- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Advancements in Automated Storage and Retrieval Systems: A Comprehensive Review

Zeenat Khan1* and Mohsin Bilal Ahmed2

1Department of Biotechnology, Capital University of Science & Technology, Islamabad, Pakistan

1Institute of Mechanical and Manufacturing Engineering, Khawaja Fareed University of Engineering and Information Technology, Rahim Yar Khan, Pakistan

Submission:January 03, 2025; Published:January 20, 2025

*Corresponding author:Zeenat Khan, Department of Biotechnology, Capital University of Science & Technology, Islamabad, Pakistan

How to cite this article: Zeenat K, Mohsin Bilal A. Advancements in Automated Storage and Retrieval Systems: A Comprehensive Review. Robot Autom Eng J. 2025; 6(3): 555684. DOI: 10.19080/RAEJ.2025.06.555684

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Abstract

Automated Storage and Retrieval Systems (ASRS) are transforming modern warehouse management by automating inventory storage and retrieval, significantly improving operational efficiency, accuracy, and space utilization. The increasing inefficiencies and errors associated with manual storage systems have led industries to adopt automated solutions that can handle complex, large-scale operations. This paper examines the role of ASRS in enhancing warehouse management, focusing on key technological advancements such as robotics, sensors, Artificial Intelligence (AI), and the Industrial Internet of Things (IIoT). These technologies enable ASRS to optimize inventory management through real-time data collection, predictive maintenance, and enhanced decision-making capabilities. Additionally, the integration of ASRS with AI algorithms allows for self-optimization and adaptability, improving overall warehouse productivity while reducing operational costs. The paper also discusses the impact of ASRS on Industry 4.0, where these systems play a pivotal role in enabling smart, interconnected manufacturing and logistics environments. A comparative analysis of manual versus automated systems highlights the considerable advantages of ASRS, including higher throughput rates, reduced human error, and improved space utilization. Through a review of relevant literature and industry applications, this study underscores the transformative potential of ASRS in modern industrial settings and its contribution to the efficiency and sustainability of warehouse operations.

Keywords: Automated Storage and Retrieval Systems (ASRS); Warehouse Management; Industry 4.0; Robotics and AI; Industrial Internet of Things (IIOT)

Highlights: •Comparison of manual vs. automated storage systems for efficiency.

•Role of ASRS in optimizing warehouse space and operational accuracy.

•Integration of robotics, AI, and IIOT for smart warehouse management.

•Impact of predictive maintenance on cost reduction and system uptime.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Introduction

Automation has become a key driver of transformation in industries, enhancing efficiency, precision, and scalability [1]. By automating repetitive tasks, it reduces human involvement in manual processes, leading to increased productivity, consistent output, and significant cost savings [2]. In particular, Automatic Storage and Retrieval Systems (ASRS) have transformed warehouse operations by utilizing advanced technologies such as robotics, sensors, and intelligent software to automate storage, retrieval, and inventory management [3]. ASRS provides benefits like optimized space utilization, improved inventory accuracy, and faster processing times, while also reducing errors and labor costs [4]. Common types of ASRS include Vertical Lift Modules (VLMs), Automated Storage and Retrieval Machines (AS/RS), Horizontal Carousels, and Robotic AS/RS, each designed to meet specific storage and industry needs [5]. Overall, automation, operations andough ASRS, plays a critical role in improving operational efficiency, ensuring high precision, enabling continuous operations, and reducing the need for human intervention.

Manual storage systems have traditionally been the primary method for managing warehouse operations, relying heavily on human labor for tasks like picking, sorting, and storing items [6]. This dependence often leads to inefficiencies and errors, with challenges in optimizing space and adapting to fluctuating inventory needs [7]. In contrast, automated storage systems leverage advanced technologies such as robotics, sensors, and computerized controls to enhance efficiency, accuracy, and speed in inventory management [8]. These systems also maximize space utilization through vertical storage solutions. Although the initial cost of automated systems is higher, the long-term advantages, including improved productivity, reduced labor costs, and enhanced inventory accuracy, justify the investment [9]. In the framework of Industry 4.0, Automated Storage and Retrieval Systems (ASRS) are integral by connecting with the Industrial Internet of Things (IIOT), enabling real-time data collection and predictive maintenance [10]. ASRS also supports autonomous operations, optimizing efficiency with AI-driven decision-making and machine learning [11]. The integration with robotics and AI improves material handling, increases flexibility, and facilitates the creation of “lights-out” warehouses, which operate with minimal human involvement [12]. Overall, ASRS is a vital component of smart manufacturing, significantly boosting efficiency and transforming warehouse operations.

The design of Automated Storage and Retrieval Systems (AS/ RS) requires adherence to industry standards, such as those set by the American Society of Mechanical Engineers (ASME), to ensure safety, reliability, and compliance [13]. However, in laboratory environments, full compliance with these standards may not always be practical due to smaller scale and flexibility requirements [14]. In such cases, key safety and electrical code requirements must still be followed. Different design approaches, including economic, engineering, and concurrent strategies, are employed to optimize cost-effectiveness, functionality, and collaboration throughout the design process [15]. Safety and efficiency are critical in ASRS design and operation, with safety protocols focusing on risk assessments, protective barriers, and emergency mechanisms. Efficiency is achieved through thoughtful system design, optimization algorithms, and efficient workflows [16]. Regular maintenance, employee training, and safety audits are essential for continuous improvement, ensuring that safety and efficiency are balanced to enhance productivity and minimize risks in industrial settings. The increasing inefficiencies and inaccuracies of traditional manual storage systems have driven the need for advanced automated solutions in warehouses and industries [17]. This paper emphasizes the role of Automatic Storage and Retrieval Systems (ASRS) in improving operational efficiency, accuracy, and space utilization, especially within the context of Industry 4.0. Through a comparative analysis of manual and automated systems, the study explores key technological advancements, including robotics, sensors, and artificial intelligence (AI), that make ASRS essential for optimizing warehouse management. It also investigates the integration of these systems with the Industrial Internet of Things (IIOT), focusing on their impact on real-time data collection, predictive maintenance, and overall cost reduction. The methodology involves a review of relevant literature and industry applications to evaluate the performance and potential benefits of ASRS in modern industrial applications.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Automation System

