Calculation of Yearly Output of Reusable Materials of Ship Recycling Industry in Bangladesh

Khandakar Akhter Hossain*

Member (Engineering), Chittagong Port Authority, Bangladesh

Submission: May 28, 2018; Published: June 21, 2018

*Corresponding author: Khandakar Akhter Hossain, Member (Engineering), Chittagong Port Authority, Bangladesh

How to cite this article: Khandakar A H. Calculation of Yearly Output of Reusable Materials of Ship Recycling Industry in Bangladesh. Recent Adv Petrochem Sci. 2018; 5(3): 555663. DOI: 10.19080/RAPSCI.2018.05.555663

Introduction

Ship recycling is an engineering process of recovery reusable material by dismantling end-of-life (EOL) ships in commercial [1] and safe way. In past, ship recycling activity was concentrated in industrialized countries mainly USA, UK, Germany, Turkey, etc until 1960s, [2]. In early 1980s, old ships are coming for recycling to India, China, Pakistan, Bangladesh and other East Asian yards [3] where health and safety standards are nominal. There are around forty ship-recycling yards existing along coastal belt at Chittagong of Bangladesh. The local ship recycling industry provides country’s main source of steel, household appliance, recondition equipment and machinery and creates good opportunity of employment. This industry generates revenues for government and contributes to the national shipbuilding industry [4,5]. The restraining nature of the industry is the main problem. As a result, the actual situation, on ground data collection and actual output of the industry is never assessed extensively. Actual fact is that, a very few studies have been found so far but mostly those were based on limited preliminary or secondary data analysis [6-11]. As a result, the calculation and assessment are questionable and so any policy making decision based on the study is not technically sound [12-18]. To fulfill the both aspects, extensive study is necessary which will be useful to develop a viable and sustainable recycling technique through calculating reusable and waste material from the different types and sizes of EOL ship [12] for local yards.

It is a review research paper [14] and will discuss the viable economic technique for calculation of reusable and waste material from ship recycling industry of Bangladesh; justify the sustainability of material flow analysis (MFA) technique for local yards. In this research work more than one dozen ship yards have been selected to accumulate the data for a quite substantial period of time for various types and sizes of 26 EOL ships generally dismantled by the local yard in Bangladesh. Data collection format has been designed and reusable metal, equipment, items and waste materials are segregated elaborately. After processing all data collected from different yards, the amount of actual output of reusable and waste materials have been calculated for different types and sizes of ships. However, material flow analysis (MFA) technique and software STAN [15,16] has been applied to calculate and analyze the reusable and waste materials. The study will be helpful for both policy makers and stake holders who can able to assess the actual output of local ship breaking yards of Bangladesh.

Present Global and Bangladesh Ship Recycling State

The world-wide ship recycling industry dismantles around 1,000 large ocean-going vessels per year, such as container ships, cargo & bulkers, oil & gas tankers (LNG, LPG), passenger ships and other types of ships, in order to recover steel and other valuable metals or recyclable items. However at present almost all ship recycling activities are concentrated in five countries: the three South Asian countries (India, Bangladesh, China and Pakistan), China, and Turkey. As per ship-breaking platform source [6] the major ship-breaking countries of the world in 2015 have been shown in Figure 1 below. Further capacity is available in North America (US, Canada, Mexico) and within the European Union (amongst others Denmark, Belgium and UK). At present, South Asia is undoubtedly the global centre for ship recycling activities. Global major recycling yards are located in India, Bangladesh, Pakistan, China and Turkey. These countries are main ship recycling centers in terms of annual lightweight tonnage (LDT) recycled. The ship recycling yards compliant with either the international standards for HSE management or the ship recycling regulations such as Hong Kong convention and EU ship recycling regulation are considered harmless to environment, health and safety of the workers.

