Quality Assessment of Corn-Breadfruit-Date Flour and Sensory Evaluation of Chin-Chin Prepared Using the Composite Flours

Ihuoma Ahaotu1, Ordinakachi Eze1 and Ndukwe Maduka2*

1Department of Microbiology, Faculty of Science, University of Port Harcourt, Port Harcourt, Nigeria

2Department of Biological Science, College of Natural and Applied Sciences, Wellspring University, Nigeria

Submission:June 21, 2021; Published: August 06, 2021

*Corresponding author: Ndukwe Maduka, Department of Biological Science, College of Natural and Applied Sciences, Wellspring University, Benin City, Edo State, Nigeria

How to cite this article: Ihuoma A, Ordinakachi E, Ndukwe M. Quality Assessment of Corn-Breadfruit-Date Flour and Sensory Evaluation of Chin-Chin Prepared Using the Composite Flours. Adv Biotech & Micro. 2021; 16(3): 555940 DOI:10.19080/AIBM.2021.16.555940

Abstract

The benefits of utilizing indigenous crops in developing countries as a potential substitute to wheat usually processed into flour need to be maximized. In this study, a confectionery popularly known as chin-chin was prepared using corn-breadfruit-date composite flour formulated in the ratio 70:20:10, 60:30:10, 50:40:10 and 40:50:10 which were labelled X1, U1, D1 and L1, respectively. Microbiological analysis, functional properties and proximate analysis of the composite flours were carried out using Standard methods. Sensory evaluation of chin-chin samples prepared using the composite flours were evaluated using 9-point Hedonic scale. The total bacterial count (TBC) of the composite flours exceeded 7 log10CFU/g limit recommended by International Commission on Microbiological Specification for Food (ICMSF). The frequency of occurrence of bacteria isolated from the composite flours were Bacillus sp. (44 %), Staphylococcus aureus (22 %), Escherichia coli (17 %), Proteus sp. (11 %) and Streptococcus sp. (6 %) while the fungal isolates were Aspergillus sp. (26 %), Candida sp. (17 %), Microsporum sp. (17 %), Cladiosporum sp. (8 %), Penicillium sp. (8 %), Chaetomium sp. (8 %), Beauveria sp. (8 %) and Ochroconis sp. (8 %). The oil absorption capacity, bulk density, water absorption capacity, gelatinization temperature, and swelling capacity of the composite flours were within the range of 1.13±0.02 - 1.71±0.08 g/ml, 0.72±0.06 - 0.75±0.07 g/cm3, 1.27±0.06 - 2.10±0.05 g/ml, 76.33±0.72 - 81.33±1.42 oC and 10.43±0.57-10.70±0.17 g/ml, respectively. The protein, ash and moisture content of the composite flours were within the range of 10.06±0.42 - 13.54±0.38 %, 1.21±0.16 - 1.90±0.17 % and 1.05±0.12 - 1.20±0.17 %, respectively. Moisture content, swelling index and bulk density of the composite flours; mouthfeel, aroma and appearance of the chin-chin samples prepared using the composite flours showed no significant differences (p>0.05). Although the sensory report showed that chin-chin samples prepared using the composite flours were generally acceptable, the most preferred sample was prepared using Sample LI.

Keywords: Malnutrition, Wheat flour, Natural sweetener; Confectioneries; Snack

Introduction

The fight against malnutrition prevalent in many developing countries by means of incorporating highly nutritious, but less utilized crops into diets championed by the world food programme need to be sustained. Promoting the utilization of composite flour to increase the supply of protein and minerals essential for growth and maintenance of human body could prevent nutrition-related diseases from manifesting [1,2]. In Nigeria, the increase in demand for snacks especially ready-to-eat baked products and confectioneries made from wheat flour is encouraging massive importation of wheat from European countries [3]. This development is pushing the prices of wheat-based products available in the markets above the reach of many Nigerians. In a bid to reverse the trend, supplementing wheat flour with non-wheat flour made from indigenous and affordable crops such as cassava, potato, yam and plantain is aimed at increasing the yield of locally grown crops and reduce the level of wheat importation [4-9].

Flour processed from a single crop could be deficient in some essential nutrients, not able to meet the nutritional needs of individuals facing health challenges such as obesity, diabetes and heart-related diseases [10,11]. Some of these limitations could be addressed using composite flour which also offers economic benefits. Thus, several studies on composite flours have been carried out. Yet, more studies are still required for continuous improvements [12]. In that regard, African breadfruit (Treculia africana) was selected for processing into flour to overcome the limitation of short shelf life of 5 days after it has been harvested [13,14]. Also selected for processing into flour is date palm fruit (Phoenix dactylifera L) to serve as a natural sweetener in the production of chin-chin. Since it is estimated that annual loss of 2 million tons of the surplus production of date palm fruit (moisture content ≈ 64.5 %) occur due to inability to process date palm fruits into useful products, it was selected for processing into flour. Lastly, the selection of corn (Zea mays L.) among other cereals such as wheat for processing into flour is due to its abundant supply in the country Nigeria [13,15].

Corn is among the most important cereals grown in Nigeria used for feeding humans and animals [16, 17]. It is referred as maize in many English speaking countries. The literal meaning of maize (American Indian word) is ‘that which sustain life’ [16,18]. According to Qamar et al. [19], maize contain 4.50-9.87 % protein, 2.17-4.43 % fat, 11.6-20.0 % moisture, 1.10-2.95 % ash, 2.10- 26.70 % fibre and 44.60-69.60 % carbohydrate. Maize is a rich source of dietary fiber, vitamins and minerals [19,20]. Globally, maize is ranked second behind wheat with regards to output of cereal crops [16]. Among the cereals consumed by Nigerians with regards to quantity, maize is rated second behind sorghum. [21]. Among all cereals, maize possess the highest genetic yield potential. Therefore, it is referred as ‘queen of cereals’ [22]. Maize kernel can be eaten raw; preferably eaten after subjecting it to cooking or roasting. Processing of maize kernel give rise to so many maize products such as corn flour, corn meal, corn oil, corn flakes, tortillas, tortilla chips, among others [19,23,24]. According to Abiose & Ikujenlola [25], maize provides the highest percentage of energy source in the national diets of 22 countries across the globe which include 16 African countries. In Nigeria, the industrial sector utilizes more than 60 % of maize grown across the country in the production of flour, beer, maize flakes, malt drink, syrup, dextrose, starch and animal feed. Maize flour could be supplemented in wheat-based products such as bread, cake, chin-chin, among others [26].

In the last 5, 000 years, the palm date (Phoenix dactylifera L. Family Arecaceae) has been a very important source of food for people living in the Middle East and North Africa region. In recognition of the usefulness of the fruit abundantly produced by the palm date, it is referred as the sacred tree, the tree of life and ‘the bread of the desert [15,27]. The local Hausa name for date palm fruit is debino. Date palm tree thrives mainly in Northern part of Nigeria dominated by the Hausas [28,29]. It produces a popular fruit that has a sugary taste which is mainly glucose and fructose. As a result of high sugar content of date palm fruit, it is regarded as an ideal substitute to refined sugar majorly for the purpose of producing confectioneries. Other benefits include lowering the risk diabetic patients are exposed to due to increasing blood sugar level, rich fiber content, antioxidants and flavonoids [11,15,30,31]. The fruit of date palm is usually eaten raw as a sweet berry [31,32]. It is a rich source of carbohydrates (65.00 %), protein (17.09 %), moisture (64.34 %), fiber (12.55 %), ash (9.8 %) and fat (9.61 %), dietary fiber (6.5-11.5 %) [28].

African breadfruit is the common name given to Treculia africana which describes a tree commonly seen growing in tropical parts of Africa [33]. The tree produces a large yellow fruit with spongy texture containing edible small seeds [34]. It is usually found growing near streams or swampy areas in the forest [35]. African breadfruit has been given different names by different ethnic groups in Nigeria. It is called ukwa, bere foo foo, ediang, ize and bafufuta by the Igbos, Yorubas, Efik and Ibibios, Benin and Hausas, respectively [36,37]. The tree grow abundantly in west and eastern states in Nigeria [34]. African breadfruit is affordable and abundant in supply during its season [38]. Traditionally, it is usually boiled, roasted or toasted before it can be eaten [14,39]. African breadfruit is used as a substitute for yam in preparing traditional foods because it is cheaper. Therefore, it is generally regarded as poor man’s food [40]. African breadfruit is a cheap source of protein to many families in rural areas. Roasted breadfruit seeds are sold together with palm kernel as a roadside snack [37,41]. According to Obi and Akubuo [42], African breadfruit contain crude protein (13.35 %), fat (10.12 %), ash (1.96 %), crude fibre (2.83 %), and carbohydrates (62.01 %). African breadfruit is a rich source of potassium, calcium, phosphorus, vitamin B, ascorbic acid, niacin, riboflavin, thiamin, pyridoxine and carotene. Reasonable amount of Omega-3 and Omega-6 fatty acids are present in African breadfruit [35,40-43]. Processing African breadfruit into its kernel usually carried out domestically is quite laborious and time-consuming [42]. African breadfruit kernels processed into flour could be used as a soup thickener. It can as well be used in preparing many products such as pastries, cookies and confectioneries [43].

Chin-chin is a popular fried snack among Nigerians. It is prepared using wheat flour, eggs and other ingredients. Ndife et al. [44] and Lemchi et al. [26] used composite flour which include maize flour to prepare chin-chin. In a related study, Folorunso et al. [45] and Ugwuanyi et al. [46] also used composite flour which include date flour and breadfruit flour to prepare chin-chin, respectively. The chin-chin produced were generally acceptable according to their sensory reports, but the microbiological quality of the composite flours which could affect wholesomeness of the samples (chin-chin) were not reported. In recent times, the use of refined sugar in the production of confectioneries is raising health concerns. Therefore, the use of natural sweeteners such as agavar raw honey, corn syrup, maple syrup, brown rice syrup, xylitol, stervia, molasses, black strap molasses, and date sugar is regarded as a good alternative. A well acceptable chin-chin was produced by Folorunso et al. [45] using wheat-date flour blend. However, affordability of the snack could be a challenge due to inflation which is currently affecting wheat flour in the local markets. Therefore, this study is aimed at evaluating the microbiological quality, functional properties and nutritional composition of corn-breadfruit-date flour and sensorial acceptability of chin-chin prepared using the composite flours.

