Effects of Particle Size, Soybean Oil and Water Content during Cooking on the In Vitro Resistant Starch of Cornmeal

Kelly C Massarolo1*, Cláudia F J Ferreira1, Larine Kupski2 and Eliana Badiale-Furlong1

1Laboratório de Micotoxinas e Ciência de Alimentos, Universidade Federal do Rio Grande- FURG, Brasil

2Laboratório de Análises de CompostosOrgânicos e Metais, Universidade Federal do Rio Grande -FURG, Brasil

Submission: May 11, 2018;Published: July 05, 2018

*Corresponding author: Kelly Cristina Massarolo, Laboratório de Micotoxinas e Ciência de Alimentos, Escola de Química e Alimentos, Universidade Federal do Rio Grande - FURG, Avenida Itália km 8, Campus Carreiros, Rio Grande, RS, Brasil, Tel: +55 5332336796; Email: kelly_massa@hotmail.com

How to cite this article:Kelly C M, Cláudia F J F, Larine K, Eliana B F. Effects of Particle Size, Soybean Oil and Water Content during Cooking on the In VitroResistant Starch of Cornmeal. Nutri Food Sci Int J. 2018; 7(1): 555703. DOI:10.19080/NFSIJ.2018.07.555703.

Abstract

Resistant starch has attracted interest due to conferring functional properties to foods. Cornmeal is consumed after being submitted to some processing and preparation, which can affect the resistant starch content in the final product. The aim of this work was to find the interference of cornmeal’s particle size on resistant starch content and to establish the conditions of cooking that promote the highest resistant starch content when preparing cornmeal based foods, such as cornmeal:water proportion and the amount of soybean oil used. To achieve the aim, the in vitro starch digestibility of hydrothermal treated cornmeals was evaluated by experimental design CCD 22, carried in order to optimize the cornmeal:water proportion and the amount of soybean oil conditions that promote the major resistant starch formation. The best condition of hydrothermal treatment was applied in cornmeals with different particle sizes. The fine-ground cornmeal showed the highest resistant starch content (201.6mg/g). Applying hydrothermal treatment in the cornmeal:water proportion of 1:5w/v and 3% of soybean oil, the content of resistant starch has increased significantly (21.9%). Under these conditions, the resistant starch content was increased 39.8% and 45.4% for medium-ground and coarse-ground cornmeals, respectively. These findings can inspire other studies with different cooking conditions and starch and other ingredients interactions during processing, to obtain starch-based foods with lower glycemic inde

Keywords: Amylose-lipid complex; Digestibility; Hydrothermal treatment; Cornmeals; Soybean oil; Corn (Zea mays);

Abbreviations: RS: Resistant starch; CCD: Central Composite design

Introduction

Corn (Zea mays) is used for human nutrition due to its specific physicochemical properties, such as high levels of starch, proteins with low levels of gliadin fraction, gluten free, dietary lipids, hypoallergenics, phytochemicals, dietary fiber and a delicate flavor [1].

The use of cornmeals has been increased by the demand to produce gluten free products, a protein found in the endosperm of some cereals such as wheat, barley and rye [2], which can cause harm to health, in some individuals in population. Cornmeals are obtained by corn milling processes [3] and have different particle sizes, that can affect physicochemical characteristics and the product quality [4,5].

The main cornmeal component is starch [6], which digestibility is modified by hydrothermal treatment [7]. Starch digestion and absorption are crucial for the control of blood sugar levels in metabolic disorders [8]. Therefore, resistant starches to digestive enzymes have been recommended for diets that prevent the damage of the syndrome.

Resistant starch is not digested in the small intestine, it goes to the large intestine where it is fermented by bacterial microflora [9]. Its content in food is related to properties such as amylose content [9,10], amylopectin branch chain length [11], amylose/amylopectin ratio [12], processing conditions such as milling, fermentation, quantity of water, time and temperature storage and its interactions with other compounds in food [9,13].

