Effect of Taro Flour Addition on the Functional and Physiochemical Properties of Wheat Flour and Dough for the Processing of Bread

Md Bellal Hossain*

Department of Nutrition and Food Engineering, Daffodil International University, Bangladesh

Submission: March 27, 2016; Published: June 20, 2016

*Corresponding author: Md Bellal Hossain; Department of Nutrition and Food Engineering, Daffodil International University, Bangladesh, Tel: 8801680378493; Email: drbellal@daffodilvarsity.edu.bd

How to cite this article: Md Bellal H. Effect of Taro Flour Addition on the Functional and Physiochemical Properties of Wheat Flour and Dough for the Processing of Bread. Nutri Food Sci Int J. 2016; 1(2): 555556. DOI: 10.19080/NFSIJ.2016.01.555556

Abstract

Taro is a plant widely produced in tropical areas for its underground corms. In connection with this, the incorporation of taro flour into wheat-based products has been reported to increase their keeping quality. Before consideration is given to taro flour as a substitute for wheat in bread manufacture, it is necessary to characterize the functionality of the composite flour and dough. The physiochemical properties of taro-wheat flour mixed dough were WAC, WSC, OAC and RI of 10%, 20% and 30% (w/w) respectively. The results showed that WAC significantly increased from 130% (wheat flour) to 290% (30% composite flour), while RI significantly decreased from 32% to a mean value of 10%. Principal component analysis revealed that WAC and OAC formed a group of variables negatively correlated with a second group made of RI. This outcome suggested that in order to guarantee the quality of bread made from wheat–taro composite the level of taro addition should not exceed 10%. The present study investigated the physicochemical properties of wheat–taro composite flour for commercial bread production.

Keywords: Taro; Flour; Dough; WAC; OAC; RI

Introduction

Taro is a plant widely produced in tropical areas for its underground corms. Taro roots contain a wealth of organic compounds, minerals, and vitamins that are essential for human health and can benefit our overall health in a number of different ways. It contains significant amount of dietary fiber and carbohydrates, as well as high levels of vitamin A, C, E, B6, and foliate, as well as magnesium, iron, zinc, phosphorous, potassium, manganese, and copper as trace elements. Taro also provides some protein, but the amount is almost negligible as compared with wheat flour in food production areas [1]. Taro root is mainly consumed by athletes for long lasting energy. This is because it contains a low glycaemic index which is good for athletes to reduce fatigue; One cup of cooked taro can give 187 calories energy which may loss body weight; Taro fiber gives the feeling of being full for a longer time even after a small meal i.e., increase digestion for clear stomach. Taro roots can give 19% of the daily required Vitamin E that is required to prevent the risks of a heart attack; it is low glycaemic properties and acts as anti aging agent due to trace element rich sources . A few varieties of Bangladesh having good amount of vitamin A with poly phenol compounds which are great antioxidants to protect even from cancer [2].

Taro corms are highly perishable owing to their high moisture content. In order to limit post-harvest losses and improve the production and consumption, production and utilization of taro flour have been envisaged. In connection with this, the incorporation of taro flour into wheat-based products has been reported to increase their keeping quality. Given these characteristics, taro flour has much potential for use in food formulations. Indeed, taro has been shown to be an important ingredient in the production of beverages and for partial replacement of wheat flour in bread, cookies, taro-based desserts and miscellaneous taro-based products [3-5].

There is thus generally thought to be much potential for the partial substitution of wheat flour with taro in order to diversify and upgrade taro use in non wheat- producing countries. However, although the incorporation of taro flour into wheat-based products has been reported to increase their keeping quality. It is evident that much care has to be exercised in the combination of ingredients in the composite flours so as to guarantee the quality of the product made from them. Studies carried out so far on the replacement of wheat flour with taro flour have concentrated only on the physical quality of the end product [3].

Rita Elsie Sinful [6] resulted that bread with 30 percent taro flour had the highest rating in color while the bread with 50 percent taro flour had the highest rating in texture among a group of selected panelists. And assumed the preference of the panelists for the sensory attributes of the wheat flour bread may be due to the familiarization of consumers to the normal whole wheat flour. Afar Octal [7] showed that substitution of wheat flour with taro flour slightly decreased protein, fat and phosphorus contents, while increased calcium, potassium and fiber content of weaning food formula. Dough properties are important factors influencing the quality of bread made from it. Knowledge of the effect of varying levels of incorporation of taro flour on wheat dough characteristics can thus be used for optimizing replacement of wheat with taro flour without significant modifications of the properties of the dough. Such information would open up real opportunities for greater use of taro in bread processing.

