A Study of the Current State of Biogas Production in Zimbabwe: Lessons for Southern Africa

Jane Kaifa and Wilson Parawira*

Department of Biological Sciences, Bindura University of Science Education, Zimbabwe

Submission: November 20, 2018; Published: March 27, 2019

*Corresponding author: Wilson Parawira, Department of Biological Sciences, Bindura University of Science Education, P Bag 1020, Bindura, Zimbabwe

How to cite this article: J Kaifa, Wilson P. A Study of the Current State of Biogas Production in Zimbabwe: Lessons for Southern Africa. Adv Biotech & Micro. 2019; 13(3): 555865. DOI: 10.19080/AIBM.2019.13.555865

Abstract

This study sought to establish the current state of biogas production in Zimbabwe. The study established the number, size of biogas plants, type of biogas plants, the donors/funders involved in biogas technology, how the biogas and digestate is being utilized and the challenges faced in the running of the plants. The study was carried out using questionnaires administered to Ministry of Energy and Power Development Rural Electrification Agency (REA) Head Office, REA Provincial Offices and to biogas users (plant owners). Results from the investigation revealed that there were around 711 biogas plants in the country in 2017. These include 650 household plants, 48 institutional plants and 13 municipal plants. Around 90% of the plants owners were using cow dung as the substrate, 8% were using sewage, 1% was using pig manure and 1% co-digested jatropha seed cake and cow dung. Multiple partners were involved in biogas plant construction, which included the government, Non-Governmental Organizations (NGOs), local authorities and individuals. The study revealed that about 56% of the plants were constructed by the government and NGOs, 24% by the government, NGOs and individuals, 11% were constructed by individuals alone, 7% were constructed by the government alone and 2% by local authorities and NGOs. Around 97% of biogas plant holders were using biogas for cooking, 1% for lighting, 1% for space heating in pig and poultry farming and 1% were not using the biogas. The study concluded that biogas technology has been adopted in Zimbabwe as an alternative energy source; however, the technology is still in its infancy. To improve adoption rate of the technology, there is need for education and communication on the benefits associated with this technology. The use of low-cost prefabricated digesters, setting up appropriate policy and institutional frameworks and provision of loans could also facilitate uptake of biogas technology and help reduce energy poverty in the country.

Keywords: Biogas; Renewable energy; Anaerobic digestion; Bio digestate; Southern Africa

Highlight

a. Biogas technology has been adopted in Zimbabwe as an alternative energy source although the technology is still in its infancy.

b. There is need for education and communication on the benefits associated with this technology to the people.

c. There are still many challenges being faced by biogas plant owners and developers.

Introduction

The cost of energy has increased significantly over the past years due to the increasing global demand for energy and the decreasing availability of fossil fuels. In Zimbabwe the frequency of load shading is too high, and the availability of grid electricity has become a cause for concern [1]. highlighted that in 21 Sub Saharan countries including Zimbabwe, less than 10% of the population has access to electricity. Global energy supply is highly dependent on fossil fuels e.g. crude oil, lignite, coal and natural gas. Zimbabwe’s major source of electricity is hydroelectricity from Kariba and thermal electricity from Hwange. Zimbabwe generated about 1300 MW against a demand of 2200 MW and was importing 100 MW from Zambia, 300 MW from South Africa’s power utility ESKOM and 40 MW from Mozambique in 2012 [2]. The situation has not changed. The greater population in rural Zimbabwe depends on firewood and this is leading to deforestation and desertification. According to the energy policies and management, world market utilization was forecasted to increase by 44% between 2006 and 2030 [3].

There is need for alternative energy sources from locally available resources. Many countries are adopting environmental policies promoting the production and utilization of alternative, sustainable and renewable energy sources [4]. Among these sources is green energy production through the anaerobic digestion of agricultural feedstock like manure and food industry waste products aimed at producing biogas. Zimbabwe is facing environmental problems caused by pollution by organic waste from industry, agriculture and households. Biogas technology provides an excellent way of using such organic waste for energy generation and the digested substratum (digestate) is used as a fertilizer while managing organic waste. The use of biomass for energy production is one of the most promising alternatives, sustainable and renewable energy sources. Anaerobic digestion consists of a chain of metabolic reactions i.e. hydrolysis, acidogenesis, acetogenesis and methanogenesis performed by a wide range of micro-organisms and producing biogas and a digested product (digestate), that can be used as an organic fertilizer.

Biogas presents a broadly applicable and environmentally sustainable bioenergy practice which offers manifold benefits to health, food, agriculture, energy, environment and sanitation. It bears the potential to facilitate economic development of Zimbabwe. Use of biogas technology can benefit African societies by providing a clean fuel from renewable feedstock and can help end energy poverty [1]. Biogas can be used for various energy services e.g. heat, power or a vehicle fuel. It reduces the use of fossil fuel derived energy and reduces global warming and climate change, pollution, improve sanitation, reduce demand for wood and charcoal for cooking and provide a high-quality fertilizer. Biogas technology can serve a means to overcome poverty which poses a great constraint to economic development of Africa [5]. Biogas production from agricultural residues, industrial waste and municipal waste has an advantage over the use of other biofuels such as biodiesel and bioethanol because in biogas technology there is no competition for land, water and fertilizers with food crops as in the case of bioethanol and biodiesel production [5].

