A Comparative Assessment of Operating Characteristics of a Diesel Engine using 20% Proportion of Different Biodiesel Diesel Blend

Senthil Ramalingam*, Silambarasan Rajendran and Pranesh Ganesan

Department of Mechanical Engineering, University College of Engineering ViHupuram, India

Submission: April 06, 2017; Published: September 13, 2017

*Corresponding author: Senthil Ramalingam, Department of Mechanical Engineering, University College of Engineering Villupuram, India, Email: drrs1970@gmail.com

How to cite this article: Senthil R, Silambarasan R, Pranesh G. A Comparative Assessment of Operating Characteristics of a Diesel Engine using 20% Proportion of Different Biodiesel Diesel Blend. Recent Adv Petrochem Sci. 2017; 3(1): 555601. DOI:10.19080/RAPSCI.2017.03.555601

Abstract

The objective of the present work is to find out the viable substitute fuel for diesel and control of pollutants from compression ignition engines. Therefore, in this present investigation an attempt has been made to study the effect of 20% proportion of five different biodiesel diesel blend in diesel engine. The 20% proportion of biodiesel such as Jatropha, Pongamia, Mahua, Annona and Nerium and 80% of diesel and it is denoted as J20, P20, M20, A20 and N20 are used in the present investigation. The experimental results showed that the brake thermal efficiency of the different biodiesel blend is slightly lower when compared to neat diesel fuel. However, N20 blend, have shown improvement in performance and reduction in exhaust emissions than that of other biodiesel diesel blends. From, the experimental work, it is found that biodiesel can be used up to 20% and 80% of diesel engine without any major modification

Keywords: Biodiesel diesel blend; Performance; Emission; Diesel engine

Introduction

The various types of vegetable oil, animal fats, used frying oil, waste cooking oil, edible oils and non-edible oils that can be used as alternate fuels for diesel. The exhaust emission such as CO, HC, and PM can be reduced considerably, while using biodiesel blends as a fuel [1]. The effects of blending a biodiesel with other fuels, with specific properties such as lubricity, cetane number, flash point, kinematic viscosity, oxidative stability and exhaust emission were discussed. The biodiesel and its blends increase the NOx level in the exhaust emission [2]. The rapeseed oil biodiesel has lower smoke emission and higher brake specific fuel consumption compared to that of diesel fuel. The ignition delay for standard diesel, B20, B5, B70 and B100 fuels were calculated 8.5 °C, 7.75 °C, 7.25 °C, 6.50 °C and 5.75 °C CA respectively [3].

The CO emission of diesel is 0.09% but soya bean biodiesel and its blends are less than 0.05% at high engine load. The NOx was slightly higher for biodiesel and its blends and the peak cylinder pressure was higher compared to that of diesel fuel. The difference of NOx emission between diesel and biodiesel blends is not more than 100/ppm. The peak cylinder pressures are 8.12MPa and 8.11MPa for biodiesel and diesel respectively [4]. The biodiesel blend showed performance very close to that of diesel fuel. Further, the ethanol and methanol blends yielded lower brake power, higher SFC and lower CO emission [5].

The conducted experiments were conducted on a four cylinder four stroke DI and turbo charged diesel engine using biodiesel blends of waste oil, rapeseed oil and corn oil with normal diesel. The peak cylinder pressure of the engine running with bio diesel was slightly higher than that of diesel and this was due to advance combustion process initiated by higher lubrication effects of bio diesel. Further, the use of biodiesel increases the BSFC up to 15% due to its lower heating value, higher viscosity and density [6]. The experiments were conducted on a four cylinder four stroke diesel engine using bio diesel made from corn oil. The NOx emission was higher for biodiesel and its blends. Further, the B100 biodiesel reduced 15%, 40%, and 30% for CO, CO2 and HC emissions respectively when compared to diesel fuel at various operating conditions [7].

The experimental study on a four stroke DI diesel engine using various bio diesels such as cotton seed oil, soya bean oil, sunflower oil, rapeseed oil, palm oil, corn oil and olive kernel oil and their corresponding methyl ester at the blend ratio of 10/90 and 20/80 were conducted. The tested bio diesel blends irrespective of the raw feed stock material used for their production, can be used safely in the diesel engine at small blending ratio along with normal diesel fuel [8]. The effect of vegetable oils and their methyl esters such as raw sun flower, raw cotton seed oil, raw soya bean oil and their methyl esters, refined corn oil, distilled opium poppy oil and refined rape seed oil on the performance and emission characteristics of a four stroke, direct injection diesel engine was discussed.

