Northern Europe Processing Technique, Nutritional Composition, Quality and Safety, Flavour Compounds," Bio-Chemical Change During Pickle Curing of North Sea Herring (Clupea harengus) of Britain

Mansur MA*1, Uddin MN1, Rahman S2, Horner WFA3 and Uga S4

1Department of Fisheries Technology, Bangladesh Agricultural University, Bangladesh

2Asahi Consultants Ltd., Bangladesh

3International Fisheries Institute, University of Hull, UK

4Department of Nursing, Kobe Women's University, Japan

Submission: December 06, 2017; Published:January 31, 2018

*Corresponding author: Mansur MA, Professor, Department of Fisheries Technology, Faculty of Fisheries, Bangladesh Agricultural University, Mymensingh-2202, Bangladesh, Email: mansurft63@gmail.com

How to cite this article: Mansur MA, Uddin MN, Rahman S, Horner WFA, Uga S. Northern Europe Processing Technique, Nutritional Composition, Quality and Safety, Flavour Compounds, Bio-Chemical Change During Pickle Curing of North Sea Herring (Clupea harengus) of Britain. Oceanogr Fish Open Access J. 2018; 6(1): 555679. DOI: 10.19080/OFOAJ.2018.06.555679

Abstract

The Northern Europe processing technique of pickle curing of North Sea herring (Clupea harengus) of Britain was studied. Recognizable characteristics of this technique were also identified. At the same time the nutritional composition, protein degradation, sensory property, quality and safety of pickled herring was studied by laboratory research. Pre-spawning and post-spawning North Sea herring (Clupea harengus) of Britain was pickle cured by Northern Europe processing technique. Whole fish and gipped fish were stored in polypropylene barrels for pickle curing using pure salt and normal salt in different barrels. Nutritional composition i.e. protein, lipid, ash, moisture were 18.65-21.00%, 9.0018.10%, 2.96-3.11% and 50.47-57.12% respectively. Quality in terms of TVB-N and TMA-N were 65.29-79.77mg/100g and 4.9-11.5mg/100g respectively. Sensory properties (colour, texture, flavour) were quite acceptable but the pre-spawning herring stored with pure salt produced best product. Protein degradation took place during ripening, the rate of which was higher in pickled herring prepared by using pre-spawning herring with pure salt. In Northern Europe processing technique, storage temperature, physiological condition i.e. whether pre-spawning or post-spawning, presence or absence of gut influenced the rate of ripening. The safety indicator histamine level remained below the Maximum Allowable Limit (20mg/100g).

Keywords: Pickled herring; Northern europe processing technique; Nutritional composition; Biochemical change; Quality; Safety

Introduction

Pickle Curing or Pickling has different meaning in different countries. In the UK and other countries of Europe the term pickle curing or pickling refers to the technology of oily fish preservation in which the fish is preserved in airtight barrels in a strong pickle formed by salt dissolving in the body fluids of fish [1]. Horner WFA [2] defined the "Pickle Curing" or "Pickling" as a process of fatty fish preservation for a longer period of time by immersing in concentrated brine which restricts the atmospheric oxygen and ultimately retards rancidity reactions, although some rancidity is desirable in the development of characteristic flavour. However, in the United States this term is used for the uncooked fish products that have been preserved by first salt brining and finally by acidifying in vinegar which usually contains a variety of spices [3]. In Europe this type of processing is called marinating and the products are called marinades. In this article the term pickling and pickled fish is used to mean the British and European pickled fish. Among the fish salting methods 'pickle curing' technique may be different from the other techniques but the principle is same i.e. the lowering of water activity (aw) of fish muscle by increasing the concentration of solutes using salt, and antimicrobial agent. Normally the small pelagic fish e.g. Herring is used for pickling in Britain.

Pickle curing or Pickling is a type/kind of fish salting. Salting is the oldest method of fish preservation. This traditional method of fish preservation, is practiced in many countries of the world. Salting together with other curing methods, smoking and drying, have continued as preservation technique virtually unaltered from prehistory to the present. Fatty fish species, which are difficult to preserve by other process, produce a characteristic aroma and flavour on salting. This aroma and flavour is liked by the consumers. Salting is suitable for preserving fish in humid climates too. In India, Bangladesh, Myanmar, Thailand and Sri- Lanka salted fish is a common fishery product. In some countries e.g. in Malaysia, Indonesia and some parts of India, Thailand salted fish is subsequently dried.

In UK and other countries of Europe salted fish is liked by the consumers although the salt percentage in the final product is an important attribute to the consumers. In the fishery product 5 % (wet weight basis) salt is believed to be necessary to have an inhibitory effect on micro-organisms [4]. But this level is too high for the modern British taste. Research organizations in Britain are looking at lower salt concentration in combination with acetic acid and lactic acid to assess the inhibitory effect. "Maatje" herring (lightly salted herring) is a common food commodity in some parts of Europe (notably the Netherlands) and heavily salted fish is mainly produced in the Scandinavian countries and to a less extent in the other countries of Europe. Fish preservation by salt, both dry salting of cod and pickle curing of herring, was very important in Britain at the beginning of 19th century. At present the preservation of fish by use of salt for domestic consumption in Britain is minimum. Only lightly salted herring (Maatje cured) is produced in some parts of Britain. Dry salting of cod and pickle curing of herring is practiced in some of the curing factories for export. Now-a-days pickle curing is particularly practiced in north-east Scotland and the Shetland island of Britain.

Although heavily salted fish is now less popular in Western Europe than the good quality fresh and frozen alternatives available throughout the year, certain products such as "Maatje cured" herring remain popular in some parts of Western Europe. The heavily salted processing or heavy salted process is still in use for the pickle curing of herring in Northern Europe and some parts of Britain. The demand for pelagic fish species in Britain has been increased for the last 20 years mainly as a result of the perceived benefits to health though it is still small compared to the opportunities open to British Fishermen. One of the important themes of marketing activity of SFIA (Sea Fish Industry Authority) of Britain is the promotion of the health benefits of oil-rich fish such as herring and mackerel particularly in reducing heart disease [5].

