Semiconductor Fab Energy Optimization and Data-Intensive Energy Efficiency Modeling

Hsiao-Ping Ni1* and Wai Oswald C2

1School of Manufacturing Systems and Networks, Arizona State University, Tempe, AZ, United States

2School of Sustainable Engineering and the Built Environment, Del E Webb School of Construction, Arizona State University, Tempe, AZ, United States

Submission: April 5, 2024;Published: May 08, 2024

*Corresponding author:Hsiao-Ping Ni, School of Manufacturing Systems and Networks, Arizona State University, Tempe, AZ, United States, Email: hsiaopin@asu.edu

How to cite this article:Hsiao-Ping N, Wai Oswald C. Semiconductor Fab Energy Optimization and Data-Intensive Energy Efficiency Modeling. Eng Technol Open Acc 2024; 5(5): 555674.DOI: 10.19080/ETOAJ.2024.05.555674

Abstract

HVAC systems’ design, installation, operation, and maintenance affect their performance and efficiency. This paper examines several modeling approaches, including white box, black box, gray box, and other notable modeling techniques that optimize HVAC system efficiency and longevity. To achieve accuracy, models require reliable and large amounts of data, which can be captured using Artificial Intelligence and Machine Learning (AI/ML). AI/ML is used to develop data-intensive HVAC energy modeling to address equipment degradation and therefore optimize system performance and efficiency. Codes, standards, specifications, and energy models determine system performance after installation, during commissioning, and operation. Future research will continue to apply AI to study how modeling can be redesigned to improve energy efficiency.

Keywords:Semiconductor Fabrication Plants; Make-Up Air Unit (MAU); HVAC System Optimization; Energy Efficiency; Data-Intensive Modeling; Equipment Degradation

Abbreviations:HVAC: Heating, Ventilation, and Air Conditioning; SMF: Semiconductor Manufacturing Facility; AI: Artificial Intelligence; ML: Machine Learning; DL: Deep Learning; NN: Neural Network; ANN: Artificial Neural Network; CNN: Convolutional Neural Network; RNN: Recurrent Neural Network

Introduction

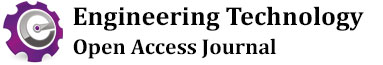

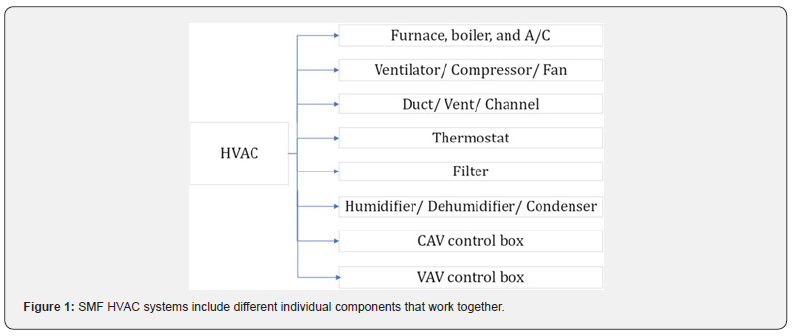

HVAC systems provide thermal comfort and healthy indoor environments for occupants and support manufacturing. (Figure 1) shows typical integrated and interrelated SMF HVAC systems. They are crucial for maintaining optimal environmental conditions in SMFs to ensure efficient chip production [1]. The performance and energy efficiency of HVAC systems depends on various factors or data sources, including design, installation, operation, and maintenance. (Figure 2) demonstrates the structure of modeling methods of three distinct approaches: white-box, black-box, and gray-box models. Especially, black-box models (data- driven/ empirical/ inverse methods) generally apply AI and ML methods to build predictive models [2] and provide good prediction accuracy [3-5]. However, they require a large amount of data to be built due to ML techniques [2,6]. By combining these three categorical modeling methods, a comprehensive system analysis, design, and optimization can be achieved.

