [25,26].

Sensitivity analysis of different quality poultry feed mills

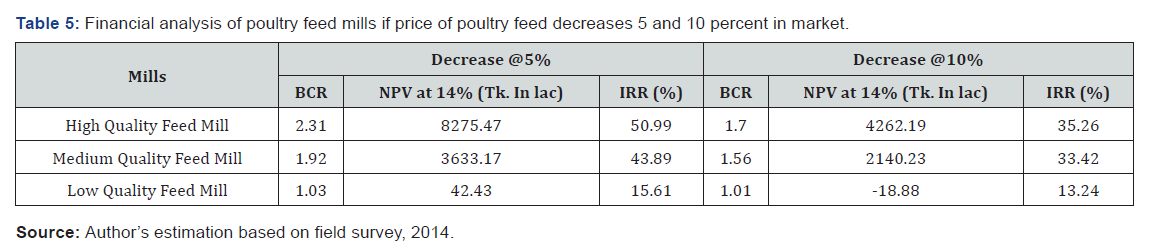

Considering decrease in 5 and 10 percent poultry feed: The evaluation of financial analysis as stated in Table 5 has been done on the basis of certain assumptions as stated earlier. It was assumed that the prices of all cost items as well as flow of income would remain constant during the farm’s life. This short of assumptions may turn out to be unrealistic in an uncertain world. The result of sensitivity analysis shows how the investment decision changes with the changes in the value of any variable in the discounted cash flow analysis. The profitability of poultry feed mill may be expected to be sensitive to price and yield uncertainty which effects on gross benefits of the feed mill. Even the mills themselves may not perform in the way expected. Many authors’ (e.g. [22,23]) also argue that the problem of uncertainty is another knotty problem to which there is no tidy solution. A great deal will inevitably depend upon the judgment of those making the decision. Only one vital factor such as price of feed decrease to the market is considered in this study for the sensitivity analysis. The aim of this section is to analyze what happens to profitability under the changed circumstances.

It is evident from financial analysis; the poultry feed mills were making high profits. Sensitivity analysis was conducted based on the assumptions that all benefits and investment of capital costs would happen in profitability of the feed mills; if price of poultry feed decrease 5 percent or 10 percent, respectively and if price of raw materials increase 5 percent or 10 percent, respectively (Table 5). In case of 5 percent decrease of feed price in market shows that BCR was 2.31, 1.92 and 1.03 respectively a high, medium and low-quality feed mill which indicates the benefit cost ratio of high-quality feed was better than medium and low-quality feed. Considering 20 years’ time period and 14 percent discount rate, the NPVs from poultry feed mill were also positive. The average NPV of high, medium and low-quality feed mills was also positive. The NPV of high, medium and low-quality feed mill were Tk. 8275.47 lack, Tk. 3633.17 lack and Tk. 42.43 lack respectively which indicates the net present values of high-quality feed mill was more than medium and low-quality feed. The positive NPVs indicate that poultry feed mills are considered to be financially sound and the project are said financially viable because average IRR of high, medium and low-quality feed mill. And IRR of high, medium and low-quality feed mills were 50.99%, 43.89% and 15.61%, respectively that is higher than the normal bank rate (Table 5). In view of these circumstances, the sensitivity analysis showed that poultry feed mills were highly sensitive. This implies that if the price of poultry feed price decrease at 5 percent in market then poultry feed mill could run their business but some mills were making loss and reluctant to operate feed mill.

Sensitivity analysis has been done taking into account 10 percent decrease of feed price in market. Summary results of these analyses are presented in Table 5 shows that benefit cost ratio (BCR) was 2.31, 1.92 and 1.03, respectively a high, medium and low-quality feed mill which indicates the benefit cost ratio of high-quality feed was better than medium and low quality feed. The average NPV of high and medium quality feed mills was also positive but low-quality feed mill was negative. The NPV of high, medium and low-quality feed mills were Tk. 4262.19 lack, Tk. 2140.23 lack and Tk. -18.88 lack, respectively which indicates the net present values of high-quality feed mill was more than medium and low-quality feed. The positive NPVs indicate that poultry feed mills are considered to be financially sound and the project are said financially viable because average IRR of high and medium quality feed mill but low-quality feed mills financially was not viable. And IRR of high, medium and low-quality feed mills were 35.26%, 33.42% and 13.24%, respectively that is higher than the normal bank rate. In view of these circumstances, the sensitivity analyses showed that poultry feed mills were highly sensitive.

