An Overview of Hybrid Ring Spinning Methods

Banu Nergis*

Department of Textile Engineering, Technical University of Istanbul, Turkey

Submission: October 25, 2017; Published: December 12, 2017

*Corresponding author: Department of Textile Engineering, Technical University of Istanbul, Istanbul, Turkey, Email: uygunf@itu.edu.tr

How to cite this article: Banu N. An Overview of Hybrid Ring Spinning Methods. Curr Trends Fashion Technol Textile Eng. 2017; 1(5): 555572. DOI: 10.19080/CTFTTE.2017.01.555572

Introduction

Ring-spinning accounts for about two third of global long and short staple yarn production. The main reason for the dominance of ring-spinning over other spinning systems is its versatility in terms of yarn linear density and fibre type, and also the superior quality of ring-spun yarns over those produced by other systems. The main disadvantage of the spinning system is the yarn production rate due to limitations in spindle speed (productivity), high power consumption, traveller wear and heat generation and yarn tension [1].

The technology behing ring spinning remained largely unchanged for many years and most of the technical advances in ring spinning aimed at improving the performance of the existing technology. During the past decades, much attention was paid to improve the quality of ring spun yarns, and to achieve higher production rates. Consequently, many novel and effective spinning technologies have appeared, such as compact spinning, Siro-spinning, Solo-spinning, etc. [2].

The most critical part of the conventional ring spinning system is the zone between the nip line of the delivery rollers and the twisted end of the yarn which is called the "spinning triangle" In this zone, the fibers do not have any twist. The edge fibers in the spinning triangle make little or no contribution to the yarn tenacity and they lead to yarn hairiness. In compact spinning, the "spinning triangle” is eliminated and almost all fibers are incorporated into the yarn structure under the same tension. This results in an increasein yarn tenacity, yarn abrasion resistance and reduction in yarn hairiness. Pneumatic compact spinning is the most widely used compacting system which utilises the airflow force to condense the fibre bundle in the spinning triangle [3].

During the production of siro yarns two parallel rovings are introduced to the drafting region of conventional ring spinning system at a predetermined spacing. Rovings are then twisted together to form a two ply yarnthat yield improved yarn characteristics [4,5].

Solospinning is a wool spinning technology which provides the means to produce a singles yarn which change the yarn structure in such a way that the yarn is more similar to the plied yarn. During the Solospun yarn production a pair of rollers held in a bracket is clipped onto a conventional ring spinning frame. Each roller is positioned where it interacts with the emerging drafted fibre strand before twist insertion. The roller-fibre interaction subtly changes the structure of the yarn, which dramatically increases its abrasion resistance [6].

Invention and application of modified/new spinning methods to produce finer yarn with higher quality are still ongoing. Below some modified machine configurations based on ring spinning technology and properties of the yarns producedusing these systems areoutlined. It should however, be noted that of the presented techniques, not all have been launched as commercial machines.

The Solo-siro spinning system is a new system which can produce a distinctive yarn structure by combining Solo and Siro spun processes [7,8]. The results of studies on Solo-siro spun yarns showed that these yarns have a coherent self-locking structure in which fibre slippage is restricted. The tensile deformation of such a yarn is dominated by fibre break-age rather than by the weakening of the structure due to fibre slippage, thereby increasing yarn strength and elongation [9]. Utilising Solo-siro spinning system significatly improves worsted blended wool/polyester yarn hairinessand abrasion resistance.

The sirofil spun yarn is manufactured using a modified siro spinning technology, in which one of the siro elements is replaced by a filament [10,11]. Filament yarn and a staple fibre roving are fed separately at a fixed distance to the nip of the front drafting roller, as shown in (Figure 1). Filament and rovingform a tri-angular zone which is twisted together to build the sirofil yarn structure.

The sirofil spun technology manufactures the composite spun yarn with a helical form, where the filaments are twisted along with the longitudinal direction on the surface of the spun yarn.

