Electrically Conductive Yarns (ECY) for Health Monitoring: A Review

Sultan Ullah1*, Muhammad Adnan Saeed1 and Zeenat Akhter2

1Department of Mechanical Engineering, Gazi University, Ankara, Turkey

2College of Electrical and Mechanical Engineering, National University of Science and Technology, Pakistan

Submission: January 13, 2024;Published: March 04, 2024

*Corresponding author: Sultan Ullah, Department of Mechanical Engineering, Gazi University, Ankara, Turkey

How to cite this article: Sultan U, Muhammad Adnan S, Zeenat A. Electrically Conductive Yarns (ECY) for Health Monitoring: A Review. Curr Trends Fashion Technol Textile Eng. 2024; 9(1): 555753. DOI: 10.19080/CTFTTE.2024.09.555753

Abstract

Electrically conductive yarns (ECY) possess the property of carrying the signal from one end of the yarn to the other to work as sensors, actuators, and communication devices. Conductive yarns in health monitoring applications are used for disease diagnosis and assessment of patient condition by sensing and transmitting the signal. In this paper, only human body health monitoring is the main target to discuss specifically the products and technologies based on conductive materials. In the medical field, polymeric conductive yarns are found with some superior properties of sensitivity, and flexibility, and have high strain monitoring. Smart textiles having electronic devices are embedded into the structure for transmitting; and receiving signals are suitable for products with technical features, and monitoring of health. Conductive yarn properties depend on wire types, diameters, and material characteristics. Polyaniline-coated polyester yarns are stable environmentally with excellent flexibility. The usability of the whole health monitoring system increases by using wireless technologies. Furthermore, making conductive yarns with zero resistivity, low cost, and multiple features is of great interest in the future smart textiles market.

Keywords: Electrically Conductive Fibers; Yarns; Fabrics; Health Monitoring; E-Textile

Introduction

Smart Textiles

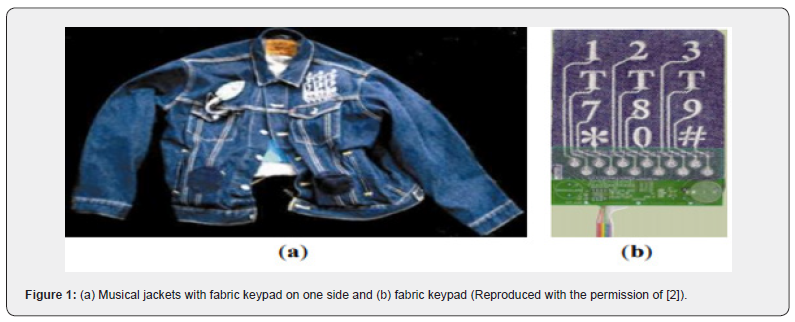

Smart textiles are intelligent textiles that can sense and react to environmental stimuli. The E-textile system is fabricated by the development of electrical devices like sensors, energy harvesting, actuators, storage items, etc. and applications are shown in Figure 1 [1,2]. Smart textiles interact with the environment and such e-textiles exist in different shapes and compositions (woven, knitted, or non-woven) [3]. The term e-textiles represents the class of fabric structures that sense and respond to environmental changes and the multificated environment for smart textiles is represented in Figure 2 [4,5].

Smart textiles can perceive and respond to a specific stimulus by embedding various components/parts of electronics into structures (yarns, fabrics, or garments) [6]. Smart textiles with the perspective of energy conduction, and transformation, as well as serve the function of protection from environmental hazards [7]. The parts having considerable weight and interest in e-textiles are sensitive sensors, flexible transistors, and stretchable electronic tools integrated into yarns, fabrics, or garments [8]. The great potential of smart textiles in the medical area has many end uses like early recognition, treatment, compliance monitoring, physical therapy, and many others [9]. Further integration of electronic devices within clothing has increased the growth of e-textiles due to developments in materials science and electronics [10]. Moreover, the market of smart textiles currently close to $100m and is expected to grow towards $5bn in 2027 [11]. Smart textiles have many phenomenal uses in the medical field by using pressure sensors [12]. The origin of the stimulus may be electrically powered, heat, chemical reaction, or other [13]. E-textiles sensing ability can be made through both intrinsic and extrinsic means [14]. Smart textiles often used well-specialized materials, to realize the sensor function [15]. Smart textiles monitoring systems with sensor materials containing the design and development, the coated yarn has the potential to contribute significantly [16]. In the field of research value for applications in health monitoring, the sensors with high sensitivity and stretchability are of great importance [17].

