Discussions About Incorporated Graphite On Unitary/Binaries Matrices Geopolymeric Systems: Part A

Madeleing Taborda Barraza*, Juliano Rodrigues Spínola, Laura Silvestro and Philippe Jean Paul Gleize

Department of Civil Engineering, Federal University of Santa Catarina, Brasil

Submission: October 14, 2022; Published: November 03, 2022

*Corresponding author: Madeleing Taborda Barraza, Department of Civil Engineering, Federal University of Santa Catarina, Brasil

How to cite this article: Madeleing T B, Juliano R S, Laura S, Philippe J P G. Discussions About Incorporated Graphite On Unitary/Binaries Matrices Geopolymeric Systems: Part A . Trends Tech Sci Res. 2022; 5(4): 555669. DOI: 10.19080/TTSR.2022.05.555669

Abstract

This work assessed the graphite incorporation on binary geopolymeric matrices, aiming to improve their mechanical performance. The graphite was previously added to the alkaline solution and dispersed via sonication. The geopolymeric pastes were cured for 8 days at 40°C and were evaluated through isothermal conduction calorimetry, compressive strength, flexural strength, open porosity, and X-ray diffraction. Comparatively, when graphite was added into a metakaolin-based system, the presence of the nanomaterial caused reductions of 34% and 55% in compressive and flexural strengths, respectively. Conversely, incorporating a graphite content of 0.1 wt.% on a system containing 30% fly ash and 70% metakaolin increased the compressive and flexural strengths by 166.0% and 184.0%, respectively. The results suggested that the effect of graphite addition is conditioned to the type of matrix where it is incorporated. The graphite incorporation possibly caused discontinuities in the systems with better performance (i.e., metakaolin-based), reducing their mechanical properties.

Keywords: Geopolymer; Strength; Isothermal Calorimetry; Graphite; Porosity

Abbreviation: MK: Metakaolin; FA: Fly Ash; K: kaolinite; Q: Quartz; H: Hematite; G: Magnetite; P: Sulfate; I: Illite; GRAP: Graphite Powder; AS: Activator Solution; HS: Sodium Hydroxide; SS: Sodium Silicate; ICC: Isothermal Conduction Calorimetry

Introduction

Geopolymer systems continue to be searched because they constitute an alternative binder for civil construction elements [1-3]. In research, it is common characterized unitary systems to understand them physical and chemical properties, manufacturing techniques and his durability [3-4]. However, it has been identified that unitary systems may be easier to register chemical and physical instability [5-6] and the incorporation of another phase may improve the system with alternative compounds and tourns the samples manufacture more ecological. For this reason, there is a greater appeal for the execution of binary geopolymeric systems [7-10]. Materials such as fly ash, blast furnace slag, rice husk ash, and waste from biomass burning or from industries are commonly used [11-12]. However, a replacement of precursors does not always mean improved mechanical performance. Specifically, the performance of each material depends on its reactivity, which varies from case to case. What determines the feasibility of use is the purpose of its application. Thus, it is possible to make use of binary systems with a regular mechanical performance that can guarantee reasonable durability.

Specifically, about geopolymers, even defined as polymer inorganic can register a ceramic response and from there, a series of typical disadvantages arise, such as fragility and crack propagation. In this sense, the incorporation of carbon-based nanomaterials proves to be a great complementary alternative to the system, mainly due to the benefits of compatibilization between nanomaterials and cementitious materials [13-15]. Many authors indicate that materials such as carbon nanotubes, silicon carbide whiskers and graphene oxide favor the mechanical performance of systems due to the effects they are capable of promoting [9,15], such as densification capacity (by the action of points of nucleation -seed effect) [16] and the contribution of mechanical properties inherent to the incorporation itself, either by increasing the mechanical resistance, thermal resistance, to chemical attack or by the excellent capacity of electric conductivity [14,17].

Despite the benefits, nanomaterials, when participating in nanocomposites, need special treatment to unleash the potential nature of each of them. The application of physical or chemical techniques that guarantee good dispersion of these in the matrix is necessary [18,19]. Thus, with the intention of developing different unitary and binary geopolymer systems, the effects that the introduction of graphite nanoparticles, dispersed by ultrasonication, can cause on the mechanical performance of nanocomposites based on fly ash and metakaolin in different proportions are evaluated.