Materials and Methods

African breadfruit was collected from the forest (Farmland) located few miles away from Port Harcourt International Airport, Omagwa using aluminium basin sterilized with 70 % ethanol. About 3 Kg of corn was purchased from traders selling cereals at Choba market, along East-West road, Port Harcourt, Rivers State using sterile polythene bags. Date palm fruit weighing about 500 g was purchased from a hawker at Uniport junction, along East-West road, Port Harcourt using a sterile polythene bag. All the materials were quickly taken to Microbiology Laboratory, University of Port Harcourt for analyses.

Preparation of flours

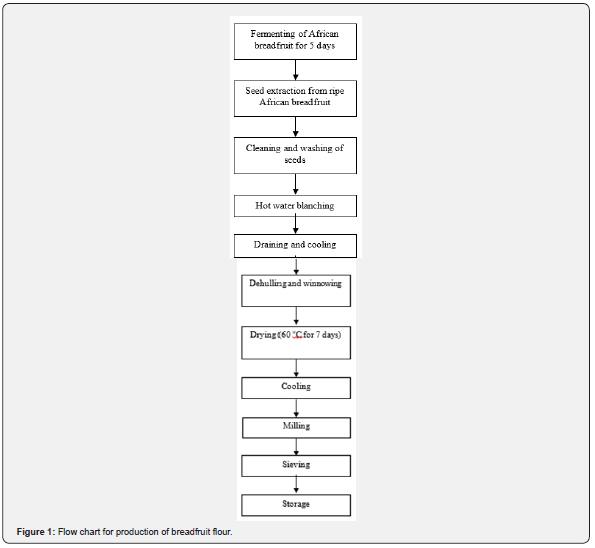

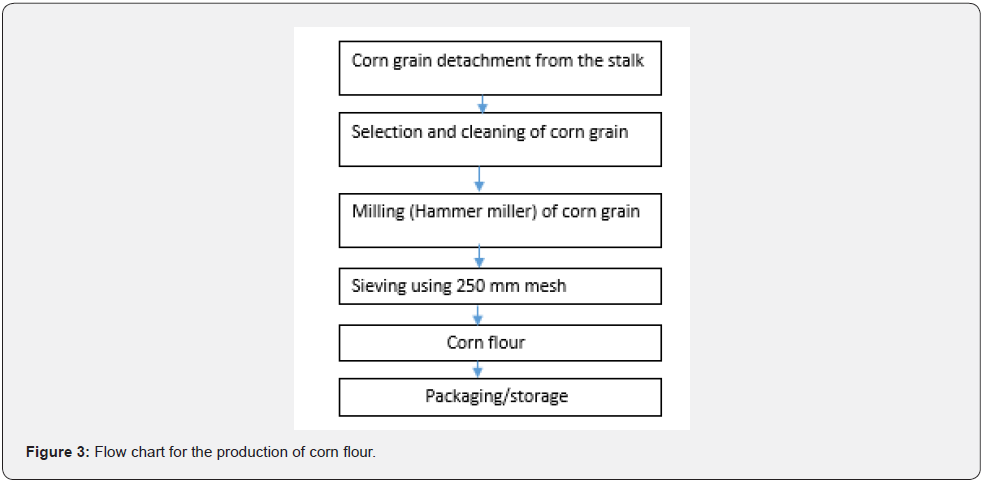

Preparation of African breadfruit, date and corn flours were carried out using the methods described by Olaoye and Onilude [14], Folorunso et al. [45] and Adedeji & Tadawus [47], respectively with some modification.

Preparation of composite flour

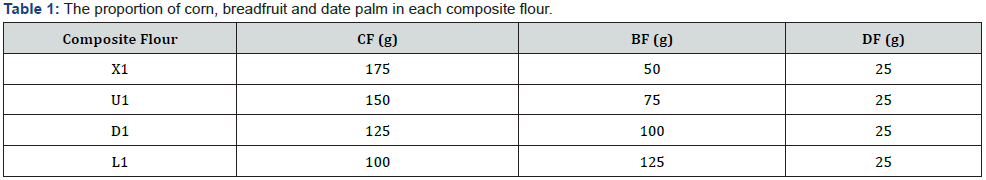

Composite flour that comprise of corn, breadfruit and date flour were formulated in the ratio of 70CF: 20BF: 10DF (first blend), 60CF:30BF: 10DF (second blend), 50CF:40BF: 10DF (third blend) and 40CF:50MF: 10DF (fourth blend) using a wellcalibrated electronic balance (Metler MT-2000). Table 1 shows the weight of breadfruit flour, corn flour and date flour which constitute 250 g of each composite flour (Figures 1-3).

Key: CF- Corn flour, BF-Breadfruit flour; DF-Date flour.

Serial dilution

Ten-fold dilution of each of the composite flours were prepared using sterile water. A suspension of 1 g composite flour sample was added in 9 ml sterile water, swirled gently for 2 min. to ensure even distribution of the flour sample. The tubes containing 9 ml of sterile water was labelled (10-1) - (10-6). A sterile pipette specifically for each sample transferred from one dilution of the flour suspension to the next was done until the last dilution (10-6) was reached.

Microbiological Analysis

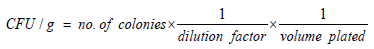

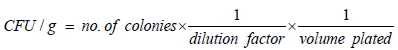

Total heterotrophic bacterial count

The dilutions (10-4), (10-5) and (10-6) of each composite flour was plated out on nutrient agar (Biomark Laboratories, India) plate using the spread plate method. The inoculated plates were incubated (plates kept inverted) at 37 oC for 48 h using an incubator manufactured by Axiom Medical LTD, UK. The total number of colonies on the culture plates were counted after the incubation period using a hand tally counter. The result obtained was calculated using the formula below and expressed as colony forming units per gram (CFU/g).

Total fungal count

The procedure used for determining the total heterotrophic bacterial count was applied in determining the total fungal count except that the (10-4), (10-5) and (10-6) dilutions were plated out on Sabouraud dextrose agar (L-S Biotech, India) and incubated at 25 °C for 7 days. The total number of colonies on the culture plates were counted after the incubation period using a hand tally counter. The result obtained was calculated using the formula below and expressed as colony forming units per gram (CFU/g).

Purification of the isolates

With the aid of sterilized wire loop, discrete colonies were picked from the bacterial and fungal culture plates and subcultured repeatedly into a freshly prepared nutrient agar and Sabouraud dextrose agar plates, respectively to obtain pure colonies. The pure colonies were stored on agar slants for further identification of the isolates.

Identification of the isolates

Identification of the bacterial isolates were based on morphological and biochemical characteristics. The morphological characteristics include the shape of colonies, colonial outline, colonial evaluation, colour, consistency and size. Motility test was carried out using the method described by Varghese & Joy [48]. Gram staining and biochemical tests were carried out on the bacterial isolates using the procedure described by Cheesbrough [49] and Isu & Onyeagba [50]. The biochemical tests include catalase, endospore stain, and sugar fermentation (glucose and lactose). Lactophenol cotton blue staining of the fungal isolates were carried out and morphological result observed was recorded using the procedure described by Isu & Onyeagba [50].

Functional properties

Functional properties which include swelling capacity, water absorption capacity, oil absorption capacity, bulk density and gelatinization temperature of the composite flours were determined.

Water and oil absorption capacity

Oil and water absorption capacity of the composite flour samples were determined using the method described by Sosulski et al. [51]. One gram (1 g) of the sample was mixed with 10 ml soybean oil (specific gravity 0.9092) and 10 ml of water, respectively. The mixtures were allowed to stand at ambient temperature (28 ±2 °C) for 30 min., then centrifuged for another 30 min. at 3000 rpm. Water absorption was observed and reported as percentage water bound per gram flour.

Gelatinization temperature

Gelatinization temperature of the composite flour samples were determined using the method described by Shinde [52]. One gram (1 g) of flour sample was weighed accurately in triplicate and transferred to 20 ml screw-capped tubes. Ten millilitre (10 ml) of water was added to each sample and heated slowly in a water bath until a solid gel was formed. On completion of gel formation, the temperatures of the gel were measured and the average noted as the gelatinization temperature.

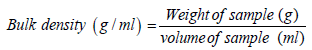

Bulk density

The bulk density of the composite flour samples were determined using the method described by Jones et al. [53]. The volume of 100 g of the flour sample was measured in a measuring cylinder (250 ml) after tapping the cylinder on a wooden plank until no visible decrease in volume was noticed. Based on the weight and volume, the apparent (bulk) density was calculated.

Swelling Capacity

The swelling capacity of the composite flour samples were determined using the method described by Okaka & Potter [54]. Ten milliliter (10 ml) graduated cylinder was filled with the flour sample to 10 ml mark. Then, distilled water was added to arrive at a total volume of 50 ml. The top of the graduated cylinder was tightly covered and mixed by inverting the cylinder. The suspension was inverted the second time after 2 min and left to stand for additional 8 min. The volume occupied by the flour sample was recorded after 8 min.