Health Monitoring Systems

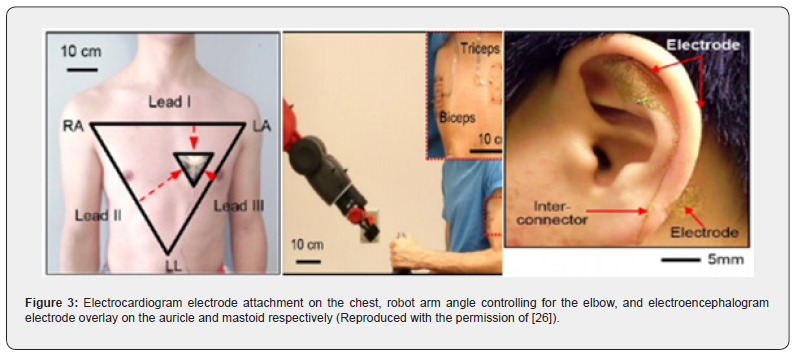

Wearable health monitoring system provides real-time medical monitoring services, and is the combination of computer, communication, medical, and technologies that integrates many characteristics. Wearable Healthcare systems need electrodes that are skin adhering to provide maximum comfort for the patients and to process, carry the signals with low resistance [18]. Growing inhabitants are infected from various kinds of infections while some are chronic age-related disorders. To deal, ensure the monitoring of all those disorders by using conductive materials in wearable healthcare systems is the evolution of diagnostic technologies in the field of medicine [19]. There are two types of health monitoring from both construction (structure), and individual (human) body. Telecommunication and information technologies allow patients and medical staff to communicate easily, and reliably and move the data from one end to another in real-time remote health monitoring systems [20]. Structural health monitoring has very simple uses due to its multimodal nature [21]. There are various techniques/approaches in the structural health monitoring research field like the acoustic emission approach used for structural defects detection [22]. Health monitoring systems have the ability of bio-signals indication at any position. Modern healthcare devices are facilitated more with technology as per the requirements of the users [23]. Health monitoring devices containing conductive fibers/yarns/fabrics process the signals from one end to another end/portion of the structure as per the requirements [24]. Health monitoring devices have the potential for physiological tip-off and such waves provide an efficient way for disease diagnosis and health assessment [25,26]. Figure 3 represents the electrocardiogram electrode attachment on different regions.

Health monitoring systems continuously collect data from the body of humans by changing their health status with time. Moreover, the sensors used in health monitoring systems are highly flexible and comfortable to maintain a natural interaction with the human body [27]. Smartphone-based medical devices are more famous and widely used all over the globe for fitness purposes. Heath monitoring devices can be reduced (miniaturized) in size to handle complex computation and sensing efficient information [28]. Metamaterials textiles with sensor lattice for cordless skeleton are capable of observing constantly the health conditions of people by reducing human errors, and also analyse the better understanding of diseases from their origin [29]. Body health monitoring systems by using wearable sensors, the device properties are bio-friendly, lightweight, and attenuated with a good span of sensitivity. Optical fiber-based sensors on attachment to human skin have the potentials to monitor carpus (wrist) vibration, breathing, and pounding of fingers [30]. The usability of the whole health monitoring system increases by using wireless technologies [31]. Health monitoring allows patients and medical staff better communication from one site to another like health information data [32].

Materials

Health Monitoring Based on Fibers

Wet spinning and melt spinning’s are the processes/methods of fibers preparation which is electrically conductive [33]. The type of materials, fibers configuration, and fibers arrangement are the main factors for determining the performance of smart textiles [34]. Conductive fibers may also have electrical as well as delivering good antimicrobial, anti-static, and electromagnetic shielding properties [35]. Conducting polymers/fibers made from the thermosetting materials (non-thermoplastic) at low temperatures, such as fibers degrade and cannot be remelted or reuse [36]. A materials/fibers electrical conductivity would be superior to the less dense fibers and vice versa [37]. Polymer optical fiber sensors may detect the damages, their recovery is very well at the initial stage, consequently reducing the conservation prices [38]. Sensors made from various textiles fibers along with good conductivity for health monitoring purposes are the extension sensors, pressure sensors, moisture sensing, etc. [39]. Fiber optics against electromagnetic radiation, the sensors have been reported largely in previous years because fibers immunity/ exoneration was of tremendous quality [40]. Carbon nanotubes, graphene nanoplates, carbon nanofibers, and carbon black have good electrical conductivity [41]. Conductive metal nanoparticles, metal films, and CNTs along with graphene are promising materials to make flexible sensors [42]. On the aramid fibers (twaron) surface the deposition of silver nanoparticles can be made through cross-stacking of PDMS (polydimethylsiloxane) emulate a capacitive sensor [43]. Health monitoring based on fibers with carbon materials having hierarchical structures, flexible pressure sensors, highly sensitive, fast response, and durable sensors has been made [44]. Fiber-based smart textiles are assumed to the underweight, comfortable, and resilient. Fibers like conductive polymers, carbon-based materials, metals, and metal-oxide nanoparticles are promising materials/fibers for wearable electronic devices [45]. Repeated stretching may decrease the conductivity of conductive fibers due to the inner layer damaging. However, in conductive fibers, as compared to thin films the resistance change or change in resistance due to stretching is very low showing high conductivity [46]. Conductive fibers are used in wearable electronics by directly woven into textiles. Moreover, stretchable conductive fibers are used in underwater wearable electronics which can work as wireless charging [47].