Materials and Methods

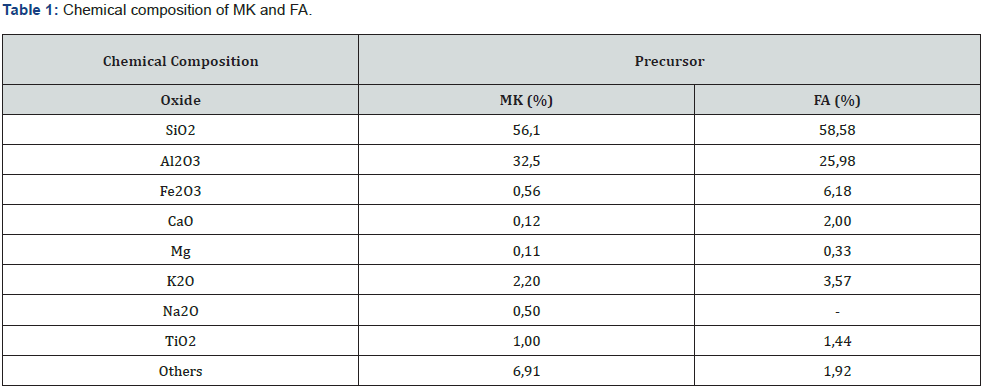

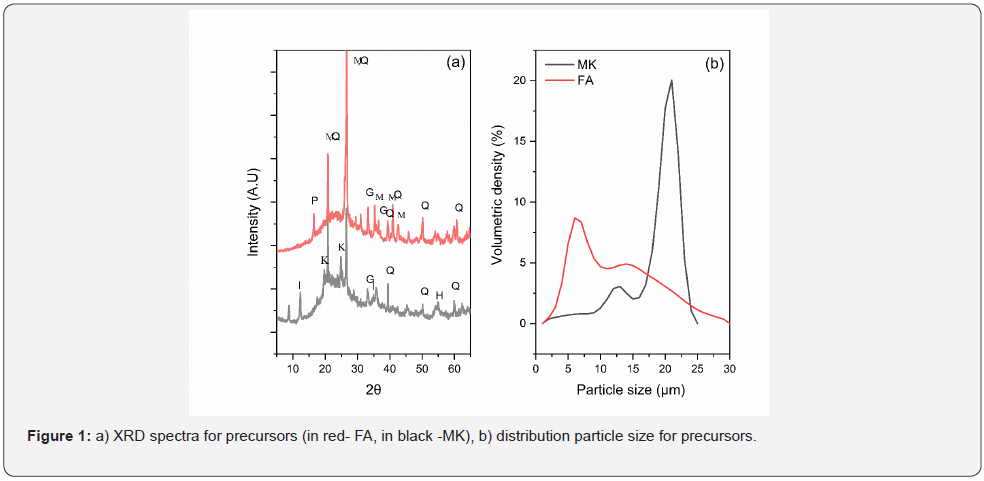

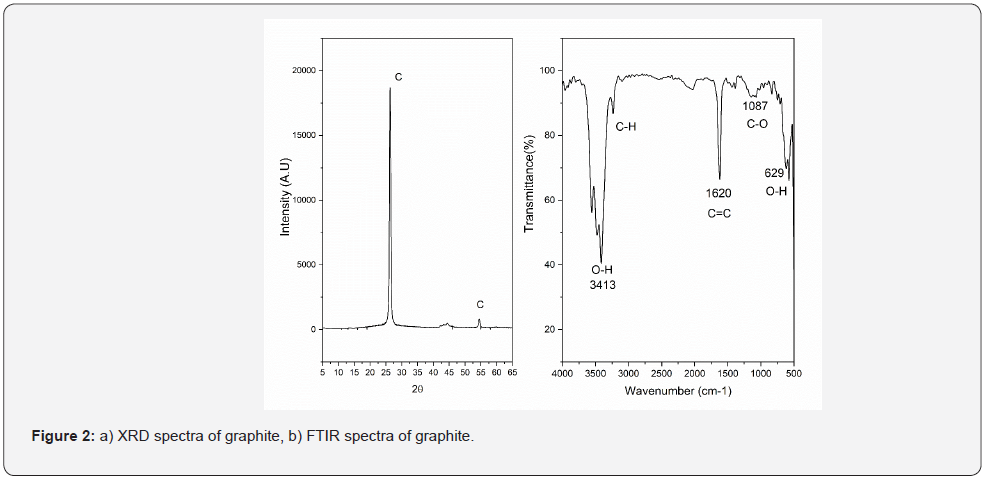

As material precursors, commercial metakaolin (MK) and fly ash (FA) were used. MK was obtained from Metacaulim do Brasil, São Paulo, Brazil, and FA from Candiota thermoelectric plant. The chemical composition of each one is shown in table 1. MK and FA mineralogical phases are illustrated on figure 1a, and the particle size distribution is showed on figure 1b. For MK, mean particle size was was 20,6μm whereas the mean particle size for FA was 4,62 μm. The X-ray spectrum of both materials defined minerals like kaolinite (K), quartz (Q), hematite (H), Magnetite (G), Sulfate (P) and of illite (I), both registered anamorphous phases associated to its nature. The geopolimeric system was activated by sodium silicate solution acquired from MQB S.A with silica modulus (Ms) equal to 2,33 and NaOH, microbeads were get it from Neon LTDA., a product with 98% purity. At last, graphite powder (GRAP) was purchased from XFnano Materials Company, China, with 3-9 nm thickness and 98% carbon content. XRD spectra and FTIR chemical bonds are registered on figure 2.