Materials and Methods

Materials

Selected Corms of taro (ColocasiaesculentaL.Schott), namely Ponchomukhi (Bangla) was used in the study. The corms were freshly harvested from an experimental farm at the Northern areas and taken to the laboratory, where it was washed, cleaned and rinsed with copious amounts of tap water before being used for the study. Other ingredients were wheat flour, yeast, salt collected from local market.

Methods

Experimental design and procedure

Clean taro corms were hand-peeled and cut into slices 0.5 cm thick, which was soaked in 0.5% NaCO3 Solution after boil the difference in weight before and after infrared drying of 2 g samples at 1050C. Crude fat was determined after drying and extraction with ether for 8 h in a Sox let apparatus. The ash content was determined by heating at 550 0C and then weighing the remaining grey ash. The total nitrogen was determined after digestion in concentrated sulfuric acid followed by Micro Kjeldhal methods for determination of ammonium, then converted to protein values using a conversion factor of 6.25.Total carbohydrate was determined by difference.

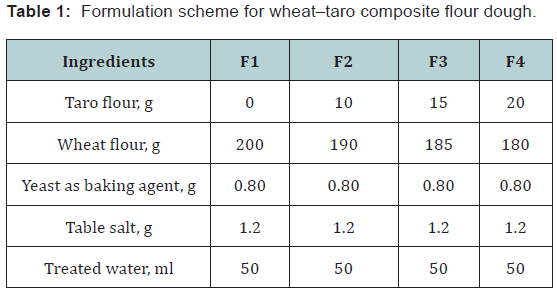

Functional properties of composite flour

Water absorption capacity (WAC) was determined essentially by the method of Phillips et al. [9]; water solubility index (WSI) was measured according to the method of Anderson et al. [10] and oil absorption capacity (OAC) was estimated by the method of centrifuging a known quantity of flour saturated with Palm oil (Sodecoton, Garoua, Cameroon) following the procedure of Sosulski [11]. The retrogradation index (RI) was evaluated by gravimetric measurements of the synergic water separated from the paste sample, with some modifications [12]. Precisely, 1g of flour was mixed with 5ml distilled water in a centrifuge tube. The suspension was boiled for30 min and cooled under tap water. The gel obtained was keep at 4 0C for 8 days, after which the tubes were equilibrated at room temperature over a period of 2 h. The free liquid was separated by centrifugation, weighed and expressed as a percentage of the total water weight of sample before centrifugation. at 100 0C for 15 minutes, then decant the water using muslin cloth as filter . The slice of taro was dried to a brittle texture in a convection oven at 45 ± 3 0C for 24 h. Dried slices were fine-milled (500 μm) into flour using an electric grinder (Collate, Polymer, France, Kinematical, Luzernerstrasse, Germany), packaged in polyethylene bags and stored in a desiccators until required for further analysis. Wheat–taro composite flour was produced by mixing in a blender (Moulinex brand, Paris, France) and four levels of incorporation (0%, 10%, 20% and 30%) of taro flour into wheat flour, using a 3 × 4 factorial design shown in (Table 1).

Proximate analysis

Analysis of taro flour for crude lipid, ash and moisture content was carried out using AOAC [8] methods, while proteins [4] and available carbohydrates content using subtraction methods of calculation. Moisture content of the flour was determined from

Statistical Analysis

Data obtained were subjected to analysis of variance (ANOVA) to identify differences among treatment means.

Results and Discussions

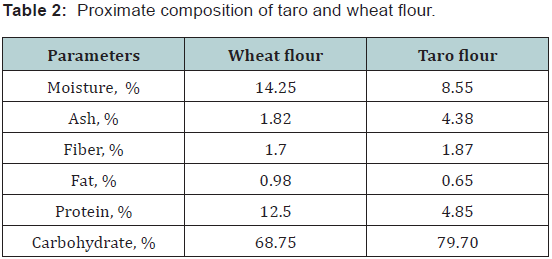

Chemical composition

The chemical composition of taro and wheat flours is presented in (Table 2). On a comparative basis, taro flour contains appreciable amounts of minerals, as can be inferred from their ash content (4.38%) compared to that of wheat flour (1.82%). On the other hand, the level of available carbohydrates in wheat flour (68.75%) falls within the range of that of taro studied (79.70%). Comparable values were also observed on the crude fiber levels of wheat (1.7%) and taro (1.87%) flours. Although wheat flour is generally low in fat content (0.98%), this value is much higher than in taro flour.

Irrespective of the taro, levels of crude proteins (4.85%) in taro flours were significantly (p <0.05) lower than that of wheat flour (12.5%). It is evident from these results that one of the major compositional differences between wheat and taro flours resides in their levels of proteins.

