Petroleum Refinery Wastewater Treatment Options - Microbial Fuel Cells (MFCs) an Emerging Technology - Current Status and Future Prospects

A MerlineSheela*

Centre for Environmental Studies, Anna University, Chennai, Tamil Nadu

Submission: January 20, 2020; Published: February 05, 2020

*Corresponding author: MerlineSheela A, Centre for Environmental Studies, Anna University, Chennai, Tamil Nadu, India - 600 025

A MerlineSheela. Petroleum Refinery Wastewater Treatment Options - Microbial Fuel Cells (MFCs) an Emerging Technology - Current Status and Future Prospects. Recent Adv Petrochem Sci. 2020; 7(1): 555704 DOI: 10.19080/RAPSCI.2020.07.555704

Abstract

During the petroleum refining process a large volume of water with complex chemical composition, containing emulsified oil, phenols, sulfide, mercaptans, ammonia, cyanides and other micropollutants are generated. There is a need to treat the water before discharging into the environment without which it causes severe environmental problem. In this paper the conventional treatment methods employed for removing the pollutants, the recent advancement, the possibility of using Microbial Fuel Cells (MFCs) for simultaneous degradation of pollutants with electricity generated is reviewed.

Keywords: Petroleum refinery wastewater; Treatment; Conventional; Microbial fuel cells (MFCs); Future prospects

Abbreviations: COD: Chemical Oxygen Demand; CVD: Catalytic Vacuum Filtration; UV: Ultrafiltration; NF: Nanofiltration; RO: Reverse Osmosis; EC: electrocoagulation; SBBR: Spouted Bed Bioreactor; MBBR: Moving Bed Bioreactor; HA: Hydrolysis acidification; TDS: Total Dissolved Solids; MFCs: Microbial Fuel Cells

Introduction

The major role played by petroleum industry includes the exploration, extraction, refining, transporting and marketing of petroleum products [1]. The products of this industry are fuel oil and gasoline, petroleum and raw materials for many chemicals products such as pharmaceuticals, solvents, fertilizers, pesticides, synthetic fragrances and plastics. The major problems faced by these industries are the disposal of oil residues generated during various processes including storage, processing and transportation. The crude oil refineries generate significant amount of oil sludge which is a complex mixture of alkanes, aromatic hydrocarbons, NSO (Nitrogen – Sulfur – Oxygen containing compounds), and asphaltene fractions and all these compounds are legally classified as hazardous waste [2].

The wastewater generated from petroleum refinery is around 0.4 to 0.6 times the volume of crude oil processed [3]. The wastewater generated from the petroleum refineries are having the large amount of priority pollutants which are characterized by high concentrations of aliphatic and aromatic petroleum hydrocarbons of 1-40 carbon atom salong with cycloalkanes phenols and poly cyclic aromatic hydrocarbons [4]. It is observed that the pollutants in the wastewater are refractory in nature and detrimental and harmful to plant and aquatic life as well as surface and ground water sources [5,6]. Hence, an effective treatment method should be adopted to remove the pollutants from the wastewater before discharging into the environment.

Wastewater facilities in these plants usually rely on many expensive pretreatment steps to reduce the concentration of these organic contaminants before any final biological purification step. These pretreatment methods followed by the treatment units may include ultrafiltration, adsorption, coagulant and coagulant aides, and electrochemical process [7].

