Carbon Nanotube-Based Super Black coatings for Stray Light Mitigation

Bahlawane N1*, Pachot C2 and Lafont U2

1Luxembourg Institute of Science and Technology, Europe

2European Space Research and Technology Centre, Europe

Submission: October 02, 2017; Published: November 20, 2017

*Corresponding author: Bahlawane N, Luxembourg Institute of Science and Technology, Europe, Email: naoufal.bahlawane@list.lu

How to cite this article: Bahlawane N, Pachot C, Lafont U. Carbon Nanotube-Based Super Black coatings for Stray Light Mitigation. JOJ Material Sci. 2017; 3(1): 555609. DOI: 10.19080/JOJMS.2017.03.555609

Abstract

Stray light is one of the factors impacting the performance of optical imaging devices in terms of sensitivity and resolution. The off-axis parasitic radiations can be strongly minimized using complex baffles with black coated inner walls. The state-of-the-art developments place the carbon-containing black coatings as materials of choice. The potential of the randomly oriented carbon nanotube coatings, made by a single pot chemical vapor deposition process is highlighted in this contribution.

Keywords: Super black coatings; Chemical vapor deposition; Carbon nanotubes

Introduction

Optical imaging implements electromagnetic radiation (X-rays to sub-millimeter) to deliver valuable data for various applications including medical diagnostic, materials and devices characterization, chemical reaction monitoring, earth observation and astrometry. Enormous efforts are therefore devoted to the further improvement of its resolution and sensitivity. The parasitic background signal in optical imaging is related to stray light in the opto-mechanical systems. This stray light is due to numerous sources such as bright objects near the line of sight, thermal radiation, contaminated optical surfaces and reflection on the inner walls of the baffles. These issues are further emphasized for space applications.

In the field of astrometry a loss of 40% of the accuracy can be induced by stray light at the magnitude of 20 (4 10^5 times fainter than can be seen with naked eye) as it was speculated for the Gaia telescope [1,2]. Lofdahl [3] investigated the stray light in ground-based solar telescopes using accurate photometry. The stray light in such instruments produces an aureole that extends several solar radii off the solar disk. Authors measured little percent noise intensity and a reduced contrast.

Optical payloads implement, in general, highly sophisticated baffles/vanes systems and black surface finishing blocking and attenuating the scattered light, and thereby limiting the deterioration of the geometric and/or radiometric image quality. In this context several black surface finishing processes are commercially available such as these based on black anodization Table 1 (Martin Black), black paints (e.g. Aeroglaze, Ames 24E, DeSoto…), plasma spraying (e.g. J-Black developed for infrared astronomy [4]) and electro deposition. These processes, feature clear limitations when the structures to be coated arecomplex and do present thin walls or sharp edges.

Recently other black surface finishing treatments have been introduced into the market, including the Acktar advanced coatings based on a Physical Vapor Deposition process, [5] and Surrey nano systems, which is based on photo-thermally activated chemical vapor deposition of vertically aligned carbon nanotube (VA-CNT) [6]. Both are per see line-of-sign processes with limited implementation on complex three-dimensional structures. The thermal chemical vapor deposition, which is not a line-of-sight process, was implemented by Nasa’s Goddard Space Flight Center for the growth of VA-CNT [7,8]. In this process however, the substrate temperature exceeds 700 °C, which is an issue for many materials such as aluminum and some special alloys. Furthermore, VA-CNT can be turned to optically reflective mirror via mechanical contact [9,10]. Therefore, the development of innovative super black coating material was identified as a milestone by the European Space Agency [11].

On-going developments

Based on the measured transmission and reflection spectra, the calculated impedance of the CNT coatings matches to the surrounding air, resulting on near perfect absorption [12]. Nevertheless, attaining sufficient adhesion requires embedding these CNTs ina structural matrix, which inherently decrease their light absorption. [13] reported on the application, via a costeffective spray Bera et al. deposition technique, of CNT-boehmite (AlOOH) composite coatings that feature an absorption of 97.5% and withstand adhesion scotch tape test. Similar optical performance was reported in the best cases with CNT-binder composite coatings obtained using the same process [14]. The implementation of spray technique is appropriate for coatings on three-dimensional structures with limited complexity.

Thermal chemical vapor deposition process was investigated to enable the growth of CNTs at low temperatures [15,16]. Hereby an innovative catalyst-promoter concept was implemented to grow CNTs at ≥330 °C starting from ethanol vapor as a carbon source. While the catalyst is either cobalt or nickel, the promoter is selected among highly basic oxide materials such as MgO. Single step process enables the growth of CNTs on various substrates including on aluminum, titanium and glass. The growth yields randomly oriented CNTs which makes the optical properties less sensitive to mechanical contacts.