Health Monitoring Based on Yarns

Sensors are made from conductive yarns and such yarns can be unified into the structures. Many electrodes and sensors containing conductive and piezoresistive yarns have many applications in the field of e-textiles [48]. Electrically conductive yarns into electrodes are quite useful in a situation for long term monitoring and healthcare [49]. Wearable systems containing conductive yarns for individual finger movements and wrist pulse with stretchable strain sensor [50]. The skin temperature can be measured by imparting temperature sensors within the textiles. Skin temperature sensors maybe not useful in some places where the temperature difference is small as compared to the large temperature difference [51]. Silver yarns in smart textiles are mainly used in threads for connections that have the same damaging effect of both washed and unwashed samples [52]. Conductive textiles by using yarns as a wearable electrode for physiological monitoring of signals are used in ECG (electrocardiogram) [53]. Research is made on strain sensors comprising conductive wool yarn along with the development of soft robotics and healthcare applications as well [54]. Variations in yarn TPI (twist/inch) may enhance the strength of conductive yarns and a large number of items can be made from these stainless staple fibers for final use [55]. Strain range for stretchable conductive yarns of composite with high elongation at break is used in sensors [56]. Smart textiles may be used for energy harvesting, health monitoring, and biomedical sensors [57]. Electrically conductive yarns (ECY) are made with the desired properties at the different ratios of fiber to obtain the need for a particular desired product [58].

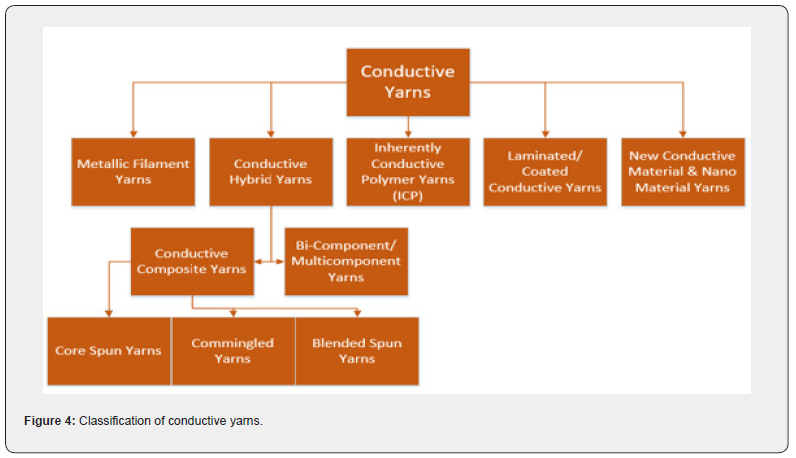

Conductive yarns classification is shown in Figure 4 [2]. Health monitoring using conductive yarns is one of the most demanding areas of research, being consummate the textile-based smart technologies. Electronic elements and electrically conductive yarns (ECY) are consolidated into the textile substrate to work as sensors, actuators, and communication purposes [59]. Electrically conductive yarns (ECY) are used for smart wearable devices to make various products and yarns is linked in between embedded controller, gyroscope, and rest of the instrument portion [60]. Nylon/Ag conductive yarns with some high properties of sensitivity, flexibility, and stability and have tremendous applications for high strain monitoring in the field of medical [61]. Conductive yarns make the textile circuit board as the washing process damage the connection elements [62]. Carbon nanotubes yarn sensors have good deformation along with high sensitivity [63]. The core-sheath yarns are inserted into the products having the ability to identify the motion of a human. Human body motions may be walking, running, jumping, and later on, signals are generated for healthcare monitoring purposes [64]. PDMS-CB (polydimethylsiloxane carbon black) based on stretchable strain sensor are used for non-human body health monitoring (structural) [62]. Researchers are engaged to make flexible electronic devices and to embed them into the fabric structure for getting various features [63]. Bespoke testing chamber for conductive yarn testing was achieved in an acoustic environment [65]. Wearable sensor systems quantifying physical and chemical signals are the tools for health monitoring [66]. Smart textiles cover the section of observation for customizing treatment of individuals with high sensitivity [67]. Several polymers conductivity can be enhanced using a processing agent by several orders of magnitude [68]. Smart textiles having electronic devices are embedded into the structure for transmitting, receiving signals are suitable for products with smart features, and monitoring of health [69]. Smart sensors can be made from carbon nanotube as raw materials with desirable properties. Those desirable properties of carbon nanotube may be achieved individually or in a composition like electrical, heating, mechanical, and optical properties [70]. Silicone materials with insertion of polyester yarn having stainless-steel rod from which conductive yarn are prepared for the transmission of an electrical signals [71]. Sensors made from carbon-based materials in the form of yarns are most probably used for strain monitoring, concentration of ions, biomolecules concentration, and change in heat [72]. Contemporary, innovation in smart textiles products for health monitoring using conductive yarn for various purposes [73]. Properties related to strength, modulus of electrically conductive yarns made up of different fibers/materials having graphene coating are mainly applicable for mechanical characteristics [74]. Mostly, textile-based sensors are attached directly to the body and they are comfortably fit [75]. For wearable health-monitoring electronics, graphene has been analyzed as the most promising material [76]. Hybrid polyurethane yarns strength and modulus are low, therefore, corresponding yarns still in search of better mechanical properties [77]. Graphene oxide coating over polyamide yarn provides durable electrically conductive yarns (ECY) with excellent fastness to washing properties as well [78]. Wearable sensors are mostly used for sensing human body movement during walking, running, or jumping by transmitting signals, and safe the patient from any future danger [79]. Stretchable electronics need flexible materials for the development of conductive yarns [80]. For the monitoring of joint angles, the wearable sensors fabricated from conductive yarns of nylon and spandex materials/fibers have a good feel of materials, dry easily, and a hindrance to mildew [81]. Electrically conductive yarns have many applications in weave able, knittable, and wearable yarn supercapacitors [4]. Polymers with conduction characteristics in the form of yarn and nanofillers are added to the spinnable polymers to achieve the desired properties [82]. As far as flexibility of conductive yarn is concerned, polypropylene is suited well. These materials also require excellent coating over the yarn surface for maintaining insulation in the existence of water [83]. Applying load/stress on elastic conductive yarns cannot reduce the conduction properties [84]. Yarns with greater conduction are made/spun from the oxide of metals, CNTs, and polymers [85]. Polyaniline coated polyester electrically conductive yarns (ECY) are stable environmentally, tremendous strength as per the requirement, and pliability [86]. Conductive yarn properties depend on wire types, diameters, and roving count [87]. Mechanical damage for conductive yarn is detected at less strain, with no indication of an electrical signal [88]. Shorter the distance between the layers of conductive yarns would result in better protection from the electric field [89]. Coating textile yarns by conducting polymers an immense variety with low surface resistivity of the conductive structure has been made [90].