This implies that if the price of poultry feed price decrease at 10 percent in market then poultry feed mill could run their business but some mills were making loss and reluctant to operate feed mill that means if price fall 10 percent then average performance of poultry feed mill for both categorize would be in loosing condition. Though some high-quality feed mills could able to incur bank rate but they also not interested to continue their business due to very low return from business. On the other hand low quality feed mill stopped producing feed because average BCR of poultry feed mill were less than unity, NPV was negative and IRR was undetermined.

Considering decrease in 5 and 10 percent of raw materials: Sensitivity analysis has been done taking into account 6 percent increase of raw materials price in market. Summary results of these analyses are presented in Table 6 shows that benefit cost ratio (BCR) was 2.33, 1.94 and 1.12, respectively a high, medium and low-quality feed mill which indicates the benefit cost ratio of high quality feed was better than medium and low quality feed. The average NPV of high, medium and low-quality feed mills was positive. The NPV of high, medium and low-quality feed mill were Tk. 8393.81 lack, Tk. 3695.32 lack and Tk. 294 lack, respectively which indicates the net present values of high-quality feed mill was more than medium and low quality feed.

The positive NPVs indicate that poultry feed mills are considered to be financially sound and the project are said financially viable because average IRR of high, medium and lowquality feed mills financially was viable. And IRR of high, medium and low-quality feed mills were 51.42%, 44.30% and 24.45% respectively that is higher than the normal bank rate. In view of these circumstances, the sensitivity analyses showed that poultry feed mills were highly sensitive. This implies that if the price of raw materials was increased at 5 percent in market then poultry feed mill could run their business but some mills were making less benefit and reluctant to operate feed mill that means if price increased 5 percent then average performance of poultry feed mill for both categorize would be in loosing condition. Though some high-quality feed mills could able to incur bank rate but they also not interested to continue their business due to very low return from business.

Sensitivity analysis has been done taking into account 5 percent increase of raw materials price in market. Summary results of these analyses are presented in Table 6 shows that benefit cost ratio (BCR) was 2.06, 1.72 and .99 respectively a high, medium and low-quality feed mill which indicates the benefit cost ratio of high-quality feed was better than medium and lowquality feed. The average NPV of high, medium and low-quality feed mills was positive. The NPV of high, medium and low-quality feed mill were Tk. 6645.57 lack, Tk. 2786.62 lack and Tk. -81.99 lack respectively which indicates the net present values of highquality feed mill was more than medium but low-quality feed was negative (Table 6). The positive NPVs indicate that poultry feed mills are considered to be financially sound and the project are said financially viable because average IRR of high and medium financially was viable and sound but low-quality feed mills was not viable. And IRR of high, medium and low-quality feed mills were 44.90%, 38.13% and 12.70% respectively that is higher than the normal bank rate. In view of these circumstances, the sensitivity analyses showed that poultry feed mills were highly sensitive. This implies that if the price of raw materials was increased at 10 percent in market then poultry feed mill could run their business but some mills were making less benefit and reluctant to operate feed mill that means if price increased 10 percent then average performance of poultry feed mill for both categorize would be in loosing condition. Though some high-quality feed mills could able to incur bank rate but they also not interested to continue their business due to very low return from business. On the other hand low quality feed mill stopped producing feed because average BCR of poultry feed mill were less than unity, NPV was negative and IRR was undetermined.