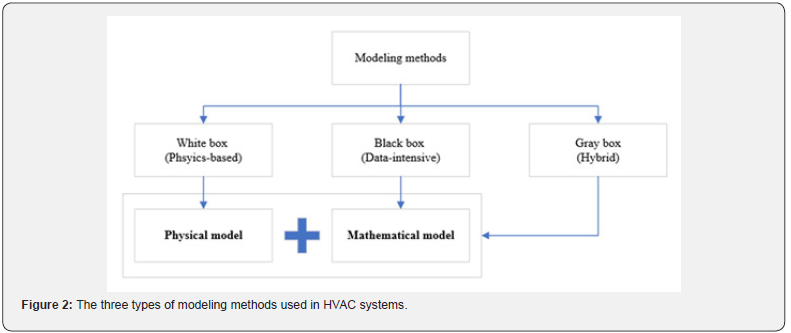

The integration of AI and ML techniques can enhance HVAC system optimization by capturing and analyzing large amounts of data [7]. (Figure 3) illustrates the relationships between AI and HVAC by using data and modeling. Those data-intensive approaches in AI and ML can be employed to generate novel solutions and predict future outcomes in HVAC system optimization. Within AI and ML, DL techniques might be appropriate for accurate predictions and for capturing complex systems. In recent years, DL models (e.g., deep reinforcement learning, deep neural networks, convolutional neural networks, and transfer learning) in AI methodologies have been widely applied to HVAC system analysis [8-16]. In this case, HVAC degradation modeling can be achieved by using NNs in DL with the goal of data-intensive energy optimization and energy efficiency.

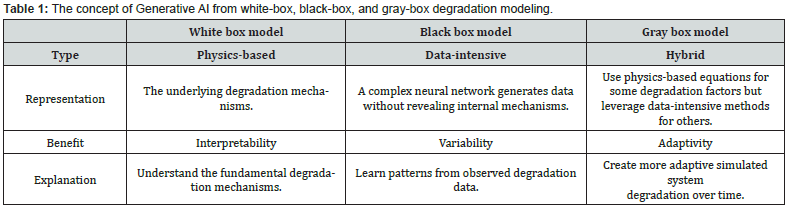

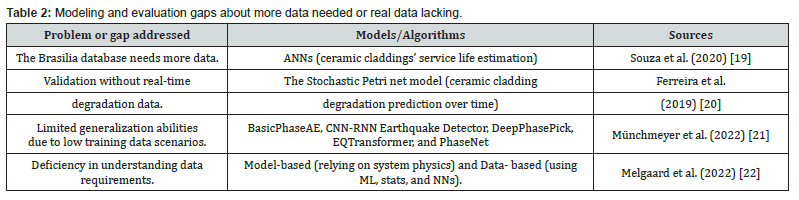

AI tools, such as Generative AI, can improve prediction accuracy and control in HVAC systems [17]. NNs can be the architecture in Generative AI for the modeling process for HVAC. (Figure 4) illustrates developing Generative AI models requires NNs. (Table 1) shows Generative AI is tied to degradation modeling from white-box, black- box, and gray-box perspectives. Generative AI can play a role in addressing equipment degradation in HVAC systems when it is used in the context of predictive maintenance and system optimization. (Table 2) presents some works showing that more data is needed for modeling. Generative AI models are highly suggested to generate new, original content through NNs.

Therefore, the optimization of HVAC systems through AI-assisted techniques is highly considered to enhance performance and energy savings [18].

Discussion

This paper focuses on applying Generative AI in HVAC systems for energy efficiency optimization, predictive maintenance modeling, and data augmentation for predictive models (Figure 5) provides a diagram for Generative AI to model the SMF HVAC.

The problem to be addressed is degradation affecting system performance and operation efficiency over HVAC systems’ lifecycle. The data collection is to gather historical data on the performance and temperature conditions of HVAC components and to analyze the lifecycle. For instance, temperature, humidity, and airflow data in any HVAC system such as MAUs can be used to begin the modeling process. Figure 6 illustrates the air processing for a cleanroom MAU that generates the data needed for modeling and conditions of outdoor air provided for a cleanroom. The learning dataset provided by inputs from the data collection plays a critical role in Generative AI modeling by providing the necessary information and examples for training the model to generate new data samples that closely resemble the original dataset. In the evaluation process, the validation dataset from outputs serves to guide decisions and analyze errors to see how to optimize the Generative AI model. When the model performance assessed using the validation dataset is positive in leading to the development of a robust and reliable Generative AI model, the degradation problem can be effectively executed.

Generative AI models can help identify the most efficient operating parameters by modeling different control strategies and environmental conditions, potentially reducing wear and tear on components and extending equipment life. The integration of Generative AI in HVAC systems can lead to better management, improved energy efficiency, and extended equipment lifespan.

Conclusion

Many semiconductor companies are implementing energy efficiency in their fabs [23]. In SMF, the design, installation, and operation of HVAC systems for cleanrooms are very energy intensive. Even though these existing modeling methods require a large amount of measured and historical data, emerging trends, and technologies such as Generative AI are being applied to those data-intensive HVAC energy modeling for system optimization to reduce energy consumption. It is becoming increasingly popular to use intensive data, combined with machine learning algorithms, to optimize HVAC control strategies to enhance energy efficiency.