Proximate Analysis

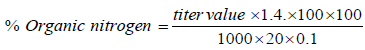

Protein content

The Kjeldahl method was used in determining the protein content of the composite flour samples. One gram (1 g) of the sample was weighed into a clean conical flask (20 ml). Three gram (3 g) of digestion catalyst was added into the conical flask followed by 20 ml concentrated sulphuric acid and the sample was heated to digest. The content of the flask’s colouration changed from black to sky-blue. The digest was cooled to room temperature and was diluted to 100 ml with distilled water. Twenty milliliter (20 ml) diluted digest was measured into a distillation flask and the flask was held in place on the electrothermal heater. The distillation flask was attached to a Liebig condenser connected to the receiver containing 10 ml of 2 % boric acid indicator. Forty milliliter (40 ml) sodium hydroxide was injected into the digest via a syringe attached to the mono-arm steelhead until the digest became strongly alkaline. The mixture was heated to boiling and the distilled ammonia gas passed through the condenser into the receiver beaker. The colour of the boric acid changed from purple to greenish as ammonia distillate was introduced into the boric acid. The distillate was titrated with standard 0.1N hydrochloric acid solution until the colour returned to purple from greenish. The volume of hydrochloric acid added to effect this change was recorded as titter value. The protein content was calculated using the formula below.

Where titter value = the volume of HCl used in titrating the ammonium distillate.

1.4 = nitrogen equivalent to the normality of HCl used in the titration 0.1N.

100 = the total volume of digest dilution

100 = percentage factor

1000 = conversion factor from gram to milligram

20 = integral volume of digits analysed or distilled

0.1 = the weight of sample in gram digested.

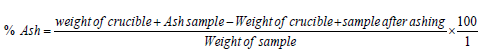

Ash content

Ash content of the composite flours were determined using the furnace method. One gram (1 g) of the dried sample was weighed into a porcelain crucible which was previously preheated and weighed. The crucible was inserted into a muffle furnace and regulated to a temperature of 300 °C for three hours. The crucible with the content was placed inside a desiccator and allowed to cool to room temperature and re-weighed. Ash content was calculated using the formula below.

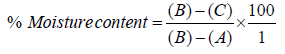

Moisture content

The AOAC [55] method was used in determining the moisture content of the composite flour. An aluminium dish previously cleaned and dried at 105 °C for 5 min. was allowed to cool inside a desiccator to room temperature and weighed (A). Two grams (2g) of composite flour was weighed into the dish and reweighed (B). The dish containing composite flour sample was heated at 105 °C inside an oven until constant weight was achieved (approx. 5 h). The dish was transferred to a desiccator, allowed to cool and reweighed (C).

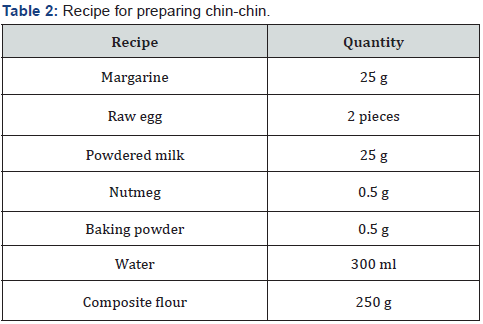

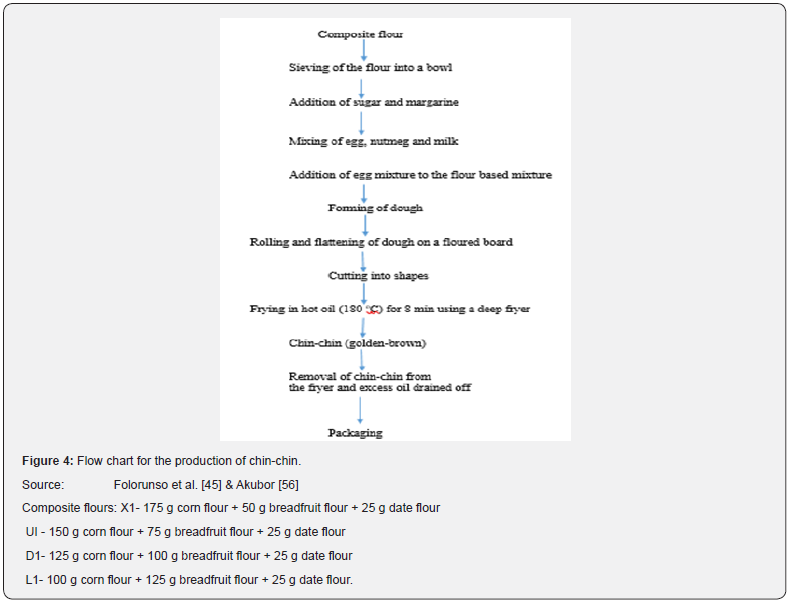

Production of chin-chin

A list of ingredients including the quantity of each ingredient used in preparing chin-chin is presented in Table 2. The flow chart depicted in Fig. 4 explains the process for preparing chin-chin (snack) as earlier described by Folorunso et al. [45] and Akubor [56] with slight modification. The chin-chin samples prepared using each of the composite flours (X1, U1, D1 and L1) were labelled accordingly for sensory evaluation (Figure 4).

Composite flours: X1- 175 g corn flour + 50 g breadfruit flour + 25 g date flour

UI - 150 g corn flour + 75 g breadfruit flour + 25 g date flour

D1- 125 g corn flour + 100 g breadfruit flour + 25 g date flour

L1- 100 g corn flour + 125 g breadfruit flour + 25 g date flour.

Sensory evaluation

The sensorial acceptability of the chin-chin samples prepared using the composite flours were evaluated based on the colour, taste, aroma, appearance, mouthfeel and overall acceptability. Ten (10) member semi-trained sensory panelists evaluated the samples using a 9-point Hedonic scale in line with the procedure described by Ihekoronye & Ngoddy [57] with slight modifications. Sensory score 9 is the highest rating interpreted as like extremely whereas sensory score 1 is the least interpreted as dislike extremely. The panelists were instructed to use a glass of potable water provided to rinse their mouth before putting each sample in the mouth for sensory evaluation.

Statistical analysis

Data generated were subjected to analysis of variance (ANOVA) using IBM SPSS version 23 statistical package software. Duncan’s Multiple Range Test (DMRT) at p = 0.05 was also used to separate the Means.