Currently the country is facing food shortages and food production is more important and competes out completely the production of energy crops for biodiesel and bioethanol. Biogas production systems are relatively simple and can operate at small and large scales in urban and rural locations. The Zimbabwean government has a national energy strategy which includes renewable energy development with the aim to replace fossil fuels. The government through the Rural Electrification Agency is constructing biogas digesters at rural boarding schools and mission hospitals aiming to provide affordable and environmentally friendly energy to Zimbabwe.

Energy available in the country for use does not meet demand. Only around 10% of the population has access to electricity. To those with access to electricity, the cost of electricity is too high beyond the affordability of many. There is depletion of fossil fuels due to increasing global demand. The frequency of power cuts i.e. load shading has increased and energy availability has decreased to levels causing concern. However, the country is facing challenges of pollution caused by organic waste from industry, agriculture, households and sewage disposal. Solid waste pollution levels are becoming a health threat to the general population of the country. Organic waste can be used to produce biogas which is a source of energy and digestate which can be used as an affordable and environmentally friendly fertilizer to support the agro-based economy of the country.

Access to energy for cooking and lighting is a very real issue faced by rural populations across Zimbabwe and other African countries. Demand for fuel wood currently outstrips supply and its use can result in deforested woodlands. Bio gas is a gas produced from the anaerobic breakdown of organic waste materials. It is primarily a mix of methane and carbon dioxide, a combustible product which can be used as a renewable and easily controlled fuel. Since it can be produced from regionally available raw materials, it offers a potentially affordable and sustainable means for rural householders to meet their energy needs. A biogas digester is required to make biogas. This is a plant providing the conditions for anaerobic decomposition of organic waste into useable fuel. The outputs from the digester are biogas and slurry which can be used as a fertilizer. This research intends to establish the current state of biogas technology in Zimbabwe with the intention to inform and guide policy when planning, implementing and managing biogas.

Biogas technology is one of the renewable technologies in Africa that can ease Africa’s energy and environmental problems. Biogas technology is still in its infancy in Africa, although recent initiatives have resulted in the accelerated uptake and understanding of the technology in the various African countries [6]. Digesters have been installed in several African countries that utilize a variety of waste such as from slaughterhouses, municipal wastes, industrial waste and animal dung. National biogas programmes have been implemented in Kenya, Uganda, Ethiopia, Tanzania, Rwanda, Cameroon, Burkina Faso and Benin [7]. A number of NGOs joined in the promotion of the technology and accelerated awareness and dissemination of information on biogas technology. The results from the biogas initiatives and national programs resulted in an increase in the number of installed biogas digesters and possible technical skills. The increase is most seen in the nine countries highlighted above supported by SNV where at least 17,000 digesters were installed from 2007 to 2012 [8]. However, the Chinese fixed dome and the Indian floating cover biogas plants have been constructed in most African countries, which are not reliable and have poor performance. In most cases these plants were constructed in schools, health clinics, mission hospitals and farms [9].

There is need to introduce more efficient reactors to improve the yield of biogas. The major hurdles to efficient implementation of biogas technology include cost for construction and maintenance of the plants, negative image of the technology caused by past failures, inexperienced contractors and consultants which result in poor quality plants. There are no properly educated operators, lack of credibility, lack of technical knowledge on maintenance and repair. There is also failure by governments to support biogas technology through focused energy policies [9]. highlighted that lack of reliable information on the potential of the technology, uninformed or poorly informed policy makers and absence of pilot studies are some of the setbacks of biogas technology in Africa. The provision of loans, government assistance, community workshops, wide scale communication and implementation of prefabricated digesters could have a significant impact on the increased uptake of the technology in Africa. The adoption of biogas technology in Africa would contribute to the economic prosperity of the continent as a whole [7].

The Government of Zimbabwe through the Ministry of Energy and Power Development is promoting domestic biogas technology using animal waste [10]. Other organizations which are complementing the efforts include the Silveira House, Biomass Users Network and the Agricultural Engineering Institute among others. The national biogas programme has been set by the government in partnership with HIVOS, Ministry of Energy and Power Development and SNV to promote biogas technology and provide access to clean energy for cooking and lighting. More than 70 biogas masons have been trained to take up the installation of biogas plants as well as 18 fabricators [8]. This has seen an improvement in the lives of a few rural households. The common biogas designs that are promoted are the Chinese fixed dome and the Indian floating Gas holder plants. The Indian type was found to be more expensive because of the metal gas holder. Biogas plants have been constructed for municipals, households, hospitals and schools. However, no research has been done to establish the current state of biogas technology in Zimbabwe and it is the aim of this research to establish the current state of biogas and digestate production in Zimbabwe.