Acknowledgments

The authors would like to thank an undisclosed sponsor for sponsoring this research.

Conflict of Interest

The authors declare no conflict of interest.

References

- Reddy VJ, Hariram NP, Ghazali MF, Kumarasamy S (2024) Pathway to Sustainability: An Overview of Renewable Energy Integration in Building Systems. Sustainabil 16(2): 638.

- Guidotti R, Monreale A, Ruggieri S, Turini F, Giannotti F, et al. (2018) A Survey of Methods for Explaining Black Box Models. ACM Computing Surveys 51(5): 1-42.

- (2013) American Society of Heating and E. Air-Conditioning, 2013 ASHRAE Handbook Fundamentals vol. SI. Atlanta: ASHRAE, 2013.

- Afram A, Janabi-Sharifi F (2015) Black-box modeling of residential HVAC system and comparison of gray-box and black-box modeling methods. Energy & Buildings 94: 121-149.

- Afram A, Janabi-Sharifi F (2015). Gray-box modeling and validation of residential HVAC system for control system design. Appl Energy 137: 134-150.

- Braun J, Chaturvedi N (2002) An Inverse Gray-Box Model for Transient Building Load Prediction. HVAC&R Res 8(1): 73-99.

- Ahmad T, Madonski R, Zhang D, Huang C, Mujeeb A (2022) Data-driven probabilistic machine learning in sustainable smart energy/smart energy systems: Key developments, challenges, and future research opportunities in the context of smart grid paradigm. Renewable Sustainable Energy Rev 160: 112128.

- Du Z, Liang X, Chen S, Zhu X, Chen K, et al. (2023) Knowledge-infused deep learning diagnosis model with self-assessment for smart management in HVAC systems. Energy 263: 125969.

- Shin S, Baek K, So H (2023) Rapid monitoring of indoor air quality for efficient HVAC systems using fully convolutional network deep learning model. Building & Environ 234: 110191.

- Xiao Z, Gang W, Yuan J, Chen Z, Li J, et al. (2022) Impacts of data preprocessing and selection on energy consumption prediction model of HVAC systems based on deep learning. Energy and Buildings 258: 111832.

- Taheri S, Ahmadi A, Mohammadi-Ivatloo B, Asadi S (2021) Fault detection diagnostic for HVAC systems via deep learning algorithms. Energy & Buildings 250: 111275.

- Gao Y, Miyata S, Akashi Y (2023) How to improve the application potential of deep learning model in HVAC fault diagnosis: Based on pruning and interpretable deep learning method. Appl Energy 348: 121591.

- Namatēvs I (2018) Deep Reinforcement Learning on HVAC Control. Inf Technol Manag Sci 21: 29-36.

- Chen Y, Tong Z, Zheng Y, Samuelson H, Norford L (2020) Transfer learning with deep neural networks for model predictive control of HVAC and natural ventilation in smart buildings. J Cleaner Product 254: 119866.

- Wang M, Wang Z, Geng Y, Lin B (2021) Interpreting the neural network model for HVAC system energy data mining. Building & Environ 209: 108449.

- Liu T, Xu C, Guo Y, Chen H (2019) A novel deep reinforcement learning based methodology for short-term HVAC system energy consumption prediction. Int J Refrigeration 107: 39-51.

- Yan K, Chong A, Mo Y (2020) Generative adversarial network for fault detection diagnosis of chillers. Building and Environ 172: 106698.

- Merabet GH, Essaaidi M, Haddou MB, Qolomany B, Qadir J, et al. (2021) Intelligent building control systems for thermal comfort and energy-efficiency: A systematic review of artificial intelligence-assisted techniques. Renewable Sustainable Energy Rev 144: 110969.

- Souza J, Silva A, De Brito J, Dias JL, Bauer E (2020) Evaluation of the deterioration of ceramic claddings by application of artificial neural networks. Journal of Performance of Constructed Facilities 34(5): 04020084.

- Ferreira C, Canhoto Neves L, Silva A, De Brito J (2019) Stochastic Petri-net models to predict the degradation of ceramic claddings. Building Res & Info 47(6): 697-715.

- Münchmeyer J, Woollam J, Rietbrock A, Tilmann F, Lange D, et al. (2022) Which picker fits my data? A quantitative evaluation of deep learning based seismic pickers. J Geophysical Res 127(1): e2021JB023499.

- Melgaard SP, Andersen KH, Marszal PA, Jensen RL, Heiselberg PK (2022) Fault Detection and Diagnosis Encyclopedia for Building Systems: A Systematic Review. Energies 15(12): 1-50.

- Rosen MA, Kishawy HA (2012) Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainabil 4(2): 154-174.