Devices for Monitoring Operating Parameters of The Ship Mechanisms

Alexander Evgenievich Semenov and Sergey Anatolyevich Putilin*

Department of Heat power engineering and refrigerating machines, Astrakhan state technical University, Russia

Submission:September 26, 2020; Published:November 10, 2020

*Correspondence author: Sergey Anatolyevich Putilin, Department of Heat power engineering and refrigerating machines, Astrakhan state technical University, Russia

How to cite this article:Alexander E S, Sergey A P. Devices for Monitoring Operating Parameters of The Ship Mechanisms. Oceanogr Fish Open Access 002 J. 2020; 12(5): 555846.10.19080/OFOAJ.2020.12.555846

Abstract

The results of experimental measurement of ship system parameters using new electronic devices are presented. The surface temperature of the compressor, oil separator, and linear receiver was measured using a thermal imager. The obtained thermograms clearly visualize the operational characteristics of the tested equipment. In addition, the description of obtaining the temperature of the internal environment based on the results of measuring the temperature of the outer surface of the pipeline using a pyrometer is presented.

Keywords: Measurement; Operational Parameters; Pyrometer; Thermal Imager; Ship Systems

Introduction

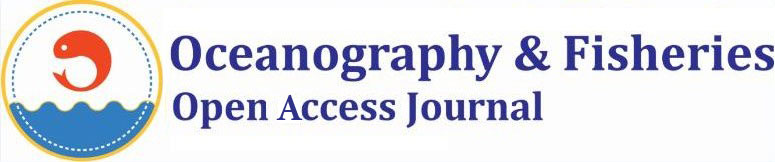

The instrument-making industry produces many new convenient electronic devices. Such as pyrometers, thermal imagers. These devices are now used in everyday life and everyday situations. But in the practice of operating ship mechanisms are not used. Rules and instructions for the operation of tanks, pipelines, compressors, and other marine equipment clearly define the measurement locations, time intervals for measurements, instrument error, and many other values. These parameters and characteristics are obtained from the analysis of emergency situations. Recorded in the governing documents, we can say, the blood of victims of incidents and accidents. This, of course, is not subject to change or adjustment. However, the operating rules do not prohibit the use of additional measuring equipment. This can help improve the quality of service for ship systems. Note the oil separator shown in Figure 1 [1].

The lower part of the device has a temperature 10 degrees lower than the top [1]. It was assumed that there was an accumulation of oil in the lower part of the separator, which was later confirmed. A defect in the oil transfer system from the separator to the compressor crankcase was detected in a timely manner. With the help of a thermal imager, the level of liquid in closed containers is well detected. Visualization of the level in a small receiver is shown in Figure 2 [1]. The thermogram clearly shows the differentiation (by temperature) of the parts of the device caused by the presence of liquid in the lower part of it. Similar images are also obtained on large apparatuses, pipelines of ship strapping.

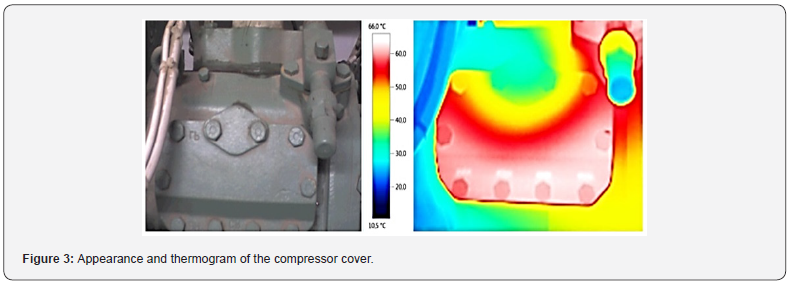

One of the important issues of operation is timely detection of overheating of equipment or its parts. This is usually done by the organoleptic method. The use of this method depends to a large extent on the quality of training and experience of the service personnel. To exclude the “human factor” from the process of diagnosing equipment overheating, it is better to use a thermal imager. The thermogram of the top cover of the compressor, obtained using a thermal imager [1], is shown in Figure 3, where no increased heating is detected, but the heating value is well reflected.

To quickly estimate the temperature of the medium flowing through the pipeline, you can use the measurement of its wall temperature. A pyrometer is used for this purpose. The value of the pipe wall temperature differs from the temperature of the medium flowing in the pipeline. You must enter an amendment. Works are devoted to finding the value of this correction. Their value is 1 - 2 oC for metal pipelines with ambient air on one side and process fluid inside [2,3].

It should be noted that the machine crew serving the ship’s systems does not have time to carry out additional measurements and studies that are not provided for in the technological regulations. The measurements described above are intended for developing and creating a computer program to support technical decision-making when a fault or defect is detected. In other words, connecting artificial intelligence at the fault detection stage to develop the correct technical solution for regulating the parameters and characteristics of ship devices and eliminating the occurrence of errors related to the “human factor”.

References

- SA Putilin, AE Semenov (2017) International scientific conference of scientific and pedagogical workers of the Astrakhan state technical University, AGTU publishing house, Astrakhan, Russia.

- Semenov A E (2017) calculation of the temperature of a refrigerating agent as measured by a thermal imager. In: АЕ Semenov, SА Putilin WORLD SCIENCE: PROBLEMS AND INNOVATIONS: collection of articles of the XIII International scientific and practical conference. Science and Education,Penza, Russia, Pp. 240.

- Semenov A E (2018)Determination of the medium temperature of the pipeline binding of ship compressors by the temperature of the outer wall. Bulletin of the Astrakhan state technical University. Series: Marine engineering and technology 2018(1): 81-86.