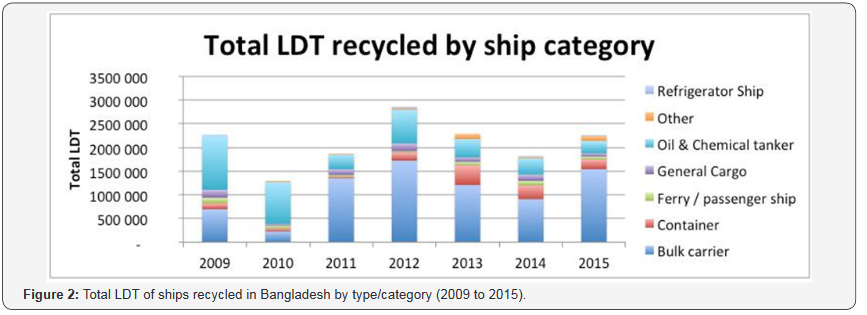

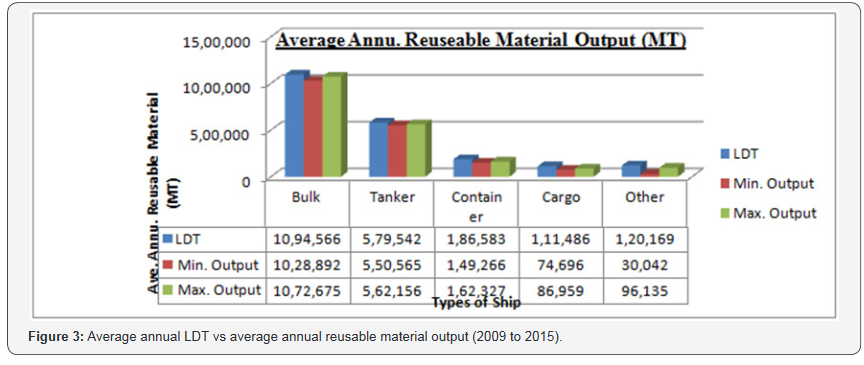

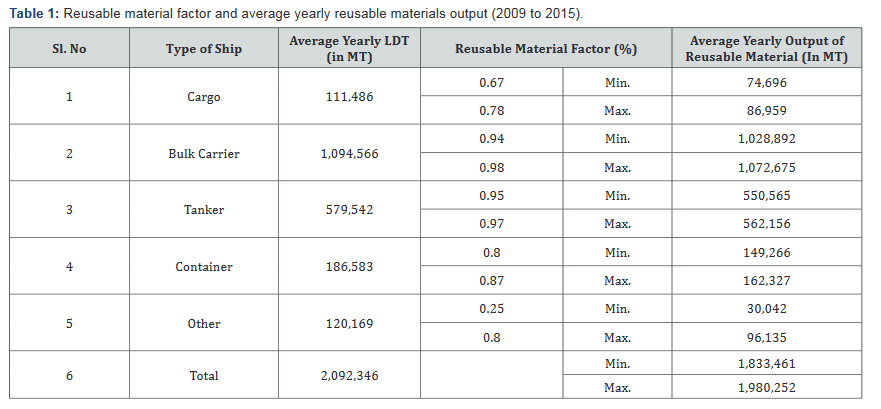

In Bangladesh, average 200 different types of obsolete ships are recycled annually in different yards located in Chittagong. Those different types of ships are bulk carrier, tanker, container carrier, cargo carrier, passenger or ferry, refrigerator ship, LPG, LNG, floating pontoon/restaurant, and other different types of ships [13]. In Figure 2 below, total number of different types/category of ships recycled annually in Bangladesh between the years 2009 to 2015 has been shown. Again, from on ground statistics of ship recycling yards of Bangladesh, we can see that, average 2000000 Light Dead-Weight Ton (LDT) different types of obsolete ships are recycled annually in different yards in Bangladesh. In Figure 3 below, total LDT of different types/category of ships recycled in Bangladesh between the years 2009 to 2015 has been shown. Reusable material factor and average yearly reusable materials output has been shown in Table 1 below (Detailed estimation, analysis and calculation has been shown in my PhD thesis paper).