Treatment Methods Adopted

The methods such as electrocoagulation and sorption are employed for the efficient removal of suspended solids as well as oil and greases from petroleum industry wastewater [8]. It is also efficiently treated by Fenton and photo-Fenton process. Even though, the method was considered as the best treatment option in removing the pollutants, further optimization might have required [3,9,10]. The petroleum refinery wastewater with high concentration of Chemical Oxygen Demand (COD) and salinity could be efficiently (99%) treated with Catalytic Vacuum Filtration (CVD) [11]. The permeate obtained by Ultrafiltration (UV) was subjected to granulated carbon coupled Nanofiltration (NF) was found to be suitable for further purification by Reverse Osmosis (RO) [12]. Continuously Stirred Tank Bioreactor (CSTR) in which mixed microbial consortium of Aeromonas punctate, Bacillus cereus, Ochrobacteriumintermediun, Stenotrophomonasmaltophila and Rhodococcus sp. were used for 95% COD removal with the reduction of residual petroleum hydrocarbon from 320 mg TPH l-1 to 8 mg TPH l-1. Further, high degradation of n – alkanes (C10 - C35) was achieved [13]. Sulfide in the wastewater was removed by chemical precipitation [14]. Electrochemical oxidation in which by anodic oxidation efficient removal of organic pollutants from petrochemical wastewater was achieved [15]. A three-step process in which electrocoagulation (EC), Spouted Bed Bioreactor (SBBR) with Pseudomonas putida immobilized in Polyvinyl Alcohol gel and an adsorption column packed with granular activated carbon produced from agricultural waste was employed to treat the Petroleum refinery wastewater [16]. Suspended ceramic carriers are having efficient biofilm forming capacity which could be used in Moving Bed Bioreactor (MBBR) to treat water [17]. Hydrolysis acidification (HA)-anoxic-oxic (A/O) process could treat the wastewater from petroleum refinery, but further advanced treatment is required for 100% removal [18]. Further, it was demonstrated that for efficient removal of pollutants powdered activated carbon method was found to be the suitable treatment in which removal was achieved by biodegradation and adsorption [19]. All these treatments are expensive and requiring more energy. Further, due to the low BOD/COD ratio (< 0.2) and high Total Dissolved Solids (TDS) the wastewater generated from petroleum refineries are resistant to biological treatment. To overcome all these issues a treatment method is needed. Microbial Fuel Cells (MFCs) have been employed for treating recalcitrant pollutant from several types of wastewaters including Petroleum refinery wastewater [20].

Microbial Fuel Cells (MFCs)

In Microbial Fuel Cells (MFCs) microorganisms are employed directly to generate electricity from biochemical energy and considered a novel approach for treating many industrial wastewater [21]. Among the various technologies available at present for electricity generation, in recent years MFCs have attracted much attention. The various factors affecting Performance of MFcs are operating variables (type of substrate, biodegradability, substrate concentration pH and microbial species) and designing variables (MFC structure, anode and cathode material and type of separator) [22]. It was studied extensively that bioelectricity production through MFC using variety of substrates including domestic wastewater [23-26], landfill leachate [27] and wastewaters generated by various industries such as starch processing [28], molasses [29], brewery [30], dairy [31], rice mill [32], paper recycling [33], coking [34], textile industry [35,36].

