Fire Protection of Wood and Structures with Mineral Paints

Sergii Guzii*

V Bakul Institute for Super hard materials NASU Ukraine, Avtozavodskaya Str 2, Ukraine

Submission: October 06, 2022; Published: December 07, 2022

*Corresponding author: Sergii Guzii, V Bakul Institute for Super hard materials NASU Ukraine, Avtozavodskaya Str 2, Kyiv, 04074, Ukraine

How to cite this article: Sergii G. Fire Protection of Wood and Structures with Mineral Paints. Trends Tech Sci Res. 2022; 5(5): 555671. DOI: 10.19080/TTSR.2022.05.555671

Abstract

The paper presents the results of fire tests of mineral paint for wood and structures based on it. Mineral paint tests were carried out in accordance with the EN 13823: 2010 + A1: 2014 (SBI method) procedure, namely: the rate of heat release, smoke generation, total heat release, total smoke generation, indices of ignition rate and smoke content were determined. It has been established that mineral paint is characterized by non-combustibility, absence of flaming particles and droplets, burning droplets; lateral flame spread to the edge of the substrate. Mineral paint, during the fire test, has low heat generation, smoke generation and combustion rate. The indicated indicators are achieved due to the compositional composition of the mineral paint and primer, as well as the mechanism of their action. The composition of the primer prevents the destruction of lignin and fibres of cellulose and hemicellulose due to the reflection of heat fluxes and their distribution within the paint layers. In the paint layers, under the influence of a temperature gradient, a two-stage process of dehydration of mineral components occurs, as a result of which vapours of physical and chemically bound water are released with the formation or formation of a porous layer of anhydrous aluminosilicates of a zeolite-like composition. The formation of a porous structure contributes to both heat dissipation and resistance to high temperatures. In the investigated mineral paint, the indices of the ignition rate indices (FIGRA0.2MJ, W/s), smoke content (SMOGRA, m2/s2) and total smoke production (TSP600s, m2) are 1.3, 25 and 2 times lower than the indices regulated by the standard.

Keywords: Fire protection; Wood; Mineral Paints

Abbreviations: THR: Total Heat Release; TSP: Total Smoke Production

Introduction

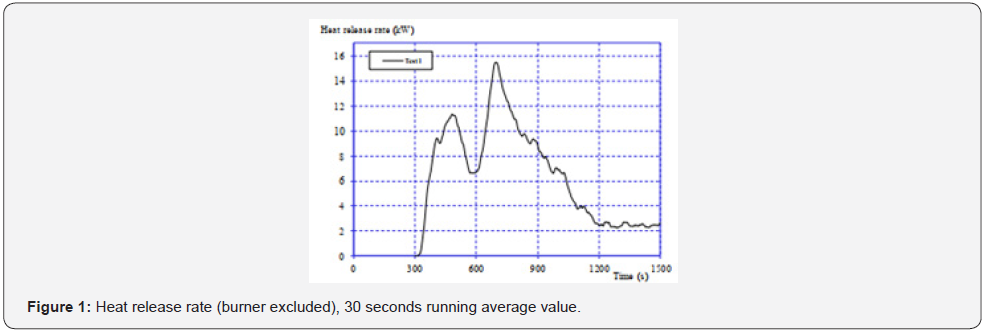

The use of mineral paints and coatings for fire protection of wood and structures based on it is relevant today [1-5]. The purpose of the work was to study fire retardant mineral paints for wood according to European standards Testing ISO/IEC 17025 RISE Research Institutes of Sweden AB. RISE has by performed a fire test according to EN 13823:2010+A1:2014 (SBI method). The test is for informatory purpose. According to information, the products have the following composition (Table 1): fire protective mineral coating consisting of paint applied on to a plywood board with Euro class D-s2,d0 and a nominal thickness of 9mm. The test results relate to the behavior of the test specimens of a product under the particular conditions of the test; they are not intended to be the sole criterion for assessing the potential fire hazard of the product in use.