The vegetable oil methyl ester's performance and emission characteristics were closer to the diesel fuel and it can be used as a substitute for diesel fuel [9]. The experiments were conducted by using soybean oil, peanut oil, corn oil, sunflower oil, rapeseed oil, palm oil, palm kernel oil, and waste fried oil. The diesel engine fuelled with vegetable oil methyl ester could potentially produce the same engine power, but with a reduction in the exhaust gas temperature (EGT), smoke and total hydrocarbon (THC) emission and with a slight increase in nitrogen oxides (NOx) emission [10].

The increase in brake thermal efficiency and decrease in specific fuel consumption were observed in the case of esterified mahua oil (at 75% mahua oil blends) compared to that of diesel fuel [11]. The emission of CO and HC were too low for mahua oil methyl ester and oxides of nitrogen were slightly lower compared with diesel. The thermal efficiency for mahua methyl ester is 28.31% and it is due to more oxygen content present in the biodiesel [12]. The thermal efficiency for mahua oil methyl ester was at par with diesel and significant drop in emission such as hydrocarbon, carbon monoxide and smoke emission. Further, the mahua is a renewable fuel having lower emission and the performance was similar to that of diesel [13].

The karanja oil (B100) reduced CO and smoke emissions by 50% and 45% respectively, while 15% increase in the NOx emission was observed with the same fuel. Further, the BTE for B100 and its blends was almost closer to the BTE of diesel fuel [14]. The performance and emission of a diesel engine fuelled with pongamia pinnata methyl ester (PPME) and its blends with the diesel fuel were discussed. The blends of PPME of 40% (B40) could replace the diesel for diesel engine because of their low emission and better performance [15]. The experiments on the performance and emission characteristics of a single cylinder, naturally aspired, four strokes, DI diesel engine fuelled with cottonseed oil and its blends were conducted.

The exhaust emission including PM, smoke and CO were reduced by 24%, 14% and 24% respectively and 10% increase in NOx emission for biodiesel [16]. There is a slight increase in BTE, BSFC and reduction in NOx and soot emission for using various blends of jajoba oil. Further, the engine performance can be improved while using jajoba methyl ester with minor modifications in the engine operating conditions such as injection timing and injection pressure [17]. The HC and CO emission for coconut biodiesel blends of 5% and 15% were reduced considerably and CO2 and NOx emission were increased with biodiesel blend ratio. Further, the coconut blend at 5% and 15% can be used with diesel as an alternate fuel [18]. The sesame oil with diesel fuel can be used as a fuel without any modification in the diesel engine. Further, the exhaust emission level for sesame oil was lower than that of diesel fuel, except NOx emission [19]. The brake thermal efficiency for pure diesel was 29.6% and for pure jatropha was 21.2% at full load. Further, the smoke, HC and CO emission were decreased and NOx, and CO2 increased for jatropha fuel when compared to that of neat diesel fuel [20].

The experiments were conducted on a four stroke single cylinder CI engine using mustard oil and neem oil blend with the diesel fuel. The smoke, HC and NOx emission were observed for biodiesel blend. The esterified mustard oil at 20% blend satisfies the important fuel properties as per ASTM specification [21]. The experiments were conducted on a single cylinder four stroke water cooled diesel engine using edible vegetable oils such as nerium, jatropha, pongamia, mahua and neem oil with diesel fuel. The diesel engine runs successfully at 20% blends without affecting the engine performance. Among, the various vegetable edible oils, nerium biodiesel showed better performance than the others. Further, the biodiesel showed lower smoke and HC and higher NOx emission [22].

The 20% blends of madhuca indica showed better performance than the pongamia pinnata and neat diesel fuel. The HC, CO and smoke emission were reduced drastically for madhuca indica. However, the CO2 and NOx emission slightly increased compared to Pongamia pinnata and neat diesel fuel [23]. The experiments were conducted on a single cylinder four stroke DI diesel engine using annona methyl ester (AME) and its blends with diesel. The AME at 20% blend shows better performance and lower exhaust emission. Further, the CO and HC, smoke emission reduced considerably and NOx emission slightly increased for the various proportions of annona methyl ester [24].