Materials and Methods

Source of raw material

Pre-spawning and post-spawning herring (Clupea harengus) were used for pickle curing separately. In the north-east part of Britain the pre-spawning herring was caught from a fishing ground known as piper field in the North Sea, 90-110 miles north east from Peterhead, Scotland. Herring fish were caught by the drifter fishing boat of Denholm Seafood Group, Alexander Buchan Ltd., Peterhead. After capture the catch was pumped from the net through a de-watering device into RSW tanks at -2° C and the drifters returned to the port within 24 hours. The catch was unloaded by an on-board winch-operated scoop net digging the catch out of the RSW tanks and transferring them via a hopper to polypropylene tanks of about 1m3 capacity which were fork lifted to the adjacent processing factory. At this stage the temperature of fish remained around 0° C. In the factory the fish were kept in chill room until processing to pickle curing. The post-spawning herring (Clupea harengus) was caught from another fishing ground of the North Sea located at off Scarbrough by the drifters of same Fishing Company and returned to the fishing port at Peterhead which required 24 hours journey by the drifter fishing boat. The other steps in the drifter fishing boat were same as for the pre-spawning herring (Clupea harengus).

Source of salt

Salt was obtained from Denholm Sea Foods, which were bagged in Edinburgh. Another batch of salt was collected from Cawoods Fish Curers, Hull which are used for dry salting of Cod in that factory.

Preparation of pickled herring

Northern Europe technique of pickle curing was followed. The processing steps e.g. gibbing/gipping, rousing, packing in barrel, filling the barrel, closing the barrel, storage for ripening etc. are almost same as those prepared in different parts of Britain.

Another step "stenciling" was common in pickle curing process in ancient time. This step was followed after the step "closing of barrels". This stenciling step was necessary in ancient time because wooden barrels were used in pickle curing at that time. Stenciling is appropriate for wooden barrels. Now-a-days polypropylene barrels are used for pickle curing of herring. Stenciling is not carried out incase of polypropylene barrels. Stenciling is not necessary for polypropylene barrels. The Northern Europe pickle curing process described and discussed in the next section (Results and Discussion) of this paper. More batches of pickled herring were prepared from whole herring and gipped herring using pure salt and normal salt from prespawning and post-spawning fish to know the composition, quality and safety aspect of pickled herring prepared by northern Europe method. The objective of preparing extra batches was to see the possibility of pickling of whole herring fish i.e. omit gipping/gibbing step.

Transportation and storage

The polypropylene barrels packed, filled and sealed for pickle curing of herring were transported from Peterhead, Scotland to Hull, England by refrigerated vehicle which required 24 hours journey. During transportation the herring fish in the polypropylene barrels were in chilling temperature (0-5° C) inside the vehicle. Final storage was done at 0-5° C in a chilled store of Fish processing Industry. During storage the barrels were occasionally rolled on the floor in horizontal position to prevent fish from sticking together.

Laboratory analysis

Laboratory analysis was performed in The University of Hull. For this purpose sample preparation for laboratory analysis was done in the laboratory of International Fisheries Institute. All laboratory analysis were performed in the Research Laboratory of the Department of Applied Biology, University of Hull.

Nutritional composition

Nutritional composition in terms of protein, lipid, ash, moisture was estimated by the methods of A.O.A.C [6].

Bio-chemical analysis for Safety aspect

Safety aspect of the pickled herring was conducted by estimation of histamine, salt concentration, lipid characteristics (peroxide value, TBARS thiobarbituric acid reactive substances), estimation of TVB-N and TMA-N, pH of the pickled herring.

Estimation of histamine was done by colorimetric method developed by Hardy & Smith [7]. Estimation of Peroxide value was done by the method described by Egan et al. [8] which was adopted from Wood and Aurand [9]. TVB-N and TMA-N estimation was done by the method proposed by Analytical Methods Committee [10] pH of the pickled herring muscle was measured by placing the chopped piece directly on the Cardio sensor of the Horiba Compact pH meter C-1 after calibration by adjusting the standard and slope settings with the pH 4 and 7 buffer solution. Protein degradation was studied by the estimation of free alpha amino nitrogen and peptide level during ripening time of pickle curing. Estimation of free alpha amino nitrogen was carried out according to EBC-Ninhydrin method [11] . Peptide content was calculated as the difference between the result of TNBS (Tri-nitro-benzene-sulphuric acid) method, which is a modification of the method reported by Satake et al. [12] and EBC-Ninhydrin method.

Salt concentration was estimated by the titremetric method. Six fillets from different fish were skinned and finely homogenised in a homogeniser. An amount of 25g of accurately weighed homogenised sample was blended with 225ml of distilled water. This was filtered through Whatman No. 1 filter paper. An aliquot of 10.00ml of the filtered homogenate was titrated against 0.1N AgNO3 using potassium chromate (5% solution in water) as indicator. NaCl content was calculated from the following equation:

1ml 0.1N AgNO3 = 0.005845g NaCl

%NaCl in fish = S x 90

where S is the NaCl content in 10.00ml aliquot

Monitoring of texture change was done by using an Instron Tensile Tester Model 112 with the following set up:

50Kg load cell

Chart speed : 50cm/min

Cross head speed : 10cm/min

5Kg full scale deflection

The probe attachment was a brass cylinder of 14mm diameter.