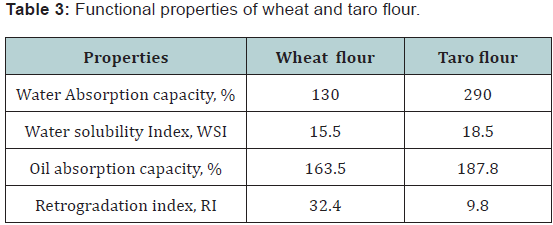

Functional properties

The functional properties of wheat and taro flours are given in (Table 3). In general, flour obtained from the taro corm used exhibited higher water absorption capacity (WAC) as well as higher oil absorption capacity (OAC) than wheat flour, while the retrogradation index was much higher for wheat than for taro flour. The high synergic value observed for wheat flour compared to taro flours may be attributed to the differences in amylose content, given the fact that starch with high amyl pectin content has been reported to retrograde slowly[13,14].

It may also be attributed to the difference in the starch granules size, which has been shown to be smaller for taro starch. In fact it has been shown that flours containing large-sized starch granules exhibit higher synergic (%) values, while those having small sized starch granules show lower synergic [11,13]. Such differences obviously imply that the incorporation of taro flour into wheat would modify the properties of the composite flour.

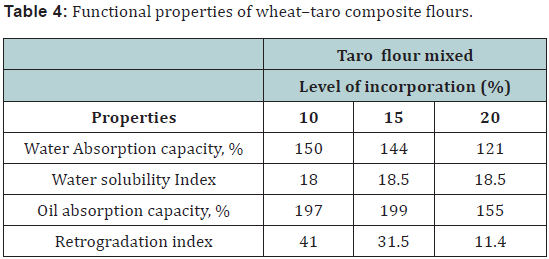

(Table 4) presents the functional properties of wheat flour as affected by the level of incorporation of taro flour. In general, no varietal differences were observed in the effect of taro incorporation on OAC and WSI. However, the level of taro flour significantly (p <0.05) affected WAC, WSI, and retrogradation

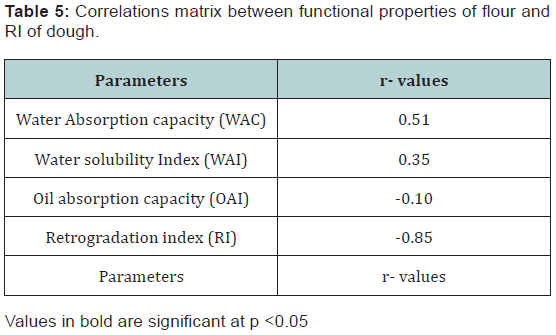

Linear correlations (Table 5) showed that an increase in the level of taro in the composite flour generally tended to increase WAC (r = 0.51), and WSI (r = 0.35) levels, and to reduce that of OAC (r = −0.10) and retrogradation index (r = −0.81).These correlations were, however, not significant, with the exception of that of the retrogradation index. WAC plays a major role in the functionality of dough. In particular, WAC has been shown to be related to dough consistency [11,13].

Generally it was observed that WAC of the composite increased with incorporation of taro flour. The observed increase of WAC could be ascribed to the high level of carbohydrate in taro flour, which was as high as 89%. According to these authors [15] the observed increase may be due to the increase in protein or fibers in the blends. Conversely, however, in another study where wheat flour was progressively replaced w/w protein – it was observed that WAC decreased with hard flour – a starchy staple i.e., soft wheat flour with about 70% w/w carbohydrate and 30% with an increase in hard wheat flour content of composite [12,16]. This suggests that other factors such as carbohydrate structure could influenced the WAC. The functional properties of flours have been shown to be correlated to the theology of dough made from them, and equally correlated to the sensory qualities of deep-fried product [17,18].

The consequence was that most of the variation in the theology of dough was related to its hydration capacity. This was evident from the observation of significant correlations observed between such functional properties as WAC, OAC and the retrogradation Index parameters (Table 4). WAC has a significant effect on the consistency of dough, and also depends on the structure of molecules in the flour. According to Kinsella, the level and structure of protein and starch have an effect on the hydration pattern of flour and modify the consistency of dough [13,19].

In practice, the maximum level of incorporation of a non-wheat product in composite flour depends mostly on the acceptability of the end product. In this respect, a formulation of wheat–taro composite bread with 15% of taro flour has been reported. These authors observed that besides the color, another significant attribute imparted to bread by taro flour was its increased moistness and keeping quality, resulting from exceedingly high absorption of liquid by wheat–taro composite flour. The superior quality of wheat–taro may result from the initial high moisture capacity, due to the fairly high percentage of mucilage in taro flour. This has been proved in the present study, which revealed that the retrogradation index was much higher for wheat dough than for wheat–taro composite.

