Technology of Drying Medicinal Plants in Water-Heating Drying Installation

Safarov Jasur and Sultanova Shaxnoza*

Tashkent State Technical University, Republic of Uzbekistan

Submission: July 28, 2017; Published: August 18, 2017

*Corresponding author: Sultanova Shaxnoza, Tashkent State Technical University, Tashkent100095, Republic of Uzbekistan, Email: sh.sultanova@yahoo.com

How to cite this article: Safarov J, Sultanova S.Technology of Drying Medicinal Plants in Water-Heating Drying Installation. Agri Res & Tech: Open Access J. 2017; 9(4): 555771. DOI: 10.19080/ARTOAJ.2017.09.555771

Abstract

This article presents the results of experiments on the process of drying medicinal plants on a water-heating drying plant. Drying is one of the main methods of harvesting plant material. It is in the process of releasing the herbal raw materials from moisture with the aim of longer storage. There is a fairly common, erroneous view that plants need to be dried in the sun. The water-heating drying unit was developed by the authors on the territory of the Tashkent state technical university. On the part of the authors, a special technology has been developed for skins and support of temperature parameters based on theoretical and conducted research when drying medicinal plants, a relatively low temperature of 60-65 °C is used. This selection of temperature makes it possible to preserve the properties and quality of the dehydrated product. In addition, the article contains some reviews on the work of this kind.

Keywords: Technology; Medicinal plants; Installation; Drying; Water heating; Temperature; Process

Introduction

The processes of dehydration, drying, that is, the processes of removing moisture from the product, are of great importance in various branches of the food industry and are inextricably linked to each other. According to the doctor of technical sciences Slutskaya T.I., doctor of technical sciences Mezenova O.Ya., doctor of technical sciences Kim E.N. By drying is understood the process of removal from the materials of any liquid, as a result of which the relative content of the dry part increases.

At the same time, during the drying process of food products, mainly water is removed, so the drying process is understood as the process of dehydration of materials [1].

The main difference between drying and mechanical methods of separation of moisture or its chemical absorption is an increase in temperature and the transition of the solvent from the liquid phase to the gaseous phase. Effective application of the drying process is impossible without the use of modern high-intensity dryers [2].

Drying naturally takes too much time. Now this method of processing medicinal raw materials is used extremely rarely. In most medium and large enterprises, special equipment is used for this, which also has several drying regimes.

Materials and Methods

The choice of the type and design of the drying plant and schemes for the organization of material and heat flows is carried out based on the following groups of requirements:

a. Ensuring the required final values for the temperature and humidity of the material, as well as the waste air streams.

b. The requirements expressing the quality of the results of the process of this group can be attributed to the dispersion of humidity and temperature.

c. Restrictions on various kinds of physico-chemical, organoleptic changes in final products.

d. Corresponding to the above requirements, appropriate levels of adjustment of the mode parameters and phase contact conditions are provided.

The system decomposition of the problem of analysis and synthesis of a complex interrelated complex of heat and mass, aerodynamic, hydrodynamic, mechanical and other phenomena requires, at the initial stage of the study, the results of analyzing the temperature fields.

The theoretical bases of calculations of thermophysical processes of heat and mass transfer in the period of drying medicinal plants carried out by the authors require knowledge of specific values of heat and moisture exchange coefficients. Obtaining these values is possible only in the process of carrying out special laboratory, semi-industrial and full-scale studies. Experimental studies of the drying process of plant raw materials were carried out by us at the laboratory of the Tashkent State Technical University.

The main requirement for these experiments was the most accurate reproduction of heat and mass transfer processes in the convective drying of medicinal plants. The main requirement for these experiments was the most accurate reproduction of heat and mass transfer processes in the convective drying of medicinal plants.

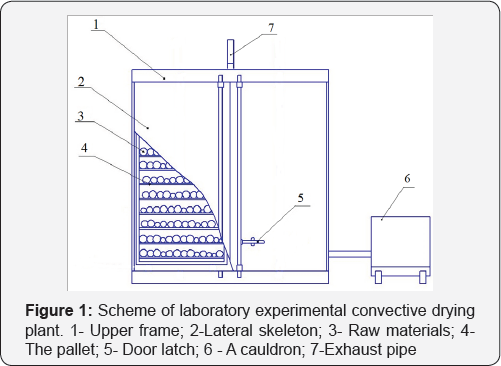

For carrying out laboratory studies, an experimental convection drying plant was made that allows the dewatering process and fixing of the optimum parameters of suitable medicinal plants for drying (Figure 1).

The design of the drying plant allows it to be easily transported by means of installed wheels. Also, if necessary, you can transport it with the help of a tow truck.

Drying temperature is selected individually for each type of product, based on the content of BAS in raw materials. Drying is carried out at a temperature that does not denature enzymes, which results in continued lysis reactions during the entire drying process.

For the ideal removal of bound moisture in the raw materials, the temperature and velocity of the coolant are regulated, based on the morphological and biochemical characteristics of the raw materials.

This installation allows you to conduct research: the dynamics of heat and moisture transfer in the layer of a drying medicinal plant; Values of specific moisture capacity and moisture conductivity of grass; Aerodynamic resistance of the layer, depending on the moisture content and density of the dehydrated plant.

The water-heating dryer operates on natural gas (or coal, wood, briquettes, electricity, oil products) using a cauldron.

In a container-type dryer, the heat transfer medium is drawn by a line of heat conducting pipes. Metal tubes and withstand the long-term impact of active elements released from the product during the drying process. Heat-transfer pipes are attached to the frame of the drying chamber by means of special fixing elements. Hot water is used as the heat agent.

The removable pallets are placed in the convection dryer.

After loading the raw material into the chamber, the dryer boiler is ignited. The temperature is heated to 90-100 °C, with this heating the temperature inside the drying chamber reaches the required temperature to 60-65 °C. This temperature is considered the most optimal for drying medicinal plants [3]. In order to maximize the preservation of the final product during the drying process, the temperature is maintained automatically with the help of a thermostat located in the chamber.

Conclusion

Based on the conducted studies of temperature profiles on the pallets of a water-heating periodic dryer, the following can be concluded: the essence lies in the fact that the installation takes into account the adsorption properties of the substances saturable drying products, that is, determine the intrinsic rates of adsorption and desorption of substances in the wet state, in accordance with which the mode of drying of the product is established. As a result of this drying, a product with a layered distribution of the substances contained in the product is obtained, which allows the maximum preservation of the useful biologically active substances of the products [4].

In the course of experimental studies, the regularities of the change in intensity and speed of drying for medicinal plants were studied, which made it possible to determine the moisture content of the material at any time and representing a qualitative picture of the course of the drying process at different periods.

Convective drying plant allows obtaining high-quality final products. In addition, low-temperature dehydration of products allows maximum preservation of useful biologically active substances of final products.

References

- Artyukhova SA (2001) Technology of products from hydrobionts.Safronova TM, Shenderyuk VI, Kolos M (Eds.), p. 496.

- Lebedev PD (1963) Calculation and design of drying plants. Gosenergoizdat M, p. 320.

- Sultanova ShA (2017) Development of a convective drying plant of container type intended for medicinal plants. Chemical Technology. Control and management 1(73): 36-40.

- Safarov JE, Sultanova ShA Mobile drying plant for drying medicinal plants. Samara State Technical University, I All-Russian scientific- practical conference with international participation. Food industry and public catering: the current state and prospects for development. pp. 217-218.