Ship Recycling Estimation Technique and Results

MFA as Estimation Technique. The author of this article has inspirited from both operations management and environmental engineering to implement a well-known technique to estimate reusable and waste the ship recycling industry. This article will explains that MFA, an assessment tool used in environmental engineering, is the most practical tool for calculating reusable and waste material output from ship recycling industry. The methodology and input data for carrying out MFA on a ship recycling yard has explained in brief. In this research work the MFA is implemented using 26 of different types and size of EOL ships. By using the software STAN [16] an MFA can be carried out. STAN is useful not only to produce a graphical representation of a waste management system but also to determine the types of materials that flow into, within and out of the system

Methodology and input data for mfa

For carrying out an MFA on any ship recycling yards, following steps need to be followed. It can start with defining the space and time boundaries of the system. Then, reusable material composition of EOL ship(s) must be determined. At the same time waste material composition of EOL ship(s) to be recycled and disposed off must be determined. Then, various steps of the ship recycling process must be recognized. Then, flow diagrams can be created using the suitable or open source software like STAN. Finally, the flow diagrams need to be analyzed.

Steps for ship recycling process

The required number of feasible steps needs to be finding out of an MFA on a ship recycling yard to determine the optimum steps of the ship recycling process. Though ships are recycled by employing different docking methods (i.e. beaching, slipway, alongside and dry dock) in different parts of the world, the process of dismantling and recycling a ship takes place in a series of steps which are independent of the method employed to dock the vessel. Ship recycling is generally performed by cutting away large sections of the ship’s hull, which are then moved to shore for further dismantling. The entire recycling process can be divided into three main phases-precutting, cutting and post-cutting. Each phase of the ship recycling process is a process in itself because some form of transformation takes place [15,16]. The pre-cutting process involves various surveys and hull preparations for gas cutting. The cutting process is the process where actual cutting of steel hull and machinery into small pieces takes place. The postcutting process involves sorting and segregation of materials. Each of these processes can be examined further to determine other processes that take place within them.

Results

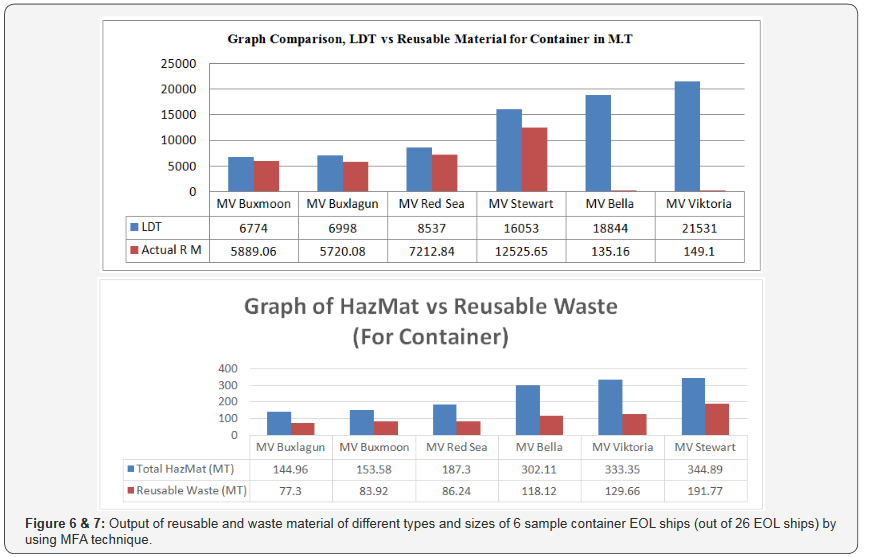

The most basic level of the reusable and waste material flow diagrams for recycling of a sample container EOL ship (out of 26 EOL ships), developed by software STAN, is shown in Figure 4 & 5 respectfully in local yards in Bangladesh. This figure combines the three main processes: pre-cutting, cutting and post-cutting. These diagrams provide more insight into the basic level of the ship recycling process by showing the quantities of materials flowing into and out of each sub-process, in terms of percentage of LDT. The red colored flows represent the user defined data while the flows in black represent the data calculated by STAN. The box outlined in blue represents a process having sub-processes. Material flows in these diagrams depict the maximum obtainable amount of each material calculated with respect to the assumptions made for this research. The general and exclusive data, analysis, result, graph and output has been described in detail in my PhD research work. Estimation and output of reusable and waste material of different types and sizes of 6 sample container EOL ships (out of 26 EOL ships) by using MFA technique has been shown in Figure 6 & 7 respectively.