Health Monitoring Based on Fabrics

Power system with self-sustainability in which the devices/ tools of wearable energy harvesting and energy-storing are inserted/integrated [91]. Among all the preparatory processes of producing fabrics, woven made fabrics are found the best conductivity [92]. Conductive yarns from which smart clothing are made with outstanding corrosion protection property, and phenomenal uses of electromagnetic shielding in the field of e-textiles [93]. Military and civilian getting benefit from the conductivity-based fabrics made from conductive yarns especially of woven made structure [94]. Researchers made advancement in e-textiles by adding some technology-based features into sensors applications or through wireless communication technology. To perform diversity measurement, the neonate wears a baby jacket having patches (sensors) at six different positions that sense bipotential signals [95]. The exploitation of information and communication technology for healthcare systems presents a challenge to science [96]. A rapid change of interest in new sensing and monitoring devices for healthcare has witnessed in the last decade [97]. Woven fabric made from the electrospinning of PVDF yarns are highly sensitive, better time of response, and durability [98]. Plain weave fabrics have higher sensitivity as compared to satin and twill weave fabrics [99].

Conclusion

In this review paper, we have found that electrically conductive yarns (ECY) are highly sensitive and carry an electrical signal from one end to another. These signals are carried by the application of pressure/stress/load/force or by some mechanical means. Electrically conductive yarns with low resistivity can transmit high current with less or no obstruction. Electrically conductive yarns have many uses in the field of smart textiles or e-textiles such as smart socks, jackets, suits, etc. Smart socks comprise of conductive yarns in different positions such as heel, ball, and toe regions. The electrical signal is generated by applying pressure on the conductive yarns’ regions and among these yarns’ spandex provide soft-touch, quick-drying, and mildew resistance. The properties of conductive yarn depend on wire types, diameters, and materials characteristics. Electrically conductive yarns (ECY) of fibers like flax, glass, and polypropylene having graphene coating are tremendously known for better mechanical properties. In the medical field, nylon/Ag conductive yarns with high sensitivity, stability, and flexibility are used for health monitoring as well. The electrical conductivity of yarns decreases over time due to the washability factor. Researchers are still trying to make ECY having good electrical conductivity after washing several times. Moreover, Smart textiles may be used for energy harvesting, health monitoring, and biomedical sensors.

References

- Chatterjee K, Tabor J, Ghosh TK (2019) Electrically conductive coatings for fiber-based E-Textiles. Fibers 7(6): 1-46.

- Stoppa M, Chiolerio A (2014) Wearable electronics and smart textiles: A critical review. Sensors 14(7): 11957-11992.

- Lee J, Kwon H, Seo J, Shin S, Koo JH, et al. (2015) Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv Mater 27(15): 2433-2439.

- Devaux E, Koncar V, Kim B, Campagne C, Roux C, et al. (2007) Processing and characterization of conductive yarns by coating or bulk treatment for smart textile applications. Trans Inst Meas Cont 29(3-4): 355-376.