Criteria

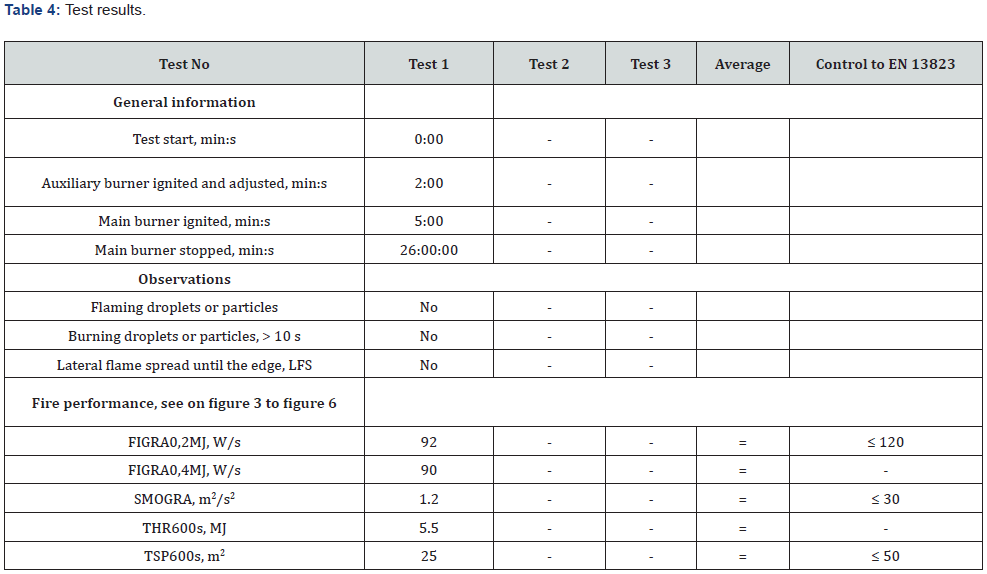

According to Table 1 in “Fire classification of construction products and building elements – Part 1: Classification using test data from reaction to fire tests”, EN 13501-1:2019. To meet class ”B-s1,d0”, construction products excluding floorings and linear pipe thermal insulation products have to meet the following limits when tested according to EN 13823:

• FIGRA0.2 MJ ≤ 120 W/s

• LFS < edge of specimen

• THR600s ≤ 7.5 MJ

• SMOGRA ≤ 30 m2/s2

• TSP600s ≤ 50 m2

• No flaming droplets / particles within 600s.

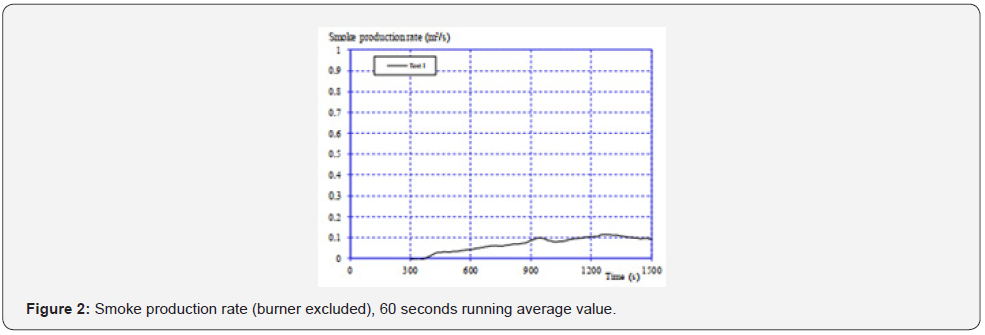

Additionally, construction products excluding floorings and linear pipe thermal insulation products have to meet the following limits when tested according to EN ISO 11925-2: Flame tip must not reach 150mm vertically from the point of application of the test flame, within 60s from the time of application. 30s exposure time. Deviation from standard. Only one test was carried out, instead of the three stipulated in the standard. The paint system was mounted according to EN 13823:2010, 5.2.2 d. It was applied to a plywood board by RISE. The short wing had less paint applied than nominal, see measured data on page 5 below. The short wing constitutes 33% of the specimen surface approximately. The backing board was standing directly behind the plywood board. The plywood board fulfil the requirements given in EN 13238.