Conclusion

The substitution of wheat flour (10%) with taro flour resulted in dough of different physic chemical characteristics, depending on the amount and the type of starch used. The composite flour at the 10% substitution level showed physical properties similar to wheat bread samples, especially for products from taro-wheat composite flour. The taro-wheat composite flour had the lowest setback and processing stability, which indicated low staling or aging of dough for bread substituted with taro flour. The composite bread would serve as functional food because of the high trace element content. The composite bread with taro-flour substitutions will be nutritionally superior (have higher minerals and crude fiber content) to whole wheat bread. Consumer’s enlightenment on the nutritional benefits of the taro flour substituted functional foods would help to improve the sensory acceptability of composite bread. Further studies on the range of substitution, sensory quality and textural properties of composite breads could be helpful to find the suitable substitution level for taro flour

Acknowledgement

The authors wish to thanks the authority of Proem Agro Foods Ltd. For technical support of the study under Bread Processing unit. The outcome of this study was a part of Bachelor Engineering degree for Nutrition and Food Engineering under faculty of Allied Health Sciences, Daffodil International University.

References

- Ron BH, Wills RB, Lim JS, Greenfield H, Bayliss-Smith T (1983) Nutrient composition of taro (Colocasia esculenta) cultivars from the Papua New Guinea highlands. Journal of the Science of Food and Agriculture 34(10): 1137-1142.

- Amy CB, Ana Valiere, (2004) The Medicinal Uses of Poi. Nutr Clin Care 7(2): 69-74.

- Jane J, Sheen L, Chen J, Kasemsuwan T, Nip WK (1992) Physical and chemical studies of taro starch and flours. Cereal Chem 69(5): 528- 535.

- Nip WK, Vargo D, Whitaker CS (1994) Application of taro flour in cookie formulation. Int J Food Sci Techno 29(4): 463-468.

- Hong GP, Nip WK (1990) Functional properties of precooked taro flour in sorbets. Food Chem 36(4): 261-270.

- Rita Elsie (2011) Sanful Organoleptic and Nutritional Analysis of Taro and Wheat Flour Composite Bread. World Journal of Dairy & Food Sciences 6 (2): 175-179.

- Afaf OA, Abd El-Aziz M, Jihan MK, Zeinab M Abd-Ghany (2013) Effect of Substitution of Wheat Flour with Taro Flour on Some Properties of Weaning Food Formula. Journal of Applied Sciences Research 9(6): 3985-3991.

- Association of Official Analytical Chemists (1990) Official Methods of Analysis, (15th edn). AOAC, Washington, DC, USA.

- Phillips RD, Chinnan MS, Branch AL, Miller J, Mc Watters KH (1998) Effects of pre-treatment on functional and nutritional properties of cowpea meal. J Food Sci 53(3): 805-809.

- Anderson RA, Convay HF, Pfeifer VF, Griffin EL (1969) Roll and extrusion cooking of grain sorghum grits. Cereal Sci Today 14(11): 372-375.

- Sosulski FW (1962) The centrifuge method for determining flour absorption in hard red spring wheat. Cereal Chem 39: 344-350.

- Kinsella JE (1976) Functional properties of proteins foods. Crit Rev, Food Sci Nutr 1(3): 219-280.

- Njintang YN, Mbofung CMF (2003) Kinetics of starch gelatinisation and mass transfer during cooking of taro (ColocasiaesculentaL. Schott) slices. Starch/St¨arke 55(3,4):170-176.

- Bamidele EA, Cardoso AO, Olaofe O (1990) Rheology and baking potential of wheat plantain composite flour. J Sci Food Agric 51(3): 421-424.

- Njintang YN, Mbofung CMF, Waldron KW (2001) In vitro protein digestibility and physicochemical properties of dry red bean flour. effect of processing and incorporation of soybean and cowpea flour. J Agric Food Chem 49 (5): 2465-2471.

- Boggini G, Tusa P, Pogna NE (1994) Bread-making quality of drum wheat genotypes with a typical protein compositions. Tecnica Molitoria 45:825-835.

- Singh J, Singh N, Sharma TR, Saxena SK (2003) Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem 83: 387-393.

- Boggini G, Tusa P, Galterio G (1996) Reliability of analytical parameters in evaluation of bread and pasta-making properties of durum wheat. Ital J Food Sci 8: 41-48.

- Chang SM, Liu LC (1991) Retrogradation of rice starches studied by different scanning colorimetry and influence of sugars, NaCl and lipids. J Food Sci 56(2): 564-570.