Control Seawater Intake Biofouling

Jonathan A French*

Retired from CDM Smith, Inc., Boston, USA

Submission:September 19, 2022; Published:October 07, 2022

*Correspondence author: Jonathan A French, Retired from CDM Smith, Inc., Boston, USA

How to cite this article: French, Jonathan A. Control Seawater Intake Biofouling. Oceanogr Fish Open Access J. 2022; 15(3): 555912. DOI: 10.19080/OFOAJ.2022.15.555912

Abstract

Increasingly, we resort to taking in seawater for desalination, cooling, or both. Sometimes there are problems of biofouling of the intake system: at the intake screens, or in the pipeline, and / or at the onshore end of the pipeline where the flow is usually pumped up to a plant for cooling or desalination.

Biofouling control measures that may be considered include screens at the offshore end of the intake pipe system; air backwash of those screens; at the offshore end of the intake system; chemical dosing of the intake pipe wall; excavation of biomass collected at the shore end of the intake system; use of a shorter intake pipeline, even though the water quality nearer shore may be inferior to that found farther and deeper from shore.

Keywords: Biofouling; Mollusks; Jellyfish; Seawater intakes; Retrofit

Introduction

Increasingly, we resort to taking in seawater for desalination, cooling, or both.

Unfortunately, an intake system is ideal for establishing and nurturing biofouling, a term used here to mean any obstruction of flow due to flora or fauna, whether jellyfish haplessly tangled in the intake screens, or seaweed attached to the screens, or mussels on the wall of the intake pipe arriving as spat and staying to grow to “restaurant-grade” adults. All these and other forms of biofouling constrict the flow area and roughen the flow boundary.

Biofouling can also mean the accumulation of massive amounts of such life forms at the forebay of a pump station at the onshore end of the intake pipeline. Bulk amounts must be excavated so as to not clog the pumps. Beyond the pumps and approaching the desalination or other process plant, a “pretreatment” unit is often imperative to remove fine concentrations of silt, algae, dissolved organic carbon, and other organic material that may clog reverse osmosis membranes or other delicate process equipment.

“Biofouling”, an international, peer-reviewed, multi-disciplinary journal, publishes pure and applied work on protein, microbial, fungal, plant and animal fouling and its control, as well as studies of all kinds on biofilms and bioadhesion. Some of its content deals with seawater intake problems.

There is a growing body of literature on seawater intake for cooling and desalination, but as yet little of it deals with biofouling.

Addressing Biofouling Problems: Anticipate, Design, (Try to) Fix

To discuss what follows, let us assume the usual system of an offshore intake tower, a pipeline to shore, and onshore pumping to some sort of pre-treatment system to remove silt, algae, dissolved organic carbon, and other organic material that may clog the membranes of a reverse osmosis desalination plant [1]. Exceptions will be noted.

Anticipate the Nature, Magnitude, and Seasonality of Biofouling at a Planned Seawater Intake Site.

To plan any important coastal structure, it is normal and important to develop a good understanding of:

a) nearby coastal maritime activities

b) bathymetry

c) sub bottom profiling and substance (e.g., sand, rock)

d) tide regime (range, max/min pattern)

e) wind regime (seasonally)

f) wave regime (seasonally)

g) current regime (seasonally)

h) temperature and salinity depth profiles at several stations from shore (seasonally)

Additionally, for possible biofouling problems at a new coastal structure, seek information on:

i) algal concentrations (seasonally, species)

j) jellyfish presence/blooms (seasonally; species)

k) Note growths of biomass on local rocks and pilings (flora and fauna)

l) Seek out any biofouling problems on existing nearby intakes or other facilities

To the greatest extent possible, gather this information from existing documents, initial field observations, and discussions with local water people. If necessary, mount a 12-month study of water quality and the presence of plankton, nekton, and other seasonal biotic populations.

Then upon entering the process of planning and designing the intake system, draw conclusions as to the nature, magnitude, and seasonality of any biofouling issues.

During the operational life of the system, and as any biofouling problems occur, note the manner in which they are handled, and feed the information forward, to plan proper remediation.

Design the intake system to best anticipate any biofouling issues

To discuss what follows, consider a conventional system as posited above, and assume a recovery rate of about 45 percent at a desalination plant. Assume an assault on this system by a menu of biofoulants that can accumulate on the intake screens, yet in part also pass through the screens and attach on the inner wall of the pipe, and yet also in part collect in the pump station forebay, and with their fines continuing through pumping to be removed at a pretreatment unit.

