Temperature Dependent Lattice Distortion in High Entropy Alloys

Fuyang Tian*

Institute for Applied Physics, University of Science and Technology Beijing, China

Submitted: October 17, 2023; Published: November 08, 2023

*Corresponding author: Fuyang Tian, Institute for Applied Physics, University of Science and Technology Beijing, China

How to cite this article: Fuyang T. Temperature Dependent Lattice Distortion in High Entropy Alloys. JOJ Material Sci. 2023; 8(2): 555734. DOI:10.19080/JOJMS.2023.08.555734

Keywords: Lattice distortion; Cantor’s alloy; X-ray diffraction; Thermal conductivity

Opinion

Due to the local atomic arrangements affected by local mechanical strain, bonding energy, and electronic and magnetic coupling, high entropy alloys exhibit varying degrees of intrinsic lattice distortion. Whereas, the lattice distortion accompanies by the atomic displacement originated from thermal vibration. In this short review, the estimation of lattice distortion is discussed.

In 2004, the novel concept named as high entropy alloys (HEAs) or multi-principle alloys was reported [1,2]. The random occupation of atomic sites in the crystalline HEAs by these elements with different size inevitably results in a severe degree of local lattice distortion. Large atoms push away their neighbors and small ones have extra space around. None of atoms perfectly reside on the ideal lattice sites. The severe lattice distortion hypothesis is one of four principles in HEAs [3]. It is known to strongly have an effect on the physical properties of single phase HEAs, such as increased hardness and decreased electrical and thermal conductivity containing electron and lattice contributions [4].

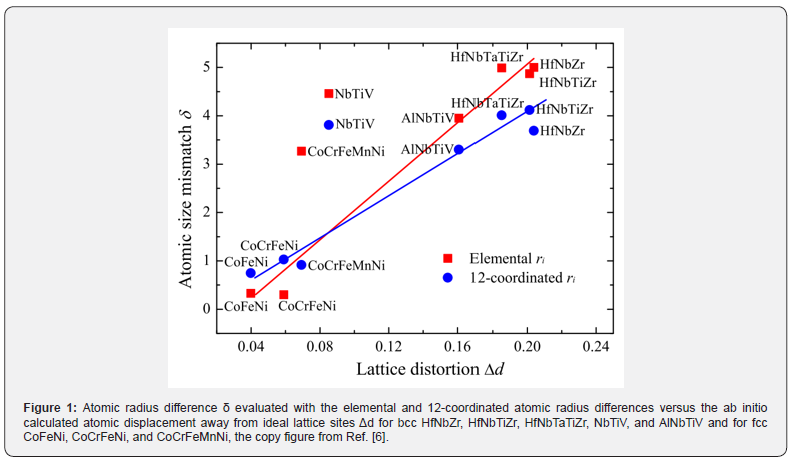

In order to quantify the degree of lattice distortion, the atomic radius difference (δ) and the atomic displacement away from ideal lattice sites (Δd) were defined. Guo et al. [5] combined δ with the mixing enthalpy and mixing entropy to discuss the formation of single-phase HEAs [5]. Song et al. [6] used the ab initio calculations to accurately calculate the Δd at 0 K and found the severe lattice distortion of bcc HEAs, compared to fcc HEAs (Figure 1) [6]. In experiments, the assessment of lattice distortion was carried out using the total scattering method, comparing with the measured pair distribution functions (PDFs) [7]. More recently, Tan et al. extracted experimentally the averaged atomic pair distance to estimate the local lattice distortion [8]. Kang et al. [9] calculated the Voronoi volume of alloying elements in Cantor’s alloy to estimate the local lattice distortion [9].

However, the degree of lattice distortion in HEAs remains poorly understood, due to the effect of thermal vibration on the measurement of lattice distortion. At finite temperature, the lattice distortion is composed of the thermal atomic displacement and static atomic displacement. Whereas the suitable techniques for probing such information, or the presence of complicating factors is lack in the assessment of the data.

To reduce the thermal atomic displacement, one approach is how to eliminate the thermal contribution by the measurement under cryogenic conditions. For example, some attempts have been made to isolate the static component from the thermal vibration by reducing the temperature. Okamoto et al. [10] attempted to separate the thermal component by reducing the temperature to 25 K, measuring the local atomic displacement from a series of single crystal samples using synchrotron X-ray diffraction (XRD) [10]. The local displacement could solely arise from the static component at 25 K. Tan et al. [11] performed the variable temperature study using synchrotron XRD down to 5 K [11]. However, they were unable to isolate the static atomic displacement. In other word, it is still unclear if the low temperature was sufficient to fully eliminate the thermal contributions to the lattice distortion, especially the zero-point vibration induced the atomic displacement could not be ignored.