- Ghahremani HM, Latifi M (2017) Overview of wearable electronics and smart textiles. Journal of the Textile Institute 108(4): 631-652.

- Zhao J, Fu Y, Xiao Y, Dong Y, Wang X, et al. (2020) A Naturally Integrated Smart Textile for Wearable Electronics Applications. Adv Mater Technol 5(1): 1-6.

- Sarif UPMS, Md Syduzzaman, Farhana K, Ahmed S (2015) Smart Textiles and Nanotechnology: A General Overview. Journal of Textile Science & Engineering 5(1): 1-7.

- Liu M, Pu X, Jiang C, Liu T, Huang X, et al. (2017) Large-Area All-Textile Pressure Sensors for Monitoring Human Motion and Physiological Signals. Advanced Materials 29(41): 1-9.

- Nesenbergs K, Selavo L (2015) Smart textiles for wearable sensor networks: Review and early lessons. IEEE International Symposium on Medical Measurements and Applications (MeMeA) 2015-Proceedings 15(10): 402-406.

- Hughes RT, Dias T, Cork C (2018) A historical review of the development of electronic textiles. Fibers 6(2): 1-15.

- Jansen KMB (2019) How to shape the future of smart clothing. in Proceedings of the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing and Proceedings of the 2019 ACM International Symposium on Wearable Computers-Ubi Comp/ISWC ’19, New York, New York, USA: ACM Press pp. 1037-1039.

- Gomes P, Tama D, Yao Y, Abreu MJ, Souto AP, et al. (2018) Development of pressure sensors for smart textiles. IOP Conference Series: Materials Science and Engineering 460(1): 1-14.

- Schneegass S (2017) Introduction to Smart Textiles. Springer International p. 1-15.

- Castano LM, Flatau AB (2014) Smart fabric sensors and e-textile technologies: A review. Smart Materials and Structures 23(5): 1-27.

- Amft O (2016) Smart Eyeglasses, e-Textiles, and the Future of Wearable Computing. Advances in Science and Technology 100: 141-150.

- Haddad PA, Servati A, Soltanianet S, Servati P, Ko F (2019) Roll-to-roll electrochemical fabrication of non-polarizable silver/silver chloride-coated nylon yarn for biological signal monitoring. Textile Research Journal 89(17): 3591-3600.

- Nan N, He J, You X, Sun X, Zhou Y, et al. (2019) A Stretchable, Highly Sensitive, and Multimodal Mechanical Fabric Sensor Based on Electrospun Conductive Nanofiber Yarn for Wearable Electronics. Advanced Materials Technologies 4(3): 1-11.

- La TG, Qui S, Scott DK, Bakhtiari R, Kuziek JWP, et al. (2018) Two-Layered and Stretchable e-Textile Patches for Wearable Healthcare Electronics. Adv Healthc Mater 7(22): 1-11.

- Hao Y, Foster R (2008) Wireless body sensor networks for health-monitoring applications. Physiological Measurement 29(11): 27-56.

- Lin M, Qing X, Kumar A, Beard SJ (2001) Smart Layer and Smart Suitcase for Structural Health Monitoring Applications. Smart Structures and Materials 2001: Industrial and Commercial Applications of Smart Structures Technologies 4332(408): 98-106.

- Zhang J, Tian GY, Marindra AMJ, Sunny AI, Zhao AB (2017) A Review of Passive RFID Tag Antenna-Based Sensors and Systems for Structural Health Monitoring Applications Sensors 17(2): 1-33.

- Bhuiyan MY, Bao J, Poddar B, Giurgiutiu V (2018) Toward identifying crack-length-related resonances in acoustic emission waveforms for structural health monitoring applications. Struct Health Monit 17(3): 577-585.

- Ha M, Lim S, Ko H (2018) Wearable and flexible sensors for user-interactive health-monitoring devices. Journal of Materials Chemistry B 6(24): 4043-4064.

- Guo R, Wang XL, Yu WZ, Tang JB, Liu J (2018) A highly conductive and stretchable wearable liquid metal electronic skin for long-term conformable health monitoring. Sci China Technol Sci 61(7): 1031-1037.

- Wang X, Liu Z, Zhang T (2017) Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small 13(25): 1-19.

- Liu Y, Pharr M, Salvatore GA (2017) Lab-on-Skin: A Review of Flexible and Stretchable Electronics for Wearable Health Monitoring. ACS Nano 11(10): 9614-9635.

- Gao W, Ota H, Kiriya D, Takei K, Javey A (2019) Flexible Electronics toward Wearable Sensing. Acc Chem Res 52(3): 523-533.

- Mahmud MS, Wang H, Alam AMEE, Fang H (2017) A Wireless Health Monitoring System Using Mobile Phone Accessories. IEEE Internet Things J 4(6): 2009-2018.

- Harbouche A, Djedi N, Erradi M, Othman JB, Kobbane A (2017) Model-driven flexible design of a wireless body sensor network for health monitoring. Computer Networks 129: 548-571.