Materials and Methods

The research was carried out in Zimbabwe, a land locked country located in Southern Africa. Zimbabwe is divided into eight provinces and two cities with provincial status. Zimbabwe has an agro-based economy, and this gives the country enormous potential in biogas technology. To establish the current states of biogas production in Zimbabwe, four types of questionnaires were designed, pilot tested and administered. Stratified sampling was used to administer the four types of questionnaires to Ministry of Energy and Power Development; Rural Electrification Agency Head Office and Provincial Offices as these have the mandate to provide energy and oversee all projects on energy generation in the country. Random sampling was used in administering questionnaires to biogas plant owners.

The first type of questionnaire was for the Ministry of Energy and Power Development. The first part of this questionnaire was intended to collect data on the number, size and biogas plant designs in Zimbabwe. The second part of the questionnaire collected data on the substrates used in the biogas plants. The third part of the questionnaire looked at funding for the construction of the biogas plants in Zimbabwe. The fourth part looked at how the biogas and digestate is being utilized. The last section was intended to capture data on the challenges faced by Ministry of Energy and Power Development in Biogas Technology and ways through which Biogas Technology can be improved in Zimbabwe.

The second type of questionnaire was administered to Rural Electrification Agency (REA) Head Office in Harare. The first part of this questionnaire intended to collect data on the number, size and biogas plant designs constructed by REA. The second part of the questionnaire collected data on the substrates used in the plants. The third part intended to collect data on the distribution of these plants in the country. The fourth section collected data on the funding for biogas plant construction. The fifth section collected data on the utilization of biogas and digestate. The last part of the questionnaire collected data on the challenges faced by REA in Biogas Technology and ways to improve biogas technology in Zimbabwe.

The third type of questionnaire was designed for REA provincial offices and was administered to 8 provinces. The first part of this questionnaire collected data on the number, size and biogas plant designs. The second part collected data on the substrates being used in biogas plants in the province. The last section collected data on the challenges faced by in the provinces in biogas technology and ways of improving biogas technology in Zimbabwe. The fourth type of questionnaire was administered to biogas users (plant owners). The first part of the questionnaire collected data on when the plant was constructed, size and biogas plant design. The second part collected data on the substrate used on the plant and availability of substrate. The third part was on how the biogas and digestate is utilized and the benefits of biogas technology. The last section collected data on the challenges being faced in running the plant, ways of improving biogas production in plants and biogas technology in Zimbabwe. The questionnaires were administered to households and institutions in 3 Provinces selected randomly i.e. Mashonaland West, Harare and Mashonaland East. A total of eleven biogas plants were visited by the researcher on the basis of accessibility to the researcher. Biogas plants visited by the researcher are in Mashonaland West, Mashonaland East and Harare Province.

Results

Number of Biogas Plants in Zimbabwe

Zimbabwe has embarrassed biogas technology as an alternative source of energy. This resulted in the construction of household, municipal and institutional biogas plants in the country. Around 711 biogas plants have been constructed in the country to date. Figure 1 shows the progress of biogas plant construction in Zimbabwe from 2012 to 2017. There was a slight increase in number of biogas plants from 2012 to 2013 and a gradual increase was noted from 2013 to 2017.

Types of Biogas Plants in Zimbabwe

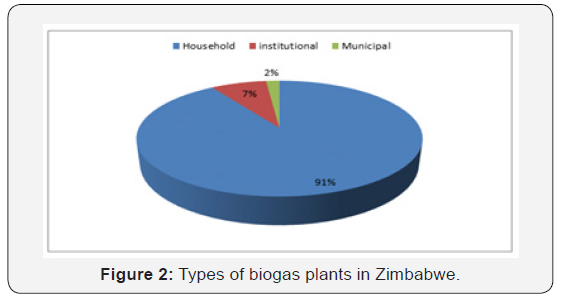

Figure 2 shows the distribution by size of the biogas plants in Zimbabwe. Household biogas plants ranged in size from 4 m3 to 30 m3. Institutional biogas plants were located at hospitals, prisons and schools. These plants ranged in size from 50m3 to 200 m3. Municipal biogas plants were located in sewage treatment plants and market places for waste management. Figure 2 shows that around 91% of the biogas plants in Zimbabwe were household plants, 7% were institutional and only 2% were municipal biogas plants. Currently, there are no industrial biogas plants in Zimbabwe.

Distribution of Institutional Biogas Plants

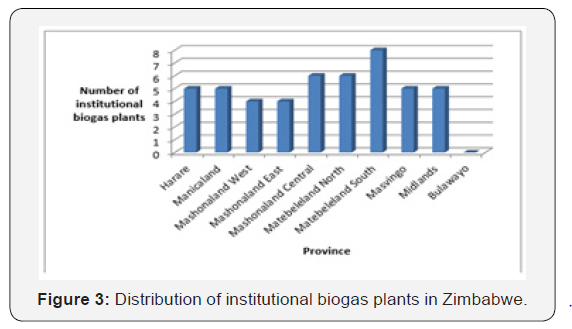

Institutional sized biogas plants were mainly 50 m3, 100 m3 and 200 m3 Figure 3 shows the distribution of institutional biogas plants in Zimbabwe. Figure 3 shows that institutional biogas plants were adopted in 9 provinces of the country, except in Bulawayo. There were around 48 institutional biogas plants in Zimbabwe. The minimum numbers of institutional biogas plants [4], were recorded for Mashonaland East and Mashonaland West. The highest number of institutional biogas plants [8], was recorded in Matabeleland South. All the institutional biogas plants were constructed by the government through the Rural Electrification Fund (REF), with the exception of two which were funded by Environmental Africa.

