Abstract

The challenges for the manufacturing industry to make their entire manufacturing processes sustainable under the keywords decarbonization and circular economy are enormous. All components and systems must undergo re-design processes. These are lengthy, place high demands on the use of other and new previously unknown materials, as well as their processing and recycling possibilities. These processes are on the one hand time-consuming and cost-driving. One approach is being discussed that shows the possibility of shortening these processes by using digital twins and artificial intelligence.

At the same time, such an opportunity is a challenge for both strategic and operational management. Growing complexity and the resulting higher coordination effort also challenge project management, which must address these opportunities. These positions are presented and discussed here. Ultimately, it is not a question of whether but when the process changes described here will be implemented in industrial manufacturing processes. Operational management must also prepare for this. The core question is: How to design and manage planetary future of man?

Keywords:Re-Design; Re-Manufacturing; Digital Twins powered by AI; Challenges for Project Management of the Future

Circular Economy: A Challenge for The Global Economy

Decarbonizing production processes and introducing a circular economy is a global challenge for the manufacturing industry for sustainable development. Industry-specific differences must be overcome. A circular economy can be defined as an economy that aims to keep materials and energy at their highest value for as long as possible [1].

According to Korhonen et.al. [2], circular economy is the use of cyclical material flows, renewable energy sources and cascading energy flows. It contributes to all three dimensions of sustainable development and limits the throughput flow to a level that nature can tolerate and utilizes ecosystem cycles in economic cycles by respecting their natural reproduction rates. This presents the manufacturing industry with a complex challenge: all components, systems and ongoing production processes must undergo a complete redesign to close material cycles, extend product lifecycles and enable material recycling. For example, the number of components in a passenger car has increased from the original 7,000 individual parts to 30,000 within forty years. For modern commercial airplanes, this is up to 2,000,000 [1] components.

These challenges are like trying to make a carpet fly. The previous take-make-waste approach and what I call green wonderland are not effective here. The methodological concepts for strategic and operational management are not yet sufficiently developed to enable a holistic approach. Proposals are under discussion, but experience from implementations and their effects on project management are still pending [3].

According to available data, only 13% of all raw materials used in production processes in the Federal Republic of Germany will be secondary raw materials in 2024 [4]. Worldwide, circular processes are reported for just over 7% (www.circularity-gap.world/2023). However, awareness of a circular economy is clearly growing [5].

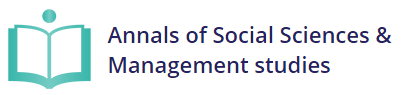

Kirchherr et.al. [6] described four main obstacles to the implementation of the circular economy in 2018: in addition to the obvious lack of available data, there is a shortage of the necessary capital. Further obstacles exist at the legislative level and there are also question marks over the behavior of buyers and consumers.

These obstacles interact with each other, which can lead to chain reactions, as shown in Figure 1. The challenge of introducing a circular economy for strategic and operational management can be summarized in one sentence as follows: How to design and manage the planetary future of man? [3]. Answers to this question must be found in the fields of poverty reduction, war prevention and avoidance of environmental destruction and resource exploitation.

This raises the question of how innovation management and project management can be designed to provide sufficient support for these changes.

Management Systems for The Circular Economy - an Unresolved Issue

A change in human behavior is a prerequisite for a turnaround [7]. Thinking further, this means a complete redesign of all components and systems in products such as cars, airplanes, etc. to largely recycle materials and thus contribute to the recycling of raw materials and the avoidance of waste [8]. All components of a product must undergo a redesign during the ongoing process - a very ambitious task with a high degree of difficulty and complexity.

As outlined above, the industry’s readiness for production and manufacturing processes has so far been rather rudimentary. Studies have shown a rather pronounced tendency not to address these issues strategically and operationally [9, 10]. Older statements showed that, on the one hand, knowledge and skills are not or not sufficiently available [11]. On the other hand, there is a deficit in management methods for both strategic and operational management [3, 12].

Management consultants McKinsey estimates the market potential for a circular economy in consumer goods alone at €650 billion per year in the medium term. The Federation of German Industries, together with the consulting firm Deloitte, assumes an increase of €12 billion per year in gross value added and an effect of 120,000 jobs by 2030 [4].

Production in the sense of a circular economy can be defined as a concept in which the idea of several product life cycles together with energy and material savings and value creation while avoiding waste are integrated components in product design and development strategies [13]. Approaches such as Product as a Service, as practiced by ABB with its robotics division [14], or Production as a Service are initial approaches here [15].

An EU directive [16] describes a framework for waste prevention, with waste reduction defined as the primary goal. Remanufacturing only takes second place here.