Studies shown that extrusion cooking process increases the resistant starch content in foods, with positive correlation with humidity, storage time [14] and amylose/amylopectin ratio [12]; hydrothermal treatment of corn starch also promotes formation of resistant starch [7], particularly when preformed with lipid addition associated to high moisture contents [15].

Interactions between starch and other compounds such as lipids have been in focus of researches due to their impacts on food properties and nutrition [15,16], as starch-lipid complexes and other similar compounds shown resistance to hydrolysis by amylases [17,18].

There is an interest on developing products with low glycemic index carbohydrates. In this context, resistant starch emerges as an alternative to reduce energy availability, therefore, the increase on its contents in food promotes benefits on health and on food functional properties [19]. Preparation of foods with higher resistant starch contents from cornmeals is important, therefore the aim of this work was to verify the cornmeal particle size (fine, medium and coarse), moisture conditions and amount of soybean oil that promotes a higher content of resistant starch during food preparation from cornmeals.

Materials and Methods

Reagents and samples

Cornmeals with different particle sizes (fine, medium and coarse) and soybean oil where obtained on Rio Grande - RS, Brazil’s local market. Fungal alpha-amylase enzyme (30U/mg) produced by Aspergillus oryzae was obtained from Novozymes Corp., Sigma-Aldrich Co., Switzerland, fungal protease enzyme (500U/g) produced by Aspergillus oryzae was obtained from Novozymes Corp., Sigma-Aldrich Co., Denmark and fungal amyloglucosidase enzyme (6U/mL) produced by Aspergillus niger was obtained from Sigma-Aldrich Co., Germany.

Cornmeals characterization

Particle-size distribution of fine, medium and coarse grounded cornmeals was determined using sieve openings of 0,71; 0,50; 0,35; 0,25 e 0,14mm. Composition was determined by protein, ash and lipid content, according to AOAC methods [20].

Amylose content was determined according to colorimetric method by Martinez and Cuevas [21], with adaptations. Extraction of cornmeal’s amylose was performed with ethyl alcohol 95% (v/v) and NaOH 1M solution. Colorimetric reaction was performed with iodine 2% solution (w/v) and the amylose content was determined using amylose standard curve (4- 24μg/mL) in a spectrophotometer with a wavelength of 620nm.

The total starch content of the solution of each gelatinized sample was determined by iodometry and the starch-iodine complex was quantified in a spectrophotometer at 620nm using a starch standard curve (0.05-0.21mg/mL) [22]. Amylopectin was estimated by the difference between total starch and amylose.

Experimental design to study the effect of the addition of soybean oil and water on the RS formation during hydrothermal treatment

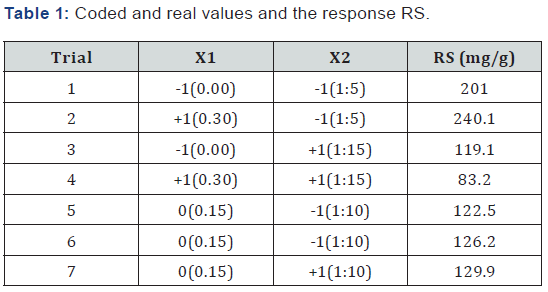

The hydrothermal treatment was performed by electric plate cooking, according to Giacomelli et al. [23]. The fine cornmeal was added in boiling water with salt (1%) and homogenized until the end of the treatment. The electric plate temperature was maintained at 120 °C for 40 min. The variables cornmeal:water proportion and amount of soybean oil were defined by CCD 22 (Table 1), with the RS content as the response variable.