Conclusion

It is clear that compound broiler feeds of different feed manufacturers has differed between analytical value and manufacturer value of various nutritional composition of metabolizable energy value. There is much difference in crude protein content and metabolizable energy content. The crude protein was lower than requirements and metabolizable energy was higher than requirements. The analytical value of EE was higher than manufacturer value. Further research is needed to dig down the limit of lowering the protein and increasing the ME value of broiler feeds of manufacturers. Because, the analytical value of EE was higher than manufacturer value which has influence of health hazard. The findings of the study the benefit from high quality feed are higher than medium and low-quality feed. It is evident that the high-quality poultry feed mills were highly profitable comparatively medium and low-quality feed mills considering the real condition. The results of sensitivity analyses clearly indicate that poultry feed mills were price sensitive. If price fall in the market, then they can marginally sustain in the market but if it is more than 5 percent then they will reluctant to operate poultry feed mill. So, we can say, profitability of poultry feed mills appears to be negatively correlated with decrease of poultry feed price in market. If price of raw materials price were increased in the market, then they can marginally sustain in the market but if raw materials price were increased 10 percent then average performance of poultry feed mill for both categorize would be in loosing condition. Though some high-quality feed mills could able to incur bank rate but they also not interested to continue their business due to very low return from business. On the other hand, low quality feed mill stopped producing feed because average BCR of poultry feed mill was less than unity.

Acknowledgement

We express our thanks to Bangladesh Agricultural University, the villagers and respondents from the study areas, feed mills who participated and contributed to accomplish this study. The authors are also extends their gratitude’s to anonymous coauthors for their valuable time, constructive comments and useful suggestions to improve the manuscript. We also acknowledge the University of Tsukuba, Japan for technical support to carry out the research paper.

Compliance with Ethical Standards

None.

Conflict of Interest

The authors declare that there is no issue of competing interest.

References

- De Omena MC, Navarro DMAF, De Paula JE, Luna JS, De Lima MF, et al. (2007) Larvicidal activities against Aedes aegypti of some Brazilian medicinal plants. Bioresour Technol 98(13): 2549-2556.

- Al-Reza SM, Bajpai VK, Kang SC (2009) Antioxidant and antilisterial effect of seed essential oil and organic extracts from Zizyphus jujuba. Food Chem Toxicol 47(9): 2374-2380.

- Adzu B, Amos S, Wambebe C, Gamaniel K (2001) Antinociceptive activity of Zizyphus spina-christi root bark extract. Fitoterapia 2(4): 344- 350.

- Nisar M, Adzu B, Inamullah K, Bashir A, Ihsan A, et al. (2007) Antinociceptive and antipyretic activities of the Zizyphus oxyphylla Edgew. leaves. Phytother Res 21(7): 693-695.

- Perveen M Qaiser (2005) Pollen flora of pakistan–xliv. Rhamnaceae. Pak J Bot 37(2): 195-202.

- Jan G, Khan MA, Gul F (2009) Ethnomedicinal plants used against jaundice in Dir Kohistan valleys (NWFP), Pakistan. Ethnobotanical leaflets 2009(8): 7.

- Sher H (2011) Ethnoecological evaluation of some medicinal and aromatic plants of Kot Malakand Agency, Pakistan. Scientific Research and Essays 6(10): 2164-2173.

- Khan MA, Khan SA, Qureshi MA, Ahmed G, Khan MA, et al. (2011) Ethnobotany of some useful plants of Poonch Valley Azad Kashmir. Journal of Medicinal Plants Research 5(26): 6140-6151.

- Sher Z, Khan Z, Hussain F (2011) Ethnobotanical studies of some plants of Chagharzai valley, district Buner, Pak J Bot 43(3): 1445-1452.

- Kaleem WA, Muhammad N, Khan H, Rauf A (2014) Pharmacological and phytochemical studies of genus Zizyphus. Middle-East J Sci Res 21(8): 1243-1263.

- Jabeen A, Khan MA, Ahmad M, Zafar M, Ahmad F (2009) Indigenous uses of economically important flora of Margallah hills national park, Islamabad, Pakistan. African Journal of Biotechnology 8(5): 763-784.