Summary

Biodiesel is substitute for diesel fuel and one of the best ways to reduce the exhaust emissions without any modification in the existing engines. Biodiesel is used in standard diesel engine results substantial reduction in emission of unburned hydro carbon, carbon monoxide and particulate. Experiments were conducted using various biodiesels such as soya bean, peanut, sunflower, jatropha, mahua, coconut, rape, karanja, neem, mustard, linseed, cotton seed and castor. But very few experiments were conducted using combination of nerium, annona, jatropha, pongamia and mahua. It is found that these biodiesels are easily available, cheaper and its properties are very closer to diesel fuel and if planned to use. Hence, in the present investigation an attempt has been made to the study the effect of 20% proportion of different biodiesel-diesel blend on performance and emission characteristics of diesel engine

Materials and Method

Biodiesel

Biodiesel can be defined as the diesel oil which is naturally prepared from vegetable oils and animal fats. It can be used either in its pure form or blended with various chemical concentrations as per the requirement of specifications. The properties of biodiesel are identical to that of the standard diesel. It does not contain sulphur or any other chemical pollutants. Due to this it does not produce any harmful poisonous gases during combustion. At the same time normal petrol and diesel oils produce large amount of harmful poisonous gases during combustion. Many experts predicted that the biodiesel will be used as the main fuel for powering domestic vehicles. An important advantage to be mentioned about biodiesel is that it produces 80% less carbon dioxide compared with normal petroleum fuel.

Sources of biodiesel

Biodiesel can be derived from edible and non-edible oils. The edible oil has limitations when used in diesel engine. The non-edible oils have the advantages of use in diesel engine because of availability cheaper and they are not commercially used. These oils are derived from Jatropha Curcus, Pongamia Pinnata, Neem (Azadirachtaindica), Mahua, Castor, Linseed, Kusum Schlecheratrijuga), Annona, Nerium etc.

Advantages of biodiesel: Biodiesel is an alternative to petroleum and diesel. It is eco-friendly, bio-degradable, nontoxic and free from sulphur, lead and aromatics. It gives similar torque, horse power and mileage with diesel fuel. It is easy to store and handle. Due to its lubricating properties, engine parts function smoothly. It has increased life of the engine. Its detergent properties keep the injection fuel pump and filter clean. It has a very high flash point making it one of the safest of fuels and it gives higher combustion efficiency.

Disadvantages of biodiesel: Biodiesel have drawbacks of short-term cold weather starting, plugging and gumming in filters and lines, engine knocking, long-term choking of injectors, carbon deposits on piston and head of the engine, excessive engine wear, failure of engine lubricating oil due to polymerization. Considering the above advantages, Nerium, Annona, Jatropha, Pongamia and Mahua biodiesel are identified for the present study to conduct experiments in a DI diesel engine.

A. Jatropha: Jatropha curcas, locally known as ratanjyot, belongs to the family of Euphorbiaceae. It is a quick yielding plant that survives in degraded, barren, forest land and drought prone areas and is cultivated as hedge on the farm boundaries. This oil is gaining popularity due to its good properties and has been accepted and recommended by National Biodiesel Board of India as a source of alternative fuel for blending in the commercial diesel.

B. Pongamia: Pongamia oil is derived from pongamia tree, found everywhere in India up to an altitude of 1200m with a maximum height of 16m. Each shell of the fruit contains 1 to 2 kidney shaped brownish red kernels. It is non-edible oil. The oil is squeezed from the seeds (nuts) of pongamia containing in a shell.

C. Mahua: Mahua (Madhuca Indica) oil is non-edible oil available in plenty in the tropical countries like India. The two major species of genus Madhuca found in India are MadhucaIndica (latifolia) and Madhucalongifolia (longifolia). This plant is common in deciduous forests. The seed and oil potential of this tree in India is varies from 180,000tons to 500,000tons. Madhucalatifolia is a medium sized to large deciduous tree, distributed in South India, and ever green forests.