Distribution of Municipal Biogas Plants in Zimbabwe

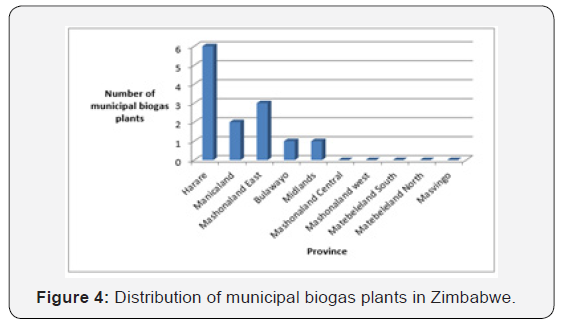

Municipal biogas plants were constructed in some sewage treatment plants and market places in Zimbabwe for waste management and energy provision. Figure 4 shows the distribution of municipal biogas plants in Zimbabwe. There were thirteen municipal biogas plants in Zimbabwe. The highest number of municipal biogas plants was recorded in Harare, these included Firle and Crow borough constructed for waste management and the 4 digesters at Mb are Musika for energy provision and waste management which were yet to be commissioned. In Manicaland there were two plants, one located at Sakubva and the other at Mutare town works. There was only one municipal biogas plant in Bulawayo and one in Midlands. There were no municipal biogas plants in Mashonaland Central, Mashonaland West, Matabeleland South, Matabeleland North and Masvingo.

Substrates Used in Biogas Plants in Zimbabwe

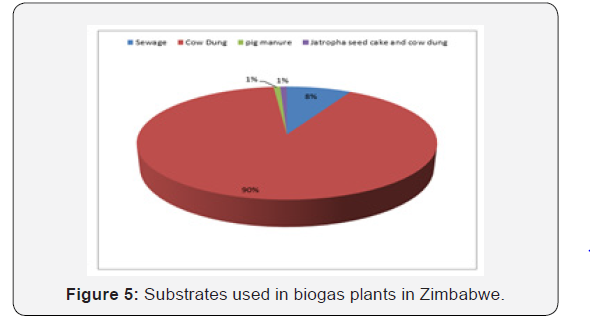

Biogas plants in Zimbabwe were found to be using sewage, cow dung and pig manure as substrates. There was co-digestion of Jatropha seed cake and cow dung in Mudzi and Mtoko districts of Mashonaland East. Figure 5 shows that 90% of the biogas plants were feeding cow dung into their digesters, 8% were using sewage, in 1% of the plants there was co-digestion of Jatropha seed cake and cow dung and 1% used pig manure only. In Zimbabwe, there was no biogas plant using entirely chicken manure and kitchen waste as a substrate, but they were being used as additional feedstock in a few institutional biogas plants.

Funding of Biogas Plants

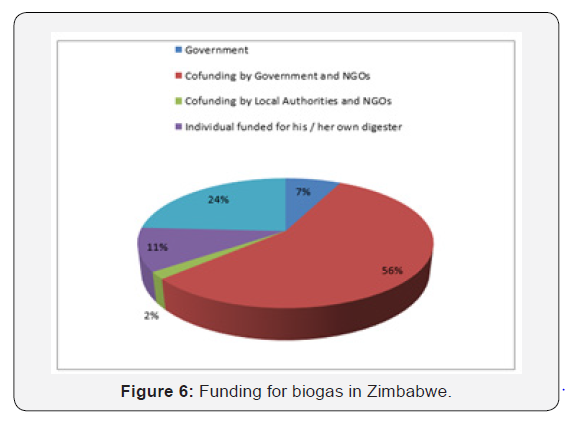

In Zimbabwe biogas plant construction was being funded by the government, Non-Governmental Organizations (SNV, HIVOS, Environmental Africa and WWF), schools, individuals and UNICEF. Around 400 household plants constructed before 2012 were cofunded by the government and NGOs. For the 173 household plants constructed after 2012, people were given half the number of bags of cement, builders and end user training as a technology promotional incentive. This was funded by the government, SNV, HIVOS, EA, WWF and UNICEF. The individuals provided the other half number of bags of cement and all the other materials needed for construction of the plant. For the 6 household digesters constructed in Mudzi and Motoko districts, funding was provided by WWF, Environmental Africa and government. The individuals provided locally available materials e.g. river sand, pit sand, quarry stones and farm bricks. All institutional biogas plants were funded by the government through the Ministry of Energy and Power Development. These plants were constructed by REA except 2 institutional biogas plants that were funded by Environment Africa. Fig 6 shows the involvement of multiple partners in the promotion of biogas technology. About 7% of the biogas plants were funded by the government alone. These are mainly institutional biogas plants. Around 56% of the biogas plants were funded by NGOs and the government, 24% by government, NGOs and individuals, 11% were funded by individual biogas plant owners alone and 2% by local authorities and NGOs Figure 6.