MFCs in Treating Petroleum Refinery Wastewater

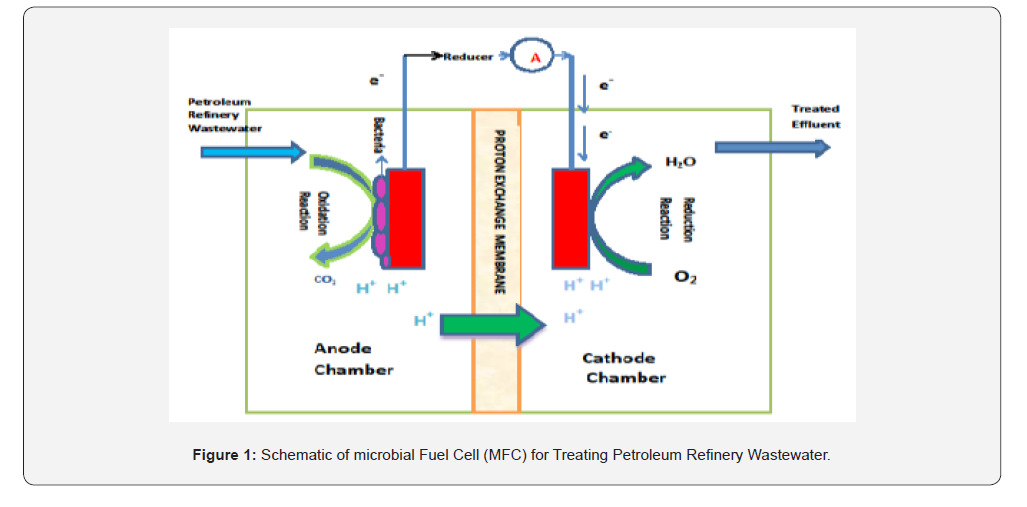

The petroleum refinery operations are complex in nature, requires large volumes of water for the process and varying composition [37]. In addition to the hydrocarbons, the petroleum refinery wastewaters are having constituents such as sulfides, ammonia, nitrates and heavy metals which are less biodegradable and sometimes toxic to microbes [38]. So for only limited studies are available on the potential of using MFCs for the simultaneous treatment of Petroleum refinery wastewater and generation of electricity was demonstrated. Further, the influence of characteristics of packing material on the electricity generation and degradation efficiency of the pollutants was studied [39]. Granular Activated Carbon (GAC) was found to be the suitable packing material for stable voltage production and lowest mass transfer resistance than Granular Graphite (GG) in MFC when treating petroleum refinery wastewater. For improving the performance of treatment of petroleum refinery wastewater single chamber MFC with air – cathode with additional voltage supply for a short period was employed. By this there was an increase in power output from 45mWm-2 (control) to12mWm-2(500mV applied). There was89% removal of diesel range organics achieved at this voltage [40]. Continuous mode operation of MFC showed higher performance (220±1.4mWm-2) along with the removal of COD, sulfide oil and gas over batch mode [41]. The schematic showing MFC for treating wastewater with electricity is illustrated in Figure 1.

Future Prospects

Further research is needed for efficient treatment of petroleum refinery wastewater as it is recalcitrant for microbial degradation and toxic. Extensive research on optimization of parameters, adaptability of biocatalyst and bio electrochemistry of petroleum refinery wastewater treatment and applied potential condition is required for more electricity production and better degradation of pollutants. Another important aspect taken into consideration is characteristics of packing material used in MFCs and their influence on power output. Since the Petroleum Refinery wastewater is complex in nature with wide range of pollutants the microorganisms could be affected or inhibited by the toxic pollutants. Hence, it is required to use microbial consortium which is having wide array of enzyme system to degrade the pollutants and electricity generation simultaneously than a pure culture. Utilization of immobilized or entrapped microbial culture on a carrier material such as gel is another area of research for better performance of MFCs for degradation of such type of wastewaters and simultaneous electricity generation. With the immobilized culture the microorganisms are protected against the toxic compounds in the water and viable for a long time. Also in a controlled manner they could be released into the system so that the stability and sustainability is maintained. For simultaneous degradation of pollutants in petroleum refinery wastewater and bioelectricity generation if the major issues are addressed, the MFC technology could be the one among the best system for renewable energy production which is the requirement for current situation.

References

- Jafarinejad A (2017) Activated sludge combined with powdered activated carbon (PACT process) for the petroleum industry wastewater treatment: A review. Chemistry International 3(4): 368-377.

- Hou B, Xie SX, Chen M, Jin Y, Hao D, et al. (2013) The Treatment of Refinery Heavy Oil Sludge. Petroleum Science and Technology 31(5): 458-464.

- Coelho A, Castro A, Dezotti M, Sant Anna GL (2006) Treatment of petroleum refinery sour water by advanced oxidation processes. Journal of Hazardous Materials 137(1): 178-184.

- Sponza DT, Gök O (2010) Effect of rhamnolipid on the aerobic removal of polyaromatic hydrocarbons (PAHs) and COD components from petrochemical wastewater. Bioresour Technol 101(3): 914-924.

- Verma S, Prasas B, Mishra IM (2010) Pretreatment of petrochemical wastewater by coagulation and flocculation and the sludge characteristics. J Hazard Mater 178(1-3): 1055-1064.