Compact-Siro spinning technology is the combination of both Compact and Siro-spinning. It is conducted on a compact ring frame by feeding two rovingsat the same time. As compact spinning system minimises the size of the spinning triangle, the yarn properties are better in comparison to conventional ring yarns. Yarn properties further improve with compact siro system where features of both Com-pact and Siro Yarns are incorporated in the yarns produced using this system. Compared with compact single yarn, Compact-Siro spun yarn has a more com-pact and clear surface structure, a more uniform and smoother shape, and less hairiness [12,13]. Cross-section of Compact-Siro yarn is smoother and closer to being circular when compared with a sirospun yarn. Studies revealed that compact siroyarn spun on pneumatic compact spinning system has remarkable properties as compared to ring spun siro yarn. It has better evenness, lower number of imperfections and very low yarn hairiness with improved tensile properties [14-16].

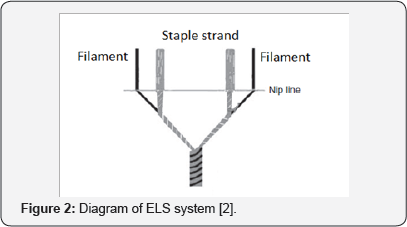

In the Siro-system, the fiber strand is initially separated into double strands which causes fewer fibers in each strand compared with the one strand in conventional ring system. This might result in end breakages during production depending on the yarn count. In some cases, filaments are introduced between the strands right into the center of the resultant yarn to enhance the yarn strength. However, the filaments just reinforce strength of the resultant yarn instead of each spinning strands. A new concept of ring spinning was raised in an attempt to overcome this situation. The Embeddable and Locatable spinning (ELS) enables the location of filaments and staple strands in such a way that each staple strand could be reinforced by the filaments, and staple fibers could be well embedded into the resultant yarn structure [2]. Two filaments are located at the outer position and the two staple fiber strands are fed between them (Figure 2). It is theoretically proved that super-fine and multi colored yarns could be produced successfully; even staple fibers of low quality could be spun into a fine yarn of high qualities in this novel spinning system.

Jet-ring spinning technology combines the ring spinning andair-jet spinning technologies. In jetring, an air-jet is positioned between the yarn guide (pigtail) and the frontroller nip of the ring spinning machine. The air-jet creates upward swirlingof air against the direction of movement of the yarn. The yarn spun on ring spinning machine with a false twister presents a much more compact structure, which potentially contributes to the reduced yarn hairiness and increased yarn strength. In addition, a slight variation in the diameter of the modified yarn can be observed. For the bestperformance, parameters such as air pressure and the distancebetween the front roller nip and the air-jet, design parameters of the jet must be optimized [17,18].

Another application of the nozzle component is the Compactjet spinning system. In the Compact-jet system, the nozzle is mounted below the compacting unit. The Jetring and Compactjet spinning systems produce less hairy yarns with no adverse effect on the other yarn properties. The Compact-jet spinning system, com-pared with the Jetring spinning, is more effective in terms of yarn proper-ties [19,20].

Siro-jet machine configuration is also developed placing air jet nozzles in the siro spinning system between the front roller nip and yarn guide on the siro spinning machine [21,22]. The results suggest that when an air-jet nozzle is incorporated below the front roller nip, allowing the twisting yarn to pass through the nozzle, yarn hairiness can be significantly reduced.

The indispensable efforts for elevating the performance of the existing ring spinning technology and ring yarns result in the modification of ring spinning machines by adopting various spinning techniques on these machines. Studies show that yarns produced using hybridspinning methods based on ring spinning technology have primarily reduced yarn hairiness as well as higher abrasion resistance and, higher strength. The proposed techniques appear promising in improving the performance of ring spun yarns.

References

- Gordon S, Hsieh YL (2007) Cotton: Science and Technology. Woodhead Publishing Limited and CRC Press LLC.

- Weilin X, Zhigang X, Xin W, Jun C, Weigang C, et al. (2011) Embeddable and locatable spinning. Textile Research Journal 81(3): 223-229.