X1:Soybean oil amount (g); X2: Proportion of cornmeal:water

Resistant and available starch

The determination of available and RS was performed according to AOAC method 996.11 modified by Walter, Silva and Perdomo [24]. The in vitro method quantifies the RS after the removal of starch digestible fraction by enzymatic treatment, simulating the hydrolysis that occurs in the digestive tract (mouth, stomach and small intestine), with α amylase, protease and amyloglucosidase enzymes. The remaining starch (resistant) was solubilized with dimethylsulfoxide and again hydrolyzed by amylolytic enzymes

The determination of the starch fractions (available and resistant) after hydrolysis was performed by quantifying the glucose released in each step using the 3,5 dinitrosalicylic acid (DNS) reduction [25] and using a conversion factor of 0.9, to convert free glucose into starch.

Statistical analysis

Data analysis of variance (ANOVA), followed by Tukey Mean-Difference test, were performed in Statistica 6.0 program. Differences with probability value of p<0.05 were considered significantly.

Results and Discussion

Cornmeal characterization

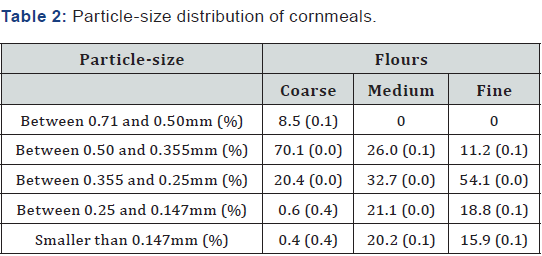

The particle-size distribution for the 3 types of cornmeals is as described on the packaging by the supplier. The coarse grounded presented 78.6% of the particles larger than 0.35 mm, the medium had 58.7% of the particles with sizes between 0.25 and 0.50 mm and the fine 88.8% of the particles smaller than 0.35 mm (Table 2).

Results expressed as mean (RSD) n=3. RSD= relative standard deviation.

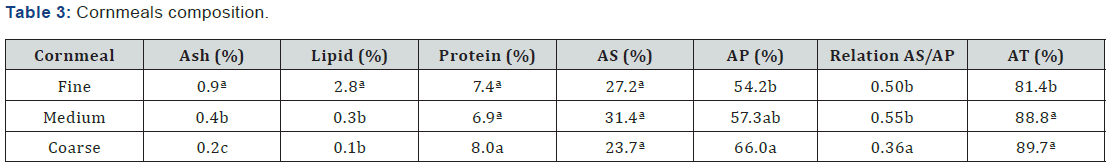

In addition to the difference in particle size, cornmeals present a difference in its composition. The fine cornmeal had a higher content of ash (0.9%) and lipids (2.8%) when compared to other cornmeals (Table 3).

Results expressed as mean (n=3). Different superscript letters in the same column indicate significant differences (p<0.05). AS=amylose, AP=amylopectin, AT=total starch

There is no significant difference (p> 0.05) in the protein content of the cornmeals, in the study by Shi et al. [4] similar results were verified since the milling process does not affect the primary structure and the protein content in cornmeal.

The coarse cornmeal has the highest content of amylopectin (66.0%). The same cornmeal had the lowest amylose/amylopectin ratio (0.36), the medium cornmeal had the highest value (0.55), followed by the fine cornmeal (0.50). The amylose/amylopectin ratio in the cornmeal composition may contribute to changes in RS content [12]. In this way, the fine and medium cornmeal, because of the higher amylose/ amylopectin ratio, have a higher potential to form a higher RS content.

Optimization of the hydrothermal treatment for RS formation

The results of RS in the CCD for the 2 variables under study (soybean oil amount, and proportion of cornmeal:water) are shown in (Table 1).

In this design, the RS content ranged from 83.2 to 240.1mg/g, however the best result for the RS was found in trial 2, which showed less proportional cormeal:water, at level -1 (1:5) and more soybean oil amount at level +1 (0.3g).