- Samreen U, Ibrar M, Naveed S, Khatak I (2016) Ethnobotanical study of subtropical hills of Darazinda, Takht-e-Suleman range FR DI Khan, Pakistan. Pure Appl Biol 5(1): 149-164.

- Khan MA, Khan MA, Hussain M, Mujtaba G (2012) Medicinal plants used in folk recipes by the inhabitants of himalayan region Poonch Valley Azad Kashmir (Pakistan). J Basic Appl Sci 8: 35-45.

- Zvaigzne G, Karklina D, Seglina D, Krasnova I (2009) Antioxidants in various citrus fruit juices. Chemine Technologija 3(52): 56-61.

- Ozgen M, Scheerens JC, Reese RN, Miller RA (2010) Total phenolic, anthocyanin contents and antioxidant capacity of selected elderberry (Sambucus canadensis L.) accessions. Pharmacogn Mag 6(23): 198-208.

- Waseem K, Ghaffoor A, Rehman SU (2002) Effect of fruit orientation on the quality of litchi (Litchi chinenesis Sonn) under the agro-climatic conditions of Dera Ismail Khan-Pakistan. Int J Agric Biol 4(4): 503-505.

- Kamiloglu O, Ercisli S, Sengül M, Toplu C, Serce S (2009) Total phenolics and antioxidant activity of jujube (Zizyphus jujube Mill.) genotypes selected from Turkey. Afr J Biotech 8(2): 303-307.

- Razi MF, Anwar R, Basra SMA, Khan MM, Khan IA (2013) Morphological characterization of leaves and fruit of jujube (Ziziphus mauritiana Lamk.) germplasm in Faisalabad, Pakistan. Pak J Agric Sci 50(2): 211- 216.

- Qamer S, Ehsan M, Nadeem S, Shakoori AR (2007) Free amino acids content of Pakistani unifloral honey produced by Apis mellifera. Pak J Zool 39(2): 99-102.

- Gao QH, Wu PT, Liu JR, Wu CS, Parry JW, et al. (2011) Physico-chemical properties and antioxidant capacity of different jujube (Ziziphus jujuba Mill.) cultivars grown in loess plateau of China. Scientia Horticulturae 130(1): 67-72.

- Collado-Gonzalez J, Cruz ZN, Rodriguez P, Galindo A, Diaz-Banos FG, et al. (2013) Effect of water deficit and domestic storage on the procyanidin profile, size, and aggregation process in pear-jujube (Ziziphus jujuba) fruits. J Agric Food Chem 61(26): 6187-6197.

- Ecevit FM, San B, Dilmacunal T, Turk FH, Yildirim AN, et al. (2007) Selection of superior ber (Ziziphus jujuba L.) genotypes in civril region. J Agric 14(1): 51-56.

- Batos B, Miljkovic D, Perovic M, Orlovic S (2017) Morphological variability of Quercus robur L. leaf in Serbia. Genetika 49(2): 529-541.

- Hasanova S, Akparov Z, Mammadov A, Amirov L, Babayeva S, et al. (2017) Genetic diversity of chickpea genotypes as revealed by ISSR and RAPD markers. Genetika 49(2): 415-423.

- Petrovic S, Maric S, Cupic T, Rebekic A, Rukavina I (2017) Assessment of molecular and phenotypic diversity among winter wheat cultivars. Genetika 49(2): 583-598.

- Saroei E, Cheghamirza K, Zarei L (2017) Genetic diversity of characteristics in barley cultivars. Genetika 49(2): 495-510.

- Yadegari M, Ansari MH (2017) Study of multivariate analysis of quantitative traits in Iranian pumpkin lines. Genetika 49(2): 425-433.

- Jan SA, Shinwari ZK, Rabbani MA, Niaz IA, Shah SH (2017) Assessment of quantitative agro-morphological variations among Brassica rapa diverse populations. Pak J Bot 49(2): 561-567.