- Zhang YQ, Gao BY, Lu L, Yue QY, Wang Q, et al. (2010) Treatment of produced water from polymer flooding in oil production by the combined method of hydrolysis acidification-dynamic membrane bioreactor-coagulation process. J Petrol Sci Eng 74: 14-19.

- Demirci S, ErdoGan B, Ozcimder R (1998) Wastewater treatment at the petroleum refinery, Kirikkale, Turkey using some coagulants and Turkish clays as coagulantaids. Water Research 32 (11): 3495-3499.

- Rajakovic V, Aleksic G, Radetic M, Rajakovic Lj (2007) Efficiency of oil removal from real wastewater with different sorbent materials. J Hazard Mater 143(1-2): 494-499.

- Saien J, Netaji H (2007) Enhanced photo catalytic degradation of pollutants in petroleum refinery wastewater under mild conditions. J Hazard Mater 148(1-2): 491-495.

- Rubio Clemente A, Chica E, Peneula GA (2015) Petrochemical wastewater treatment by Phot-Fenton process. Water Air & Soil Pollution 226: 62.

- Yan Y, Ma H, Wang B, Mao W, Chen Y, et al. (2010) Advanced purification of petroleum refinery wastewater by catalytic vacuum distillation. J Hazard Mater 178(1-3): 1120-1124.

- Benito Alcazar C, Vincent Vela MC, Gozalvez Zafrilla JM, Lora Garcia J (2010) Study of different parameters for reverse osmosis reclamation of a petrochemical secondary effluent. J Hazard Mater 178(1-3): 883-889.

- Gargouri B, Karry F, Mhiri N, Aloui F, Sayadi S, et al. (2011) Application of continuously stirred tank bioreactor (CSTR) for bioremediation of hydrocarbon-rich industrial wastewater effluents. J Hazard Mater 189(1-2): 427-434.

- Atlas L, Buyukgungor H (2008) Sulfide removal in petroleum refinery wastewater by chemical precipitation. J Hazard Mater 153(1-2): 462-469.

- Rocha JHB, Gomes MMS, Fernandes NS, da Silva DR, Martinez Huite CA (2012) Application of electrochemical oxidation as alternative treatment of produced water generated by Brazillian Petrochemical Industry. Fuel Processing Technology 96: 80-87.

- El Naas MH, Alhaija MA, Al Zuhair S (2014) Evaluation of a three-step process for the treatment of petroleum refinery wastewater. Journal of Environmental Chemical Engineering 2(1): 56-62.

- Dong Z, Lu M, Huang W, Xu X (2011) Treatment of oilfield wastewater in moving bed biofilm reactors using a novel suspended ceramic carrier. J Hazard Mater 196: 123-130.

- Wu C, Zhou Y, Sun Q, Fu L, Xi H, et al. (2016) Applying hydrolysis acidification-anoxic-oxic process in the treatment of petrochemical wastewater from bench scale reactor to pilot scale wastewater treatment plant. Journal of Hazardous Materials 309: 185-191.

- Jafarinejad A (2017) Activated sludge combined with powdered activated carbon (PACT process) for the petroleum industry wastewater treatment: A review. Chemistry International 3(4): 368-377.

- Li Y, Yang HY, Shen YJ, Mu Y, Yu HQ, et al. (2016) Enhancement of azo dye decolourization in a MFC–MEC coupled system. Bioresour Technol 202: 93-100.

- Zhuang L, Zhang Y, Zhou S, Yuan Y, Yuan H, et al. (2012) Scalable microbial fuel cell (MFC) stack for continuous real wastewater treatment. Bioresource Technology 106: 82-88.

- Marashi SKF, Kariminia H (2012) Electricity generation from petrochemical wastewater using a Membrane-less microbial fuel cell. Second Iranian Conference on renewable energy and distributed generation.

- Ahn Y, Logan BE (2010) Effectiveness of domestic wastewater treatment using microbial fuel cells at ambient and mesophilic temperatures. Bioresource Technol 101(2): 469-475.

- Vijayaraghavan K, Ahmad D, Ibrahim MKB (2006) Biohydrogen generation from jackfruit peel using anaerobic contact filter. International Journal of Hydrogen Energy 31(5): 569-579.