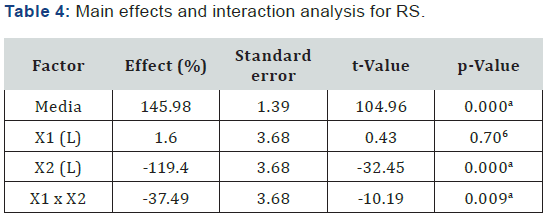

asignificant factor p<0.05. X1: Soybean oil amount (g); X2: Proportion cornmeal:water.

The proportional cornmeal:water was found to be the most relevant variable for RS content (Table 4). The RS content decreased on an average of 119.4% by increasing the proportional cornmeal:water from 1:5 to 1:15. The combined effect of soybean oil amount and proportional cornmeal:water resulted in an average decrease of 37.5% in the RS. The soybean oil amount did not present any significant effect (p>0.05) (Table 4).

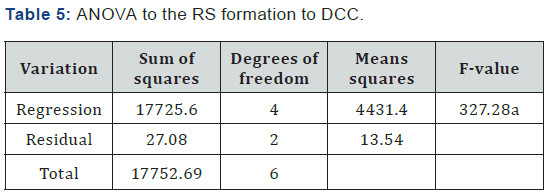

A variance analysis (ANOVA) was performed using the significant effects only (Table 5)

Regression coefficients= 0.88; F0.95; 4; 2=19.25; aF-value (regression/residual).

Based on the F-test, the model is predictive, since its Fcalculated (327.28) was greater than Ftabled (19.25); and significant, once the regression coefficient (0.88) is close to unity. The coded model was used to generate the contour diagram (Figure 1).

RS mg / g =145.98 −119.40X2 − 37.49X1 .X2 Equation 1

The greater values of the significant variables were not determined (X2 and interaction X1 and X2) because there is no possibility to reduce water in the hydrothermal treatment, which simulates the cornmeal domestic cooking process. Therefore, the proportion of cornmeal:water was defined as 1:5 and soybean oil amount 3%.

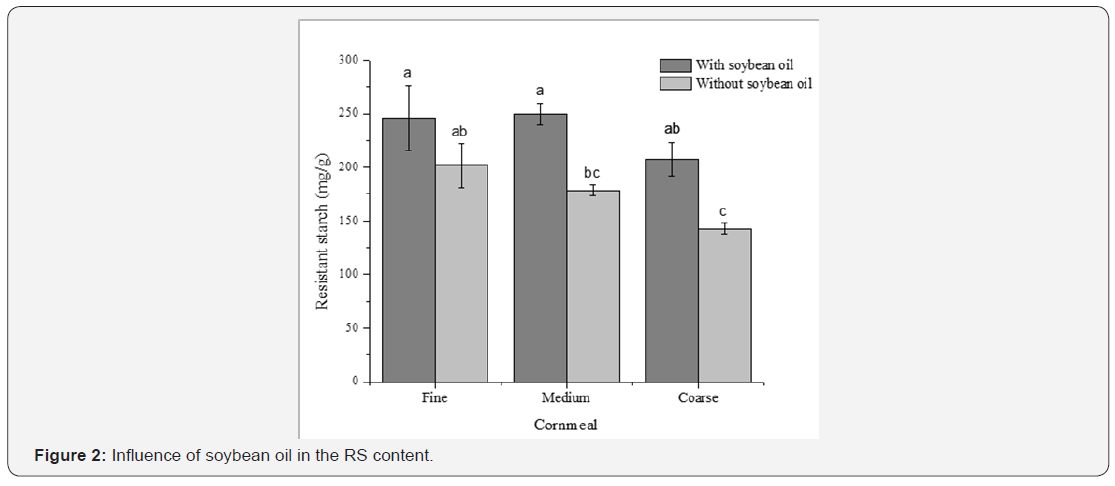

These hydrothermal treatment conditions were applied for the 3 cornmeals (fine, medium and coarse) and also treatment without oil were realized to evaluate the soybean oil addition effect on the RS content. Factor analysis showed that both the oil addition and cornmeal particle size had a significant difference (p<0.05). When the treatment without oil was carried out, the fine cornmeal showed higher RS content (201.6 mg/g) and the coarse cornmeal lower content (142.7mg/g) (Figure 2).