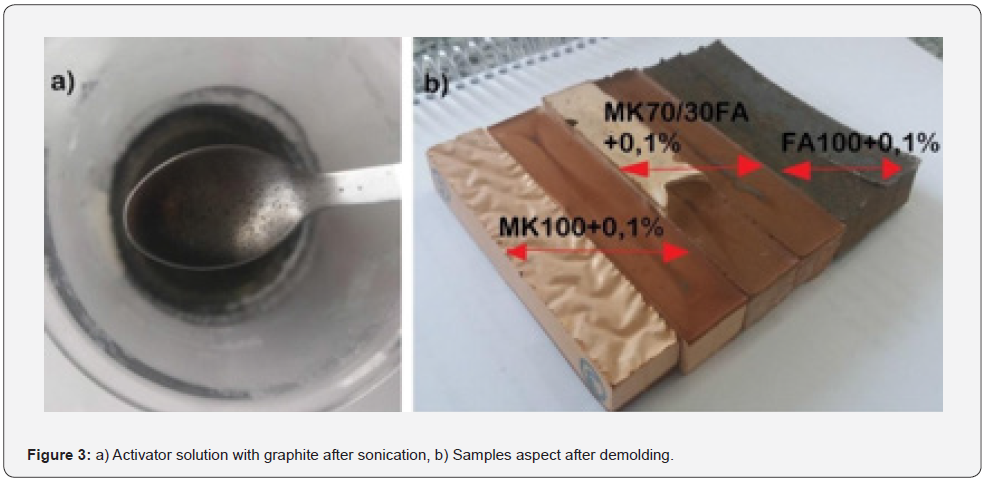

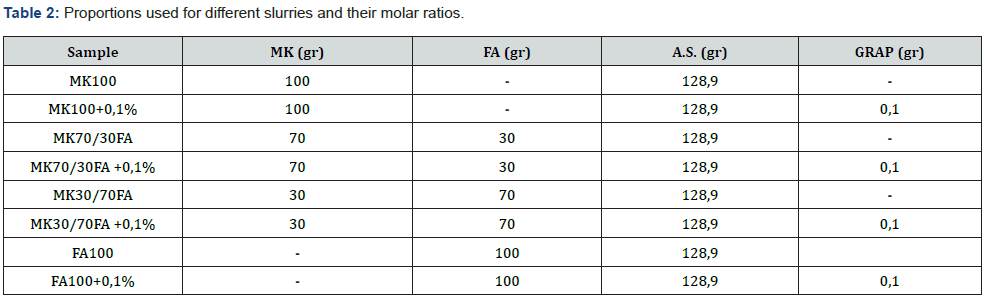

Sample preparation began with the preparation of the activator solution (A.S): dissolution of sodium hydroxide (HS) into solution of sodium silicate (SS). The proportion was a modification from [18,22]. The new mixed solution was cooled for 24 hours and then, graphite at 0,1% was added to it, which received ultrasonication energy to disperse the particles using a tip sonicator (model VCX 750 W, Sonics & Materials Inc.) for 10 minutes. Plus, a wave amplitude of 80% with 20s-cycles was applied. The aspect of solution containing (nano)graphite is illustrated on figure 3a. To prepare the paste, the activator (containing or not graphite) was added on the precursor and mixed by 5 minutes using a highpower mixer at 10,000 rpm. Then, the samples were cured at 40 °C for 8 days. After demolding, samples presented the aspect showed on figure 3b. Table 2 organizes the specification of unitary/binary systems and the investigated proportions.

A fraction of the paste was put into a calorimeter by isothermal Conduction (TA Instruments, New Castle) to register the kinetics reactions. And to analyze the hardened state was molded into prismatic shapes to measure the flexural strength and prismatic compression strength (Instron 5569 machine), both performed with a load application speed of 3000N/min and the open porosity and apparent density was calculated using the ASTM C20 -00(2022) procedure. Finally, the X-Ray diffraction (XRD) was conducted on a X-Ray Diffractometer (Miniflex II Desktop, Rigaku), operating at 30kV/15mA, 2θ from 5° to 65°, and 0.02°/s scanning rate.