Utilisation of biogas in Zimbabwe

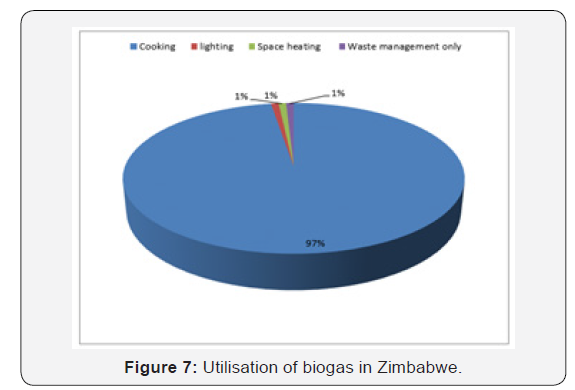

Biogas was mainly used for cooking in Zimbabwe. Figure 7 shows that 97% of biogas plant holders were using biogas for cooking, 1% for lighting, 1% for space heating in pig and poultry farming and to boil water used during slaughtering pigs and chickens e.g. at Pig Industry Board. In the remaining 1% of the biogas plants, the biogas was not being utilized and the plants were constructed for waste management.

Digestate utilization in Zimbabwe

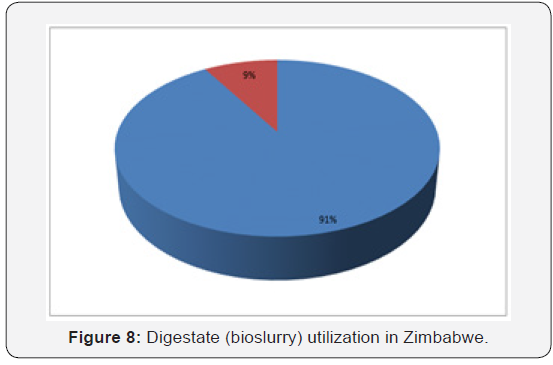

In Zimbabwe bio slurry (digestate) was used as a fertilizer to improve productivity in farms and in vegetable gardens. Figure 8 illustrates that most biogas plant owners were using bio slurry. Digestate (bio slurry) was used as biofertilizer by all biogas plants owners that were using cow dung, pig manure and chicken manure except for the plants that were using sewage as the substrate. Generally, people have a negative attitude towards bioslurry from sewage hence it is not being utilized in Zimbabwe. Some institutional biogas plants were designed in such a way that the digested slurry is directed into the sewer pipes and cannot be utilized. At the Pig Industry Board (PIB), the bioslurry was being used in the PIB farm and by farm workers in their vegetable gardens. Domboshava households were also using the bioslurry in their vegetable gardens to improve productivity.

Challenges Faced in Running the Biogas Plants in Zimbabwe

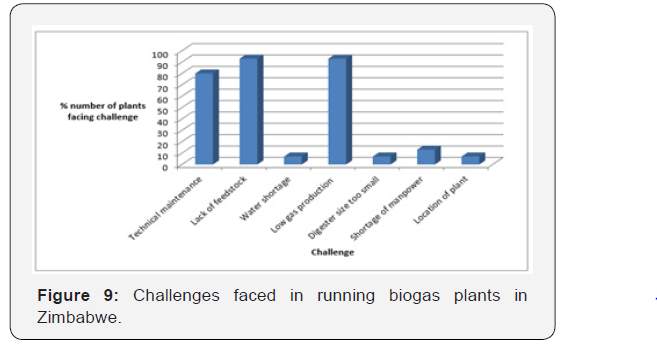

In Zimbabwe, biogas plant owners were facing a number of challenges which included lack of technical maintenance, shortage of substrate to feed into the digester, water shortage, shortage of manpower to feed substrate into the biogas plant and shortage of durable biogas appliances among others. Figure 9 shows that challenges in technical maintenance were being faced in most biogas plants in Zimbabwe. For example, there was low biogas production in hospitals. This may be due to disinfectants used in hospitals which affect the action of bacteria in the digester. Sometimes there are blockages in hospitals due to nonbiodegradable materials that are sometimes flushed into toilets by patients and health care providers. There was lack of proper care and monitoring for the biogas plant in the hospitals. No one at the hospital had the responsibility to monitor the biogas plant. In some plants, sometimes the substrate was not fed into the plant due to shortage of manpower especially in institutional biogas plants. In schools, during holidays there may be little or no feed/ sewage flow.

Most biogas plants were also facing serious shortage of substrate to feed into the plant e.g. at Chikurubi Female Prison. Sometimes they had to transport cow dung from Koala butchery to Chikurubi Female Prison. For about 90% of biogas plant owners, gas production was not meeting daily requirements e.g., at Chibhero Agricultural College, biogas was used to cook breakfast and lunch only. At Chikurubi Female Prisons, gas production was not enough to cook lunch and supper on a daily basis. Some biogas digester were located a distance away from the substrate, hence users faced challenges in transporting and feeding the substrate into the digester. This may result in inconsistency in feeding substrate into the plant e.g. at Chibhero Agricultural College the digester was located about 1 km from cattle kraal. Some plants relied on borehole water and faced challenges if the borehole broke down or if there was an electrical fault. Collecting cow dung during the rainy season was described as a night mare by some plant operators. Some biogas plants were fed manually and so it was labor intensive. Biogas users sighted a decrease in biogas production in winter or when it is cold. Entry of nonbiodegradable material into the plant e.g. stones and sand reduce the digesters, carrying capacity. At the Pig Industry Board there was more substrate than could be fed into their 50m3 digester, they needed a bigger digester.