Lower digestibility of starch with smaller particles (greater RS) was also verified in the study by Guo et al. [26], in which the in vitro starch digestibility from milled durum wheat grains with different particle sizes was evaluated. In it, the digestibility was greater for the cooked flour with larger granules (0.25-0.50mm) than for the flours with smaller particle sizes (0.15-0.25mm and less than 0.15mm). Therefore, higher interactions between the components of the cornmeal during heating occur in flours with the smaller particle size [26].

Besides the particle size, the fine cornmeal composition may contribute to the higher RS content, since this cornmeal had higher lipid content (Table 2) that can interact with the starch during the hydrothermal treatment and form an amylose-lipid complex, forming RS type 5.Figure 2

For the 3 cornmeals, the highest RS content was verified in the treatment with oil addition (Figure 2), with higher content of RS to fine cornmeal (245.7mg/g) and medium (249.3mg/g) and lowest to coarse (207.5 mg/g), increases were 21.9%, 39.8% and 45.4%, respectively.

A study with different food lipids (triglycerides, phospholipids and free fatty acids of different chain-lengths and numbers of double bonds) showed that all lipids, after cooking with starches, promoted a significant decrease in starch hydrolysis, except for corn starches waxy low amylose [27]. In the study by Chen et al. [15] the addition of corn oil and soy protein decreased the rapidly digestible starch content and increased the sum of the slowly digestible starch and RS content. It has been demonstrated that the physical barrier of corn oil, amylose-lipid complex and protein-starch matrix can promote resistance to starch digestion [15,17]. This fact can be interesting for the elaboration of food products with reduced glycemic content.

Conclusion

The cornmeal particle size interferes in the RS content, however the proportion cornmeal:water was the variable more relevant, followed by combined effect of oil amount and proportion cornmeal:water. All cornmeals, after hydrothermal treatment with soybean oil, showed an increase in the RS content in the final product, it can be associated the production of RS type 5. The interaction between starch and oil may contribute to obtaining carbohydrate-based food with low glycemic index.

Acknowledgement

The authors acknowledge the support of Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES, Brazil), Conselho Nacional de Desenvolvimen to Científico e Tecnológico (CNPq, Brazil) and Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (FAPERGS, Brazil).

References

- Wójtowicz A, Kolasa A, Mościcki L (2013) Influence of buckwheat addition on physical properties, texture and sensory characteristics of extruded corn snacks. Polish J of Food and Nutr Sciences 63(4): 239- 244.

- De la Hera E, Talegón M, Caballero P, Gómez M (2013) Influence of maize flour particle size on gluten-free breadmaking. Journal of the Science of Food and Agriculture 93(4): 924-932.

- Rausch KD, Pruiett LE, Wang P, Li Xu, Ronald LB, et al. (2009) Laboratory measurement of yield and composition of dry-milled corn fractions using a shortened, single-stage tempering procedure. Cereal Chemistry 86(4): 434-438.

- Shi L, Li W, Sun J, Qiua Y, Wei X, et al. (2016) Grinding of maize: The effects of fine grinding on compositional, functional and physicochemical properties of maize flour. Journal of Cereal Science 68: 25-30.

- Bolade MK, Adeyemi IA, Ogunsua AO (2009) Influence of particle size fractions on the physicochemical properties of maize flour and textural characteristics of a maize-based nonfermented food gel. International Journal of Food Science and Technology 44(3): 646-655.

- Somavat P, Li Q, de Mejia EG, Liu W, Singh V, et al. (2016) Coproduct yield comparisons of purple, blue and yellow dent corn for various milling processes. Industrial Crops and Products 87: 266-272.

- Chung HJ, Liu Q, Hoover R (2009) Impact of annealing and heatmoisture treatment on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydrate Polymers 75(3): 436-447.