Results and Discussion

Isothermal Conduction Calorimetry (ICC)

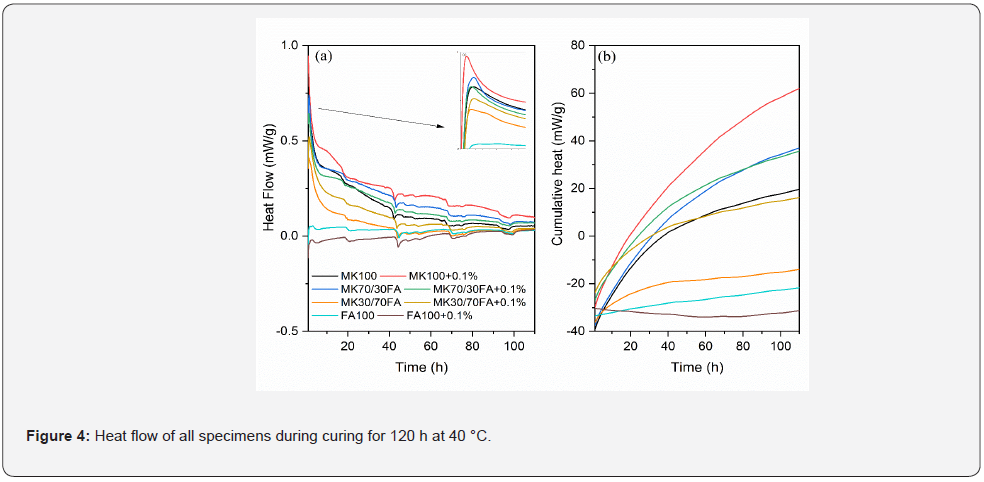

In general, as shown in figure 4a, the intensity on heat flow were proportional to the MK content and the addition of graphite in the system. For instance, metakaolin-based system with a graphite content of 0.1 wt%. (MK100+0.1%) exhibited a higher heat flow values compared to the plain pastes (MK100). Similarly, MK70/30FA +0.1% showed higher heat flow values compared to MK70/30FA. Moreover, the hear flow curves of all evaluated compositions are similar; most groups registered a single peak associated with the dissolution of precursors in the alkaline solution. Nevertheless, FA system could not develop any peaks and a “stable” flow was maintained and recorded negative cumulative heat (Fig. 4b). This phenomenon could indicate that the heat curing (i.e., temperature) was not enough to promote the reactions in this system and that it could need more time to react or higher thermal energy of activation [23].

According to the literature, binary systems that incorporated FA generally show a slow reaction kinetics on the first hours and its showed by stability on heat flow at calorimetric analysis [24]. At the same time, systems that incorporate nanomaterials can influence the intensity of heat flow peak and cumulative heat due to the effect of nucleation that the nanoparticles provide or modified the setting time [25][26][27]. This trend was observed for graphite incorporation on MK100 and MK30/70FA systems. Nevertheless, the addition of graphite does not cause any effect on cumulative heat of MK70/30FA system after 100 h.