D. Nerium: Nerium or Adelfa is an evergreen shrub that grows from 6 to 20 feet in tropical and subtropical areas worldwide including the Philippines. Its flowers may range in colour from white, pink, red and any shade between them. Seeds are numerous and are compressed with a tuft of fine, shining white and greyish silky hair. Adelfa is used in traditional medicine for the treatment of ulcers, ringworms, leprosy, eczema, hemorrhoids, herpes simplex and herpes zoster (skin shingles). It is also effective as skin insect repellant.

E. Annona: Annona squamosa is a member of the family of custard apple trees called Annonaceae and a species of the genus Annona known mostly for its edible fruits Annona. It is commonly found in India and cultivated in Thailand and originates from the West Indies and South America. It is mainly grown in gardens for its fruits and ornamental value. It is considered as beneficial for cardiac disease, diabetes hyperthyroidism and cancer. The root is considered as a drastic purgative.

Extraction of biodiesel

Three main methods have been identified for the extraction of the oil: Mechanical extraction, Solvent extraction and enzymatic extraction. Mechanical and solvent extractions are the most common methods for commercial oil extraction. Before the oil extraction, the seeds have to be dried. Seed can be either dried in the oven at 105 °C or sand dried for 3 weeks.

Soxhlet extraction (laboratory scale)

a) 50grams of seeds are crushed and taken in the testing setup.

b) 150ml of methanol is taken in the round bottom flask as solvent.

c) Reaction is kept at 65 °C.

d) Methanol recovered by retaining oil in round bottom flask.

e) Oil in the flask transferred to measuring beaker and measured.

f) The quantity of oil obtained is estimated to 1kg of seeds roughly.

Mechanical expeller (production scale)

a) Seeds are crushed using mechanical expeller to get oil. (Mechanical expeller has the capacity of 30kg/hr, 3passes).

b) For a batch, 5kg of seeds are taken to crush, each batch of seeds passed 5 times to obtain complete oil.

c) Oil obtained is collected in a glass reagent container by filtering it with filters.

d) Filtered oil is left for 10-12hrs for settling of the minute dust particles.

e) After filtering and settling, oil is stored in a reagent glass bottle

In the present investigation the requirement is limited; hence the oil is extracted through soxhlet extraction method.

Trans-esterification process

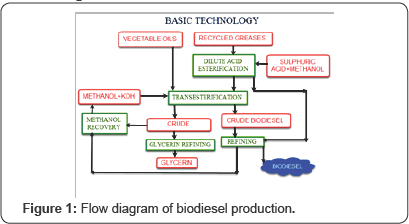

The oil extracted from the above method has high viscosity. In order to reduce the viscosity trans-esterification process has to be done. The flow diagram of biodiesel production is shown in Figure 1.

The procedure involved in transesterification process is given below.

a. 1000ml of vegetable oil is taken in a three way flask.

b. 12 grams of Sodium Hydroxide (NaOH) pellets are mixed with 200ml of methanol (CH3OH) and is taken in a beaker.

c. The NaOH is stirred with the alcohol until dissolved.

The solution obtained is mixed with oil in three way flask and it is stirred properly. The methoxide solution with oil is heated to 60 °C to 65 °C and it is continuously stirred at a constant rate for 1hour by a stirrer. The solution is poured down to the separating beaker and is allowed to settle for 8hours. The glycerin gets settled at the bottom and the methyl ester is formed at the top (coarse biodiesel). Methyl ester is separated from the glycerin. This coarse biodiesel is heated above 100 °C and maintained for 10-15minutes to remove the untreated methanol. Impurities like sodium hydroxide (NaOH) etc. are still dissolved in the coarse biodiesel. These impurities are cleaned up by washing with 350ml of water for 1000ml of coarse biodiesel.

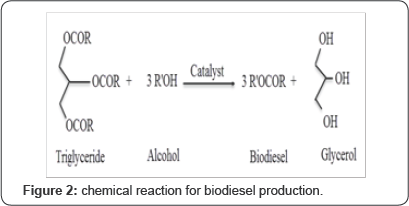

This processed biodiesel is the methyl ester of oil, which is subjected to conduct test evaluation in the diesel engine. The extracted oils obtained from the Nerium, Annona, Mahua, Pongamia and Jatropha are processed to convert into methyl ester through transesterification process. The general chemical reaction for biodiesel production is given below in Figure 2.