- Wolever TMS, Mehling C (2002) High-carbohydrate-low-glycaemic index dietary advice improves glucose disposition index in subjects with impaired glucose tolerance. Br J Nutr 87(5): 477-487.

- Sajilata MG, Singhal RS, Kulkarni PR (2006) Starch - A Review. Comprehensive reviews in food science and food safety5(1):1-17.

- Hsu RJC, Lu S, Chang YH, Chiang W (2015) Effects of added water and retrogradation on starch digestibility of cooked rice flours with different amylose content. Journal of Cereal Science 61: 1-7.

- Jane J, Ao Z, Duvick SA, Wiklund M, Yoo S, et al. (2003) Structures of amylopectin and starch granules: How are they synthesized? Journal of Applied Glycoscience 50(2): 167-172.

- Li Y, Zhang AR, Luo HF, Wei H, Zhou Z, et al. (2015) In vitro and in vivo digestibility of corn starch for weaned pigs: Effects of amylose:amylopectin ratio, extrusion, storage duration, and enzyme supplementation. Journal of animal science 93(7): 3512-3520.

- StuteR(1992) Hydrothermal Modification of Starches: The Difference between Annealing and Heat/Moisture ‐Treatment. Starch ‐ Stärke 44(6): 205-214.

- Kim JH, Tanhehco EJ, Ng PKW (2006) Effect of extrusion conditions on resistant starch formation from pastry wheat flour. Food Chemistry 99(4): 718-723.

- Chen X, He XW, Zhang B, Fu X, Jane JL, et al (2017) Effects of adding corn oil and soy protein to corn starch on the physicochemical and digestive properties of the starch. International Journal of Biological Macromolecules 104(pt A): 481-486.

- Zhu F (2015) Interactions between starch and phenolic compound. Trends in Food Science and Technology 43(2): 129-143.

- Seneviratne HD, Biliaderis CG (1991) Action of α-amylases on amyloselipid complex superstructures. Journal of Cereal Science 13(2): 129- 143.

- Karunaratne R, Zhu F (2016) Physicochemical interactions of maize starch with ferulic acid. Food Chemistry 199:372-379.

- Zhang H, Jin Z (2011) Preparation of products rich in resistant starch from maize starch by an enzymatic method. Carbohydrate Polymers 86(4): 1610-1614

- AOAC (2000) Official Methods of Analysis of AOAC International. Association of Official Analysis Chemists International Method ce, pp. 2-66.

- MartinézC, Cuevas F(1989) Evaluacion de la calidadculinaria y molinera del arroz.

- Garda-Buffon J, Baraj E, Badiale-Furlong E (2010) Effect of Deoxynivalenol and T-2 toxin in malt amylase activity. Brazilian Archives of Biology and Technology 53(3): 505-511.

- Giacomelli D, Monego B, DelagustinMG, de Borba MM,Ricalde SR, et al. (2012) Composiçãonutricional das farinhas de milhopré-cozida, moídaàpedra e da preparaçãoculinária polenta. AlimNutr 23(3): 415- 420.

- Walter M, Silva LP Da, Perdomo DMX (2005) Amidodisponível e resistenteemalimentos: adaptação do método da AOAC 996.11. Alimentos e NutriçãoAraraquara 16(1):39-43.

- Miller GL(1959) Use of DinitrosaIicyIic Acid Reagent for Determination of Reducing Sugar. Analytical Chemistry 31(3): 426-428.

- Guo P, Yu J, Wang S, Wang S, Copeland L, et al. (2017) Effects of particle size and water content during cooking on the physicochemical properties and in vitro starch digestibility of milled durum wheat grains. Food Hydrocolloids 77: 445-453.

- Ai Y, Hasjim J, Jane JL (2013) Effects of lipids on enzymatic hydrolysis and physical properties of starch. Carbohydrate Polymers 92(1): 120- 127.