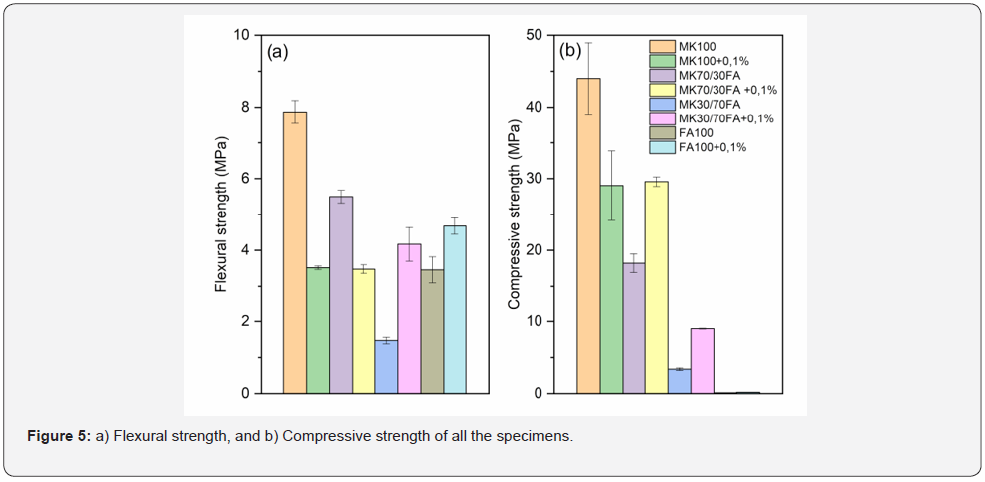

Flexural And Compressive Strength

Flexural and compressive strength were determined for 8 days. Three samples were tested by each group for bending and four regarding prismatic compression. Figure 5a, 5b allows to identify that the presence of 0.1% graphite generated a decrease on both resistances regarding the MK100-based group, affirming that this system could have consolidated a compact matrix that, with the incorporation of the nanomaterial, led to a significant increase in the fall of up to 42.30%. However, for systems containing FA the presence of the nanomaterial increased the flexural strength until to 223%. This can specify that do not exist a unique optimal addition for materials groups due to this going related to the type of matrix, and a matrix with low or medium strength ends up registering more noticeable effects than exclusive systems or with a predominance of more uniform precursors [26- 30]. Must be note that MK70/30+0,1% had opposite effects on the flexural and compressive strengths. While decreased the flexural strength by up to 37%, increased the compressive strength by up to 63%, compared to plain geopolymer paste (MK70/30). The inversion of effects on the two parameters allows us to infer that the shape factor/orientation and its morphology can improve almost one parameter and not the other. Author like [31] registered this inversion in the values and attributed it to a poor dispersion, however this justification would have caused decrease in all systems but that not happen in this case.

It should be noted that although the accumulated heat magnitudes have been obtained for the systems containing graphite, the same did not follow for the mechanical behavior. This finding could indicate that, even if exits an increase on the parameter, due to the modifications on reaction’s kinetics promote by the addition, this phenomenon is not enough to get significant macrostructural modifications that will leave to an increase in strength, such as [25] registered. An increase in the percentage of addition could be considered in order to manifest improvements in unitary systems [14, 16, 32]. Besides that, different dispersion procedures and sonication parameters can be evaluated to improve graphite dispersion and, thus, its performance in MK-based systems.