- Li JH, Chen JH, Xu F (2018) Sensitive and Wearable Optical Microfiber Sensor for Human Health Monitoring. Advanced Materials Technologies 3(12): 1-8.

- Wcislik M, Pozoga M, Smerdzynski P (2015) Wireless health monitoring system. IFAC-Papers Online 28(4): 312-317.

- Mohsin AH, Zaidan AA, Zaidan BB, Albahri AS, Albahri OS, et al. (2018) Real-Time Remote Health Monitoring Systems Using Body Sensor Information and Finger Vein Biometric Verification: A Multi-Layer Systematic Review. Journal of Medical Systems 42(12): 238.

- Xue P, Park KH, Tao XM, Chen W, Cheng XY (2007) Electrically conductive yarns based on PVA/carbon nanotubes. Composite Structures 78(2): 271-277.

- Patel PC, Vasavada DA, Mankodi HR (2012) Applications of electrically conductive yarns in technical textiles. IEEE International Conference on Power System Technology (POWERCON).

- Raji RK, Miao XH, Boakye A (2017) Electrical conductivity in textile fibers and yarns-review. AATCC Journal of Research 4(3): 8-21.

- Qu H, Skorobogatiy M (2015) Conductive polymer yarns for electronic textiles. in Electronic Textiles, Elsevier p: 21-53.

- Paiva A, Carvalho H, Catarino A, Postolache O, Postolache G (2016) Development of dry textile electrodes for electromyography a comparison between knitted structures and conductive yarns. Proceedings of the International Conference on Sensing Technology (ICST) pp. 447-451.

- Liehr S, Lenke P, Wendt M, Krebber K, Seeger M, et al. (2009) Polymer optical fiber sensors for distributed strain measurement and application in structural health monitoring. IEEE Sensors Journal 9(11): 1330-1338.

- Catarino A, Carvalho H, Dias MJ, Pereira T, Postolache O, et al. (2012) Continuous health monitoring using E-textile integrated biosensors. EPE 2012-Proceedings of the 2012 International Conference and Exposition on Electrical and Power Engineering.

- Grillet A, Kinet D, Witt J, Schukar M, Krebber K, et al. (2008) Optical fiber sensors embedded into medical textiles for healthcare monitoring. IEEE Sensors Journal 8(7): 1215-1222.

- Montazerian H, Dalili A, Milani AS, Hoorfar M (2019) Piezoresistive sensing in chopped carbon fiber embedded PDMS yarns. Composites Part B: Engineering 164(3): 648-658.

- Li Y, Miao X, Niu L, Jiang G, Ma P (2020) Human motion recognition of knitted flexible sensor in walking cycle. Sensors (Switzerland) 20(1): 35.

- Chhetry A, Yoon H, Park JY (2017) A flexible and highly sensitive capacitive pressure sensor based on conductive fibers with a microporous dielectric for wearable electronics. Journal of Materials Chemistry C 5(38): 10068-10076.

- Wang C, Xia K, Wang H, Liang X, Yin Z, et al. (2019) Advanced Carbon for Flexible and Wearable Electronics. Advanced Materials 31(9): 1801072.

- Zeng W, Shu L, Li Q, Chen S, Wang F, et al. (2014) Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications. Advanced Materials 26(31): 5310-5336.

- Zhang B, Lei J, Qi D, Liu Z, Wang Y, et al. (2018) Stretchable Conductive Fibers Based on a Cracking Control Strategy for Wearable Electronic. Advanced Functional Materials 28(29): 1-7.

- Zhang Y, Zhang W, Ye G, Tan Q, Zhao Y, et al. (2020) Core-Sheath Stretchable Conductive Fibers for Safe Underwater Wearable Electronics. Advanced Materials Technologies 5(1): 1900880.

- Paradiso R, Loriga G, Taccini N (2005) A wearable health care system based on knitted integrated sensors. IEEE Transactions on Information Technology in Biomedicine 9(3): 337-344.

- Rattfält L, Linden M, Hult P, Berglin L, Ask P (2007) Electrical characteristics of conductive yarns and textile electrodes for medical applications. Medical and Biological Engineering and Computing 45(12): 1251-1257.

- Son W, Kim KB, Lee S, Hyeon G, Hwang KG, et al. (2019) Ecoflex-Passivated Graphene–Yarn Composite for a Highly Conductive and Stretchable Strain Sensor. Journal of Nanoscience and Nanotechnology 19(10): 6690-6695.

- Lugoda P, Riely TH, Oliveria C, Morris R, Dias T (2018) Developing novel temperature sensing garments for health monitoring applications. Fibers 6(3): 1-20.

- Zaman SU, Tao X, Cochrane C, Koncar V (2019) Launderability of Conductive Polymer Yarns Used for Connections of E-textile Modules: Mechanical Stresses. Fibers and Polymers 20(11): 2355-2366.

- Acar G, Ozturk O, Golparvar AJ, Elboshra TA, Bohringer K, et al. (2019) Wearable and flexible textile electrodes for biopotential signal monitoring: A review. Electronics (Switzerland) 8(5): 1-25.