A Smart Circular Economy Framework was described as a process model based on the 10Rs (Refuse, Rethink, Reduce, Reuse, Repair, Refurbish, Remanufacture, Recycle, Recover) [17]. The implementation of these strategies and similar approaches was described by the authors that the use of digital twins is critical as enabler to leverage significant sustainable potential.

The question being discussed here in perspective relates to the possibility of how digital twins can be used for re-design processes and their continuation in components that can be subjected to remanufacturing for individual and multiple components in systems to manage them in cycles. This not only raises questions about the future design of components, but also about the materials to be used, their extraction, durability, environmental compatibility, etc. Such new developments will have a profound impact on strategic and operational managers and their methodical approach to the in organizations. Digital Twins technologies have already been discussed and described in general [18, 19] and e.g. for aerospace engineering [20] Digital Twins, which are in the first stages of development and introduction. In the construction sector for building materials, initial approaches are also being discussed [21].

New materials can enable fundamental breakthroughs in technological applications. For example, the development of inorganic crystals for batteries has been hampered by expensive trail-and-error approaches. Merchant et.al. [20] published in November 2023 the possibility of using AI to generate new structures for chemicals that can be used as components for new materials, in this case for layered materials and solid electrolytes. In materials research, machine learning and other computeraided processes are used to discover new materials. Research here ranges from corrosion-resistant aircraft components and better batteries to new drugs and catalysts. The problem is that the number of possible materials is infinite [22].

This raises the question of whether the use of digital twins powered by AI systems for the redesign of components, as required for circular processes in production, can be supported. In this context, it can be assumed that the complexity of handling these processes operationally is of a magnitude for which the previous operational management processes and thus project management are not mapped. As a result, project management can take on a completely different dimension for which we are not prepared. This is put up for discussion here.

Digital Twins Powered by AI as a Paradigm Shift in The Circular Economy?

A general description for Digital Twin is as follows: “The Digital Twin (DT) is a key technology with features such as interactive feedback between cyberspace and physical space, data acquisition, error prediction, and iterative optimization for decision making, and has become a focus of research in smart manufacturing” [23].

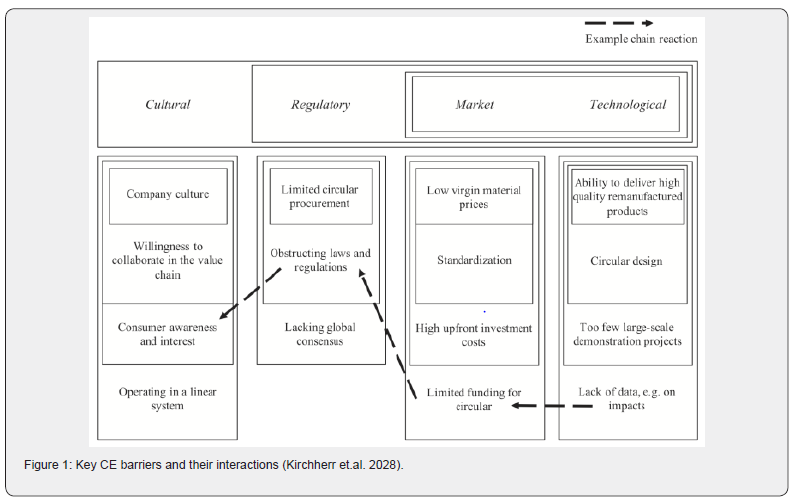

Digital twins are now available as product, technology, machine and equipment twins, as well as process twins [24]. The value of this technology has been recognized in research, business and other interested organizations, including healthcare, agriculture, urban science, aviation and planetary systems [20]. Applications in the store floor life cycle in conjunction with the product life cycle have already been described (see Figure 2).

Digital twins can be used throughout the entire life cycle of both the product and the production facility and form a link in the manufacturing process. The main task of digital twins is to help with the design and implementation of products and production facilities and to ensure performance.

Several processes, such as logistics and control processes, can be simulated in a virtual environment to support management and improve the efficiency of the process [20]. These elements can be given instructions within the manufacturing systems, creating a closed loop between the virtual and physical space. Dynamic planning in manufacturing was realized by analyzing processing time, employee skill level, cost, energy consumption and other data. This effectively reduced planning deviation and improved the efficiency and quality of planning execution. In the operation and maintenance or use and recycling phases, sensor data provides the status of machines, production lines, factories or other objects. By combining historical data, field data and twin models, a more accurate prediction can be made. Maintenance planning and remote maintenance can also be realized.