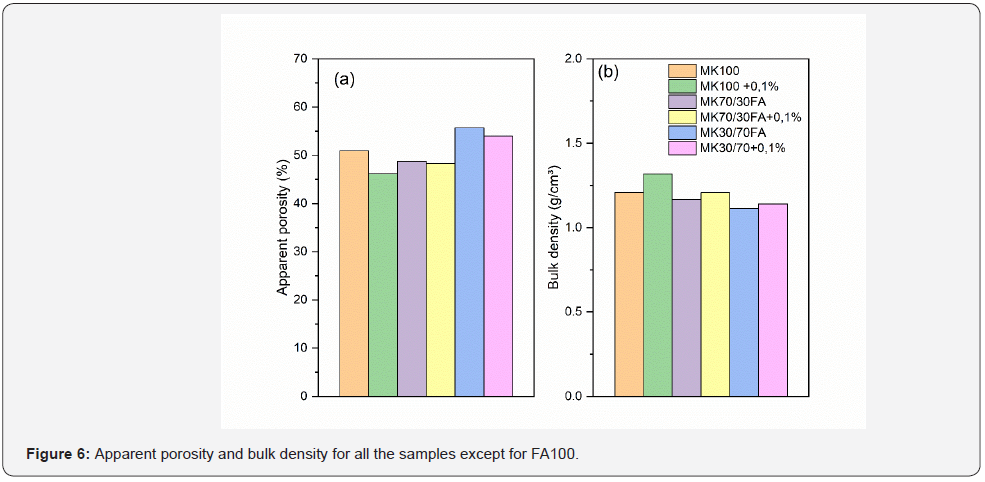

Apparent Porosity and Bulk Density

The apparent porosity of the samples is shown in figure 6. Apparently, the graphite nanoparticles contributed to the densification of the pastes once that similar or lower porosity values compared to its reference systems were registered. In addition, it can be highlighted that it was not possible to perform the test in FA100-based group because the material shows dimensional stability in contact with the water. The apparent porosity values recorded in this study were higher for systems containing exclusively FA [32] and higher for systems exclusively based on MK [18]. However, its downward trend agrees with the literature [30,28]. Additionally, an increase in apparent density can also be recorded [29,33].

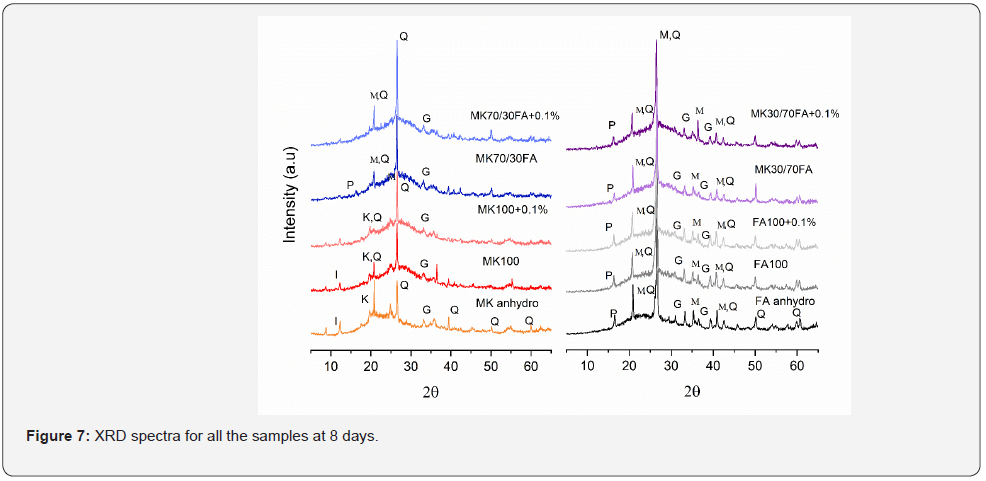

XRD analysis

In figure 7, the XRD spectra was recorded for all the samples, and it can be observed that MK has typical amorphous halo in the range 15 to 30° 2θ. After the activation, the displacement of this halo was registered in zones of greater angles near to the interval 20-40° 2θ [26-28] and the same way the FA activated develop a bump broader than the FA anhydrous [32]. These transformations are characteristic of the geopolymeric gel. However, the peak associated to carbon could be undercover by the intense peak associated to graphite’s addition. It was not observed the formation of any new phases or carbonates. This follows the interaction between the precursors once that the intensity related to one precursor started to disappear. At the same time the other shows itself in a superior quantity within the system [35].

Conclusions

Geopolymers composed of FA and MK and with the addition of a graphite content of 0.1 wt.% were produced. The nanomaterial effect was conditioned to matrix characteristics. Even when dispersion can be guaranteed in an alkaline solution (using highamplitude energy sonication), they can act as discontinuous points in the high-performance matrix, so it can be specified that:

I. A definition of a unique optimal addition for materials groups it’s not convenient for matrix with medium performance.