Biofouling control measures that may be considered:

At the intake tower:

Assume an intake tower of conventional design with screened intake ports about 2m above the seabed to avoid taking in bottom biota or wave-suspended bottom sediments. To avoid fish intake, assume an inflow velocity no greater than 0.15m/s:

a) Install air bubble curtains outboard of the screens to divert objects from entering an intake

A bubble curtain is shown to be an effective barrier to model jellyfish that are positively buoyant in a flume. However, current and wave conditions determine the efficacy of the bubble curtain as a barrier. In recent years, salmon aquaculture has struggled to mitigate the impact of harmful jellyfish species in northern Europe and beyond. Typically, large aggregations of jellyfish are carried by currents through salmon pens, leading to unsustainable mortality levels in some years. One potential solution that has been regularly proposed is the creation of a “bubble curtain” around fish pens. A bubble curtain is created by releasing compressed air from a perforated tube, or linear air diffuser, lying athwart and outboard of the intake opening and below the incoming flock of jellyfish. It forms a plume of bubbles that entrain the water to create a vertical current. Field and flume tank experiments investigated the efficacy of a bubble curtain as a jellyfish barrier at several aquaculture locations in Ireland and in a controlled flume tank.

Field tests on bubble curtains provided mixed results: a high air flow linear bubble curtain set at 5 m depth effectively deflected large-compass jellyfish (Chrysaora hysoscella), whereas a low air flow bubble curtain set at 5m depth, around a salmon farm, did not significantly impact the abundance of small hydromedusae on either side of the bubble curtain. Flume tank experiments indicated that increased air flow rate increased the transport through the air curtain of slightly negatively buoyant jellyfish but decreased the transport of slightly positively buoyant jellyfish.

Flume tank experiments indicated that increased air flow rate increased the transport through the air curtain of slightly negatively buoyant jellyfish, but decreased the transport of slightly positively buoyant jellyfish. Flume tank experiments also demonstrated that

a) increased wave height increased jellyfish transport through the air curtain

b) the lateral movement was consistent with Stokes drift, i.e., an elliptical motion that includes forward movement with each wave

These results suggest that sites with relatively high wave energy may be unsuitable for bubble curtain use and that the variable size and shape of jellyfish may be an important factor in jellyfish and bubble curtain interactions [2].

b) Air backwash the screens

At least two proprietary equipment manufacturers [3,4] have developed intake portals consisting of finely-spaced screens (of the order of a few mm), made of materials that resist bio attachment, and with air-burst backwash blowing outward through the screen grid to dislodge and remove debris, organic and non-organic, that may be clogging the screens. The air bursts are driven from an onshore compressor system, with an air feed line extending along the intake pipeline out to the intake structure. The air-burst frequency, adjustable, is of the order of once every few minutes.

c) Let the intake screens be easily detached, hauled to the surface for cleaning and other maintenance, and replaced

(Be sure to shut down plant flow for this procedure, lest divers be fatally drawn into the intake through an unscreened port.)

d) Shut down plant operation while the bloom lasts

The feasibility of shutdown of course depends on its duration, and of the flexibility of the water consumer to tolerate a lack of supply for that duration.

e) Maximize the Recovery Rate

If the ultimate process is desalination, consider maximizing the intake flow, and thus the rate of arrival of bio-problems.

f) How shallow can the intake ports be?

Ports closer to the water surface are more easily serviced/ cleaned. Negotiate with wave, tide, and navigation considerations.

Along the intake pipeline:

a) Chemically dose the intake pipe wall.

The inner wall of the intake pipe can become fouled with growths of sessile fauna and flora, to an extent that can severely reduce the flow capacity of the pipe. One measure to inhibit the growth of attached biota is to apply antifouling chemical dosant streams, either continuously or in periodic “shock” dosing treatments.

To apply dosant by simply releasing the stream from a single point at the pipe entrance is far from optimal, because the dosant stream will not spread across the flow to the pipe wall until it is carried far downstream [5]. Nor is the dosant stream needed anywhere in the flow other than at the side wall. It is far better to release the dosant uniformly around the periphery of the pipe wall at the pipe entrance. Such peripheral release minimizes the required rate of biocide use, to minimize both operational expense and possible adverse environmental impact [6].

b) Pigging

“Pigging” is a process of reaming out a partially clogged pipe by driving a plug, or “pig,” through it by hydraulic pressure. Several pig passes are usually required in an operation, starting with a very smooth, flexible pig and then using progressively stiffer pigs with bristles, and of progressively larger diameter, approaching the inner diameter of the pipe itself. The solids dislodged from the pipe wall are progressively flushed out the seaward end of the pipe.