Volatile flavour components were identified by GC-MS analysis with a Finnigan 1020 GC-MS according to the method of Mansur [13] which was adopted from the method described by [14] The method is basically trapping the volatile flavour components with Tenax TA (60-80 mesh, product of Jones Chromatography, Mid Glam, UK). Subsequently, the volatile flavour components were eluted with diethyl ether (5ml) and concentration was achieved under a stream of nitrogen. The resulting concentrate (100|il approximately) was used for GC- MS analysis.

Results and Discussion

Northern Europe processing technique of pickle curing.

Raw material

Usually the pre-spawning herring was used for pickle curing. In the north-east part of Britain the herring is caught from piper field, 90-110 miles north east from Peterhead, Scotland. Herring fish were caught by the drifters (fishing boat which use drift net in fishing) in that fishing ground. After capture the catch is pumped from the net through a de-watering device into RSW tanks at -2° C and the drifters return to the port within 24 hours. The catch is unloaded by an on-board winch-operated scoop net digging the catch out of the RSW tanks and transferring them via a hopper to polypropylene tanks of about 1m3 capacity which are fork lifted to the adjacent processing factory. At this stage the temperature of fish usually remains around 0°C. Stroud [15] stated that in pickle curing process only the herring fish is used and about 2% of the British herring catch is still pickle cured in barrels, mainly for export, a trade that, at the beginning of the 19th century accounted for more than 80% of the British coast herring.

Processing steps

For pickle curing the herring fish were first gipped or gibbed. Gibbing is a step in which the gill, intestine, stomach of herring fish are removed. Gibbing was done manually by inserting a knife at the gills and very quickly with a dexterous movement the gill, intestine and stomach are removed. The milt or roe and the pyloric caeca remain in the fish. These pyloric caeca contain enzymes which enhance proteolysis and this proteolysis is believed to play a part in the development of the characteristic flavour of pickle cured herring.

The next step of pickle curing was rousing. In rousing step the gibbed/gipped herring fishes were mixed with dry crystalline salt. Proper mixing of fish and salt is called rousing. The ratio of fish to salt is such that during rousing and subsequent packing in barrels the ratio of fish to salt of whole process is 4:1. Rousing is done manually in a plastic box. Care was taken so that gibbed herring and salt was mixed thoroughly. If 100kg of gibbed or gipped herring to be pickle cured in a polypropylene barrel then a total of 25kg salt will be required. During rousing 1215kg salt will be used. The rest 10-13kg salt will be used in the polypropylene barrels during packing the barrels with rousing fish, topping up the barrels, use in the brine preparation etc. After rousing step the rousing fish is brought to the barrels and ready for packing in the barrels.

The next step was packing in the barrels. The rousing fish were packed in polypropylene barrels in a specific manner. Most commonly accepted manner is that, first a layer of salt is put on the bottom of the barrel then a layer of fish is placed with belly uppermost and head to tail arrangement until the layer is complete. A layer of salt was spread over the fish and a new layer of fish is laid at right angle to the layer beneath with belly uppermost. These alternate layers of salt and fish were continued until the barrel was full. In this way barrel was packed with herring fish and salt.

The next step was filling the barrel. Extra two layers of fish and salt were laid on the top of the packed barrel. After two days the herring inside the barrel were shrunk due to pickle formation by the fish body fluids and salt dissolving in it so that the extra layers become immersed in the pickle. Sometimes the gibbed herring which are rousing on the same day is used to re-fill the barrel if necessary. In this way the barrel was tightly filled up- to the mark where the lid is placed. Sometimes saturated brine is poured to keep the fishes immersed in blood pickle. In the ancient time saturated brine was not used. Instead of saturated brine the filling step was repeated several times.

The next step is closing the barrel. The barrel is finally closed with lid on and made airtight with a galvanized steel collar. This step is sometimes called "sealing the barrels". The final step is storage for ripening. The sealed barrels or airtight barrels are stored at 0-5°C for ripening, i.e. development of proper flavour, taste, texture. During storage the barrels are occasionally rolled on the floor to prevent fish from sticking together. Ripening time varies from 12-15 months at this storage temperature. Storage is done in a cold store maintaining the proper storage temperature (0-5°C) (Figure).

Recognizable Characteristics of Northern Europe Method

I. Polypropylene barrels are used instead of wooden barrels.

II. Sealing of barrel is carried out instead of stenciling. Stenciling was appropriate for wooden barrels. In Northern Europe method barrel is finally closed with lid on and made airtight with a galvanized steel collar. This step is called "sealing the barrels". Now-a-days stenciling is not carried out incase of polypropylene barrels. Stenciling step is replaced by the step 'sealing the barrel' for polypropylene barrels.

III. Bung hole bore is not carried out. This was practiced for the wooden barrels.

IV. Re-filling of barrel is not carried out. Strong pickle formed by the body fluids of fish and salt dissolving in it is called "blood pickle" mainly because of its reddish-brown colour from herring blood.