In cases where DT is used to support remanufacturing, the complexity of the remanufacturing process can be reduced with the help of DT. As this remanufacturing process includes various obstacles such as different quality of recovered parts, remanufacturing by different organizations, lack of information transfer between the manufacturers and the remanufacturers, the complexity of the logistic network, etc. These obstacles can be addressed by the newer technologies such as Digital Twins and Artificial Intelligence [24].

Digital Twins can increase the level of intelligence, which can lead to more faithful models. The physical data and knowledge of the processes can be fully utilized and a deep fusion between the physical and virtual spaces can be connected through interactions. A model of the digital twin could consist of these four levels: System Models, Geometric Models, Process Models and Simulation Models [25].

Furthermore, the concept of combining discrete event simulations and agent-based modeling agent-based modeling paradigms to obtain hybrid simulations for a data-driven digital twin emulator. This can support design decisions and virtual commissioning [24]. Meanwhile, the development of the use of digital twins in production engineering through digital twin-based manufacturing systems (DTMS) has progressed to the point where it has been upgraded to a smart manufacturing system (SMS). This concept enables “fully integrated, collaborative and responsive operations that respond in real time to changing demands and conditions in the factory, supply network and customer needs through data-driven understanding, reasoning, planning and execution of all aspects of manufacturing processes enabled by the prior use of advanced sensors, modeling, simulation and analytics technologies” [26].

It is undisputed that remanufacturing is an effective method of recycling resources for sustainable production and a circular economy. In product lifecycle management (PLM), however, little importance has been attached to it to date. Implementation problems of a remanufacturing strategy such as the inability to effectively reduce uncertainties, the lack of management to track remanufacturing processes over multiple lifecycles of products and/or components, and the lack of intelligent application of technologies over an entire lifecycle that focuses on remanufacturing for multiple lifecycles, among others. As suggested by Wang et.al. [28], a predictive remanufacturing process driven by big data with a digital twin as an integration capability of smart base technology can create a new PLM paradigm.

In conclusion, it can be postulated that by combining digital twins of entire systems with AI systems, it is possible to determine which components can be redesigned and which materials can be used to enable re-manufacturing. The focus here is on accelerating this entire process and planning it as an iterative process over a time axis.

Outlook: Impact on Project Management

The statement that project management is subject to change and adaptation with technological progress is banal. On the issue of sustainable developments, including the circular economy, the IPMA (International Project Management Association) presented the ICB 4.0 Reference Guide for Sustainability at the World Congress in Capetown in November 2024 (https://bookshop. ipma.world/standards/project-management/ipma/standards/ sustainable-guide-for-project-management#). The consequences of this for organizations are currently being discussed.

The project life cycle is the focus of project management. The extension of the consideration towards shaping the future must also consider the product life cycle [29,30]. Concepts and methods for sustainable developments in the sense of circularity, such as those formulated by Braungart as the cradle-to-cradle principle in 2014, are not yet sufficiently in focus or do not meet the complexity of the issues or provide no or only insufficient guidance for management. The developments in industrial design and manufacturing processes discussed here are likely to pose new challenges for project management and therefore also for strategic management in companies.

New ideas are needed both for the design of project management processes and for the provision of appropriate organizational prerequisites to accomplish these tasks when the concept of digital twins is integrated with AI systems for re-design and in the associated material development and manufacturing processes and managed in cycles. These new ideas will probably have to be combined and expanded in a previously unknown way. This is not just about technological change, but also about the overall human consequences of this change [31]. It is a transition from previous linear management and thought processes to thinking in cycles, which is not only expected to be highly accelerated using AI-powered DT systems but will also raise the complexity of management and all those involved to new dimensions. Our current world of strategic and operational management is not prepared for this.