- Izadpanah F, Kalantari S, Hassani ME, Naghavi MR, Shokrpour M (2015) Molecular and morphological variation in some Iranian saffron (Crocus sativus L.) accessions. Genetika 47(2): 711-722.

- Arif M, Khurshid H, Uddin Siddiqui S, Jatoi SA, Ghafoor A (2017) Estimating Spatial Population structure through quantification of Oil content and phenotypic diversity in Pakistani Castor Bean (Ricinus communis L.) germplasm. Sci Technol Develop 34(3): 147-154.

- Ghafoor A, Gulbaaz FN, Afzal M, Ashraf M, Arshad M (2003) Inter-relationship between SDS-PAGE markers and agronomic traits in chickpea (Cicer arietinum L.). Pak J Bot 35(4): 613-624.

- Haliem EA, Al-Huqail AA (2013) Comparative sodium dodecyl sulfate- polyacrylamide gel electrophoresis and restricted fragment length polymorphism among fenugreek accessions. Genet Mol Res 12(4): 6284-6298.

- Dhawale RN, Mahalle MD, Paul NS (2015) Biochemical marker (Protein) based characterization of rice accessions bio-diversity in international rice molecular breeding programme. Asian J Biomedical and Pharma Sci 5(43): 31-37.

- Javaid A, Ghafoor A, Anwar R (2004) Seed storage protein electrophoresis in groundnut for evaluating genetic diversity. Pak J Bot 36(1): 25- 29.

- Iqbal SH, Ghafoor A, Ayub N (2005) Relationship between SDS-PAGE markers and Ascochyta blight in chickpea. Pak J Bot 37(1): 87-96.

- Martin JF, Birkenholz RJ (1995) Rural and Urban Adult Knowledge and Perceptions of Agriculture. Journal of Agricultural Education 36(2): 44- 53.

- Alexiades MN, Sheldon JW (1996) Selected Guidelines for Ethnobotanical Research: A Field Manual. The New York Botanical Garden, New York, pp. 306.

- Trotter RT, Logan MH (1986) Informant census: A new approach for identifying potentially effective medicinal plants. In: Etkin LN (Ed.), Plants in indigenous medicine and diet. Redgrave, Bedford Hill, New York, pp. 91-112.

- Muhammad N, Wadood SF, Khan W, Ali N, Nisar M (2018b) Intra-species profiling of Cleome viscosa growing in Swat district (Pakistan). Biosystem Diversity 26-52.

- Muhammad N, Ali N, Nisar M, Abd Allah EF, Hashem A, et al. (2018a) Genetic Diversity Within Natural Populations of the Medicinal Plant Rhynchosia minima (L.) Dc. Applied Ecology and Environmental Research 16(5): 5633-5651.

- Mohammed A, Kidanu A, Mohamed A, Asrat P, Abera K, et al. (2011) Dire Dawa Administration Program of Adaptation to Climate Change. DDAEPA. Dire Dawa, Ethiopia. pp. 133.

- Young AG, Merriam HG, Warwick SI (1993) The effect of forest fragmentation on genetic variation in an Acer saccharium. (March sugar maple) population. Heredity 71: 277-289.

- National Research Council (1991) Animals as sentinels of environmental health hazards. Washington: National Academies Press, USA, pp. 176.

- Sun B, Conceicao L, Ricardo D, Silva JM, Spranger I (1998) Separation of grape and wine proanthocyanidins according to their degree of polymerization. Journal of Agricultural and Food Chemistry 46(4): 1390- 1396.

- Hueneke FL (1991) Ecological implication of genetic variation in the plant populations. In: Falk DA & Holsinger KE (Eds.), Genetic diversity and conservation of the rare plants. Oxfords university press, New York, USA, pp. 31-44.

- Chung KT, Wong TY, Huang YW, Lin Y (1998) Tannins and human health: a review. Crit Rev Food Sci Nutr 38(6): 421-464.

- Sharma GN, Gaur A (2013) Ziziphus mauritiana Lamk-an overview. Indo American J Pharmaceutical Res 3(6): 4560-4566.