Results

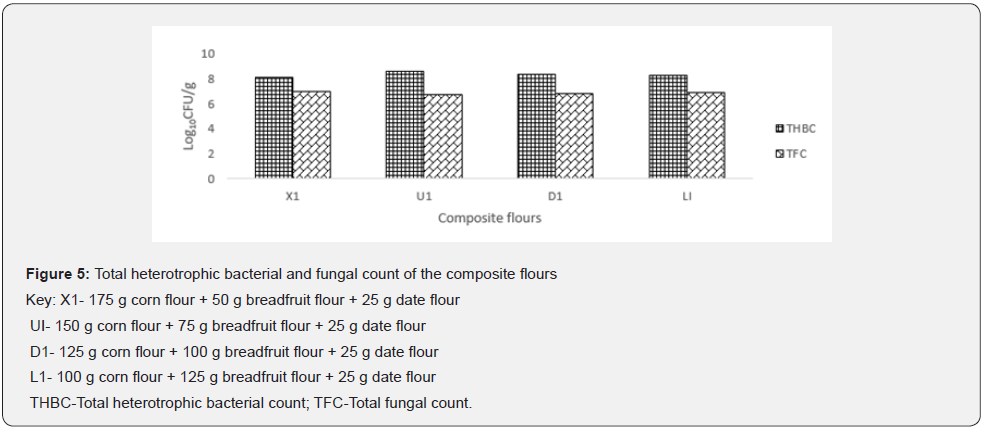

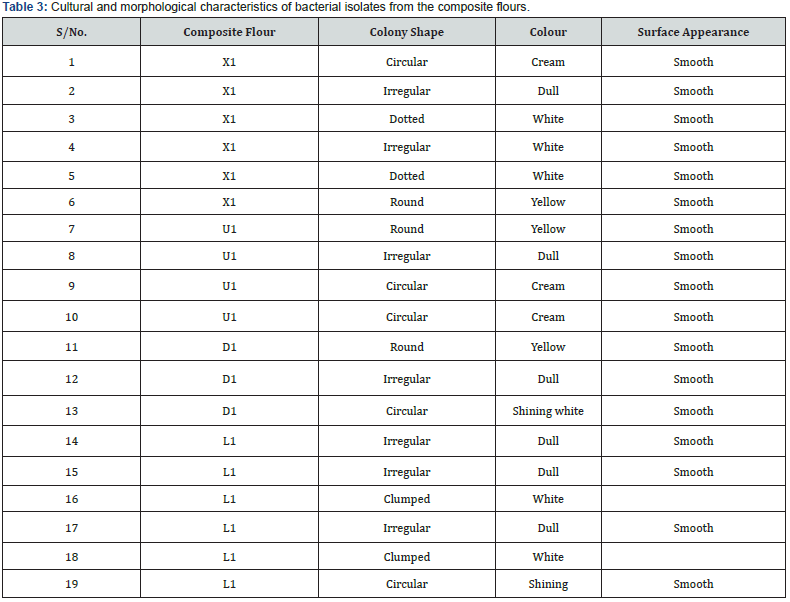

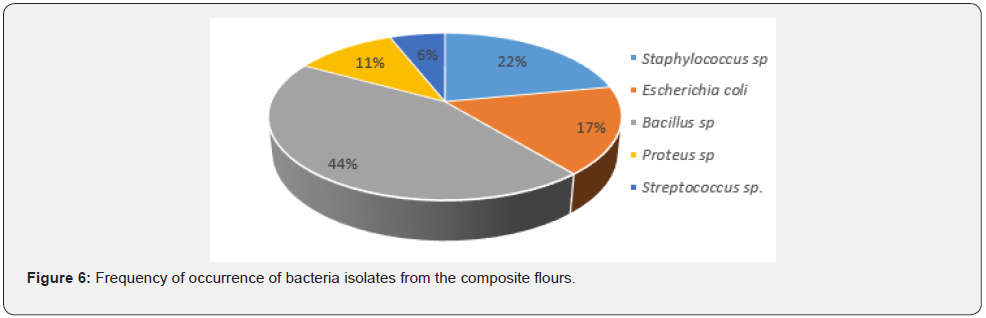

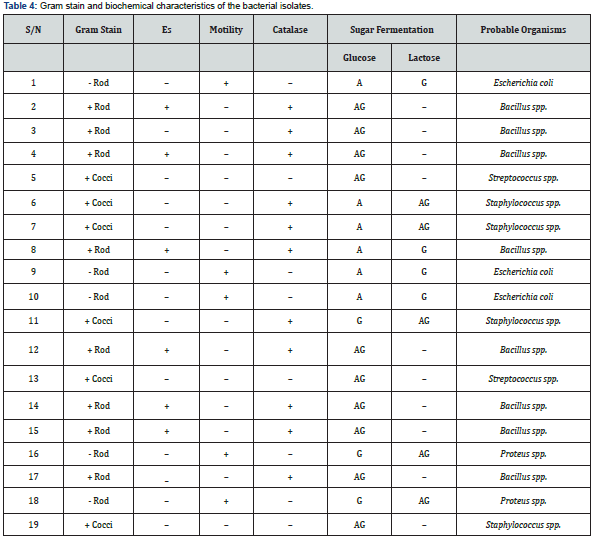

The result presented in Fig. 5 shows the total heterotrophic bacterial (THBC) and total fungal count (TFC) of the composite flours. The THBC of composite flour X1 (175 g corn flour + 50 g breadfruit flour + 25 g date flour), U1 (150 g corn flour + 75 g breadfruit flour + 25 g date flour), D1 (125 g corn flour + 100 g breadfruit flour + 25 g date flour) and L1 (100 g corn flour + 125 g breadfruit flour + 25 g date flour) are 8.15, 8.60, 8.36 and 8.25 log10CFU/g whereas the corresponding values for TFC are 6.95, 6.75, 6.83 and 6.86 log10CFU/g, respectively. There is no significant difference (p>0.05) between the THBC among the composite flours. Similarly, the TFC of the composite flours were not significantly different (p>0.05). Presented in Table 3 is the cultural and morphological characteristics of the bacterial isolates from the composite flours. Table 4 shows the result of Gram staining and biochemical tests carried out on the bacterial isolates. A total of five (5) bacterial genera were identified. They are Staphylococcus aureus, Escherichia coli, Bacillus spp., Proteus spp. and Streptococcus spp. The result shows that S. aureus and Bacillus sp. were present in all the flour samples whereas Proteus sp. was found only in the flour sample L1. E. coli was found in flour sample X1 and U1 while Streptococcus sp. was detected in flour sample X1 and D1. Depicted in Figure 6 is the frequency of occurrence of bacterial isolates from the composite flours. The result shows that Bacillus sp. (44 %) and Streptococcus sp. (6 %) had the highest and least frequency of occurrence, respectively.

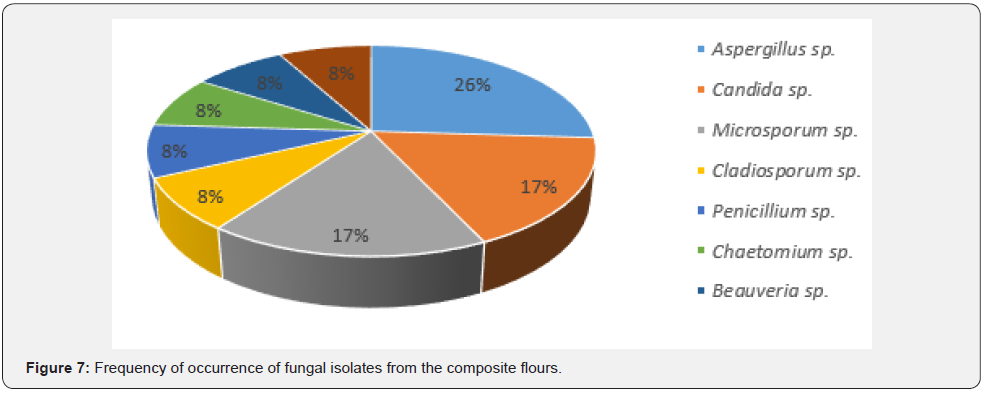

The colonial and microscopic appearance of fungi isolated from the composite flours are depicted in Table 5. A total of eight (8) fungal genera were identified from the composite flour. They include Aspergillus spp., Beauveria spp., Candida spp., Microsporum spp., Cladiosporum spp., Penicillium spp., Chaetomium spp. and Ochroconis spp. Shown in Fig. 7 is the frequency of occurrence of fungal isolates from the composite flours. The fungi genera that recorded the highest frequency of occurrence is Aspergillus spp. (26 %). However, Beauveria spp., Cladiosporum spp., Penicillium spp., Chaetomium spp. and Ochroconis spp. each recorded the least frequency of occurrence (8 %) in the composite flours.

Key: X1 - 175 g corn flour + 50 g breadfruit flour + 25 g date flour

UI - 150 g corn flour + 75 g breadfruit flour + 25 g date flour

D1- 125 g corn flour + 100 g breadfruit flour + 25 g date flour

L1 - 100 g corn flour + 125 g breadfruit flour + 25 g date flour.

Key: + represent positive result; - represent negative result; A - acid production.

G - gas production; ES - endospore stain.

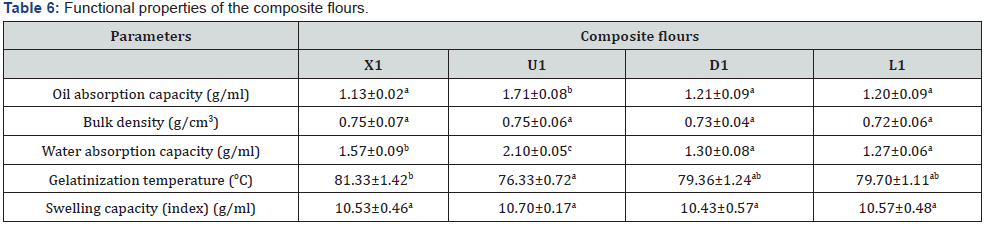

Values show means of triplicate analysis ±SD. Means with different superscript along the row are significantly different (p<0.05).

Key: X1 - 175 g corn flour + 50 g breadfruit flour + 25 g date flour

UI - 150 g corn flour + 75 g breadfruit flour + 25 g date flour

D1- 125 g corn flour + 100 g breadfruit flour + 25 g date flour

L1 - 100 g corn flour + 125 g breadfruit flour + 25 g date flour.

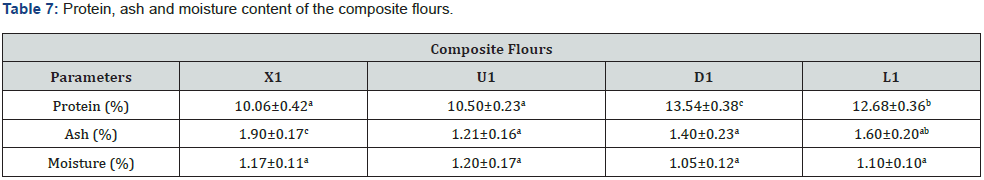

Depicted in Table 6 is the functional properties of the composite flours. The result shows that there is no significant difference (p>0.05) among the composite flour samples with regards to swelling capacity and bulk density. The swelling capacity and bulk density of the composite flour samples were within the range of 10.43±0.57 - 10.70±0.17 g/ml and 0.72±0.06 - 0.75±0.07 g/cm3, respectively. However, there were significant differences (p<0.05) in other functional properties among the composite flour samples. The functional properties include oil absorption, water absorption and gelatinization temperature which were within the range of 1.20±0.09 - 1.71±0.08 g/ml, 1.27±0.06 - 2.10±0.05 g/ml and 76.33±0.72 - 81.33± 1.42 °C, respectively. Presented in Table 7 is the moisture, ash and protein content of the composite flours which were within the range of 1.05±0.12 - 1.20±0.17 %, 1.21±0.16 - 1.90±0.17 % and 10.06±0.42 – 13.54±0.38 %, respectively. The result shows that there is no significant difference (p>0.05) in moisture content of the various composite flours. However, significant differences (p<0.05) exist among the flour samples with regards to ash and protein content.

Values show means of triplicate analysis ±SD. Means with different superscript along the row are significantly different (p<0.05).

Key: X1 - 175 g corn flour + 50 g breadfruit flour + 25 g date flour

UI - 150 g corn flour + 75 g breadfruit flour + 25 g date flour

D1- 125 g corn flour + 100 g breadfruit flour + 25 g date flour

L1 - 100 g corn flour + 125 g breadfruit flour + 25 g date flour.

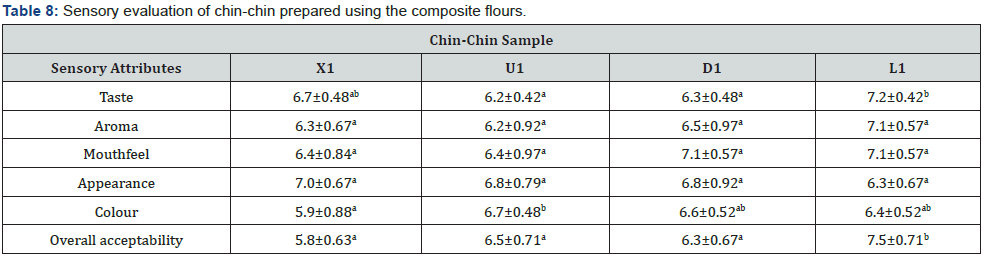

Table 8 shows the sensory report of chin-chin samples prepared using each of the composite flours. The result shows that aroma, mouthfeel and appearance of all the samples were not significantly different (p>0.05). In contrast, the overall acceptability, taste and colour of all the samples were significantly different (p<0.05). The sensory report shows that highest and lowest sensory score was assigned to overall acceptability of Sample L1 (7.5±0.71) and Sample X1 (5.8±0.63), respectively. The interpretation of the sensory score assigned to Sample L1 and X1 with regards to overall acceptability is ‘like moderately’ and ‘neither liked nor disliked’, respectively (Table 8).