Pigging is occasionally required to recover hydraulic conductivity in wastewater discharge outfalls; there it can be considered an expensive, desperate measure. French [7] has described in detail such an operation on two 80-year-old outfalls in Boston Harbor.

Pigging can also be used for scouring out biofouled seawater intake pipelines. However, it should be considered a measure even more expensive and desperate than that for outfalls because a ready source of propulsion water is not readily at hand and must be provided.

At the design stage, provision of a pig-launching tube at the seawater pump station at the shore is a small but valuable investment toward mounting an operation at a future time if ever needed.

Systems that happen to have two or more parallel intake pipelines can, with proper pumping arrangements, provide propulsion water much more conveniently than can a system with only one pipeline.

c) Oversizing

If pipeline clogging is deemed inevitable, consider oversizing the pipe diameter to provide sacrificial flow capacity.

d) Pipe lining

If pipeline clogging is deemed probable, consider lining the pipe with a material resistant to mollusk spat or algae attaching to it.

e) How short can the pipeline be?

This is a strategic decision; a shorter line means less pipeline to be subject to fouling, as well as a shorter distance to deliver air to the intake tower, if air is used there.

f) “No” pipeline: shoreline intake

In some cases, where wave activity is modest or controlled by breakwaters, seawater can be taken in directly at the shoreline, as is practiced extensively along the Saudi Arabian coast of the Arabian / Persian Gulf [8]. This arrangement eliminates the difficulties of servicing deep and offshore intake towers and intake pipelines, but the water quality nearer shore may be inferior to that found farther and deeper from shore.

g) Subsurface intake

In a small (less than 10 percent) but growing fraction of cases the seawater can be taken in through infiltration galleries buried beneath a sandy seabed. These are called indirect intakes, or well intakes, or subsurface intakes. While not suitable in all locations, the saline water they collect is pretreated via slow filtration through the subsurface soil formations in the area of source water extraction. Thus it is usually of better quality than that from open intakes in terms of solids, silt, oil and grease, algal content, natural organic contamination, and aquatic microorganisms, and a separate pretreatment system may not be needed [1]. Voutchkov [9] Chapter 6 provides an extensive description of subsurface intakes.

At the shore end of the intake system:

a) Need to remove debris.

There may be “bio-debris” (algae, seaweed, jellyfish, mussel shells, etc.) gathered at the downstream end of the intake pipe, i.e. in the forebay of the shoreline pump station. Be sure that the forebay is not covered, or has a removable cover, so that the “biomess” can be easily excavated.

b) Anticipate cleaning needs.

If planning indicates that remedial action such as pigging or backwashing may be needed, consider installing the basic components for these such as a pig insert sleeve and other useful piping during initial construction, at relatively little extra cost.

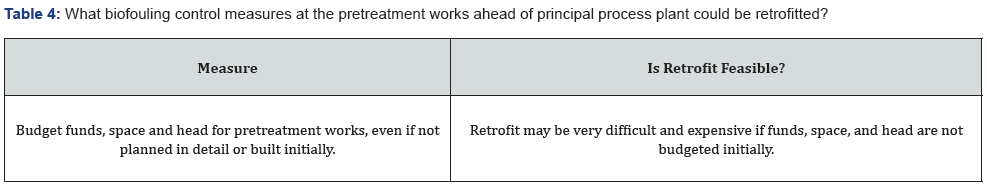

Pretreatment works ahead of principal process plant:

a) Plan ahead

Unless it is clearly evident that there will be no need for pretreatment, it is wise to budget funds, space, and hydraulic head for such a system, even if the precise nature and volume of biocontaminant is not yet determined.