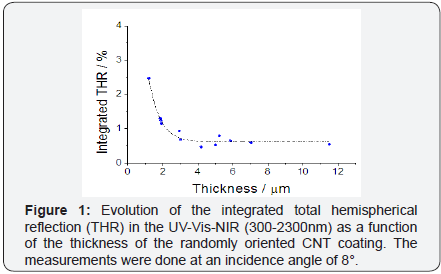

The reflection of UV-Visible-near infrared radiations decreases dramatically with the film thickness to reach a plateau at 0.7% for thicknesses above 3m as shown in Figure 1. Strengthening the randomly oriented CNT coatings could be performed in the same deposition chamber by Al2O3, using the sequential and surface limited reaction of trimethylaluminum with water vapor. Adhesion tape test could be satisfied while keeping the value of the integrated THR near 1%. Figure 2 displays the surface and cross section of a strengthened CNT coating with a thin Al2O3 layer. The morphology of the film retains a significant porosity owing to the conformal nature of the Al2O3 deposition.

Discussion and Conclusion

The most relevant weakness of the VA-CNT coating is the sensitivity to mechanical and chemical aggression as the CNTs bend easily and are directly exposed to the surrounding atmosphere. It is worth mentioning that the exposure of the black coatings to atomic oxygen is expected for applications in low Earth orbit. While the growth of randomly oriented CNT makes the films less sensitive to mechanical aggressions, the presence of an oxide covering layer decreases their sensitivity to reactive gases. The chemical nature and the thickness of the oxide layer can be adjusted to ensure a compromise between the absorption, mechanical and chemical stabilities.

The random orientation of the CNTs is furthermore beneficial as the optical response is not angle-dependent. The necessary thickness to achieve an appropriate absorption of light ranges from few micrometers, for the randomly oriented CNTs to few tens of micrometers for the aligned CNTs. Therefore, the randomly oriented CNT coating is likely more compatible with coatings on sharp edges. The main characteristics of the CNTbased super black coatings, Table 2, show a clear advantage of the strengthened randomly oriented CNT coating.

Acknowledgement

Authors would like to acknowledge the financial support of the European Space Agency (ESA) in the context of the TRP activities (4000112130/14/NL/SW, Innovative materials for super black low weigh/low cost baffles and 4000119752/17/ NL/PS, Super black coatings on real size opto-mechanical structures) and the CORE project (C15/MS/10465305; Black Select) financed by the Luxembourg National Research Fund (FNR).

References

- BBC http://www.bbc.com/news/science-environment-27824565.

- ESA (2014) http://blogs.esa.int/gaia/2014/06/16/preliminary- analysis-of-stray-light-impact-and-strategies.

- Löfdahl MG (2016) Off-disk stray light measurements for the Swedish 1-m Solar Telescope, A&A. vol. 585.

- Waddell P, Black DS (2016) J-Black: a stray light coating for optical and infrared systems. In: Conference on Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation II, Edinburgh, Bellingham, United Kingdom 99: 12.

- Miron Salomon Y, Ariel Sternberg N, Gouzman I, Lempert G, Grossman E et al. (2009) Qualification of Acktar black coatings for space application. Proceedings of the International Symposium on materials in a space Environment.

- Shang NG, Tan YY, Stolojan V, Papakonstantinou P, Silva SR (2010) High-rate low-temperature growth of vertically aligned carbon nanotubes. Nanotechnology 21(50): 505604.

- Butler JJ, Georgiev GT, Tveekrem JL, Quijada M, Getty S, Hagopian JG (2010) Initial Studies of the Bidirectional Reflectance Distribution Function of Carbon Nanotube Structures for Stray Light Control Applications. In: Conference on Earth Observing Missions and Sensors - Development, Implementation, and Characterization. Incheon, South Korea 7862.

- Quijada MA, Hagopian JG, Getty S, Kinzer RE, Wollack EJ (2011) Hemispherical Reflectance and Emittance Properties of Carbon Nanotubes Coatings at Infrared Wavelengths. In: Conference on Cryogenic Optical Systems and Instruments XIII, San Diego, CA, 8150.

- Mukherjee S, Misra A (2014) Broadband wavelength-selective reflectance and selective polarization by a tip-bent vertically aligned multiwalled carbon nanotube forest. Journal of Physics D-Applied Physics, Article 47(23): 7.

- Tanveer S, Mehran V Moghaddam, Mohamed Sultan M Ali, Masoud D, Charles A Foell, et al. (2012) Transforming carbon nanotube forest from darkest absorber to reflective mirror. Applied Physics Letters 101(6): 061913.

- Shi HF, Ok JG, Baac HW, Guo LJ (2011) Low density carbon nanotube forest as an index-matched and near perfect absorption coating. Applied Physics Letters 99(21): 3.

- Bera K, Mhaisalkar SG, Mandler D, Magdassi S (2016) Formation and performance of highly absorbing solar thermal coating based on carbon nanotubes and boehmite. Energy Conversion and Management 120: 287-293.

- Azoubel S, Cohen R, Magdassi (2015) Wet deposition of carbon nanotube black coatings for stray light reduction in optical systems. Surface & Coatings Technology 262: 21-25.

- Basheer HJ, Pachot C, Lafont U, Devaux X, Bahlawane N (2017) Low-Temperature Thermal CVD of Superblack Carbon Nanotube Coatings. Advanced Materials Interfaces 4(18): 1700238.

- Bahlawane N (2016) Carbon-nanotube-based coating and production method thereof.

- (2016) Innovative materials for super black low weight/low cost baffles. Summary Report under ESA contract 4000112130.