Values show the means of sensory analysis by ten panelists ±SD. Means with different superscript along the row are significantly different (p<0.05). Interpretation of the 9-point Hedonic scale: 9 - Like extremely; 8 - Like very much; 7 - Like moderately; 6 - Like slightly; 5 - Neither liked nor disliked; 4 - Disliked slightly; 3 - Disliked moderately; 2 - Disliked very much; 1 - Disliked extremely.

Key: X1- Chin-chin prepared using 175 g corn flour + 50 g breadfruit flour + 25 g date flour UI - Chin-chin prepared using150 g corn flour + 75 g breadfruit flour + 25 g date flour D1- Chin-chin prepared using 125 g corn flour + 100 g breadfruit flour + 25 g date flour L1- Chin-chin prepared using 100 g corn flour + 125 g breadfruit flour + 25 g date flour.

Discussion

Microbial Load

Flour is generally regarded as a microbiologically safe product as a result of low water activity which does not favour growth and multiplication of microorganisms [58]. However, the result from this study shows that composite flours which comprise of corn, breadfruit, and date flour in the ratio 70:20:10, 60:30:10, 50:40:10 and 40:50:10 had a total heterotrophic bacterial count and total fungal count within the range of 8.15 - 8.60 and 6.75- 6.95 log10CFU/g, respectively. Meanwhile, the recommendation approved by the International Commission on Microbiological Specification for Food (ICMSF) stipulated that total bacterial count exceeding 7 log10CFU/g in flour renders the product unsafe for human consumption [59]. Therefore, all the composite flour samples did not meet the requirement stipulated by ICMSF. This result will raise public health concern unless the flour samples undergo heat kill steps such as baking, frying and cooking. Any of these steps could eliminate large population of microorganisms in the samples [60].

According to N’zebo et al. [61], flour made from maize are usually more contaminated by microorganisms than flour from other crops. The ratio of corn flour in the composite flours formulated were higher than breadfruit and date flour with the exception of Sample L1. Large portion of corn flour supplemented with breadfruit and date flour could be one of the reasons responsible for high bacterial count reported for the composite flours which exceeded the limit stipulated by ICMSF. In a related study, Imarhiagbe et al. [58] reported that THBC, total coliform plate count and total staphylococcal count of maize flour sold in major parts of Benin city, Nigeria were within the range of 3.70- 3.85, 3.48-3.62, 3.48-3.61 log10CFU/g, respectively. The result of microbial analysis of date powder carried out by Hariri et al. [62] showed that bacteria was not found in two varieties of date powder while total plate count of 10 CFU/g and 14 CFU/g were recorded for two other varieties of date powder. Both reports is an indication that date flour is less contaminated by bacteria than maize flour. However, a study carried out by Umar et al. [63] reported high bacterial count in date fruits sold in selected markets in Katsina metropolis. According to research findings by Al Jasser [64], storage temperatures significantly influences the microbial load of date palm fruits. N’Guessan et al. [65] reported that total microflora in yellow and white maize flour prepared in the laboratory is 3.65 and 4.19 log10CFU/g, respectively. Meanwhile, yeast and mould in yellow and white maize flour is 2.67 and 2.05 log10CFU/g, respectively.

The total fungal count of the composite flours were within the range of 6.75 - 6.95 log10CFU/g. According to Prevention of food adulteration rules, India of 1956, yeast and mould should not be found in 0.1 g of food [66]. Although the fungal count of the composite edible flours did not meet the requirement, the process of using the flours as a raw material to prepare snack (chin-chin) could possibly reduce fungal population in the product. It should be noted that high fungal count of composite flours makes it a potential agent for food spoilage and food poisoning due to release of mycotoxins. Contamination of foods by moulds is capable of changing the appearance of the food. Off flavours could also be released inside the food due to presence of moulds [67]. Fungal contamination of date fruit palm sold in different locations were reported by Anjili et al. [32], Tafinta et al. [68] and Yusuf [69]. The use of date fruits contaminated by fungi to produce date flour could be one of the sources of microorganisms in the composite flours.

Bacterial isolates

Staphylococcus aureus, Escherichia coli, Bacillus sp., Proteus sp. and Streptococcus sp. were isolated from the composite flours which comprise of breadfruit, date palm and corn flour. A related study carried out Imarhiagbe et al. [58] which involved microbial analysis of corn flour sold in selected markets reported the presence of Bacillus sp., B. subtilis, Enterobacter aerogenes, Micrococcus sp., Staphylococcus sp., S. aureus, and Pseudomonas aeruginosa. Geographical location, source of flour and processing conditions of flour could be responsible for the differences in bacterial genera reported in the composite flours and the corn flour [58]. In another study, Oyetayo and Omenwa [70] reported the presence of Bacillus sp., Staphylococcus sp. and Micrococcus sp. in raw seeds of African breadfruit. Some of these bacterial species could persist after processing African breadfruit into flour. Thus, the source of bacterial genera found in the composite flours could be from contaminated date fruits, African breadfruit seeds and maize kernel processed into flour.

The presence of Staphylococcus aureus in the composite flours poses a public health concern because this bacterium is capable of releasing enterotoxins inside foods responsible for staphylococcal food-borne disease (SFD). Spores produced by Staphylococcus spp. are capable of withstanding high temperature. Subjecting food to heat by cooking does not easily destroy enterotoxins released by Staphylococcus spp. [67]. S. aureus is a well-known specie of Staphylococcus associated with most commonly reported food-borne diseases [71]. Contamination of food products by S. aureus is usually attributed to improper handling. This bacterium is commonly found in nasal canals. It forms part of the normal flora of the skin. Although S. aureus is regarded as being harmless on the skin, it could cause superficial skin infection and life threatening skin infections after gaining access into the body through a broken skin [67,72]. The frequency of occurrence of Staphylococcus aureus in the composite flours is 22 %.

Handling of African breadfruit, date palm fruits and corn with bare hands could be one of the sources of contamination of the samples with Escherichia coli. It has been established that for varying length of time, pathogenic E. coli is capable of surviving in the fingers and other parts of human body. Higher population of this bacterium can be found in tools that have direct contact with human body [61]. It is widely reported that presence of Escherichia coli in food products is mostly linked to faecal contamination because the bacterium forms part of the normal flora of animal and human intestine. Although E. coli isolated from the composite flours were not serotyped and their pathogenicity levels determined, there is possibility that pathogenic strains will be among the isolates. Thus, the presence of Escherichia coli in the composite flours is a public health concern [34]. The frequency of occurrence of E. coli in the composite flours is 17 %.

Spore-forming Bacillus sp. is widely distributed in nature. Diarrhea and emetic illness which manifest as nausea and vomiting are implicated with Bacillus sp. These diseases occur as a result of heat-stable enterotoxins released by the bacterium. The probable sources of contamination of the composite flours with Bacillus sp. is from soil and/or water. Most raw materials used in food manufacturing are contaminated by Bacillus sp. The population of Bacillus sp. in contaminated raw materials could reach 103/g or less. The infectious dose of Bacillus sp. is estimated at 105/g [73,74]. In the baking industry, Bacillus sp. could contaminate flour and other raw ingredients and possibly cause microbial spoilage of bakery products especially bread known as rope [75]. Among the bacterial isolates encountered in the composite flours, Bacillus spp. had the highest frequency of occurrence (44 %).

Proteus sp. has been implicated as spoilage bacterium of certain foods such as cured meats and shell eggs [76]. In a related study which involved the preparation of home-made complementary food flour, Okoronkwo et al. [77] reported the presence of Proteus spp. in maize-pigeon pea flour. The source of Proteus sp. in the composite flours could be from soil and/or water. Proteus spp. is often regarded as an opportunistic human pathogen. The bacterium usually cause diseases in immunocompromised individuals. Proteus sp. is implicated with urinary tract infections [78]. The frequency of occurrence of Proteus spp. in the composite flours is 11 %.

The presence of Streptococcus sp. in the composite flours could be from handlers of African breadfruit, date palm fruits and corn kernel. Streptococcus sp. is a pathogen that can cause human infections such as scarlet fever, pharyngities, and pneumonia [73]. Microbiological analysis of home-made complementary food prepared by Okoronkwo et al. [77] showed the presence of Streptococcus spp. Among the bacterial isolates encountered in the composite flours, Streptococcus spp. had the least frequency of occurrence (6 %).

Fungal Isolates

Aspergillus fumigata, A. caulidatum, A. clavatus, Beauveria spp., Candida rugosa, C. krusei, Microsporum canis, Cladiosporum spp., Penicillium spp., Chaetomium spp., Ochroconis gallapava and Microsporum audouinii were isolated from the composite flours. Exposure of corn, African bread fruit and date palm fruits used in preparing the composite flours to unhygienic environment could be responsible for the growth of sporulating moulds. In a related study, Yusuf [69] reported the presence of Aspergillus niger, A. nidulans, A. fumigates, Rhizopus spp. and Trichophyton rubrum in date palm fruits sold by local vendors in the market. Most of the fungal genera were not reported in the composite flours probably due to differences in geographical locations and flour processing conditions. The presence of moulds in the composite flours raises some health concern due to the possibility of moulds releasing mycotoxins responsible for severe poisoning, diarrhea, emesis, prostration and sometimes death.