V. Polypropylene barrels are occasionally rolled on floor to prevent fish from sticking together.

VI. The pickle curing process described in this paper is the typical process practiced in Northern Europe.

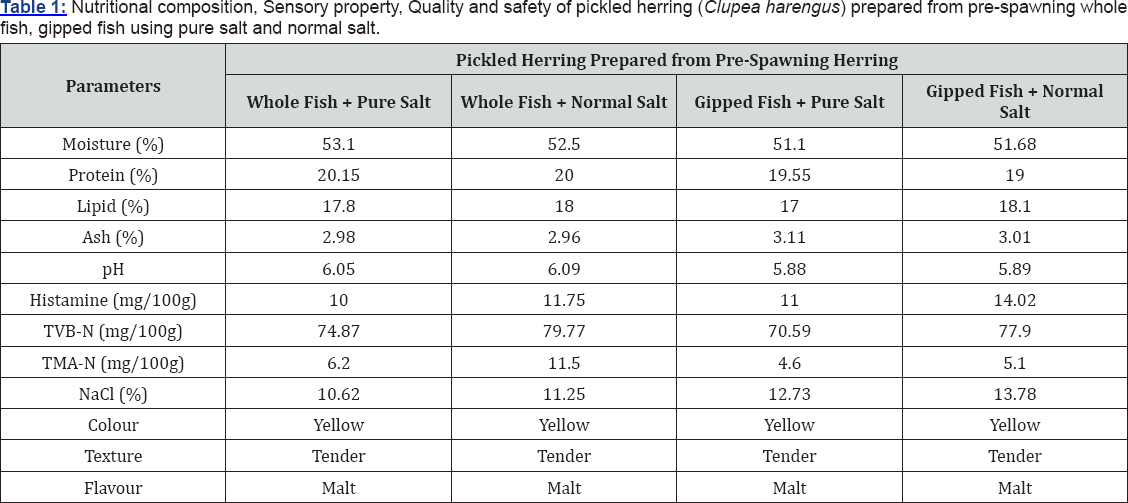

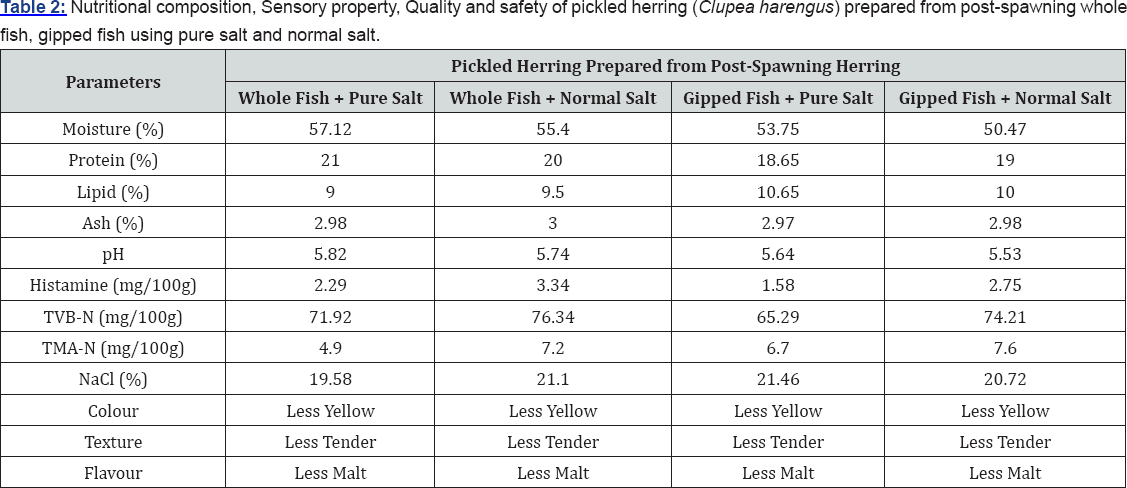

Nutritional composition, sensory property, quality and safety

Nutritional composition, sensory property, quality and safety of pickled herring are mentioned in Table 1 & 2. The composition of pickled herring prepared from pre-spawning herring and post spawning herring are comparable. The salt content in the pickled herring prepared from post spawning herring is higher (almost double) than that of the pickled herring prepared from pre- spawning herring. The reason may be the fat content in pre spawning herring is usually 17% as against 9% in the post spawning herring. The high fat content in pre spawning herring act as barrier and reduced the salt penetration rate. The moisture percentage, pH, TVB-N, TMA-N, and crude protein content of the pickled herring prepared from pre spawning and post spawning herring are almost comparable. Histamine content in the prespawning samples are significantly higher than those of the post spawning samples, but the level remains below the maximum allowable limit (MAL) in the pickled herring in all the batches.

The sensory properties (flavour, colour, texture) are better in the pickled herring prepared from pre spawning herring fish than the post spawning fish. Most noticeable difference is found in the sensory properties of the pickled herring between these batches. The flavour is usually stronger in the pickled herring prepared from pre spawning fish, which make them better as ripened product. The texture of pickled herring is also more tender in the samples prepared from pre spawning herring than those of the post spawning herring.

Results stated in Table 3 & 4 also indicate the quality and safety of the pickled herring of Britain. The parameters histamine, TVB-N, TMA, pH are usually considered appropriate parameters to assess the quality of fish and fishery products. Result indicates that the pickled herring samples were of acceptable quality and safe to eat as the histamine level is below the Maximum Allowable Limit (<20mg/100g).

Bio-chemical changes during pickle curing

In Northern Europe processing technique a number of exceedingly complex bio-chemical changes during ripening of pickled herring have been discovered which we reported in our previous publications [16-23]. Most noticeable bio-chemical changes are summarized below:

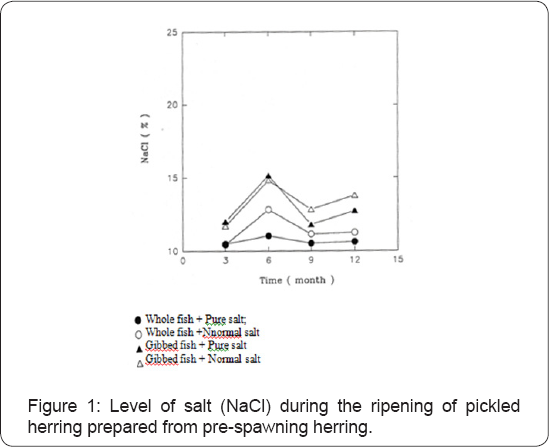

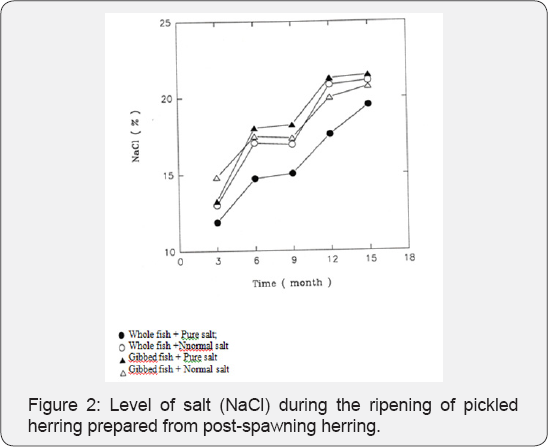

The salt concentration was significantly different in the pre-spawning and post-spawning fishes at the end of ripening process (Figure 1 & 2) but there was a very slow decrease in the pH of the fish flesh during the ripening process of pre-spawning and post-spawning fishes (Figure 3 & 4). Reason for the difference in the salt concentration is that the pre-spawning fish contained considerably higher percentage of lipid (17%) than the post-spawning fish (9%). Such high lipid acts as a barrier for salt penetration in the fish tissue. Gibbed fish having had its skin broken allows quicker access to salt. The pH of the fish muscle did not vary significantly during ripening period. Only a small drop in pH was observed in all samples which, suggested that pepsin and trypsin play an important role during the ripening time. Usually, if the pH of the fish muscle is neutral then trypsin plays the most important role in the ripening. At pH 5.5 pepsins also play an important role during maturation/ripening of salt preserved long-term storage [24].

Proteolysistakes place during pickle curing. This was indicated by the tests conducted in the laboratory. The concentrations of free alpha amino nitrogen (FAN) and peptide increased until the fish is ripened. This phenomenon is significantly influenced by the season of capture/condition of fish (pre spawning or post spawning) and the presence or absence of gut. Degree of protein degradation in the pre spawning fish is higher than those of post spawning fish during pickle curing. Similarly this rate is higher in the whole fish than in the gibbed fish. This is proved by the FAN values and Peptide values. In pickled herring processed by pure salt the whole fish possessed FAN value of 371mg/100g whereas the gibbed fish possessed FAN value of 213mg/100g. In pickled herring processed by normal salt the whole fish possessed FAN value of 403mg/100g where as the gibbed fish possessed FAN value of 215mg/100g. This trend was same for the peptide value of the pickled herring processed by pure salt and normal salt. In the pickled herring processed by pure salt the whole fish possessed peptide value of 187mg/100g where as the gibbed fish possessed peptide value of 88mg/100g. In pickled herring processed by normal salt the whole fish possessed peptide value of 195mg/100g where as the gibbed fish possessed 103mg/100g. A slight portion of protein leach out from the fish to the pickle during ripening of pickle curing. The pH and salt concentration of fish muscle also influence protein degradation during the ripening of pickled herring. It is possible that the higher salt concentration retarded the rate of proteolysis in the gibbed fishes and in all post-spawning fishes.

In general, the lipid of the salt pickled herring remains in the induction phase of lipid oxidation until the tenth month of ripening. Then proceed towards the propagation phase between the tenth and fifteenth month of ripening. This oxidative rancidity is influenced by the condition of fish i.e. pre-spawning or post spawning as well as by storage temperature. The rate of oxidative rancidity is higher in the pre spawning batch with the rise of storage temperature. The rate of oxidative rancidity is also influenced by the condition of storage i.e. whether completely immersed in pickle/brine or not. Normally less oxidation takes place in completely immersed samples.

In Northern Europe processing technique histamine in the pickled fish remains within the maximum allowable limit (MAL). This is due to high salt concentration which suppresses the histamine forming bacteria. Even at high salt concentration a small amount of histamine may still be produced by the activity of the endogenous enzymes of fish. When the initial salt penetration is allowed to proceed at 0-50C and the salt concentration in fish muscle is high then storage temperature has little effect on histamine formation. The level of histamine during pickle curing is significantly higher in pre-spawning batch than in the post spawning batch of herring. During pickle curing a portion of histamine leaches out from the fish to the brine.

In the pickled herring of Britain prepared by Northern Europe processing technique TVB-N levels in the fish increases rapidly during the first 3 months of storage but subsequently the rate of increase is very slow until the ripening is complete. TMA levels in the fish also gradually increase during ripening of pickled herring but the level is very low. The condition of fish (pre spawning or post spawning) and salt purity have little effect on the level of TVB-N and TMA-N, during ripening of pickle curing of herring fish. But the storage temperature has significant effect. Higher storage temperature results increased level of TVB-N and TMA in the fish during ripening of pickle cured herring. TVB-N and TMA-N of the pickled herring samples remained below MAL (<100mg/100g) which indicate good quality of the products.

With regard to safety aspects of the pickled herring of Britain prepared by Northern Europe processing technique the histamine level, TVB-N, TMA-N values indicate that the product is safe to eat. High NaCl content (10-21%) in the pickled herring of Britain does not allow bacterial activity and growth. This is because high salt content reduce the water activity (aw) considerably. Hence pickled herring is safe to eat. Although the histamine level is higher in the pickled herring prepared from pre-spawning samples still it remains below the Maximum Allowable Limit (<20mg/100g).

