Teamwork in Implantology: The Dental Technicianís Role in Immediate Load Using BGBAR Technique

Marco Bardelli1*, Oana Dinculescu2, and Andrea Mascolo3

1Intra Lab Dental Technologies Lab Europe, AREZZO - ITALY

2EIMS H.E.I. Malta

3UFP Portugal, EIMS H.E.I. Malta

Submission: April 04, 2018; Published: April 17, 2018

*Corresponding author: Marco Bardelli, International Lecturer, Intra Lab Dental Technologies Lab Europe, AREZZO - ITALY, Email: ibardelli@alice.it

How to cite this article: Bardelli M.,Dinculescu O., Mascolo A. Teamwork in Implantology: The Dental Technicianís Role in Immediate Load Using BGBAR Technique. Open Access J Surg. 2018; 8(5): 555747.DOI:10.19080/OAJS.2018.08.555747

Abstract

The short communication introduces the teamwork advantages in implantology through the presentation of a simplified and easily reproducible prosthetic technique that facilitates immediate load procedure in implantology.

Communication

The authors briefly explore the teamwork in implantology through two techniques that synergistically could produce high success rate in immediate loading procedures. The immediate loading concept includes all the advantages of one stage surgical procedures appreciated both for clinicians and patients. The immediate loading has become a predictable technique in implantology with specific indications in selected patients [13]. The biological key factors to consider for osseointegration to occur with immediate loading: factors affecting osteogenesis (bone formation); factors affecting peri-implant osteolysis (bone resorption); and micro-motion effects on peri-implant osteogenesis [4].

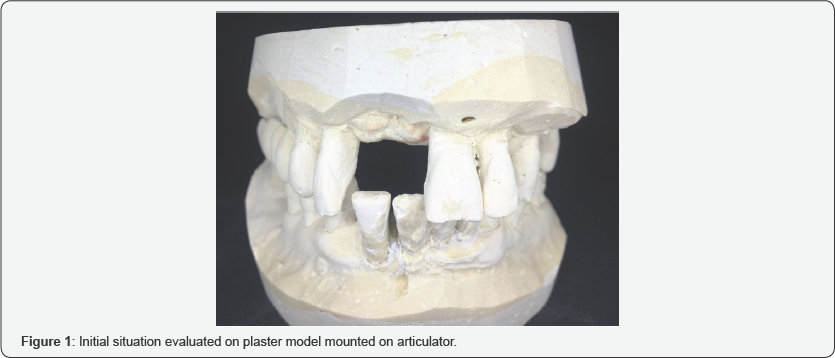

Osteogenesis is time dependent so the maintenance of implant stability is critical; the initial stability of the implant reduces in the first 3-6 weeks after placement due to remodeling and an increased ratio of woven to lamellar bone. The implant bone interface thus becomes more susceptible to the micro motion effects. The threshold at which osteogenesis will be detrimentally affected is generally considered to be 150μm (Figure 1). Clinically this can be minimized with rigid splinting of implants where applicable and the reduction of occlusal load [4,5]. The "Flat One Bridge" developed by Intra-lock International (Boca Raton, FL, USA) during the last years is a innovative immediate loading technique; The concept of this approach allows the creation of a final full- arch bridge within 72 hours from the surgical procedure [6].