Moulds such as Cladosporium spp. is associated with cutaneous infections, sinusitis, cerebral phaeohyphomycosis and pulmonary infections. Air is likely the source of contamination of the composite flours with Cladosporium spp [79]. The frequency of occurrence of Cladosporium spp. in the composite flours is 8 %. Beauveria spp is a pathogenic fungi that naturally occurs in insects (entomopathogenic fungi). The presence of this fungus in wheat flour infested with pests already infected with Beauveria spp has been reported. Pests could be the source of contamination of breadfruit, corn and/or date fruit by Beauveria spp. which were later processed into flour [80]. The frequency of occurrence of Beauveria spp. in the composite flours is 8 %. Chaetomium spp is usually present in buildings having problems associated with indoor air quality. It is responsible for sick building syndrome (SBS) which manifest symptoms which include hoarseness, wheezing, headache, fatigue, nausea, dizziness, dry skin, irritation of the eyes, nose and throat. Chaetomium spp. is associated with increased number of occurrences of respiratory tract infections. Human exposure to chaetoglobosins A and C produced by this filamentous fungus could cause adverse health effects. Various species of Chaetomium causes superficial and invasive infections [81]. The frequency of occurrence of Chaetomium spp. in the composite flours is 8 %. Possible sources of contamination of the composite flours with Ochroconis gallapava are soil, indoor and outdoor environment. In humans, some species of Ochroconis have been identified as opportunistic pathogens [82]. The frequency of occurrence of Ochroconis gallapava in the composite flours is 8 %.

The presence of Aspergillus sp. in the composite flours is a public health concern due to its capability of producing aflatoxins. It is worrisome that Aspergillus sp. had the highest frequency of occurrence (26%) among the fungal isolates from the composite flours. The persistence of spores of Aspergillus sp. in the atmosphere could be trapped by indigenous crops (corn, African breadfruit and date palm fruit) during processing into flour and/ or handling of the product which took place in the open. Later, germination of the spores on the crops might have occurred which resulted in the presence of Aspergillus sp. in the composite flours [73].

Rhinocerebral mucormycosis, genitourinary, mucocutaneous, pulmonary and disseminated infections could manifest due to infection caused by Penicillium sp. Among the fungal genera reported in the composite flours, Pencillium sp. had the least frequency of occurrence (8%). Also included in the category of fungi that had the least frequency of occurrence (8%) in the composite flours are Chaetomium spp., Beauveria spp., Ochroconis spp. and Cladosporium spp. The frequency of occurrence of Microsporum spp. in the composite flours is 17%. Preadolescent children are usually the ones affected by Tinea capitis attributed to dematophyte species which include Microsporum. The frequency of occurrence of Candida sp. in the composite flours is also 17 %. It is widely reported that Candida sp. is a common food contaminant which could also cause food spoilage [83].

Functional properties

Among the composite flours, the formulation that had the highest water absorption capacity (2.1 g/ml) is Sample U1 (150 g corn flour + 75 g breadfruit flour + 25 g date flour) whereas the sample that had the lowest value (1.27 g/ml) is Sample L1 (100 g corn flour + 125 g breadfruit flour + 25 g date flour). This result is an indication that increase in quantity of corn flour contributed to the increase in water absorption capacity of Sample L1, D1 and U1. However, exceeding 150 g of corn flour might have influenced the reduction in water absorption capacity (1.57 g/ml) reported in the Sample X1 (175 g corn flour + 50 g breadfruit flour + 25 g date flour). There is no significant difference (p>0.05) in water absorption capacity of Sample D1 and L1. Folorunso et al. [45] reported that water absorption of flour gives room for more quantity of water to be added to dough. When that happens, the baker will observe an improvement in handling characteristics of the dough. Thus, the freshness of the baked product is maintained. According to Peter-Ikechukwu et al. [11], water absorption determines the extent protein content in a product will associate in retaining water. Increased water absorption capacity of flour usually occur as a result of increase in protein content of flour.

In food formulations, oil absorption indicate the rate at which protein binds to fat. This functional property refers to the physical entrapment of oils [79]. The result presented in Table 6 shows that oil absorption capacity of the composite flours increased from 1.20±0.09 to 1.71±0.08 g/ml with increase in quantity of corn flour in the composite flour with one exception. The oil absorption capacity of Sample X1, D1 and L1. is not significantly different (p>0.05). It is suggested that better quality chin-chin can be produced using flour that has high oil absorption capacity. According to Peter-Ikechukwu et al. [11], oil absorption capacity is a parameter to be considered in preparation of baked foods, pancake, ground analogue, doughnuts and soup. Retention of mouth feel and flavour of food products is improved by absorption of oil. Soft texture of chin-chin is a mark of quality usually improved by oil retention capacity of flour used in preparing the product.

The swelling index of the flour samples were within the range of 10.43±0.57 - 10.70±0.17 g/ml. It has been reported that temperature, availability of water, species of starch and other carbohydrates as well as proteins influences the extent of swelling of flour. There is no significant difference (p>0.05) in the swelling index of all the composite flours. According to David et al. [84], increase in swelling power due to increase in water absorption lead to an improved solubility.

The bulk density of the various composite flours were within the range of 0.72±0.06 - 0.75±0.07 g/cm3. This parameter shows the heaviness of a particular flour sample. In food formulation, it is advisable to go for flour that has a low bulk density because the product derived from it have less retrogradation [11]. Less bulk is preferable when formulating infant food. On the contrary, higher bulk density is advantageous because it offers greater packaging advantage making it possible for larger quantity of flour to be packed within a constant volume. Bulk density is a function of particle size. There is an inverse relationship between particle size and bulk density [84]. There is no significant difference (p>0.05) in the bulk density of all the composite flours.

The gelatinization temperature of the composite flours were within the range of 76.33±0.72 - 81.33±1.42 °C. Gelatinization temperature is important in determining the viscosity, plasticity and elasticity of the snack (chin-chin). Lower gelatinization temperature indicates better gelling ability while higher gelatinization temperature indicates reduced viscosity, plasticity and elasticity [85]. Gelatinization temperature is important in food industry because it tend to affect the texture, uses and digestibility of starchy foods [86]. There is significant difference (p<0.05) in the bulk density of all the composite flours.

Proximate composition

The result presented in Table 7 shows that there is no significant difference (p>0.05) in protein content of Sample X1 and U1 which were reported as 10.06±0.42 % and 10.50±0.23 %, respectively. The composite flour that had the highest protein content (13.54±0.38 %) is Sample D1 (125 g corn flour + 100 g breadfruit flour + 25 g date flour). Interestingly, the protein content of composite flour sample D1 compare favourably with 14.7 % reported for wheat flour [3]. The least protein content among the composite flours was recorded for Sample X1(10.06±0.42 %).

Generally, the ash content of a product is an indication of the level of minerals contained in the product [84]. The result shows that ash content of the composite flours were within the range of 1.21±0.16 - 1.90±0.17 %. Interestingly, the ash content of the composite flours were higher than what is reported for wheat flour (0.70 %) [3]. There is no significant difference (p>0.05) in the ash content of composite flour samples U1 and D1

It has been widely reported that high moisture content in any food product favours the growth and multiplication of microorganisms leading to food spoilage. This invariably shortens the shelf life of food products [84]. The moisture content of the composite flours were within the range of 1.05±0.12 - 1.20±0.17 %. All the composite flours had a far lower moisture content compared with 9.1 % moisture content reported for wheat flour.

The implication of this result is that composite flour sample X1, D1, U1 and L1 is expected to have a longer shelf life than wheat flour. There is no significant difference (p>0.05) in the moisture content of all the composite flour samples.

Sensory characteristics

The sensory attributes which had no significant differences (p>0.05) among the chin-chin samples prepared using the composite flours include aroma, mouthfeel and appearance. However, other sensory attributes (taste, colour and overall acceptability) were significantly different (p<0.05) among the chin-chin samples. Chin-chin prepared using composite flour L1 (100 g corn flour + 125 g breadfruit flour + 25 g date flour) is the most preferred sample because the sensory panelists assigned the highest sensory score (interpreted as like moderately) for taste (7.2±0.42), aroma (7.1±0.57), mouthfeel (7.1±0.57) and overall acceptability (7.5±0.71) to the sample. The quantity of breadfruit flour (125 g) in the composite flour (Sample L1) compare with lesser quantity in other composite flours could be one of the reasons chin-chin prepared using the composite flour (L1) is the most acceptable sample. Since it has been observed that so many persons enjoy eating palm kernel and roasted breadfruit as a roadside snack, it might have influenced the sensorial acceptability of chin-chin (snack) prepared using composite flour that contains larger quantity of breadfruit flour compared with other chin-chin samples. According to Lemchi et al. [26], most of the sensory parameters of chin-chin prepared using maize and wheat flour were acceptable by the panelists. A similar sensory report was published by Ugwuanyi et al. [46] from a study that involved production of chin-chin using breadfruit, sorghum and soybean flour. In a related study, Folorunso et al. [45] reported that chin-chin prepared using date and wheat flour were acceptable by the sensory panelists. Edima-Nyah et al. [87] reported that snack bars prepared using African breadfruit seed flour, maize flour and coconut grit blends had impressive sensory properties.