II. Significant changes in accumulated heat do not guarantee an increase in mechanical behavior.

Acknowledgments

The authors are gratefully to the Brazilian government research agencies, the National Council for Scientific and Technological Development (CNPq) and the Santa Catarina Research Foundation (FAPESC), for providing financial support for this research.

References

- Singh B, Ishwarya G, Gupta M, Bhattacharyya SK (2015) Geopolymer concrete: A review of some Recent developments. Constr Build Mater 85: 78-90.

- Duxson P, Lukey GC, Van Deventer JSJ (2006) Thermal conductivity of metakaolin geopolymers used as a first approximation for determining gel interconnectivity. Ind Eng Chem Res 45(23): 7781-7788.

- Yuan L, Yichao Ma, Jian Zhang, Jiahui Men, Tao Sun, et al. (2022) Case Studies in Construction Materials Orthogonal analysis and mechanism of compressive strength and microstructure of the metakaolin-fly ash geopolymer. Case Stud Constr Mater 17: e01154.

- Pouhet R (2015) Formulation and durability of metakaolin-based geopolymers. Pp 260.

- Trincal V, Benavent V, Lahalle H, Balsamo B, Diaz L, et al. (2022) Shrinkage mitigation of metakaolin-based geopolymer activated by sodium silicate solution. Cement and Concrete Research 162: 106993.

- Geopolymers M, Kuenzel C, Vandeperre LJ, Donatello S, Boccaccini AR (2012) Ambient Temperature Drying Shrinkage and Cracking in Metakaolin-Based Geopolymers. JACerS 95(10): 3270-3277.

- Preza CRAS, Brito W da S, Santos Lima AS, Nascimento SCC, Souza JA da S (2020) Geopolimerização do Metacaulim ferruginoso com adição de cinza volante. BJD 6(3): 11768-11779.

- Cardoso GGD, Fagury RLRP, Rabelo AA, Fagury Neto E (2020) Estudo preliminar da síntese de geopolímeros baseados em metacaulim, cinzas volantes e filito da Região Sudeste do Pará. Technol Sci 2(1): 37-42.

- Bellum RR, Muniraj K, Indukuri CSR, Madduru SRC (2020) Investigation on Performance Enhancement of Fly ash-GGBFS Based Graphene Geopolymer Concrete. J Build Eng 32: 101659.

- Wang X, Zhang C, Zhu H, Wu Q (2022) Reaction kinetics and mechanical properties of a mineral- micropowder / metakaolin-based geopolymer. Ceram Int 48(10):14173-14181.

- Cai J, Li X, Tan J, Vandevyvere B (2020) Thermal and compressive behaviors of fly ash and metakaolin-based geopolymer. J Build Eng 30: 101307.

- Zhu H, Liang G, Zhang Z, Wu Q, Du J (2019) Partial replacement of metakaolin with thermally treated rice husk ash in metakaolin-based geopolymer. Constr Build Mater 221: 527-538.

- Liu C, Xiao chuan Huang, Yu-You Wu, Xiaowei Deng, Jian Liu, et al. (2020) Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnology Reviews 9(1):155-169.

- Krishna RS, Mishra J, Nanda B, Patro SK, Adetayo A, et al. (2021) The role of graphene and its derivatives in modifying different phases of geopolymer composites: A review. Constr Build Mater 306: 124774.

- Goldmann E, Górski M, Klemczak B (2021) Recent advancements in carbon nano-infused cementitious composites. Materials (Basel) 14(18): 5176.

- Da Luz G, Gleize PJP, Batiston ER, Pelisser F (2019) Effect of pristine and functionalized carbon nanotubes on microstructural, rheological, and mechanical behaviors of metakaolin-based geopolymer. Cem Concr Compos 104: 103332.

- Pich W, aksymilian Frąc, Paulina Szołdra (2022) Smart Graphite -Cement Composites with Low Percolation Threshold. Materials (Basel) 15(8):2770.