The major challenge faced by the Ministry of Energy and Power Development was insufficient funding i.e. lack of capital to implement projects and for massive awareness programs. There was lack of technical knowhow on how to fully implement the projects. There was need for a data collection platform to have an updated data base since there was uncoordinated construction by other private players and individuals.

Discussion

Biogas technology has been adopted as an alternative energy source in Zimbabwe. There has been a gradual increase in the number of biogas plants in the country. Currently, around 711 biogas plants have been constructed in Zimbabwe. These include 650 household plants, 48 institutional plants and 13 municipal biogas plants. The institutional biogas plants are located in the 9 provinces of the country and only Bulawayo metropolitan province does not have an institutional biogas plant. Around 90% of the plants owners use cow dung as the substrate, 8% use sewage, 1% use pig manure and 1% co digest Jatropha seed cake and cow dung. In some biogas plants, kitchen waste and chicken manure are used as additional feed. The feedstock available to Zimbabwe households for biogas production depends on the location and socio-economic status of households. Crop residues are another abundant source of feedstock for household biodigester holders but are not used for that purpose in Zimbabwe.

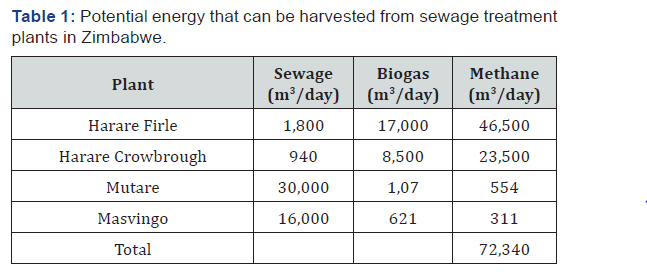

The potential for biogas in Zimbabwe is much larger than is presently exploited. Only 711 biogas plants have been constructed as the year 2016. In Rwanda 15, 000 biogas plants had been constructed by 2007, in Uganda 20,000 had been constructed by 2007 and in Ethiopia 10,000 biogas plants had been constructed by 2007 [11]. This shows that adoption of biogas technology in Zimbabwe is still in its infancy as compared to other countries in Sub Saharan Africa. Most sewage plants in the country do not have biogas digesters. Table 1 shows that around 17 000 m3 of biogas can be produced at Harare Firle and around 8 500 m3 from Crow brough sewage works per day. From the four sewage treatment plants, the biogas can be purified to methane leading to a yield of 72,340 m3 of methane per day. The methane can be compressed and bottled for use as an alternative energy source by citizens. However, in Zimbabwe a very low adoption rate of biogas technology by municipalities and non-usage of the biogas from municipalities was noted. Low adoption rate by municipalities may be attributed to high initial investment cost for constructing biogas plants, limited research on biogas technology, inadequate expertise for constructing and maintenance [12].

If this biogas was being used in electricity generation or for cooking by Harare residents this would lower the electricity usage in Harare. Adoption of biogas technology by all sewage treatment plants can significantly lower electricity usage in the country and help manage water and land pollution by biodegradable organic waste. In Zimbabwe, there are no industrial biogas plants. An anaerobic sludge blanket (UASB) reactor was installed at an opaque beer brewing factory to treat traditional opaque beer brewery waste water. The UASB reactor enabled the brewery to meet the requirements of waste water discharged into municipal sewage of Harare and the organic matter in the effluent was partly converted to methane which can be used for energy generation [9]. However, the methane was not collected and was vented into the atmosphere without being burnt. The anaerobic digester is no longer functional. Such biogas pilot phase failure can be a cause of lack of adoption of industrial biogas plants in Zimbabwe [12]. also observed that biogas pilot phase failure resulted in low adoption rate in South Africa. Inadequate expertise for construction and maintenance can be a cause for pilot phase failure of biogas technology.

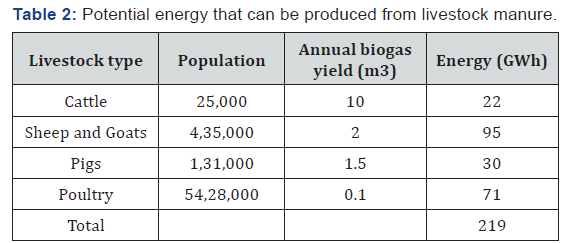

Large quantities for different feedstocks which include organic fraction of municipal waste, organic fraction of industrial waste, agricultural residues are not being utilized for biogas production in Zimbabwe. The main substrate being utilized is cattle manure while other types of manures are not being utilized. Even then, there is underutilization of the cattle manure as shown in Table 2. The potential energy that can be generated from livestock. The cattle population in Zimbabwe was estimated to be 4 to 5 million [13]. Hence the potential energy that can be generated from cow dung only is around 4400 GWh. Total energy generation from sewage, cow dung, sheep, goats, pigs and poultry manure can lower electricity usage.