Conclusion

A well-acceptable chin-chin was prepared using a composite flour which comprise of breadfruit, corn and date flour in different proportion. The total heterotrophic bacterial count and fungal count of the composite flour samples were within the range of 8.15 - 8.60 log10CFU/g and 6.75 - 6.95 log10CFU/g, respectively. The frequency of occurrence of bacteria isolates from the composite flours include Bacillus sp. (44 %), Staphylococcus aureus (22 %), Escherichia coli (17 %), Proteus sp. (11 %) and Streptococcus sp. (6 %) while the fungal isolates were Aspergillus sp. (26 %), Candida sp. (17 %), Microsporum sp. (17 %), Cladiosporum sp. (8 %), Penicillium sp. (8 %), Chaetomium sp. (8 %), Beauveria sp. (8 %) and Ochroconis sp. (8 %). The oil absorption capacity, bulk density, water absorption capacity, gelatinization temperature, and swelling capacity of the composite flours were within the range of 1.13±0.02 - 1.71±0.08 g/ml, 0.72±0.06 -0.75±0.07 g/ cm3, 1.27±0.06 - 2.10±0.05 g/ml, 76.33±0.72 - 81.33±1.42 oC and 10.43±0.57 - 10.70±0.17 g/ml, respectively. The protein, ash and moisture content of the composite flours were within the range of 10.6±0.42 - 13.54±0.38 %, 1.21±0.16 - 1.90±0.17 %, and 1.05±0.12 - 1.20±0.17 %, respectively. Sensory evaluation of chin-chin prepared using the composite flours revealed that chin-chin sample prepared using composite flour sample L1 (100 g corn flour + 125 g breadfruit flour + 25 g date flour) is the most preferred sample.

References

- Awuchi CG (2019) Proximate composition and functional properties of different grain flour composites for industrial applications. Intl. J. Food Sci 2(1)4: 43-64.

- Wekhe OE, Chuku EC, Nmom FW (2020) Determination of nutrient composition and associated spoilage fungi of different varieties of breadfruit. International J. Resear. Innovation Appli. Sci 5(11): 1-4.

- Ocheme OB, Adedeji OE, Chinma CE, Yakubu CM, Ajibo UH (2018) Proximate composition, functional, and pasting properties of wheat and groundnut protein concentrate flour blends. Food Sci. Nutri 6(5): 1173-1178.

- Berghofer E (2000) Brot als funktionales lebensmittel. Getride Mehl Brot 54(3): 173-179.

- Hugo LF, Rooney LW, Taylor JRN (2000) Malted sorghum as a functional ingredient in composite bread. Cereal Sci 79(4): 428-443.

- Bugusu B, Campanella O, Hamaker BR (2001) Improvement of sorghum-wheat composite dough rheological properties and bread making quality through zein addition. Cereal Chem 78(1): 31-35.

- Nwanekezi EC (2013) Composite flours for baked products and possible challenges-a review. Nig. Food J. 31(2): 8-17.

- Hasmadi M, Siti FA, Salwa I, Matanjum P, Abdul HM, Rameli AS (2014) The effect of seaweed composite flour on the textural properties of dough and bread. J. Appli. Phycol 26: 1057-1062.

- Noah AA (2017) Production, microbial and sensory qualities of biscuits produced from wheat-coconut-almond flour blend. Intl. J. Food Sci. Nutri 2(6): 135-138.

- Shittu T, Raji AO, Sanni LO (2007) Bread from composite cassava wheat flour. Effect of baking time and temperature in some physical properties of bread loaf.Food Resear. Intl. 40(2): 280-290.

- Peter-Ikechukwu A, Okafor DC, Kabuo NO, Ibeabuchi JC, Odimegwu EN (2017) Production and evaluation of cookies from whole wheat and date palm fruit pulp as sugar substitute. Intl. J. Adv.Engineer. Tech. Mgt. Appli. Sci 4(4): 1-31.

- Noorfarahzilah M, Lee JS, Sharifudin MS, Mohd Fadzelly AB, Hasmadi M (2014) Applications of composite flour in development of food products. Intl. Food Resear. J. 21(6): 2061-2074.

- Olaoye OA, Onilude AA, Oladoye CO (2007) Breadfruit flour in biscuit making: effects on product quality. Afri. J. Agric. Food Security 7(5): 001-004.

- Olaoye OA, Onilude AA (2008) Microbiological, proximate analysis and sensory evaluation of baked products from blends of wheat-breadfruit flours. Afri. J. Food Agric. Nutri. Dev. 8(2): 192-203.

- Ghnimi S, Umer S, Karim A, Kamal-Eldin A (2017) Date fruit (Phoenix dactylifera L.): an underutilized food seeking industrial valorization. Nutri. Food Sci. J. 6: 1-10.

- Oladapo AS, Adepeju AB, Akinyele AA, Adepeju DM (2017) The proximate, functional and anti-nutritional properties of three selected varieties of maize (yellow, white and popcorn) flour. Intl. J. Sci. Engineer. Sci. 1(2): 23-26.

- Adeniyi OO, Ariwoola OS (2019) Comparative proximate composition of maize (Zea mays L.) varieties grown in South-western Nigeria. Intl. Annals Sci. 7(1): 1-5.

- Moses MO, Olanrewaju MJ (2018) Chemical properties of corn starch as influenced by sprouting periods. Intl. J. Food Sci. Nutri. 3(6): 90-94.

- Qamar S, Aslam M, Huyop F, Javed MA (2017) Comparative study for the determination of nutritional composition in commercial and non-commercial maize flour. Pakistan J. Bot 49(2): 519-523.

- Gwirtz JA, Garcia-Casal MN (2014) Processing maize flour and corn meal food products. Annals New York Acad. Sci. 1312: 66-75.

- Sule EI, Umoh VJ, Whong CMZ, Abdullahi IO, Alabi O (2014) Chemical and nutritional value of maize and maize products obtained from selected markets in Kaduna State, Nigeria. Afri. J. Food Sci. Tech. 5(4): 100-104.

- Chhabra N, Kaur A, Kaur A (2018) Assessment of physicochemical characteristics and modifications of pasting properties of different varieties of maize flour using additives. J.Food Sci. Tech. 55(10): 4111-4118.

- Akaffou FA, Koffi DM, Cisse M, Niamké SL (2018) Physicochemical and functional properties of flours from three purple maize varieties named ‘Violet de Katiola’ in Côte d’ Ivoire. Asian Food Sci. J. 4(4): 1-10.

- Ekpa O, Palacios-Rojas N, Kruseman G, Fogliano V, Linnemann AR (2019) Sub-Saharan African maize-based foods-processing practices, challenges and opportunities. Food Reviews Intl. 35(7): 609-639.

- Abiose SH, Ikujenlola AV (2014) Comparison of chemical composition, functional properties and amino acids composition of quality protein maize and common maize (Zea may L). Afr. J. Food Sci. Tech. 5(3): 81-89.

- Lemchi SN, Mbah CA, Obi-Anyanwu JN (2016) Sensory evaluation of use of maize and yam flour in composition with wheat flour for the production of selected snacks. Intl. J. Adv. Acad. Resear. 2(2): 1-11.

- Emecheta RO, Maduka N, Ahaotu I, Odu NN (2019) Assessment of date wine clarified using commercial pectinase and Aspergillus tamari strains immobilized on biomatrix. Sci. Park J. Appli. Biotech. Resear. 3(1): 019-031.

- Agboola OS, Adejumo AL (2013) Nutritional composition of the fruit of the Nigerian wild date palm, Phoenix dactylifera. World J. Dairy Food Sci. 8(2): 196-200.

- Emecheta RO, Ahaotu I, Maduka N, Odu NN (2019) Proximate composition of date fruits and sensory evaluation of date fruit wine clarified using Aspergillus strains immobilized on biomatrix. Sci. Park J. Appli. Microbiol. Resear 4(2): 067-079.

- Peter-Ikechukwu AI, Kabuo NO, Uzoukwu AE, Chukwu MN, Ogazi C (2020) Physical and organoleptic properties of cookies produced with date fruit pulp, toasted watermelon seed and wheat flour composite. Eur. J. Agric. Food Sci. 2(2): 1-5.

- Idowu AT, Igiehon OO, Adekoya AE, Idowu S (2020) Dates palm fruits: a review of their nutritional components, bioactivities and functional food applications. AIMS Agric. Food. 5(4): 734-755.

- Anjili SM, Channya FK, Chimbekujwo IB (2015) Fungi associated with post-harvest spoilage of date palm (Phoenix dactylifera L.) in Yola, Adamawa State. Intl. J. Resear. Agric. Forestry. 2(11): 14-22.

- Onyekwelu JC, Stimm B (2008) Treculia africana. Enzyklopeädie der Holzgewächse-50. Erg.I.fg. 9/08. 1-12 pp.

- Okwori AEJ, Enokela MO, Nwankiti OO, Shidali NN (2010) Bacteriological contamination of soya bean flour sold in Makurdi metropolis, Benue state, Nigeria. J. Med. Lab. Sci 19(2): 44-51.

- Okoronkwo KA, Nwagbaoso OC, Okoronkwo BC (2020) Chemical and amino acid composition of African breadfruit (Treculia africana) IOSR Appli. Sci. 6(1): 1-10.

- Amujiri AN, Nwosu MO, Nzekwe U, Osayi EE, Sani MB (2018) Studies on the phenology of African breadfruit (Treculia africana Decne) in south eastern Nigeria. Environ. Ecol. Resear 6(4): 248-258.

- Adegbehingbe KT, Fakoya S, Adeleke BS (2017) Effect of fermentation on nutrient and antinutrient contents of fermented whole and ground African breadfruit (Treculia africana) seeds. Microbiol. Resear. J. Intl. 20(5): 1-11.

- Maduka N, Njoku HO, Odu NN (2012) The production of tempeh-like food product using African breadfruit seeds (Treculia africana). Academic Arena. 4(4): 39-43.

- Olapade AAA, Umeonuorah UC (2014) Chemical and sensory evaluation of African breadfruit (Treculia africana) seeds processed with alum and trona. Nig. Food J. 31(2): 80-88.

- Ojokoh AO, Fayemi OE, Ocloo FCK, Alakija OA (2014) Proximate composition, antinutritional contents and physicochemical properties of breadfruit (Treculia africana) and cowpea (Vigna unguiculata) flour blends fermented with Lactobacillus plantarum. Afr. J. Microbiol. Resear 8(12): 1352-1359.

- Ugwu CS, Iwuchukwu JC (2013) Processing and preservation of African breadfruit (Treculia africana) by women in Enugu North agricultural zone, Enugu state, Nigeria. Afri. J. Agric. Resear 8(11): 984-994.