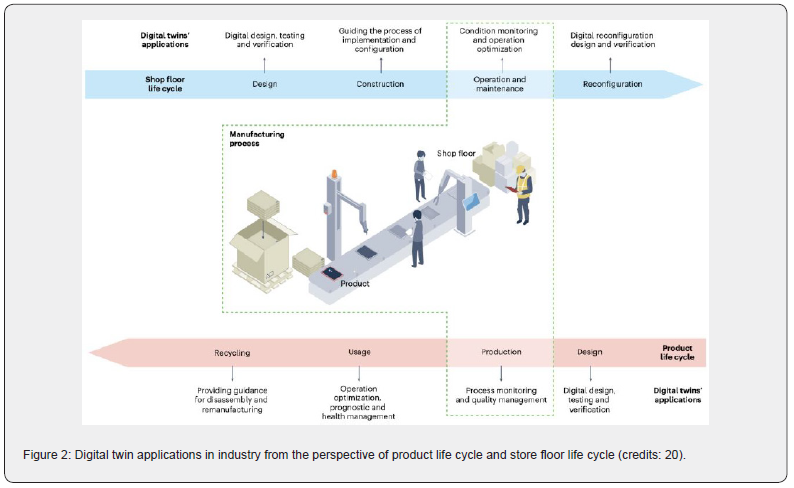

As shown in figure 3, taken from the work of Hina et.al. [32], gives an impression of the need to develop a multi-layered management system. If we focus exclusively on the upper part of the diagram, the barriers that a circular economy must deal with are pointed out. These are divided into external and internal barriers. If we focus on the internal barriers, the seven positions mentioned there indicate the need for action and coordination that would arise if the procedures envisaged here are created for AI-powered digital twins. It is to be expected that the pressure to make decisions and therefore the need for communication between all stakeholders will take on new dimensions. In my view, there is a great need for research into the development of appropriate management systems to cope with these tasks (Figure 3).

In my view, this underlines the need for action regarding the further development of project management methods. Methods such as Cross-Company Collaboration Project Management (C3PM), which have been known for some time and have proven themselves in the automotive industry, for example, and which reach into the deeper structures of suppliers, could provide approaches here. It is also to be expected that R&D activities will also have to be integrated into management by partners.

Product development and manufacturing from the perspective of a circular economy is a top management task. The supervisory bodies of companies are required to plan, decide and monitor accordingly. This is an organizational change and not just a redesign of existing business processes. All business areas - existing and future - must understand sustainability and thus circularity as the most important pillar of the company. These must be in line with the strategic goals [33].

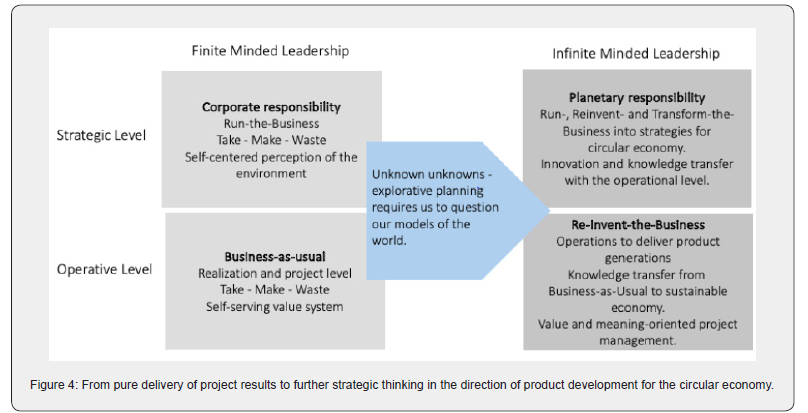

In the author’s view, the developments described require a completely different approach from both strategic and operational management. Uncertainties and risks will increase. This must be dealt with, as must an increase in complexity and the increased involvement of external partners. Project management can then no longer be seen solely as a method for delivering project results without going into more detail about the content, results and procedures. Project management becomes a design principle for the future, both for product developments, product enhancements and customer behavior and their management. The way strategic management thinks and acts must also be aligned in such a way that the focus is no longer on quarterly and annual results, nor on delivering project results on time and within budget, schedule and content. Strategic and operational managers are moving from being finite-minded leaders who focus on short-term success to infinite-minded leaders who take long-term developments into account. A management system is required that can admit open questions in the longer term, providing solutions and dealing with uncertainty and risk. The portfolio in Figure 4 shows a comparison of the differences for management between the first and second narrative compared to the third narrative.

There are many questions and few answers that go beyond initial approaches. What is needed is a simple and clear generic methodological approach that encompasses both strategic and operational management and incorporates sustainability in all its facets. This approach requires interdisciplinarity and an accumulation of available knowledge and skills. Initial descriptions have already been presented for discussion, but further developments are necessary [3].

The changes in production equipment and production methods discussed here, using Digital Twins powered by AI, will influence strategic and operational management. Innovative management methods are necessary to make this change happen. Organizations must create the conditions to make this possible.

References

- Manoury M, Bassam H (2023) Module Based Solution Engineering. Fraunhofer-IPK, Germany.

- Korhonen J, Honkasalo A, Seppälä J (2018) Circular Economy: The Concept and its Limitations. Ecological Economics 143: 37-46.

- Glitscher W (2024) We are in the driver's seat - A magic carpet ride. Journal of Investment, Banking and Finance 2(1): 01-09.

- National Circular Economy Strategy: Avoidance, Recycling, Recycling (2024) Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection.