Multiple partners are involved in biogas plant construction in Zimbabwe. These include the government, Non-Governmental Organisations (NGOs), local authorities and individuals. Around 7% of the plants were funded by the government alone, 56% were co-funded by the government and NGOs, 24% were co-funded by NGOs, government and individuals, 11% were funded by individuals and 2% by local authorities and NGOs. Biogas is mainly used for cooking in Zimbabwe. Around 97% of the plant owners use biogas for cooking, 1% for lighting, 1% for space heating in pig and poultry farming and 1% of the plant owners do not use the biogas, these were constructed for waste management only. A number of challenges were faced in the running of the biogas plants. However, the major challenge was lack of substrate. This can be attributed to the fact that the plants were oversized, or the generation of the substrate later decreased from the time the plant was constructed.

A few institutional biogas plants were constructed in the country since 2012, having around 48 institutional biogas plants. These were funded by the government. Low rate of adoption of biogas in Zimbabwe can be attributed to lack of knowledge regarding the technology. Awareness on the potential of biogas increases chances of adoption. Hence, there is need to engage multiple agencies to promote the technology including private enterprise, promoters, and users as well as interest groups to solve the constraint of lack of awareness development [14] Access to knowledge on biogas technology project has been seen to influence the level of biogas adoption [15]. Low adoption rate may be attributed to the fact that people cannot afford installing the biogas plants. Increase in the household income was found to positively influence the households’ decision to adopt biogas energy [14]. The most probable effect of income of household on adoption of biogas energy is the financial ability to install a digester system and more importantly to keep it operational. However, in Vietnam, the high cost of constructing biogas plants was overcome by the use of cheaper materials, such as plastics [14]. Hence, there is need for research on cheaper materials that can be used in biogas construction in Zimbabwe [15].

The majority of biogas plants in Zimbabwe were found to be oversize designed in relation to cattle herd or number of pigs and yet not producing enough biogas. Hence, there is need for research and consultations on the size of the digesters for households before construction. Most household plants were 6 to 9m3 and yet the substrate was not sufficient. Construction of 4m3 household digesters could have improved efficiency of the digesters. Biogas plant owners should be taught to use different types of substrates so that they are able to feed sufficient substrate quantities into the plant to realize enough biogas for their use. Oversized biogas digesters lead to digester failure due to underfeeding. In Uganda despite the efforts by government to promote biogas technology, households deadapted biogas technology within a period of 4 years after installation due to failure to sustain the cattle and pig production necessary for feedstock supply [16]. On the other hand, a few biogas digesters were undersized and there was more substrate than could be fed and yet the biogas produced did not meet the daily requirements of the users. Total disregard by the biogas implementers (government, NGOs and research centers) in involving the users or the community can be a major cause for under sizing or over sizing a biogas plant. Hence, there is need for user involvement when deciding the size of the biogas plant. Perceived Ease of Use (PEU) is a one of the key factors that motivates individuals to accept and use any given technology [15].

This is the degree to which a person believes that using the particular system would be free from effort. About 10% of the plants surveyed were located a distant from the feedstock and 20% of the plants surveyed highlighted that there was shortage of man power to feed the digester and some biogas plant users described feeding the plant during the rainy season as a night mare. In such situations the biogas technology is no longer perceived easy to use and this may lead to dis-adoption. In Central Uganda reduced family labor led to dis-adoption of biogas technology as it become difficult for few family members to operate the plant [16]. Hence, there is need for use of easy to use biogas plant design. Biogas digester installation in rural and peri-urban areas can help reduce time and cost associated with cooking fuel procurement, however, the labor associated with collecting water and feedstock as well as operating the digester need to be considered to determine whether an overall reduction in labor is achieved [17]. Poor reliability and or scarcity of fuelwood supply increases the chances of households installing biodigester, as has been the case in Tanzania [18].

Despite low adoption rate of biogas technology in Zimbabwe, biogas users were enjoying a number of benefits from the technology. The biogas was mainly used for cooking through the conventional low-pressure gas burners. Biogas burns with a clean, clear flame hence reduces air pollution. The use of biogas has reduced the use of firewood and utilization of biogas technology to full potential in Zimbabwe can reduce deforestation significantly. Cooking on the biogas stove has improved the quality of life of biogas users, reduced electricity usage and reduced energy poverty to users. Users enjoyed cooking with biogas as it can immediately be switched on and off as compared to wood and coal. However, the potential uses of biogas have not been fully exploited in Zimbabwe [19-21].