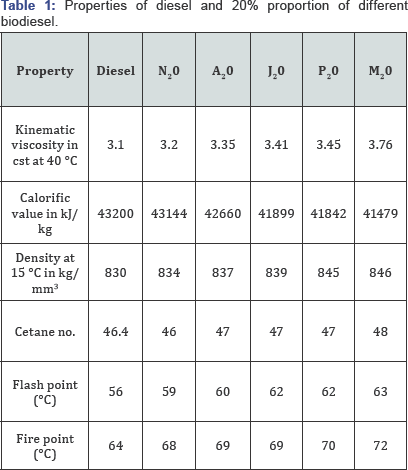

After transesterification process, the properties of methyl esters of different biodiesel are found in the laboratory at 20% blend are given in Table 1.

Experimental Procedure

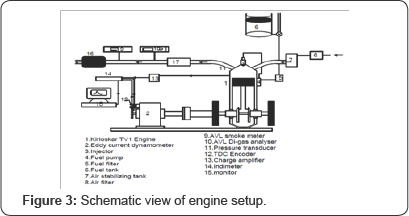

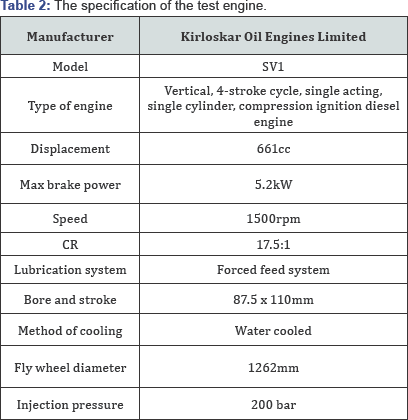

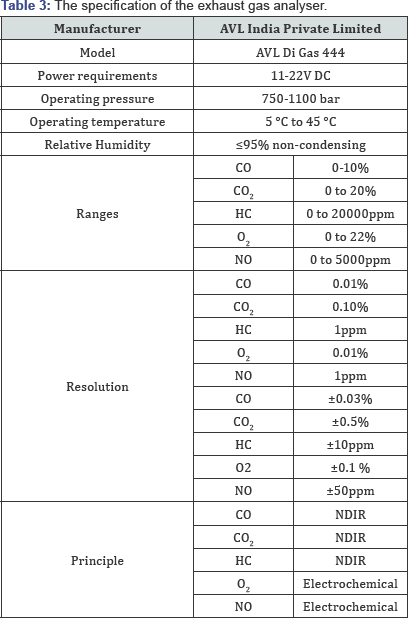

Experiments are carried out in a single-cylinder; water- cooled, naturally aspirated direct injection diesel engine coupled with an eddy current dynamometer. The schematic view of engine setup is shown in Figure 3. The specification of the test engine is shown in Table 2. An eddy current dynamometer coupled to the engine is used as a loading device. The fuel flow rate, speed, load, exhaust gas temperature and gas flow rate are measured through data acquisition system. Gas Analyzer is used to measure the CO, HC and NO emission. The specification of the exhaust gas analyzer is shown in Table 3. Experiments are carried out at steady state for different engine loads at a speed of 1500rpm.

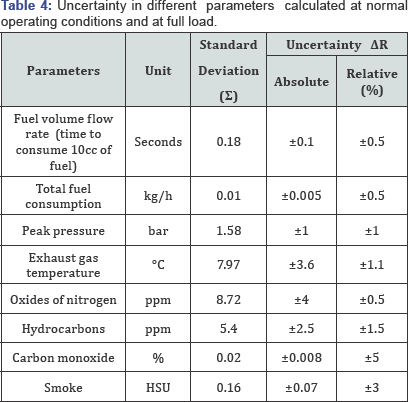

At each mode of operation, the engine is allowed to run for a few minutes until the exhaust gas temperature, the cooling water temperature, the lubricating oil temperature, as well as the emission have attained steady-state values and data are recorded subsequently. All the gas concentrations are continuously measured for 10minutes and the average results presented. The steady-state tests are repeated thrice. The results of the three tests are found to agree with one another within the experimental data that lie outside the probability of normal variations will incorrectly offset the mean value, inflate the random error estimates. Uncertainty analysis is needed to prove the accuracy of the experiments. The percentage uncertainties of various parameters like load and brake thermal efficiency were calculated using the percentage uncertainties of various instruments shown in Table 4.