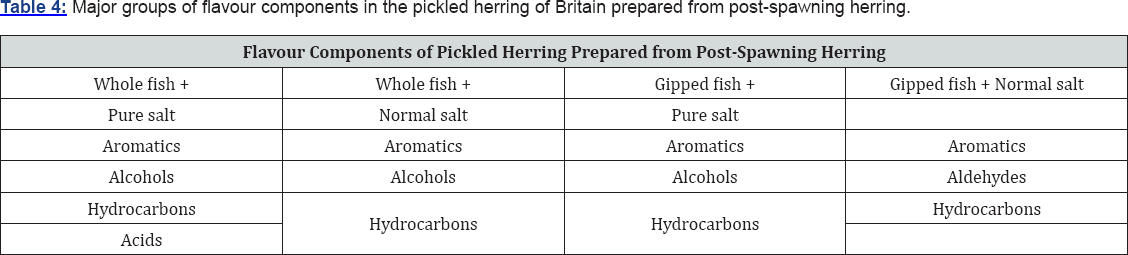

In pickled herring, flavour compounds are formed as a result of oxidative changes in lipid components. The major groups of the compounds were identified by GC-MS analysis. The major groups are aldehydes, volatile alcohols, aromatic compounds, hydrocarbons, some acids and a sugar derivative. The number of the flavour contributing volatile substance are much in the pickled herring prepared from pre spawning fish as compared to the post spawning fish. On sensory testing the pickled fish prepared from post spawning fish are found to lack characteristic ripened flavour. Gibbing and salt purity do not have any marked influence on the flavour compounds in the pickled herring.