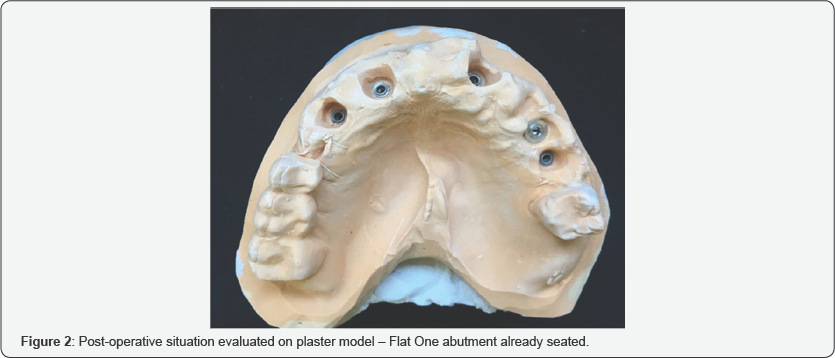

Implants with an improved nanorough low Calcium impregnated surface (Ossean) and specific designs are adapted to this immediate loading application [7]; the particularity of the treatment strategy with flat One Bridge is the use of the flat abutments. Connected to each implants, they allowed to correct immediately and definitively the problems of implant axis prior to the preparation of the implant-supported prosthesis (Figure 2).Flat One® Abutments have a flat occlusal table. This flat surface mates precisely with the cylinders in the prosthetic framework ensuring that the load of the restoration is supported by a wide, flat platform. This provides greater strength to the prosthetic system in contrast to conventional two-piece abutments that rely on a retaining screw for support. The strong metal framework enables early delivery of the prosthesis. This acts as a surgical splint and provides stabilization for the implants, especially during the healing phase. Passive fit (synonymous with "ideal fit") of the framework is assumed to be one of the most significant prerequisites for the maintenance of the bone- implant interface.

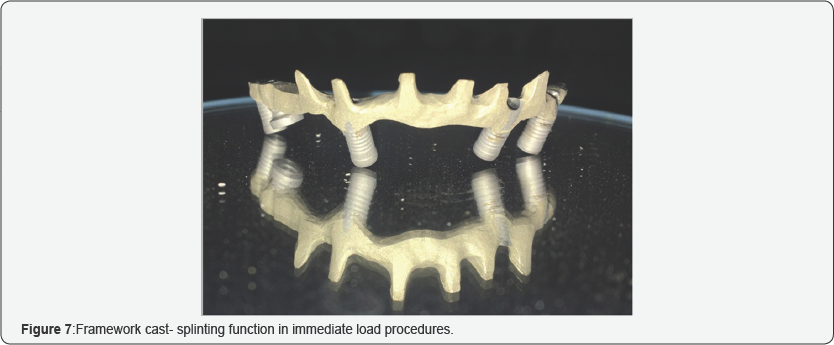

The rigid framework prevents implants micro-motion [8] and promotes primary stability and appropriate distribution of occlusal forces, since these are transmitted to the implants immediately after installation of the prosthesis. The BGAAR® Brazing Girder Bar is the junction of two metal abutments both noble and steel (chrome-cobalt) made only and exclusively with brazing material. (Mono-fusion) The framework (cast) or joining beam between two abutments is made only with the brazing material without the aid or aid of a rod or metal bar or cylinder (cobalt chromium) or noble alloy or other alloys commercially available including titanium. The "bar" length can be from few mm to some cm depending on the prosthetic restoration to be made with a variable diameter according to the technical requirements and performed only and exclusively with the brazing material; the breaking point of the brazing bar is 450N per mm q (Figure 3).