Results and Discussion

In this study of 20% proportion of jatropha, pongamia, mahaua, annona and nerium methyl ester a have been investigated. The reasons for performance improvement and emission reductions were elaborately discussed in this section.

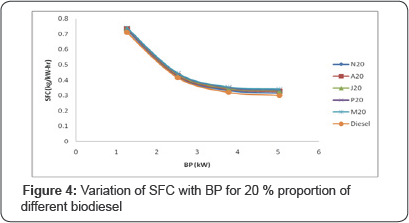

Specific fuel consumption (SFC)

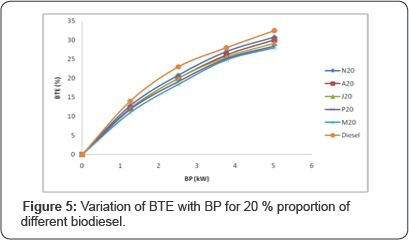

The variation of specific fuel consumption of N20, A20, J20, P20 and M20 biodiesel with brake power of the engine is shown in Figure 4. It is observed that the specific fuel consumption is lower for N20 biodiesel and other biodiesel having higher SFC. SFC is 0.315kg/kW-hr for N20 and 0.342kg/kW-hr for M20 fuel at maximum load. This is due to nerium biodiesel having higher cetane number and lower density when compared with the other biodiesel, which in turn improves the combustion. Figure 5 shows the variation of brake thermal efficiency of N20, A20, J20, P20 and M20 biodiesel with brake power of the engine. It is observed that BTE of different biodiesel is increasing with load. The maximum BTE of N20 is 30.8% and for M20 is 28% and which is 2.8% higher than that of M20 biodiesel.

This is due to the higher cetane number for N20 and having inferior properties than the other biodiesel. Further, the density of N20 is lower than that of others, which is also the reason for improving the efficiency.

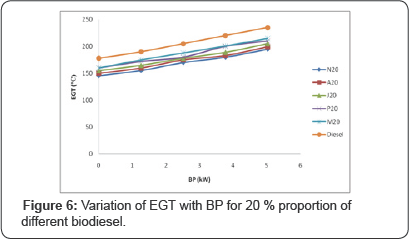

Exhaust gas temperature (EGT)

Figure 6 shows the variation of exhaust gas temperature of N20, A20, J20, P20 and M20 biodiesel with brake power of the engine. It is observed that EGT of N20 is lower than that of other biodiesel. The maximum EGT of N20 is 195 °C at full load, which is 20 °C lower than that of M20 biodiesel. This is due to N20 which has higher heating value, lower density and lower viscosity when compared with other biodiesel, and it leads to complete combustion.

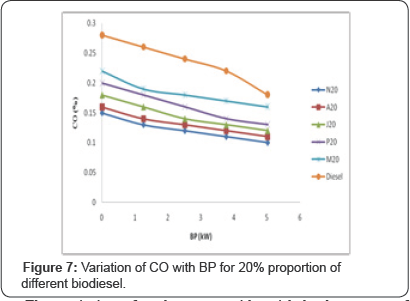

Carbon monoxide emission (CO)

The variation of carbon monoxide with brake power of the engine for N20, A20, J20, P20 and M20 biodiesel is shown in Figure 7. It is found that CO emission for biodiesel decreases with increasing load. It has been seen that among all biodiesel blends, N20 has lower CO emission than that of other biodiesel. The CO emission for N20 is 0.10% which is 0.06% lower than that of M20 biodiesel at full load. The main reason for the reduction of CO in N20 biodiesel is due to the presence of more oxygen in nerium biodiesel and its higher combustion temperature. It is observed that among the five biodiesels, M20 shows the maximum emission of CO at all loads. This is mainly due to lower heating value and higher density than other biodiesel.