- Obi OF, Akubuo CO (2018) Performance evaluation of African breadfruit (Treculia africana) seed dehuller. Sciendo Agric. Engineer. 22(4): 51-60.

- Okoye JI, Obi CD (2017) Nutrient composition and sensory properties of wheat-African breadfruit composite flour cookies. Sky J. Food Sci. 6(3): 027-032.

- Ndife J, Abasiekong KS, Nweke B, Linus-Chibuezeh A, Ezeocha VC (2020) Production and comparative quality evaluation of chin-chin snacks from maize, soybean and orange fleshed sweet potato flour blends. FUDMA J. Sci. 4(2): 300-307.

- Folorunso AA, Sabitu AO, Omoniyi SA (2018) Functional and sensory qualities of cookies and chinchin produced from wheat-date fruit flour blends. Annals Food Sci. Tech. 19(4): 657-666.

- Ugwuanyi RG, Eze JI, Okoye EC (2020) Effect of soybean, sorghum, and African breadfruit flours on the proximate composition and sensory properties of chin-chin. Eur. J. Nutri. Food Safety 12(1): 85-98.

- Adedeji OE, Tadawus N (2019) Functional properties of maize flour (Zea mays) and stability of its paste (tuwo) as influenced by processing methods and baobab (Adansonia digitata) pulp inclusion. Ukrainian J. Food Sci. 7(1): 49-60.

- Varghese N, Joy PP (2014) Microbiology Laboratory Manual. 50pp.

- Cheesbrough M (2002) Biochemical tests to identify bacteria. In Laboratory Practice in Tropical Countries. Cambridge Education, UK. 63-70 pp.

- Isu NR, Onyeagba RA (2002) Staining of microbial cells in: Basic Practicals in Microbiology Second Enlarged Edition Fasmen Communications, Okigwe, Imo State. 45-46 pp.

- Sosulski FW, Garatt MO, Sinkard AE (1976) Functional properties of ten legume flours. Intl J Food Sci Tech 9: 66-69.

- Shinde BG 2001) Isolation and characterization of starch horse grain. Unpublished MSc. Thesis, Mahatma Phule Krishi Vidyapeeth, Rahuri, India, p. 16-17.

- Jones D, Chinnaswarmy R, Tan Y, Hanna H (2000) Physiochemical properties of ready to eat breakfast Cereals. Cereal Foods World 45:164-168.

- Okaka JC, Potter NN (1977) Functional and storage properties of cowpea-wheat flour blend in bread making. Journal of food science 42(3): 828-833.

- AOAC (1995) Official methods of analysis 13th, Association of Analytical Chemistry, Washington, DC, USA. P. 10-18.

- Akubor OI (2004) Protein contents, physical and sensory properties of Nigerian snack foods (cake, Chinchin and pulf-pulf) prepared from cowpea-wheat flour blends. International J Food Sci Tech 39(4): 419-424.

- Ihekoronye AI, Ngoddy PO (1985) Integrated Food Science and Technology for the Tropics. Macmillian, London. pp. 280-281.

- Imarhiagbe EE, Obayagbona ON, Osarenotor O, Eghomwanre AF (2016) Antibiotic sensitivity pattern of bacterial isolates and physic-chemical composition of maize flour sold in major markets in Benin City, Midwestern Nigeria. Studia Universitatis Babeș-Bolyai Biologia, LXI, 2: 5-12.

- Ibeanu VN, Ene Obong HN, Peter Ogba GU, Onyechi UA (2015) Microbiological evaluation and shelf life of seed flour mixes used for infant feeding in rural northern Nigeria. African Journal of Biotechnology 4(20): 1718-1723.

- Maduka N, Egwali OB, Ire FS (2021) Microbial analysis of packaged and exposed soybean flour sold in selected markets in Benin City, Nigeria. Intl J Appli Microbiol Biotech 9(3): 51-62.

- N zebo DK, Dadie A, Anin Atchibri OL, Kouassi N, Dje KM (2017) Prevalence of enteropathogenic Escherichia coli in maize (Zea mays) or millet (Pennicetum glaucum) flours and porridges. Intl J Curr Microbiol Appli Sci 6(1): 819-833.

- Hariri A, Ouis N, Bouhadi D (2017) Effect of substitution of sugars by date powders variety H’lowa on the quality of the soft drinks. Journal of Applied Biotechnology & Bioengineering 3(6): 450-457.

- Umar ZD, Bilkisu A, Bashir A (2014) Bacteriological analysis of date palm fruits sold in Katsina metropolis. International Journal of Environment 3(2): 83-86.

- Al Jasser MS (2010) Effect of storage temperatures on microbial load of some dates palm fruit sold in Saudi Arabia market. African Journal of Food Science 4(6): 359-363.

- N Guessan YD, Bedikou ME, Zoue LT, Goualie BG, Niamke SL (2014) Physicochemical, nutritive and safety evaluation of local cereal flours sold in areas of the District of Abidjan-Côte d’ Ivoire. J Appli Biosci 83: 7579-7594.

- Ragava SC, Loganathan M, Vldhyalakshmi R, Vlmallin HJ (2016) Microbial evaluation and control of microbes in commercially available date (Phoenix dactylifera Lynn.) fruits. J Food Proc Tech 7(7): 1-4.

- Gacheru PK, Abong GO, Okoth MW, Lamuka PO, Shibairo SA, et al. (2016) Microbiological safety and quality of fried cassava chips and flour sold in the Nairobi and coastal regions of Kenya. African Crop Science Journal 24(1): 137-143.

- Yusuf CS (2019) Occurrence of fungi on date palm fruits in Mubi main market, Adamawa state. Adamawa State. Uni J Sci Resear 7(1): 130-134.

- Tafinta IY, Rabe AM, Danfulani JS, Batagarawa US, Umar M, et al. (2018) Isolation of fungi associated with date palm (Phoenix dactylifera Linn) fruits consumed within Sokoto. Merit Resear J Microbiol Bio Sci 6(8): 103-107.

- Oyetayo VO, Omenwa VC (2006) Microbial and chemical qualities of raw and trona processed African breadfruit (Treculia africana Decne). Am J Food Tech 1:77-80.

- Odu NN, Maduka N (2019) Microbiological analysis and molecular characterization of bacterial and fungal isolates present in exposed and packaged cassava, plantain and yam flour sold in selected markets in Port Harcourt, Rivers state, Nigeria. Am J Microbiol Resear 7(2): 63-72.

- Danladi S, Mohammed A, Galadima AA (2016) Evaluation of microorganisms in cassava flour (alebo) and its effect on human health. Journal of Biology and Genetic Research 2(3): 1-7.

- Adebayo-Tayo BC, Adegoke AA, Akinjogunla OJ (2009) Microbial and physic-chemical quality of powdered soymilk samples in Akwa Ibom, South Southern Nigeria. African Journal of Biotechnology 8(13): 3066-3071.

- Odetunde SK, Adebajo LO, Lawal AK, Itoandon EE (2014) Investigation into microbiological and chemical characteristics of cassava flour in Nigeria. Global Adv Resear J Microbiol 3(3): 031-040.

- Saranraj P, Geetha M (2012) Microbial spoilage of bakery products and its control preservatives. Intl J Pharm Bio Arch 3(1): 38-48.

- Rawat S (2015) Food spoilage: microorganisms and their prevention. Asian Journal of Plant Science and Research 5(4): 47-56.

- Okoronkwo CU, Nwachukwu NO, Chinenye AN (2020) Production, isolation an identification of microbes in home-made complementary food flour based on maize-pigeon pea flour. International Journal of Food Sciences and Research 2(1): 1-9.

- Otasevic ST, Natasa M (2007) Cladosporium spp. – cause of opportunistic nycoses. Acta Facultatis Medicae Naissensis, 24(1): 15-19.

- Hanan BA (2017) The electron microscopic examination of fungal distortions in the adult red flour beetle, Tribolium castaneum H. (Coleoptera: Tenebrionidae) J Entomol Nematol 9(1): 1-8.

- Fogle MR (2007) Growth and mycotoxin production by Chaetomium globosum. Unpublished Ph.D. Dissertation in Medical Microbiology, submitted to the Graduate Faculty of Texas Tech University Health Sciences Center.

- Giraldo A, Sutton DA, Samerpitak K, de Hoog GS, Wiederhold NP, et al. (2014) Occurrence of Ochroconis and Verruconis species in clinical specimens from the United States. J Clin Microbiol 52(12): 4189-4201.

- Odu NN, Maduka N (2019) Microbiological analysis and molecular characterization of bacterial and fungal isolates present in exposed and packaged cassava, plantain and yam flour sold in selected markets in Port Harcourt, Rivers State, Nigeria. American Journal of Microbiological Research 7(2): 63-72.

- David O, Arthur E, Kwadwo SO, Badu E, Sakyi P (2015) Proximate composition and some functional properties of soft wheat flour. Int J Innov Resear Sci 4(2): 753-758.

- Adepeju AB, Abiodun OA, Otutu OL, Pele LG (2015) Development and Quality Evaluation of Wheat/Breadfruit Cookies. International Journal of Technical Research and Applications 3(6): 7-11.

- Adebowale AA, Sanni LO, Oladapo FO (2005) Effect of texture modifiers on the physiochemical and sensory properties of dried fufu. Food Sci Tech Intl 11(5): 378-382.

- Drzewiecka D (2016) Significance and roles of Proteus spp. bacteria in natural environments. Microb Ecol 72(4): 741-758.

- Edima-Nyah AP, Nwabueze TU, Ojimelukwe PC (2019) Development and quality evaluation of snack bars from African breadfruit (Treculia africana), maize (Zea mays) and coconut (Coco snucifera) blends. Journal of Scientific and Engineering Research 6(5): 74-83.