- Altas S, Kadoglu H (2012) Comparison of Conventional Ring, Mechanical Compact and Pneumatic Compact Yarn Spinning Systems. Journal of Engineered Fibers and Fabrics 7(1): 87-100.

- Anbumanib N, Subramaniamc V, Gokarneshana N (2007) Influence of strand spacing on the interfibre cohesion in siro yarns. Journal of The Textile Institute 98(3): pp. 289-292.

- Khan ZA, Wang XG, Shaikhzadeh Najar S (2006) The new Solo-Siro spun process for worsted yarns. Journal of The Textile Institute 97(3): pp. 205-210.

- https://csiropedia.csiro.au/solospun/ (accessed in October 2017)

- Soltani P, Johari MS (2013) Effect of Using the New Solo-siro Spun Process on Structural and Mechanical Properties of Yarns. Fibres & Textiles in Eastern Europe 21, 3(99): 51-54.

- Ghasemi R, Dana RM, Etrati SM, Najar SS (2008) Comparing the Physical Properties of Produced Sirospun and New Hybrid Solo- Siro Spun Blend Wool/Polyester Worsted Yarns. Fibres & Textiles in Eastern Europe 16(1): 66.

- Min K, Boong SJ (2014) New Composite Yarn with Staple Fiber and Filament Controlling the Delivery Speed Ratio Fibers and Polymers 15(12).

- Yang R, Xue Y, Wang SY (2010) Comparison and Analysis of Rotor-Spun Composite Yarn and Sirofil Yarn Fibres & Textiles in Eastern Europe 18(1): 78.

- Zhigang X, Qinsheng G (2017) Comparative study of fiber trapping by filaments in conventional and diagonal sirofil systems Textile Research Journal.

- Yang RH, Wu WM (2012) Effect of Filament Pre-tension on the Performance of Solo-Sirofil Composite Yarn, Short Communications. Indian Journal of Fiber and Textile Research 37: pp. 378-380.

- Su X, Gao W, Liu X, Xie C, Xu B (2015) Research on the Compact-Siro Spun Yarn Structure. Fibres & Textiles in Eastern Europe 23, 3(111): 54-57.

- Khurshid MF (2017) Comparative Analysis of Siro Yarn Properties Spun On Ring and Pneumatic Compact Spinning Systems. Industria Textila 68(4): 4.

- Sunil Kr Sett (2014) Studies on Characteristics of Ply Yarns by Different Techniques. American International Journal of Research in Science, Technology, Engineering & Mathematics 8(2): pp. 152-155.

- Unal S, Omeroglu S (2013) Investigation of Two-fold Yarn Properties Produced as Directly by Using Different Systems in Ring Spinning, Pamukkale Univ Muh Bilim Dergisi 19(4): 165-169.

- Alagirusamy R, Das A (2010) Technical textile yarns: Industrial and medical applications, Published by Woodhead Publishing Limited in association with The Textile Institute.

- Feng J, Xu B, Tao X (2014) Structural Analysis of Finer Cotton Yarns Produced by Conventional and Modified Ring Spinning System. Fibers and Polymers 15(2): 396-404.

- Yilmaz D, Usal MR (2013) Investigation of Yarn Properties of Modified Yarn Spinning Systems with Air Nozzle Attachment. Fibres & Textiles in Eastern Europe 21(2): 98.

- Yilmaz D, Usal MRA (2010) Comparison of compact-jet, compact,and conventional ring-spun yarns. Textile Research Journal 81(5): 459470.

- Hasani H, Hasani M (2012) Simulation Approach to Investigate the Effect of the Jet Structure and Air Pressure on the Performance of Siro- jet Spinning. Fibres & Textiles in Eastern Europe 20(3): 92.

- Nejad S, Najar S, Hasani H (2011) Application of air-jet nozzle in short staple Siro spinning system. The Journal of the Textile institute 102(1): 14-18.