Method of Smoke Calculation

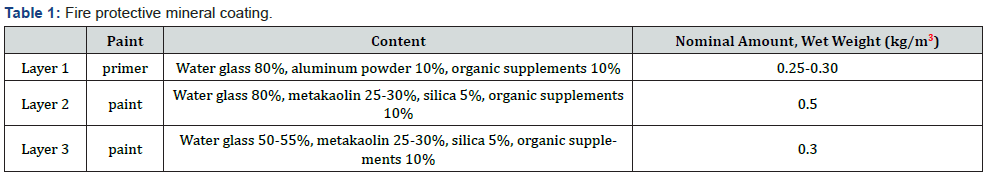

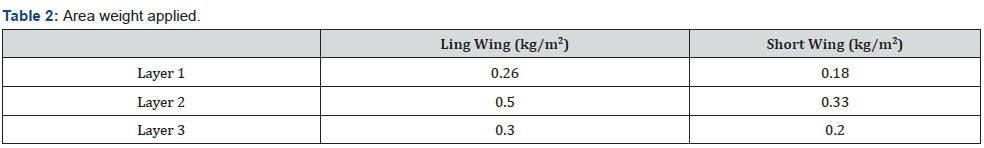

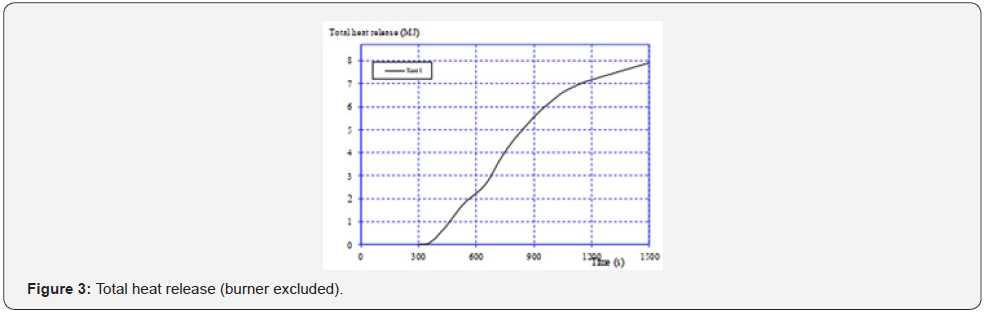

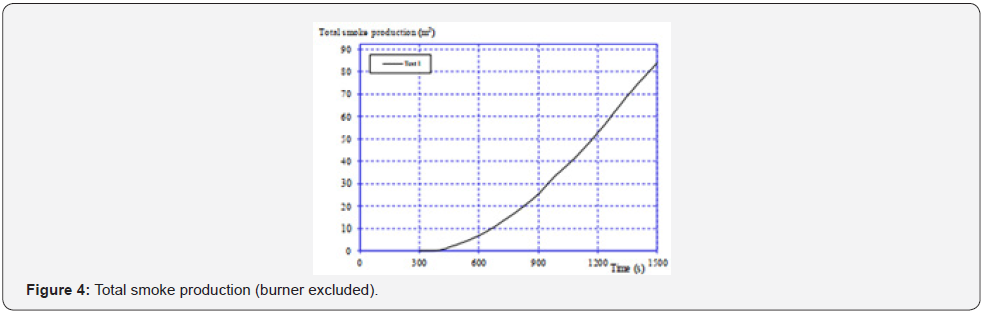

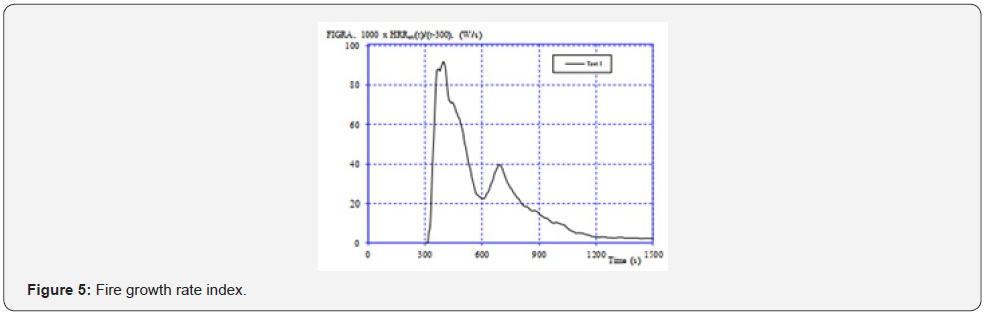

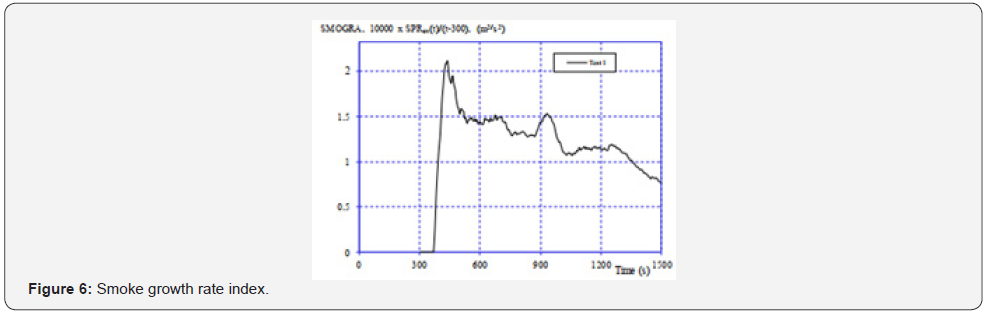

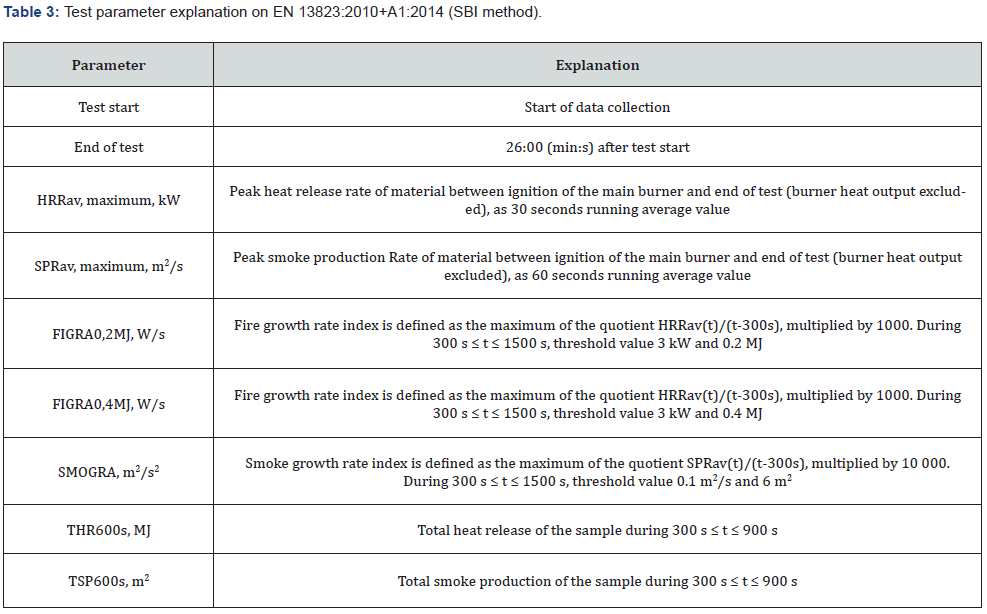

The smoke production rate, SPR, of the burner was calculated using data from the auxiliary (secondary) burner: Graph of heat release rate (HRRav) (Figure 1); Graph of smoke production rate (SPRav) (Figure 2); Graph of total heat release (THR) (Figure 3); Graph of total smoke production (TSP) (Figure 4); Graph of fire growth rate index (FIGRA) (Figure 5); Graph of smoke growth rate index (SMOGRA) (Figure 6).