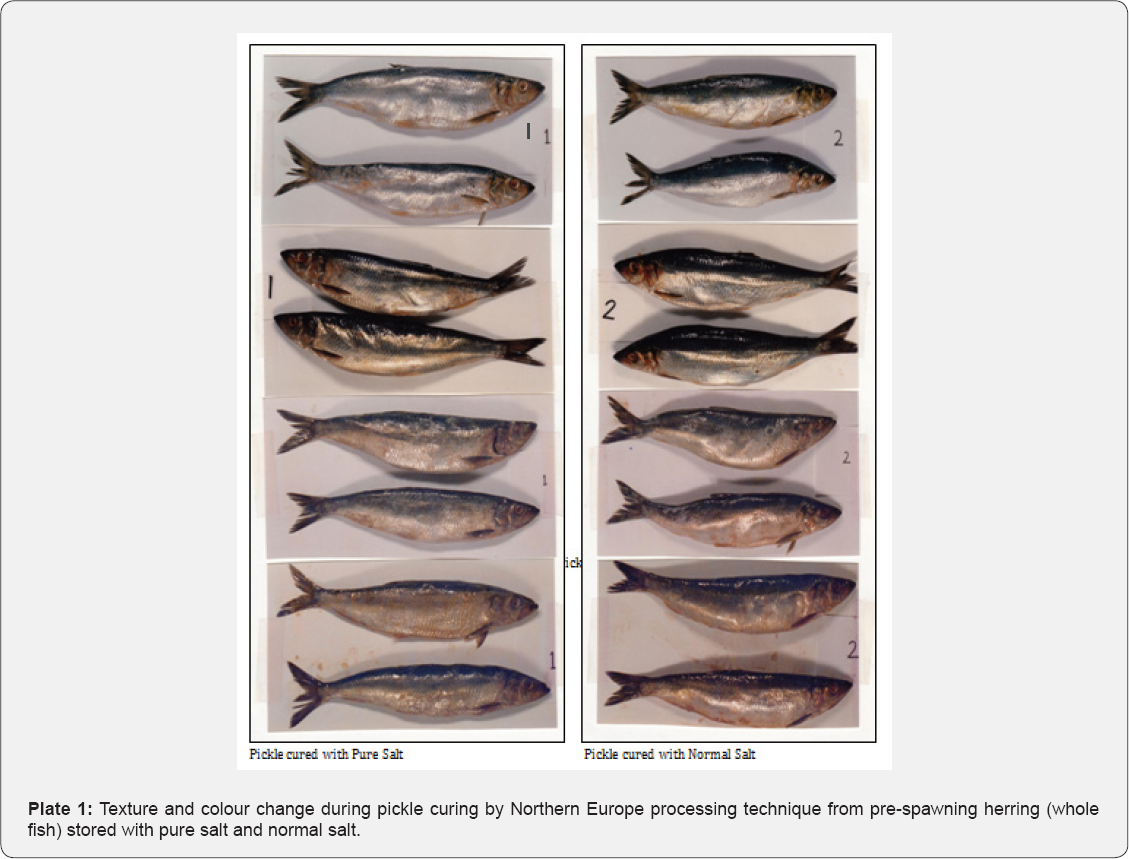

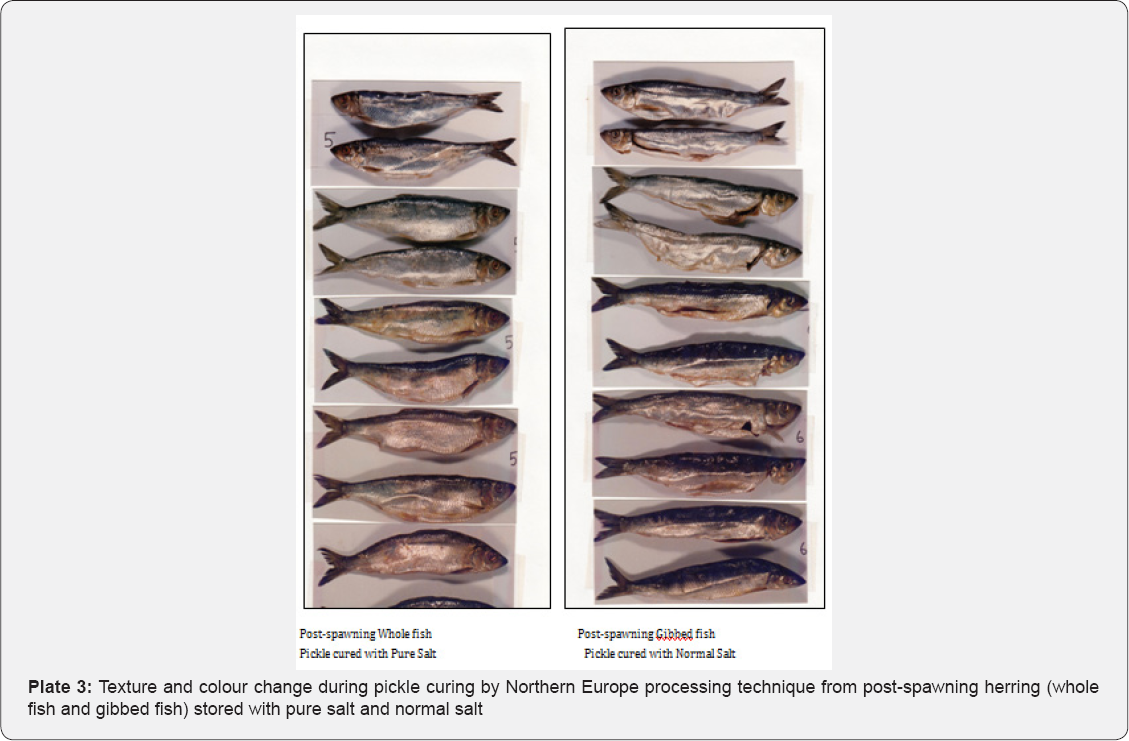

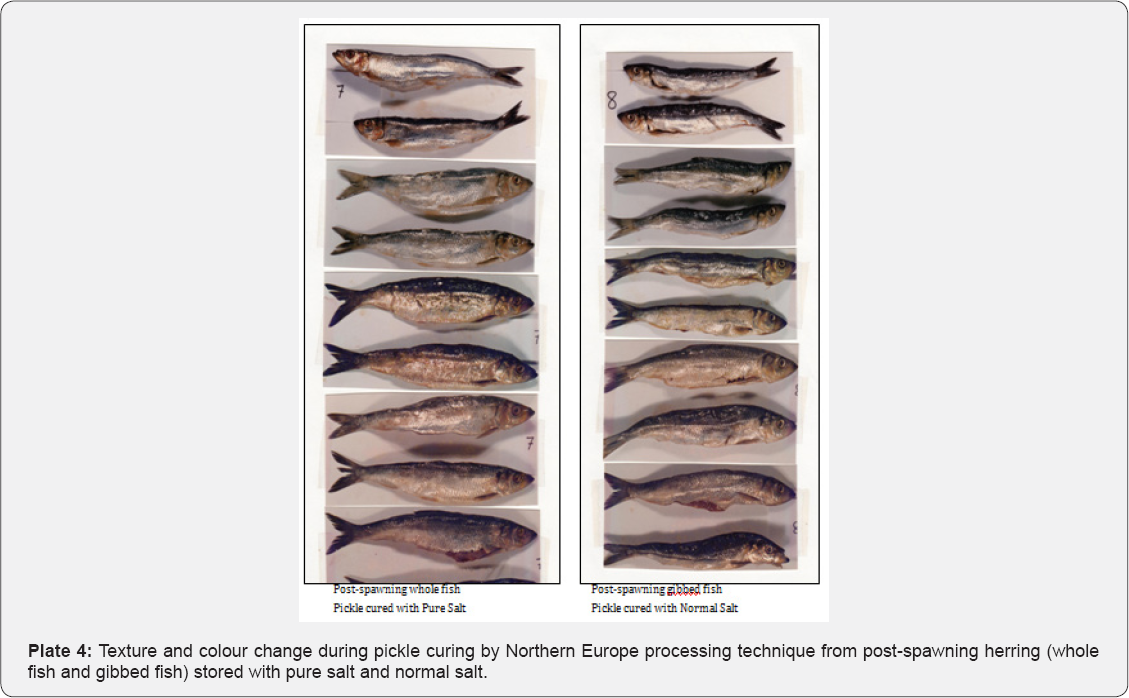

In spite of initial toughening the texture of the pickled herring become tender and lose elasticity compared to the texture of original raw fish. Whole fish samples attained better texture due to the presence of entire gut. The pickled herring prepared from pre-spawning batch attained more tendered muscle (texture) than those prepared from post-spawning herring. The pickled herring prepared from post-spawning herring normally shrunk and their shape is changed as compared to the pre-spawning samples (Plates 1-4). This was proved by instrumental analysis as well as sensory analysis of texture in the laboratory.

Colour formation on the fish skin and muscle during the ripening of pickle curing is influenced by the body composition/ spawning season, gibbing. Normally the fish skin attain yellow colour (Plates 1-4) whereas the muscle attain brown colour.

Factors Influencing the Rate of Pickle Curing

In Northern Europe processing technique the following factors influence the rate of ripening of pickled herring:

A. Storage temperature

B. Body composition/condition i.e. whether pre-spawning or post spawning

C. Presence or absence of gut.

Storage temperature: Elevated storage temperature reduces the ripening time. At 25° C the ripening time was 1.5 to 3 months as compared to 12-15 months at 0-5° C without giving rise to unacceptably high histamine levels provided that the salt equilibration is allowed to proceed at 0-5° C before high storage temperature exposure. But the sensory characteristics of the products ripened at 4° C and 25° C were different.

Body composition/condition: The ripening of pickle curing is influenced by the body composition i.e. spawning season of fish. The use of pre-spawning herring rather than post spawning herring is likely to produce a ripened product with typical desirable characteristics. The majority of the trends in the biochemical parameters showed significant differences between pre-spawning and post spawning batches of herring.

Presence or absence of gut: The ripening of pickle curing is also influenced by the presence or absence of the entire gut. Ripened pickle cured herring produced from whole fish possess better characteristic sensory properties (i.e. texture and flavour) than those produced from gibbed herring. Protein degredation is also higher in the whole fish which results the better sensory properties in the ripened herring produced from the whole fish. Salt purity do not appear to have any significant effect on the ripening process in general reinforcing literature observations that microbiological activity is of little importance in the ripening of heavily salted pelagic species. Increasing storage temperature reduces the ripening time considerably but the matured products, though equally acceptable, may be dissimilar; and the period the ripened product is at its optimum maturity is very short at higher temperature. Considering the safety aspect the pure salt should be used preferably Purified Manufactured Salt for pickle curing.