- Krohn P (2025) Closing loops requires more attention, Frankfurter Allgemeine Zeitung.

- Kirchherr J, Piscicelli L, Bour R, Kostense-Smit E, Muller J, et al. (2018) Barriers to the Circular Economy: Evidence From the European Union (EU). Ecological Economics 150: 264-272.

- Behavior as leverage (2022) nature climate change. 12: 1069.

- Otten W (2023) Interdisciplinary Committee Digital Transformation at the VDI, In: Martin Ciupek, VDI-Nachrichten.

- Peuser M, Eichenberg T (2024) Project Portfolio Sustainability Monitor 2024. GPM German Association for Project Management e.V.

- Erol S, Hörbe R (2025) Bridging the Educational Gap in Circular Design and Engineering - An Educational Concept and Case Study from Austria. In: Kohl H, Seliger G, Dietrich F and Mur S (Ed.),: Sustainable Manufacturing as a Driver for Growth, Proceedings of the 19th Global Conference on Sustainable Manufacturing, Buenos Aires, Argentina.

- https://www.business-standard.com/article/technology/nearly-three-fourth-of-internet-of-things-projects-are-failing-cisco-117052400504_1.html

- Glitscher W (2023) Re-Thinking Project Management for Circular Economy; IPMA Global Project Profession Forum, Sevilla.

- Asif FM, Bianchi C, Rashid A, & Mihai Nicolescu C (2012) Performance analysis of the closed loop supply chain 2(4).

- Sharma M, Dixit Y, Glitscher W (2023) Re-Thinking Project Management - A sustainable approach put up for discussion; 27th International Congress on Project Management and Engineering, IPMA, San Sebastian.

- Brecher C, Fey M, Loba M, Malinowski O, Ochel J, Schäfer J, et al. (2023) Sustainability in Product Lines, Empower Green Production Fraunhofer IPT Conference Proceedings.

- EU-Directive (2008) 2008/98/EG.

- Schmitt RH, Bodenbrenner M, Brings H, Montavon B (2023) Data Structures for Resilience in Life Cycle Sustainability; In: Empower Green Production, Fraunhofer IPT, Germany.

- Tao F, Zhang H, Zhang C (2024) Advancements and challenges of digital twins in industry, nature computational science 4: 169-177.

- Editorial (2024) The increasing potential and challenges of digital twins, nature computational science 4: 145-146.

- Ferrari A, Willcox K (2024) Digital twins in mechanical and aerospace engineering, nature computational science 4: 178-183.

- Keulemann G, Adams R (2024) Emergent digital possibilities for design led reuse within circular economy, urban sustainability 4: 31.

- Merchant A, Batzner S, Schoenholz SS, Aykol M, Cheon G, et al. (2023) Scaling deep learning for materials discovery. nature 624.

- Savage N (2021) Speed-sifting data for next big thing. nature 595.

- Feng Q, Zhang Y, Sun B, Guo X, Fan D, et al. (2023) Multi-level predictive maintenance of smart manufacturing systems driven by digital twin: A matheuristics approach. Journal of Manufacturing Systems 68: 443-454.

- Human-centered, resource-conserving, resilient: Solutions from research and development 2024/25 (2024) Fraunhofer Institute for Production Systems and Design Technology Berlin.

- Zhang H, Qi Q, Ji W, & Tao F (2023) An update method for digital twin multi-dimension models. Robotics and Computer-Integrated Manufacturing, 80: 102481.

- Liu S, Zheng P, & Bao J (2023) Digital Twin-based manufacturing system: a survey based on a novel reference model. In Journal of Intelligent Manufacturing. Springer.

- Wang Y, Wang S, Yang B, Zhu L, & Liu F (2020) Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. Journal of Cleaner Production, 248.

- Huemann M, Silvius G (2017) Projects to create the future: Managing projects meets sustainable development. Int J Proj Manag.

- Glitscher W (2023) Next7G Project Management - Sustainable project management for the next seven generations, Projektmanagement aktuell.

- Finn E (2025) Step Into the Free and Infinite Laboratory of the Mind; Issues in Science and Technologies, Science.

- Hina M, Chauhan C, Puneet K, Kraus S, Dhir A (2022) Drivers and barriers of circular economy business models: Where we are now, and where we are heading. Journal of Cleaner Production 333: 130049.

- Mahaligam AB (2023) Developing a Digital Ecosystem to Monitor Greenhouse Gas (GHG) Reduction Strategy for Manufacturing Plants to Reach Net Zero Emissions; Technische Universität Berlin, Germany.