- Souri H, Bhattacharyya D (2019) Stretchable and wearable strain sensors using conductive wool yarns with controllable sensitivity. Sensors and Actuators, A: Physical 285: 142-148.

- Shahzad A, Jabbar A, Irfan M, Qabir MB, Ahmad Z (2019) Electrical resistive heating characterization of conductive hybrid staple spun yarns. Journal of the Textile Institute 111(10): 1481-1488.

- Zhang S, He Z, Zhou G, Jung BM, Kim TH, et al. (2020) High conductive free-written thermoplastic polyurethane composite fibers utilized as weight-strain sensors. Composites Science and Technology 189: 108011.

- Indarit N, Kim YH, Petchsang N, Jaisutti R (2019) Highly sensitive polyaniline-coated fiber gas sensors for real-time monitoring of ammonia gas. RSC Advances 9(4): 26773-26779.

- Shahzad A, Ali Z, Ali U, Khaliq Z, Zubair M, et al. (2019) Development and characterization of conductive ring spun hybrid yarns. Journal of the Textile Institute 110(1): 141-150.

- Arquilla K, Webb A, Anderson AP (2020) Textile electrocardiogram (Ecg) electrodes for wearable health monitoring. Sensors (Switzerland) 20(4): 1013.

- Matuska S, Hudec R, Vestenicky M (2019) Towards the development of a smart wearable device based on electrically conductive yarns. Transportation Research Procedia 40: 367-372.

- Qureshi Y, Tarfaoui M, Lafdi KK, Lafdi K (2019) Real-time strain monitoring performance of flexible Nylon/Ag conductive fiber. Sensors and Actuators A: Physical 295: 612-622.

- Ismar E, Zaman SU, Tao X, Cochrane C, Koncar V (2019) Effect of Water and Chemical Stresses on the Silver Coated Polyamide Yarns. Fibers and Polymers 20(12): 2604-2610.

- Abot JL, Anike JC (2019) Structural Health Monitoring Using Carbon Nanotube Fibers. Nanotube Super fiber Materials Elsevier pp: 219-238.

- Wang L, Tian M, Zhang Y, Sun F, Qi X, et al. (2020) Helical core-sheath elastic yarn-based dual strain/humidity sensors with MXene sensing layer. Journal of Materials Science 55(14): 6187-6194.

- Riley TH, Dias T (2018) Developing an acoustic sensing yarn for health surveillance in a military setting. Sensors (Switzerland) 18(5): 1590.

- Hatamie A, Angizi S, Kumar S, Pandey CM, Simchi A, et al. (2020) Review-Textile Based Chemical and Physical Sensors for Healthcare Monitoring. Journal of The Electrochemical Society 167(3): 037546.

- Fan W, He Q, Meng K, Tan X, Zhou Z, et al. (2020) Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring Science Advances 6(11): 1-10.

- Tseghai GB, Mengistie DA, Malengier B, Fante KA, Langenhove LV (2020) PEDOT: PSS-Based Conductive Textiles and Their Applications. Sensors 20(7): 1881.

- Zhang M, Wang M, Zhang M, Gao Q, Feng X, et al. (2020) Stretchable conductive Ni@Fe3O4@Polyester fabric strain sensor with negative resistance variation and electromagnetic interference shielding. Organic Electronics 81: 105677.

- Anike JC, Abot JL (2020) Sensors based on CNT yarns. In: Carbon Nanotube Fibers and Yarns, Elsevier, pp. 213-241.

- Zhou Z, Padgett S, Cai Z, Conta G, Wu Y, et al. (2020) Single-layered ultra-soft washable smart textiles for all-around ballistocardiograph, respiration, and posture monitoring during sleep. Biosensors and Bioelectronics 155(12): 112064.

- Jang Y, Kim SM, Spinks GM, Kim SJ (2020) Carbon Nanotube Yarn for Fiber‐Shaped Electrical Sensors, Actuators, and Energy Storage for Smart Systems. Advanced Materials 32(5): 1902670.

- Lv J, Dai Y, Xu H, Zhong Y, Zhang L, et al. (2020) Transforming commercial regenerated cellulose yarns into multifunctional wearable electronic textiles. Journal of Materials Chemistry C 8(4): 1309-1318.

- Mohan VB, Bhattacharyya D (2020) Mechanical characterization of functional graphene nanoplatelets coated natural and synthetic fiber yarns using polymeric binders. International Journal of Smart and Nano Materials 11(1): 78-91.

- Qi K, Wang H, You X, Tao X, Li M, et al. (2020) Core-sheath nanofiber yarn for textile pressure sensor with high-pressure sensitivity and spatial tactile acuity. Journal of Colloid and Interface Science 561(3): 93-103.

- Xu X, Luo M, He P, Yang J (2020) Washable and flexible screen-printed graphene electrode on textiles for wearable healthcare monitoring. Journal of Physics D: Applied Physics 53(12): 125402.