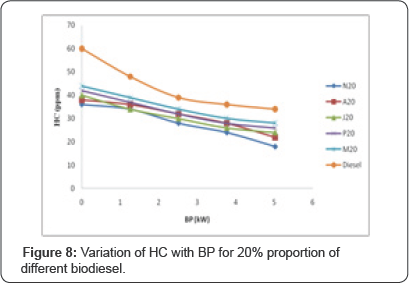

Hydrocarbon emission (HC)

Figure 8 shows the variation of hydrocarbon with the brake power of the engine for N20, A20, J20, P20 and M20 biodiesel. It is found from the graph that the HC emission decreases with increase in load. It is observed that among all biodiesel blend, N20 shows lower hydrocarbon emission and M20 shows higher hydrocarbon. It is also observed that HC for N20 is 18ppm and 28ppm for M20 at maximum load. This significant reduction of HC is due to complete combustion of N20 biodiesel in the presence of excess oxygen.

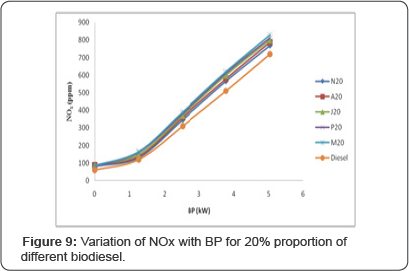

Oxides of nitrogen emission (NOx)

The variation of oxides of nitrogen with brake power of the engine for N20, A20, J20, P20 and M20 biodiesel is shown in Figure 9. It is found from the figure that NOx emission increases with the load and this is because of the increase in combustion chamber temperature with increase in load. It is observed that NOx emission for N20 is minimum when compared with other biodiesels blends at all loads. It is also observed that NOx emission is 7.3% lower than that of M20 biodiesel at full load. This reduction of NOx emission is due to the presence of oxygen in N20 biodiesel reacting with hydrocarbon instead of nitrogen.

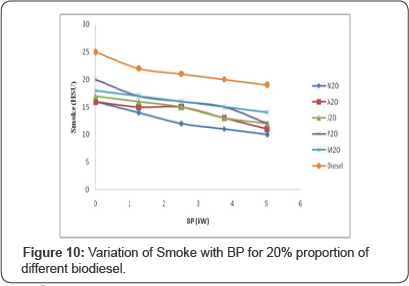

Smoke

Figure 10 shows the variation of smoke with the brake power of the engine for N20, A20, J20, P20 and M20 biodiesel. Among the different biodiesel blends, N20 showed much lower smoke emission than the other biodiesel. It is observed that smoke of N20 is 10 HSU and 14 HSU for M20 biodiesel fuel at full load. The reduction of smoke is due to the higher heating value of N20 biodiesel and higher amount of dissolved oxygen present in the N20 biodiesel. This ensures complete combustion in the combustion chamber and in turn to a reduction in smoke emission.

Conclusion

Experiments were conducted on a single cylinder, four- stroke, air cooled, direct injection diesel engine using 20% proportion of different biodiesel diesel blend and diesel. From the experiments the following conclusions are drawn.

a. Biodiesel blends showed slightly less performance than that neat diesel.

b. Biodiesel blends showed better reduction of all emissions except oxides of nitrogen. The oxides of nitrogen emission increase for all biodiesel and also increase with proportions of biodiesel blends.

c. Among the 20% proportion of various biodiesel, N20 showed better performance and reduced emission. But at the expense of NOx emission.

Hence, it can be concluded that the 20% proportion of nerium biodiesel and 80% of diesel can be used in diesel engine without any major modification.

References

- Sharma YC, Singh B, Upadhyay SN (2008) Advancements in development and characterization of bio-diesel: A review, Fuel 87(12): 2355-2373.

- Bryan RM (2009) Bio-diesel Production, properties, and feed stocks in vitro. Cell Dev Biol Plant 45(3): 229-266.

- Buyukkaya E (2010) Effects of bio-diesel on a DI Diesel engine performance, emission and combustion characteristics. Fuel 89(10): 3099-3105.

- Qi DH, Chen H, Geng LM, Bian YZH (2010) Experimental studies on the combustion characteristics and performance of a direct injection engine fuelled with dio-diesel/ diesel blends. Energy Conservation and Management 51: 2985-2992.