Considering the PDF peak width is a function of both the static lattice distortion and dynamic displacements from thermal vibration, ones utilized the mean-field representation of interatomic potentials to simulate the thermal vibration induced atomic displacement via the full width at half maximum (FWHM) of RDF. For example, Jian et al. [12] used the average interatomic potentials to estimate the thermal vibration induced atomic displacement. They found that the static lattice distortion in CoCrNi decreases as the temperature rises [12].

Another way is to determine the equation as a function of temperature. The thermal vibration induced isotropic atomic displacement parameter is often calculated by using the harmonic Debye or Einstein model. The thermal atomic displacement nonlinearly increases as temperature rises. It has been proved to be valid for thermal atomic displacement in the disordered clathrate compounds [13]. Using the molecular dynamics, we simulated the variation of total atomic displacement with temperature in fcc Co-Fe-Ni-Ti HEAs [14]. Results suggest that the lattice distortion becomes more severe with increasing temperature. In experiments, the variation in peak intensity as a function of angle was used to measure the Debye–Waller factor and estimate the thermal atomic displacement. Via the comparison of pure Ni, CoCrNi and CoCrFeMnNi HEAs, the effect instrument component is eliminated, results show CoCrFeMnNi has more severe lattice distortion than NiCoCr, whereas the lattice distortion in two HEAs keeps a constant at range of T=4.2-291K [15].

In short, the positional and dynamical behavior of HEAs is complex. Further study is required for the accurate description of lattice distortion.

References

- Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, et al. (2004) Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater 6(5): 299-303.

- Cantor B, Chang ITH, Knight P, Vincent JB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377: 213–218.

- Yeh JW (2006) Recent progress in high-entropy alloys. Ann Chim Sci Des Matériaux 6: 31.

- Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA (2013) Microstructures and Properties of High-entropy Alloys. Prog Mater Sci 61: 1-93.

- Guo S, Ng C, Lu J, Liu CT (2011) Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys 109: 103505.

- Song H, Tian F, Hu Q, Vitos L, Wang Y, et al. (2017) Local lattice distortion in high-entropy alloys. Phys Rev Mater 1: 023404.

- Owen LR, Pickering EJ, Playford HY, Stone HJ, Tucker MG, et al. (2017) An assessment of the lattice strain in the CrMnFeCoNi high-entropy alloy. Acta Mater 122: 11-18.

- Tan YY, Su MY, Xie ZC, Chen ZJ, Gong Y, et al. (2021) Chemical composition dependent local lattice distortions and magnetism in high entropy alloys. Intermetallics 129: 107050.

- Kang S, Tamm A (2023) Density functional study of atomic arrangements in CrMnFeCoNi high-entropy alloy and their impact on vacancy formation energy and segregation. Comput Mater Sci 230: 112456.

- Okamoto NL, Yuge K, Tanaka K, Inui H, George EP (2016) Atomic displacement in the CrMnFeCoNi high-entropy alloy – A scaling factor to predict solid solution strengthening. AIP Adv 6: 125008.

- Tan YY, Chen ZJ, Su MY, Ding G, Jiang MQ, et al. (2022) Lattice distortion and magnetic property of high entropy alloys at low temperatures. J Mater Sci Technol 104: 236-243.

- Jian WR, Xie Z, Xu S, Su Y, Yao X, et al. (2020) Effects of lattice distortion and chemical short-range order on the mechanisms of deformation in medium entropy alloy CoCrNi. Acta Mater 199: 352-369.

- Beekman M, Karttunen AJ, Wong NW, Zhang M, Chen YS, et al. (2022) Thermal and mechanical properties of the clathrate-II Na24Si136. Phys Rev B 105: 1-11.

- Zhou X, Song H, Guo C, Zhen Y, Tian F, Effect of short-range order on local lattice distortion, general stacking fault energy, mechanical performance of Co-Fe-Ni-Ti high-entropy alloy at finite temperature.

- Owen LR, Jones NG, Stone HJ, Playford HY (2023) Separation of static and dynamic displacements in the CrMnFeCoNi high entropy alloy. Acta Mater 119164.