“Try to Fix”: Retrofitting an Existing Intake System

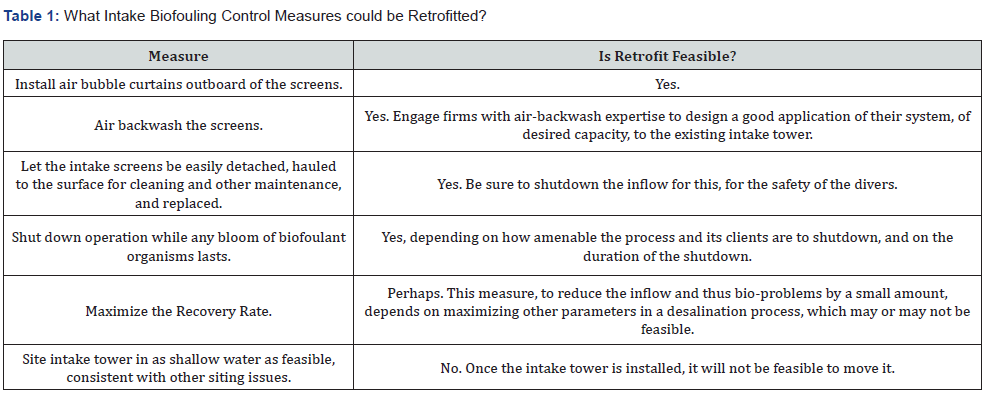

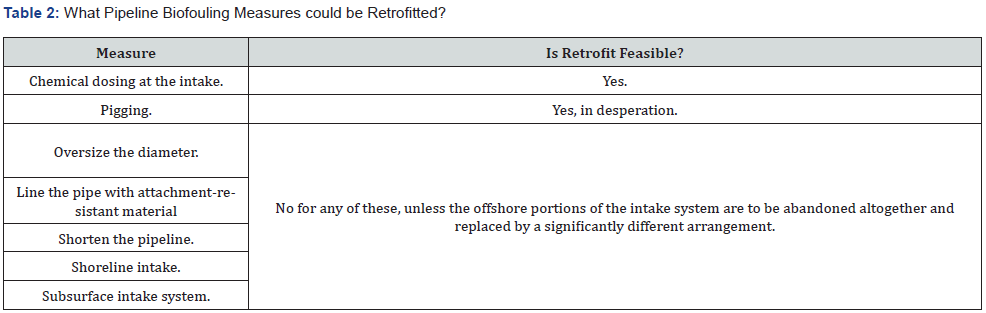

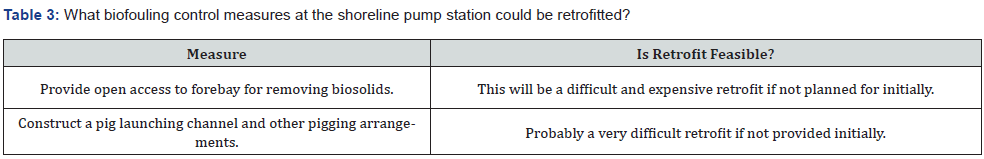

The passages above are for new design. If an existing system encounters unanticipated biofouling problems during its years of operation, a remedial program should be mounted if the system is to continue in business; but clearly not all the measures suggested above will be feasible to apply.

The following tables (Tables 1-4) provide brief assessments of how feasible the biofouling control measures suggested above would be if provided not in the initial design, but as a later remediation.

Conclusion and Recommendations

Biofouling problems in seawater intake systems are not always severe, or there would be much more discussion of it than we see. However, in some cases it has been severe enough to cripple or even shut down an intake facility.

Thorough scouting for the type and magnitude of possible biofouling problems at the early design stage is effort most valuable

a) to guide the strategic selection of intake type and location

b) to include appropriate biofouling management devices within the intake system initial design

c) if not provide, at least anticipate the possible future need to implement a device. For example, pigging may never be needed, but a few provisions in the system to facilitate pigging may be a few early dollars well spent should it come to needing to pig

Retrofitting is awkward and can be extremely expensive if measures are not anticipated in design.

References

- Cooley H (2013) Key Issues in Seawater Desalination in California: Marine Impacts. Pacific Institute, December.

- Haberlin D, McAllen R, Doyle TK (2021) Field and flume tank experiments investigating the efficacy of a bubble curtain to keep harmful jellyfish out of finfish pens. Aquaculture 531: 735915.

- https://johnsonscreens.com/products/passive-intake/.

- https://www.taprogge.com/anwendungsfelder-produkte/efficiency-in-energy-and-water-meerwasserentsalzung/in-ta-ct-bei-meerwasserentsalzung-durch-umkehrosmose/.

- French JA (2015) Thorough Dispersal of Dosants in Conduits. J Hydraulic Engineering ASCE 141(5): 1-7.

- French JA (2017) Ring Diffuser to Dispense Antifoulants at Seawater Intakes. J Hydraulic Engineering ASCE 143(9): 1-4.

- French JA (1995) Pigging Submarine Outfalls. Journal of Environmental Engineering ASCE 121(5).

- Costa H (2017) Jubail SWRO Phase 2 Seawater Intake. Project Manager | Senior Engineer - Water & Power at HR Wallingford, LinkedIn post.

- Voutchkov N (2013) Desalination Engineering Planning and Design, Water Globe Consulting, LLC, McGraw Hill, USA.