BGBAR Technical Execution Steps

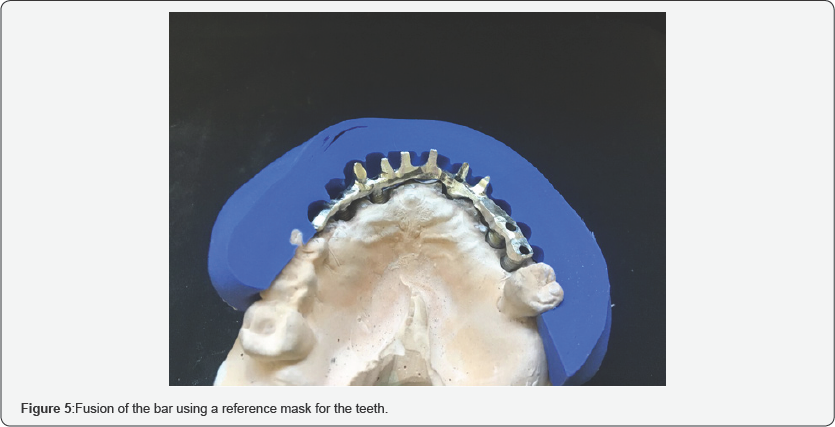

The two surfaces to be joined are heated; when the wire is fluid enters into the joint gaps and mixes with the surfaces splice by capillary diffusion. In order to braze a joint, it must be accessible only from one site; the thin fissure between the two components acts as a capillary (capillarity). The fluid thread is sucked into the slot. The girder is performed by heating the brazing wire (BGBAR® 2A Medical Device wands marketed by the exclusive Intra-lock Europa SPA supplier) at a temperature below the melting point in order to connect the two abutments. This passage is carried out several times between the two abutments (Figure 4).

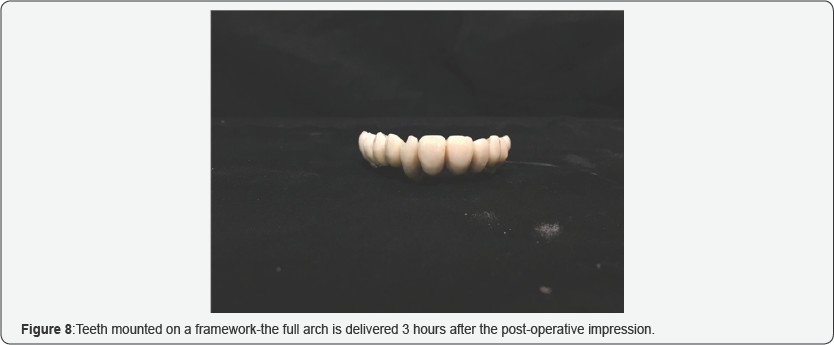

The framework can be simply executed on the master model thanks to the relatively low execution temperature and to the micro flame. This technique greatly influences both costs and execution times, considerably reducing the delivery time of the prosthetic device (Figure 7) .This technique has a delivery of 2/3 hours for the full arch and about 1/2 hours on the sectoral frameworks. An interesting technical consideration is related to the request of some clinicians to splint new fixtures with other existing implants (Figure 8). The Brazing Girder Bar offers a quick and inexpensive solution without losing the framework passivation requested in obtaining a long term clinical result. The proposed prosthetic protocol has evaluated with a 10 years follow-up recording 100% success rates.

References

- Lambert FE, Weber HP, Susarla SM, Belser UC, Gallucci GO (2009) Descriptive analysis of implant and prosthodontic survival rates with fixed implant-supported rehabilitations in the edentulous maxilla. J Periodontol 80(8): 1220-1230.

- Esposito M, Grusovin MG, Willings M, Coulthard P, Worthington HV (2007) The effectiveness of immediate, early, and conventional loading of dental implants: a Cochrane systematic review of randomized controlled clinical trials. Int J Oral Maxillofac Implants 22(6): 893-904.

- Ostman PO (2008) Immediate/early loading of dental implants. Clinical documentation and presentation of a treatment concept. Periodontol 47: 90-112.

- Cooper LF, De Kok IJ, Rojas Vizcaya F, Pungpapong P, Chang SH (2007) Immediate loading of dental implants. Compend Contin Educ Dent 28: 216-225.

- Nkenke E, Fenner M (2006) Indications for immediate loading of implants and implant success. Clin Oral Implants Res 2: 19-34.

- Covani U, Orlando B, D'Ambrosio A, Sabattini VB, Barone A (2012) immediate rehabilitation of completely edentulous jaws with fixed prostheses supported by implants placed into fresh extraction sockets and in healed sites: a 4-year clinical evaluation. Implant Dent 21(4): 272-279.

- Bucci Sabattini V, Cassinelli C, Coelho PG, Minnici A, Trani A, et al. (2010) Effect of titanium implant surface nanoroughness and calcium phosphate low impregnation on bone cell activity in vitro. Oral Surg Oral Med Oral Pathol Oral Radiol Endod 109(2): 217-224.

- Minsk L, Rose LF (2003) Compendium of Continuing Education in Dentistry 24(5): 349-354.