- Bera M, Gupta P, Maji PK (2018) Facile One-Pot Synthesis of Graphene Oxide by Sonication Assisted Mechanochemical Approach and Its Surface Chemistry. J Nanosci Nanotechnol 18(2): 902-912.

- Silvestro L, Artur Ruviaro, Geannina Lima, Paulo de Matos, De Azevedo ARG, et al. (2021) Influence of ultrasonication of functionalized carbon nanotubes on the rheology, hydration, and compressive strength of portland cement pastes. Materials (Basel) 14(18): 5248.

- Taborda Barraza M, Pelisser F, Gleize PJP (2021) Thermal-mechanical properties of metakaolin- based geopolymer containing silicon carbide microwhiskers. Cem Concr Compos 123: 104168.

- Joseph S, Uppalapati S, Cizer Ö (2018) Instantaneous activation energy of alkali activated materials. RILEM Tech Lett 3: 121-123.

- García Taengua E, Sonebi M, Hossain KMA, Lachemi M, Khatib J (2015) Effects of the addition of nanosilica on the rheology, hydration and development of the compressive strength of cement mortars. Compos Part B Eng 81: 120-129.

- Yang H, Manuel Monasterio, Dapeng Zheng, Hongzhi Cui, Waiching Tang, et al. (2021) Effects of nano silica on the properties of cement-based materials: A comprehensive review. Constr Build Mater 282: 122715.

- Huang H, Teng L, Gao X, Khayat KH, Wang F, et al. (2022) Effect of carbon nanotube and graphite nanoplatelet on composition, structure, and nano-mechanical properties of C-S-H in UHPC. Cem Concr Res 154:106713.

- Taborda Barraza M, Padilha F, Silvestro L, De Azevedo ARG, Gleize PJP (2022) Evaluation of CNTs and SiC Whiskers Effect on the Rheology and Mechanical Performance of Metakaolin-Based Geopolymers. Materials (Basel) 15(17): 6099.

- Sajjad U, Sheikh MN, Hadi MNS (2021) Experimental study of the effect of graphene on properties of ambient-cured slag and fly ash-based geopolymer paste and mortar. Constr Build Mater 313: 125403.

- Zhu X, Chenghong Lu, Wenkai Li, Siqi Zhou, Feng Lib, et al. (2022) Effects of carbon nanofibers on hydration and geopolymerization of low and high- calcium geopolymers. Cem Concr Compos133: 104695.

- Zhang G, Lu J (2018) Experimental research on the mechanical properties of graphene geopolymer. AIP Adv 8(6).

- Corso M, Berto LK, De Albuquerque ACD, De Oliveira JH, Favaro SL, et al. (2020) Incorporação de óxido de grafeno em argamassa de revestimento: uma visão sustentá Ambient Construído 20(1): 297-312.

- Ahmad F, Arshad Jamal, Mudassir Iqbal, Muwaffaq Alqurashi, Meshal Almoshaogeh, et al. (2022) Performance Evaluation of Cementitious Composites Incorporating Nano Graphite Platelets as Additive Carbon Material. Materials (Basel) 15(1): 290.

- Li M, Ren Luo, Lingling Qin, Huai Liu, Ping Duan, et al. (2022) High temperature properties of graphene oxide modified metakaolin based geopolymer paste. Cem Concr Compos 125: 104318.

- De Azevedo GS, Strecker K, De Araújo AG, Da Silva CA (2017) Produção de geopolímeros à base de cinza volante usando soluções ativadoras com diferentes composições de Na2O e Na2SiO3. Ceramica 63(366): 143-151.

- Amun Amri, Gilang Fathurrahman, Ahmad Ainun Najib, Ella Awaltanova, Aman, et al. (2018) Composites of palm oil fuel ash (POFA) based geopolymer and graphene oxide structural and compressive strength. IOP Conference Series: Materials Science and Engineering 420.

- Tambara Júnior LUD, Taborda Barraza M, Cheriaf M, Gleize PJP, Rocha JC (2022) Effect of bottom ash waste on the rheology and durability of alkali activation pastes. Case Stud Constr Mater 16: e00790.

- Zhan W, Ni L, Gu Z, Cui F, Jiang J, et al. (2021) The influences of graphene and carbon nanotubes on properties of waterborne intumescent fire resistive coating. Powder Technol 385: 572-579.