- Kloch M, Toczylowska Maminska (2020) Toward optimization of wood industry wastewater treatment in microbial fuel cells-Mixed wastewaters approach. Energies 13(1): 263.

- Mohamed SN, Hiraman PA, Muthu Kumar K, Jayabalan T (2020) Bioelectricity production from kitchen wastewater using microbial fuel cell with photosynthetic algal cathode. Bioresource technology 295: 122226.

- Li Y, Lu AH, Ding HR, Wang X, Wang CQ, et al. (2010) Microbial fuel cells using natural pyrrhotite as the cathodic heterogeneous fenton catalyst towards the degradation of biorefractory organics in landfill leachate. Electrochem Commun 12(7): 944-947.

- Lu M, Zhang Z, Yu W, Wei Z (2009) Biological treatment of oilfield-produced water: a field pilot study. Int Biodeter Biodegr 63(3): 316-321.

- Zhang B, Zhao H, Zhou S, Shi C, Wang C, et al. (2009) A novel UASB-MFC-BAF integrated system for high strength molasses wastewater treatment and bioelectricity generation. Bioresource Technol 100(23): 5687-5693.

- Feng Y, Wang X, Logan, BE. Lee H (2008) Brewery wastewater treatment using air-cathode microbial fuel cells, Appl Microbiol Biotechnol 78(5): 873-880.

- Venkata Mohan S, Mohanakrishna G, Velvizhi G, Babu VL, Sarma PN, et al. (2010) Bio-catalyzed electrochemical treatment of real field dairy wastewater with simultaneous power generation. Biochem Eng J 51: 32-39.

- Behera M, Jana PS, More TT, Ghangrekar MM (2010) Rice mill wastewater treatment in microbial fuel cells fabricated using proton exchange membrane and earthen pot at different pH. Bioelectrochemistry 79(2): 228-233.

- Huang L, Logan BE (2008) Electricity generation and treatment of paper recycling wastewater using a microbial fuel cell. Appl Microbiol Biotechnol 80(2): 349-355.

- Huang L, Yang X, Quan X, Chen J, Yang F, et al. (2010) A microbial fuel cell-electro-oxidation system for coking wastewater treatment and bioelectricity generation. J Chem Technol Biotechnol 85(5): 621-627.

- Ilamathi R, MerlineSheela A, Nagendra Gandhi N (2019) Comparative evaluation of Pseudomonas species in Single chamber microbial fuel cell with manganese coated cathode for reactive azo dye removal. International Biodeterioration & Biodegradation 144: 1-9.

- Liu SH, Tsai SL, Guo PY, Lin CW (2020) Inducing laccase activity in whiterotfungiusing copper ions and improving the efficiency of azo dye treatment with electicity generation using microbial fuel cells. Chemosphere 243:125304.

- Benyahia F, Abdulkarim M, Zekri A, Chaalal O, Hasanain H, et al. (2005) Bioremediation of crude oil contaminated soils. Process Saf Environ Prot 83: 364-370.

- Chen C, Yan G, Guo S, Yang Y (2008) Pretreatment of super viscous oil wastewater and its application in refinery. Pet Sci 5: 269–274.

- Guo X, Zhan Y, Chen C, Cai B, Wang Y, et al. (2016) Influence of packing material characteristics on the performance of microbial fuel cells using petroleum refinery wastewaters as fuel. Renewable Energy 87: 437-444.

- Mohanakrishna G, Abu Reesh IM, Kondaveeti S, Al Raoush RI, He Z, et al. (2018) Enhanced Treatment of Petroleum Refinery Wastewater by Short-term Applied Voltage in Single Chamber Microbial Fuel Cell. Bioresource Technology 253: p. 6.

- Srikanth S, Kumar M, Singh D, Singh MP, Das BP, et al. (2016) Electro-biocatalytic treatment of petroleum refinery wastewater using microbial fuel cell (MFC) in continuous mode operation. Bioresource Technology 221: 70-77.