- Li T, Wang X, Jiang S, Ding X, Qiao L (2020) Physical Study on electromechanical property of polypyrrole-coated strain sensors based on polyurethane and its hybrid covered yarns. Sensors and Actuators A: Physical 306: 111958.

- Miankafshe MA, Bashir T, Persson NK (2020) Electrostatic grafting of graphene onto polyamide 6,6 yarns for use as conductive elements in smart textile applications. New Journal of Chemistry 44(18): 7591-7601.

- Homayounfar SZ, Andrew TL (2020) Wearable Sensors for Monitoring Human Motion: A Review on Mechanisms, Materials, and Challenges. SLAS Technology 25(1): 9-24.

- Shi G, Lowe SE, Zhong YL, Zhao H (2020) Flexible and stretchable inorganic electronics: Conductive materials, fabrication strategy, and applicable devices. In: 2D Materials for Photonic and Optoelectronic Applications, Elsevier, pp. 199-252.

- Watson A, Sun M, Pendyal S, Zhou G (2020) TracKnee: Knee angle measurement using stretchable conductive fabric sensors. Smart Health 15: 100092.

- Huang Y, Hu H, Huang Y, Zhu M, Meng W, et al. (2015) From industrially weavable and knittable highly conductive yarns to large wearable energy storage textiles. ACS Nano 9(5): 4766-4775.

- Alagirusamy R, Eichhoff J, Gries T, Jockenhoevel S (2013) Coating of conductive yarns for electro-textile applications. Journal of the Textile Institute 104(3): 270-277.

- Schwarz A, Kazani I, Cuny L, Hertleer C, Ghekiere F, et al. (2011) Electro-conductive and elastic hybrid yarns - The effects of stretching, cyclic straining and washing on their electro-conductive properties. Materials and Design 32(8-9): 4247-4256.

- Liu X, Chang H, Li Y, Huck WTS, Zheng Z (2010) Polyelectrolyte-bridged metal/cotton hierarchical structures for highly durable conductive yarns. ACS Applied Materials and Interfaces 2(2): 529-535.

- Kim B, Koncar V, Dufour C (2006) Polyaniline-coated PET conductive yarns: Study of electrical, mechanical, and electro-mechanical properties. Journal of Applied Polymer Science 101(3): 1252-1256.

- Bedeloglu A, Sunter N, Bozkurt Y (2011) Manufacturing and properties of yarns containing metal wires. Materials and Manufacturing Processes 26(11): 1378-1382.

- Vries HD, Cherenack KH (2014) Endurance behavior of conductive yarns. Microelectronics Reliability 54(1): 327-330.

- Varnaite S (2010) The use of conductive yarns in woven fabric for protection against electrostatic field. Materials Science (Medziagotyra) 16(2): 133-137.

- Kaynak A, Najar SN, Foitzik RC (2008) Conducting nylon, cotton and wool yarns by continuous vapor polymerization of pyrrole. Synthetic Metals 158(1-2): 1-5.

- Ye C, Xu Q, Ren J, Ling S (2020) Violin String Inspired Core-Sheath Silk/Steel Yarns for Wearable Triboelectric Nanogenerator Applications. Advanced Fiber Materials 2(1): 24-33.

- Bashir T, Skrifvars M, Persson NK (2011) Surface modification of conductive PEDOT coated textile yarns with silicone resin. Materials Technology 26(3): 135-139.

- Kim B, Koncar V, Devaux E, Dufour C, Viallier P (2004) Electrical and morphological properties of PP and PET conductive polymer fibers. Synthetic Metals 146(2): 167-174.

- Ramachandran T, Vigneswaran C (2009) Design and development of copper core conductive fabrics for smart textiles. Journal of Industrial Textiles 39(1): 81-93.

- Bouwstra S, Chen W, Feijs L, Oetomo SB (2009) Smart jacket design for neonatal monitoring with wearable sensors. 2009 6th International Workshop on Wearable and Implantable Body Sensor Networks, BSN.

- Soh PJ, Vandenbosch GAE, Mercuri M, Schreurs DMMP (2015) Wearable wireless health monitoring: Current developments, challenges, and future trends. IEEE Microwave Magazine 16(4): 55-70.

- Yang CM, Huang WT, Yang TL, Hsieh MC, Liu CT (2008) Textiles digital sensors for detecting breathing frequency. 5th Workshop on Wearable and Implantable Body Sensor Networks, BSN2008, in conjunction with the 5th Int. Summer School and Symp. on Medical Devices and Biosensors, ISSS-MDBS.

- Zhou Y, He J, Wang H, Qi K, Nan N, et al. (2017) Highly sensitive, self-powered and wearable electronic skin based on pressure-sensitive nanofiber woven fabric sensor. Scientific Reports 7(1): 1-9.

- Yan T, Wang Z, Pan ZJ (2018) A highly sensitive strain sensor based on a carbonized polyacrylonitrile nanofiber woven fabric. Journal of Materials Science 53(16): 11917-11931.