Note: Figure 5 and figure 6 show the time relationships of FIGRA and SMOGRA respectively without applying the threshold values, see EN 13823, paragraph A.5.3 and A.6.3. Therefore, the reported single maximum values of FIGRA0,2MJ, FIGRA0,4MJ and SMOGRA may be smaller than shown in the graphs as the threshold values are applied in this case. Area weight applied (Table 2).

Conditioning

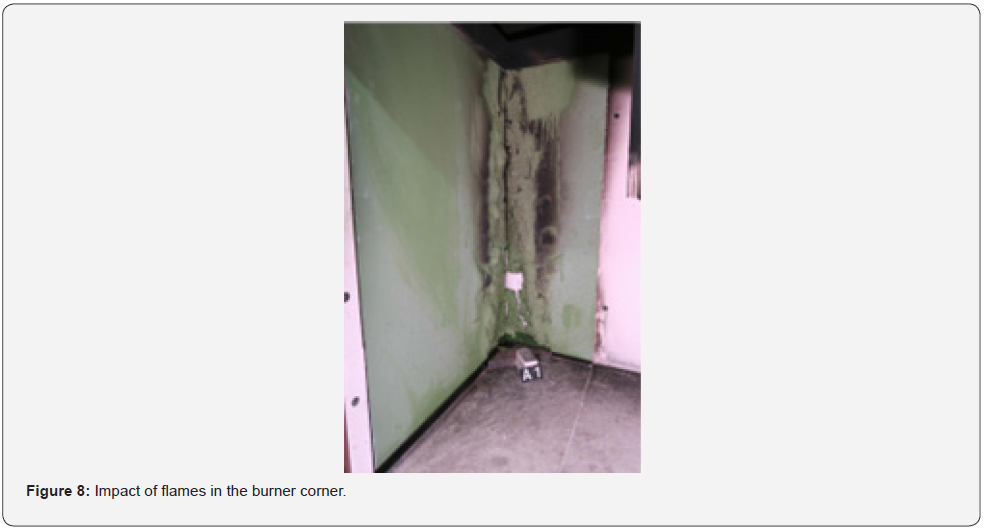

According to EN 13238 and EN 13823:2010. Constant mass: mass 1: 3695g; temperature (23 ± 2) °C; mass 2: 3694g; relative humidity (50 ± 5) %; time: 24 h. The results of tests of fireretardant mineral paint before and after exposure to a fire flame are shown in figure 7 and figure 8. The results of firing tests are given in table 3 and table 4.

Conclusion

As a result of the test carried out according to the procedure EN 13823: 2010 + A1: 2014 (SBI method), it was found that mineral paint intended for fire protection of wood and structures based on it is characterized by: non-combustibility, absence of flaming particles and drops, burning drops; lateral flame spread to the edge. Mineral paint, during the fire test, has low heat generation, smoke generation and combustion rate. In the studied mineral paint, the indices of the indices of the ignition rate, smoke content and general smoke production are 1.3, 25 and 2 times less than the indicators regulated by the standard.

Acknowledgements

The work was carried out within the framework of the budgetary theme in V. Bakul Institute for Superhard materials National Science Academy Ukraine III-7-22 (0784) “Development of new composite materials with ceramic and polymer matrices with a high level of absorption of electromagnetic radiation in a wide frequency range for the needs of electronic instrumentation, the Internet, mobile communications, etc.”

References

- Guzii S, Bazhelka I, Svitlychna N, Lashchivsky V (2020) Materials Science Forum Pp. 100619-100624.

- Sotiriadis K, Guzii S, Mácová P, Viani A, Dvořák K, et al. (2019) Journal of Materials in Civil Engineering 31(6):

- Guzii S, Kurska T, Otrosh Y, Balduk P, Ivanov Y (2021) IOP Conf. Ser: Mater Sci Eng 1162: 012003.

- Tsapko Y, Kyrycyok V, Tsapko A, Bondarenko O, Guzii S (2018) MATEC Web of Conferences 230.

- Sotiriadis K, Guzii S, Kumpová I, Mácová P, Viani A (2017) Solid State Phenomena 267: 58-62.