- Murat K, Gokhan E, Murat H (2011) Effects of the blends containing low ratios of alternative fuels on the performance and emission characteristics of a diesel engine. Fuel 112: 537-541.

- Tesfa B, Mishra R, Zhang C, Gu F, Ball AD, et al. (2013) Combustion and performance characteristics of CI (Compression ignition) engine running with bio-diesel. Energy 51: 101-115.

- Belachew T, Fengshou G, Rakesh M, Andrew B (2014) Emission Characteristics of a CI engine running with a range of bio-diesel feed stocks. Energies 7(1): 334-350.

- Rakopoulos CD, Antonopoulos KA, Rakopoulos DC (2006) Comparative performance and emission study of a direct injection diesel engine using blends of diesel fuel with vegetable oils or bio-diesel of various origins. Energy Conservation and Management 47: 3272-3287.

- Recep A, Cetinkaya S, Yucesu HS (2001) The potential of using vegetable oil fuel as fuel for diesel engines. Energy Conservation and Management 42(5): 529-538.

- BaiFu L, JyunHan H, DaoYi H (2009) Experimental study of the effects of vegetable oil methyl ester on DI diesel engine performance characteristics and pollutant emissions. Fuel 88(9): 1779-1785.

- Sudheer N (2013) Performance of C.I engine by using Bio-diesel-Mahua oil. American Journal of Engineering Research 2(10): 22-47.

- Sukumar P, Vedaraman N, Boppana VBR, Sankaranarayanan G, Jeychandran K (2005) Mahua oil (Madhucaindica seed oil) methyl ester as bio-diesel-prepartion and emission characteristics. Biomass and Bioenergy 28(1): 87-93.

- Saravanan N, Nagarajan G, Sukumar P (2010) Experimental investigation on a DI diesel engine fuelled with madhucaindica ester and diesel blend. Biomass and Bioenergy 34(6): 838-843.

- Nurun NMd, Najmul HSM, Shamin AMD (2009) Karanja (Pongamiapinnata) Bio-diesel production in Bangladesh, characterization of karanja biodiesel and its effect on diesel emissions. Fuel Processing Technology 90(9): 1080-1086.

- Suresh KK, Velraj R, Ganesan R (2008) Performance and exhaust emission characteristics of a CI engine fuelled with pongamiapinnata methyl ester (PPME) and its blends with diesel. Renewable Energy 33(10): 2294-2302.

- Huzayyin AS, Bawady AH, Rady MA, Dawood A (2004) Experimental evaluation of diesel performance and emission using blends of jojoba oil and diesel fuel, Energy Conservation Management 45(13-14): 20932112.

- Nurun NMd, Mustafizur RMd, Shamim AMd (2009) 'Biodiesel from cottonseed oil and its effect on engine performance and exhaust emissions'. Applied Thermal Engineering 29(11-12): 2265-2270.

- Liaquat AM, Masjuki HH, Kalam MA, Rizwanul FIM, Hazrat MA, et al. (2013) Effect of coconut biodiesel blended fuels on engine performance and emission characteristics. Procedia Engineering 56: 583-590.

- Sehmus A, Husamettin B, Cengizoner (2008) The comparison of engine performance and exhaust emission characteristics of sesame oil- diesel fuel mixture with diesel fuel in a direct injection diesel engine. Renewable Energy 33(8): 1791-1795.

- Gaurav P, Ambarish D, Bijiankumar M (2014) An experimental and numerical investigation of the performance combustion and emission characteristics of a diesel engine fuelled with jatropha biodiesel. Energy Procedia 54: 455-467.

- Anbumani K, Ajit PS (2010) Performance of mustard and neem oil blends with diesel fuel in C.I. engine. ARPN Engineering and Applied Sciences 5(4): 14-20.

- Prabhakar S, Annamalai K (2011) Biodiesel: an alternative renewable energy for next century. Scientific & Industrial Research 70: 875-878.

- Prabhakar S, Annamalai K, Isaac J (2012) Experimental study of using hybrid vegetable oil blends in diesel engine. Scientific & Industrial Research 71(09): 612-615.

- Senthil R, Silambarasan R (2014) Annona: a new biodiesel for diesel engine: a comparative experimental investigation. Journal of the Energy Institute 88(4): 459-469.