Conclusion

With the energy crises being experienced in Zimbabwe, it is of extreme importance that efforts to utilize alternative energy sources be increased. Biogas technology has been adopted in Zimbabwe; however, it is still in its infancy having around 711 biogas plants. These include household biogas plants, institutional biogas plants and municipal biogas plants. The plants use cow dung, sewage, pig manure and Jatropha seed cake as feedstock and are mainly fixed dome biogas plant. The household biogas plants are mainly modified CAMATEC Fixed Dome Model. The potential for biogas technology for Zimbabwe extends beyond household scale and cow dung fed biodigester. In Zimbabwe, there is great potential for increasing biogas production and improving solid waste management in urban communities through treating organic fraction of municipal solid waste in digesters. The installation of biodigester at Mbare Musika to treat such organic waste is highly commendable. Significant untapped feedstocks exist from Zimbabwe’s agro-processing and food production industries. An assessment of the potential feedstocks in Zimbabwe is needed to assure investors of the potential of biogas technology in the country. Most biogas users are highly satisfied with biogas technology. The biogas is used mostly for cooking and the substrate as a biofertilizer.

Substrate from human excreta was not being used as a result of the stigma associated with human excreta. Awareness campaigns should target to break the stigma to avoid overdependence on livestock waste and to enable urban households to access it and improve productivity. There is need for construction of more biogas plants in Zimbabwe to enable most citizens to enjoy the benefits of biogas technology. This can be achieved through introduction of biogas technology training in Universities and vocational training centers to train more contractors for biogas plants. Currently, biogas plant construction is funded by the Government, NGOs, Municipals and individuals. There is need for more players to come in e.g. private companies to improve funding for biogas technology and improve adoption. Absence of industrial biogas plants in the country is a matter causing concern. There is need for construction of industrial biodigester in industries producing organic waste to treat their waste and produce biogas for their energy needs. An assessment into the possible causes of failure of the UASB reactor at Chibuku breweries is recommended to enable improvement in future designs. Biogas technology could contribute to renewable energy production, waste management and food security in Zimbabwe. Development of the technology requires an understanding of current problems in future digester design, substrate choice and digester management. Education and communication are of importance to improving the technology. The use of low-cost prefabricated digesters set up of appropriate policy and institutional frameworks and provision of loans will have a positive impact on the adoption of the technology. There is a huge potential for the country to benefit from biogas technology if all municipalities adopt large scale biogas digesters to manage the large quantities of organic waste they receive and generate.

Acknowledgement

We acknowledge the assistance with data collection from Ministry of Energy and Zimbabwe Rural Electrification Authority (ZERA).

References

- Cai T, SYP, Y Li (2013) Nutrient recovery from wastewater streams by microalgae: status and prospects. Renewable Sustainable Energy Review19: 360-369.

- Santos FM, Pires JCM (2018) Nutrient recovery from wastewaters by microalgae and its potential application as bio-char. Bioresource Technology 267: 725-731.

- Kube M, Jefferson B, Fan L, Roddick F (2018) The impact of wastewater characteristics, algal species selection and immobilization on simultaneous nitrogen and phosphorus removal. Algal Research 31: 478-488.

- Gonçalves AL, Pires JCM, Simões M (2017) A review on the use of microalgal consortia for wastewater treatment. Algal Research 24: 403- 415.

- Zeng X, Guo G, Su MK, Danquah S, Zhang Y, et al. (2015) Bioprocess considerations for microalgal-based wastewater treatment and biomass production. Renewable and Sustainable Energy Reviews 42: 1385-1392.

- Procházková IG, Brányiková V, Zachleder T (2014) Effect of nutrient supply status on biomass composition of eukaryotic green microalgae. Journal Applied Phycology 26(3): 1359-1377.

- Alva MS, Pabello VML, Ledesma MTO, Gómez MJC (2018) Carbon, nitrogen, and phosphorus removal, and lipid production by three saline microalgae grown in synthetic wastewater irradiated with different photon fluxes. Algal Research 34: 97-103.

- Lu W, Asraful Alam Md, Luo W, Asmatulu E (2019) Integrating Spirulina platensis cultivation and aerobic composting exhaust for carbon mitigation and biomass production. Bioresource Technology 271: 59- 65.

- Rodríguez RJ, Espada J, Moreno G, Vicente J Dufour (2018) Environmental analysis of Spirulina cultivation and biogas production using experimental and simulation approach. Renewable Energy 129: 724- 732.

- Gao F (2018) Simultaneous nutrient removal and biomass/lipid production by Chlorella sp. in seafood processing wastewater. Science of the Total Environment 641: 943-953.

- Iasimone F, Taleb A, Olkiewicz M, Font J, Bengoa C (2018) Effect of light intensity and nutrients supply on microalgae cultivated in urban wastewater: Biomass production, lipids accumulation and settle ability characteristics. J Environ Manage 223: 1078-1085.

- Nguyen TDP, Le TVA, Show PL, Nguyen TT, Tran MH, et al. (2019) Bio flocculation formation of microalgae-bacteria in enhancing microalgae harvesting and nutrient removal from wastewater effluent. Bioresource Technology 272: 34-39.

- Egloff S, Tschudi F, Schmautz Z, Refardt D (2018) High-density cultivation of microalgae continuously fed with unfiltered water from a recirculating aquaculture system. Algal Research 34: 68-74.