Recommendation

MFA technique can be used by ship recycling yards for calculation of reusable and waste material and to better plan for ship recycling process through different sub-processes taking place within a recycling yard. The flexibility of MFA as a technique or tool in terms of spatial and temporal boundary settings makes it very useful, not only for calculating and planning the ship recycling process on particular yard for one or more ships but also for understanding and predicting the outputs of the ship recycling industry on the local and global level. Moreover it helps to determine the maximum revenue potential of recycling a number of ships within a particular time frame. MFA has emerged as an essential technique that can improve ship recycling and materials and waste management at ship recycling yards by determining the earning potential of each project as well as planning the utilization of resources to attain maximum profit. MFA is the viable technique and that can be used by any recycling yards for estimating and calculating reusable and waste material by understanding the material flows within the recycling process.

References

- Jain KP, Pruyn JFJ, Hopman JJ (2016) Quantitative assessment of material composition of end of life ships using onboard documentation. International Journal of Resources, Conservation and recycling 107: 1-9.

- Jain KP, Pruyn JFJ, Hopman JJ (2014) Influence of ship design on ship recycling. Maritime Technology and Engineering, pp. 269–276.

- Hossain KA (2015) Overview of Ship Recycling Industry of Bangladesh. Journal of Environmental and Analytical Toxicology 5(5).

- Zakaria NMG, Iqbal KS, Hossain KA (2010) Ship Recycling Prospects in Bangladesh, Proceeding of MARTEC 2010. International Conference of Marine Technology, BUET, Dhaka, Bangladesh.

- Iqbal KS, Zakaria NMG, Hossain KA (2010) A Study of Socio Economic and Ecological Impact of Ship Recycling in Bangladesh. The Journal of NOAMI 27(1): 35-47.

- Hisham A (2015) GRID Arendal 2015. Shipbreaking Platform.

- Sujauddin M, Koide R, Komatsu T, Hossain MM, Tokoro C, et al. (2016) Ship Breaking and Steel Industry in Bangladesh: the Material Flow Perspective. Journal of Industrial E cology 10.

- Koide R, Sujauddin M, Komatsu T, Hossain MM, Higashida K, et al. (2016) Ship Recycling Industry in Chittagong, Bangladesh: Material Flow Analysis on Ship Breaking. Journal of the Japan Society of Material Cycles and Waste Management 27: 161-175.

- Rahman SMM, Handler RM, Mayer RM (2016) Life cycle assessment of steel in the ship recycling industry in Bangladesh. Journal of Cleaner Production 135: 963-971.

- Maria S, Frank SL, Milen D, Robin B, Susan W, et al. (2010) The Ship Breaking and Recycling Industry in Bangladesh and Pakistan. Report of International Bank for Reconstruction and Development, the World Bank, Bangladesh.

- Sarraf M (2010) The Ship Breaking and Recycling Industry in Bangladesh and Pakistan. World Bank, Washington DC, USA.

- Hossain KA (2017) Ship recycling status of Bangladesh and annual reusable material output. Journal of Toxicology 2(2).

- Hossain KA (2017) Ship recycling practice and annual reusable material output from Bangladesh ship recycling industry. Journal of fundamentals of renewable energy and application 7(5).

- Stopford M (2009) Maritime Economics. In: (3rd edn), Routledge, New York, USA.

- Jain KP, Pruyn JFJ, Hopman JJ (2017) Material flow analysis as a Tool to improve ship recycling. Journal of Ocean Engineering 130: 674-683.

- Cencic O, Rechberger H (2008) Material Flow Analysis with Software STAN. Journal Environment Engineering Management 18: 440-447.

- Nost TH, Halse AK, Randall S, Borgen AR, Schlabach M, et al. (2015) High Concentrations of Organic Contaminants in Air from Ship Breaking Activities in Chittagong, Bangladesh. Environ Sci Technol 49(19): 11372-11380.

- Abdullah HM, Mahboob MG, Banu MR, Seker DZ (2012) Monitoring the drastic growth of ship breaking yards in Sitakunda: a threat to the coastal environment of Bangladesh. Environ Monit Assess 185(5): 3839-3851.