Conclusion

In Northern Europe processing technique pre-spawning whole fish produced better pickled product than the post spawning fish and gibbed fish. This pickled herring was better in terms of nutritional composition, sensory properties (colour, flavour, texture, taste), quality and safety. It is better to use pure salt preferably Purified Manufactured Salt for pickle curing.

Acknowledgement

This research was conducted as part of Ph.D. research of Dr. Md. Abul Mansur at International Fisheries Institute, University of Hull, England, UK as an ODA supported Ph.D. Fellowship of Britain. Partial financial support of EC AIR Project "Enzymatic ripening of pelagic species" (Project No. CT 93-1141) is also acknowledged. Preparation and supply of pickled herring was done by Denholm Sea Food Group, Alexander Buchan Ltd., Peterhead, Scotland, UK. Photographs of the fishes were taken in the Photographic Section of the Department of Applied Biology, School of Life Science, University of Hull, England, UK.

References

- Burgess GHO, Cutting CL, Lovern HA, Waterman JJ (1965) Salt Curing. In: Burgess GHO et al. (Eds.), Fish Handling and Processing. Her Majesty's Stationery Office, Edinburg, UK, pp. 102-119.

- Horner WFA (1992) Preservation of fish by curing. In: Hall GM (Ed.), Fish Processing Technology. Blackie Academic & Professional, Glassgow, UK, p. 31-71.

- Jarvis ND (1950) Curing of Fishery Products. Research Report 18. Fish and Wild life Service, US Govt. Printing Office. Washinton, DC, USA, pp. 146-159.

- Gram L (1991) Inhibition of mesophilic spoilage Aeromonas spp. on fish by salt, potassium sorbate, liquid smoke, and chilling. Journal of Food Protection 54(6): 435-442.

- SFIA (1991) Annual Report and Accounts 1990-91. Sea Fish Industry Authority, Edinburgh, Scotland, UK.

- AOAC (1980) Official Methods of Analysis. Association of the Official Analytical Chemists. (12th edn), Washington DC, USA.

- Hardy R, Smith JGM (1976) The storage of mackerel (Scomber scombrus). Development of histamine and rancidity. Journal of the Science of Food and Agriculture 27(7): 595-599.

- Eagan H, Kirk RS, Sawyer R (1981) Pearson's Chemical Analysis of Food. (8th edn). Churchill Livingstone, London, UK.

- Wood AC, Aurand LW (1977) Laboratory manual in Food Chemistry. Avi Publishing Co. Inc. Westport Connecticut, USA, pp. 22-23.

- Analytical Methods Committee (1979) Recommended General Methods for the Examination of Fish and Fish Products. Analyst 104: 434-450.

- Lie S (1973) The EBC-Ninhydrin method for determination of free alpha amino nitrogen. Journal of the Institute of Brewing 79(1): 37-41.

- Satake K, Okuyama T, Ohashi M, Shinoda T (1960) The spectrophotometric determination of amine, amino acid and peptide with 2,4,6-Trinitrobenzene 1-Sulfonic acid. Journal of Biochemistry 47(5): 654-660.

- Mansur MA (1995) Biochemical and Textural aspects of the ripening of pickled herring (Clupea harengus). Ph.D. Thesis. University of Hull, UK, England, pp. 229.

- Josephson DB, Lindsay RC, Stuiber DA (1987) Influence of processing on the volatile compounds characterizing the flavour of pickled fish. Journal of Food Science 52(1): 10-14.

- Stroud GD (1982) The Herring. Torry Advisory Note no. 57. Torry Research Station. Her Majesty's Stationery Office, Edinburgh, Scotland, UK, England.

- Mansur MA, Horner WFA (1997) Biochemical changes during the ripening of salt pickled herring (Clupea harengus) at tropical temperature and the influencing factors. Bangladesh Journal of Fisheries 20(1-2): 91-98.

- Mansur MA, Horner WFA (1998) Effect of salt on the level of histamine in preserved fish (herring Clupea harengus). Bangladesh Journal of Fisheries Research 2(1): 73-82.

- Mansur MA, Horner WFA (1998) Identification of flavour components in barrel salted herring (Clupea harengus) ripened at 4° C. Bangladesh Journal of Fisheries 21(2): 7-10.

- Mansur MA, WFA Horner (1998) Fat hydrolysis during the ripening of barrel salted herring at 0-5° C in polypropylene barrels. Progressive Agriculture 9(1-2): 251-255.

- Mansur MA, Horner WFA (1999) Effect of gibbing on protein hydrolysis during the ripening of salted herring at 40C in polypropylene barrels. Bangladesh Journal of Fisheries Research 3(1): 95-101.

- Mansur MA, Horner WFA (1999) Volatile aroma components of barrel salted herring at low temperature (0-5° C). Bangladesh Journal of Fisheries 22(1): 59-70.

- Mansur MA, Horner WFA (1999) Monitoring texture during ripening of salt herring (Clupea harengus) using data from stress-relaxation tests. Bangladesh Journal of Fisheries 22(1): 99-106.

- Mansur MA, Horner WFA (1999) Diffusion of protein, histamine and colour pigment in brine/pickle during the ripening of barrel salted herring (Clupea harengus) at low temperature (40C) and the influencing factors. Bangladesh Journal of Fisheries 22(2): 41-47.

- Orejana FM, Liston J (1982) Agents of proteolysis and its inhibition in patis (fish sauce) fermentation. Journal of Food Science 47(1): 198203.