Automation in General

Automation marks a significant milestone in modern industries, reshaping operational frameworks across a broad range of sectors [18]. It involves the use of technology and machinery to simplify, enhance, or replace human-driven tasks and processes, delivering considerable advantages in terms of efficiency, precision, and scalability [19]. At its essence, automation focuses on optimizing workflows by automating repetitive and routine tasks. This reduces human involvement in time-intensive, manual processes, leading to higher output consistency and throughput rates [20]. By substituting labor-intensive activities with automated systems, organizations can redirect human efforts toward more strategic and innovative pursuits, thereby driving productivity and fostering creativity. A key advantage of automation lies in its ability to improve operational efficiency. Automated systems are designed for precision and reliability, which significantly reduces the errors and inconsistencies associated with manual processes [21]. This level of consistency enhances quality control, boosts production rates, and shortens processing times [22]. Moreover, automation enables continuous operations, allowing tasks to be performed uninterrupted around the clock without human intervention, which accelerates workflows and helps meet tight deadlines [23].

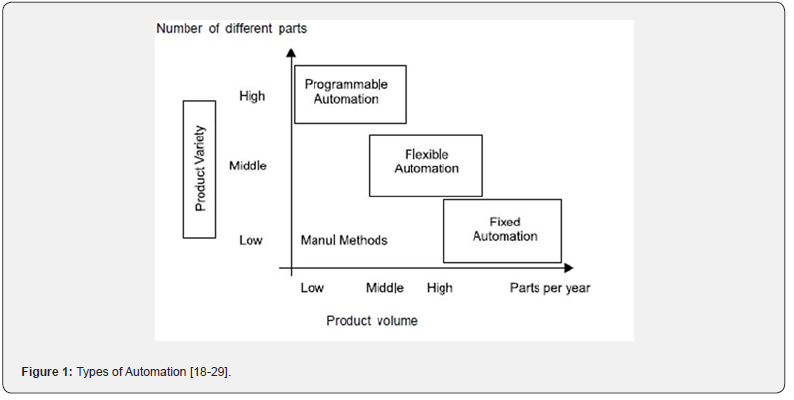

Additionally, automation plays a crucial role in reducing costs and optimizing resources. Although the initial investment in automation technology can be substantial, the long-term gains surpass these costs [24]. Automated systems help minimize waste and reduce operational expenses related to labor, energy, and materials. Over time, this leads to significant cost savings, contributing to improved profitability and sustainability [25- 28]. Manufacturing automation is broadly categorized into three types: fixed automation, flexible automation, and programmable automation, as illustrated in Figure 1 [29]. The distinctions among these types are based on the variety and volume of products they handle, as depicted below. Fixed automation refers to fully automated systems, while programmable automation involves systems that are partially automated. Flexible automation combines elements of the other two categories [30]. In conclusion, automation serves as a foundational pillar of modern industrial progress, delivering unmatched benefits in efficiency, accuracy, cost-effectiveness, and scalability. While offering transformative potential, the effective adoption of automation requires a balanced approach that aligns technological capabilities with operational needs and workforce considerations to maximize its benefits.

Automation in Warehouses and Industries

Automation in warehouses and industries has undergone a significant transformation, especially with the emergence of Automatic Storage and Retrieval Systems (ASRS) [31]. These systems have revolutionized conventional storage approaches, bringing about greater efficiency, precision, and operational optimization across diverse industrial applications [32]. ASRS marks a critical advancement in warehouse automation, employing advanced technologies like robotics, sensors, and intelligent software systems to automate the storage and retrieval of goods [33]. These systems replace manual tasks by automating the movement, storage, and retrieval of items within warehouse facilities [34]. Typically, ASRS consists of automated cranes, robotic systems, and conveyors that manage designated storage and retrieval operations with minimal human involvement, streamlining workflows [35]. The implementation of ASRS offers notable benefits, one of the most prominent being space utilization optimization [36]. With vertical storage designs and advanced handling systems, ASRS ensures maximum use of available warehouse space [37]. This benefit is particularly significant in urban areas where real estate costs are high, allowing organizations to store more inventory within limited physical space [38,39]. Furthermore, ASRS dramatically improves accuracy and precision in inventory management. Equipped with sophisticated control and tracking mechanisms such as RFID technology or barcode scanners, these systems enable real-time monitoring of inventory levels and locations [40]. This precision reduces errors in stock counts, prevents overstock or shortages, and enhances demand forecasting, leading to improved customer satisfaction and cost efficiency [41]. Additionally, ASRS automation significantly boosts operational efficiency by handling time-intensive and labor-heavy processes like sorting and picking with greater speed and accuracy [42]. This enhanced efficiency accelerates order processing, facilitates continuous operations, and ensures higher throughput rates to meet strict timelines.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Classifications of Automatic Storage and Retrieval System

The following are the most commonly used types of Automatic Storage and Retrieval Systems in industries:

Vertical Lift Modules (VLMs)

Vertical Lift Modules are automated storage solutions consisting of vertical columns that house trays or carriers. These columns are equipped with an automated elevator mechanism that delivers the desired tray or carrier to a designated access point [43]. The operation of VLMs is managed by a computerized control system, which oversees the vertical movement of the storage trays. When an item is requested, the system locates the tray containing the item and transports it to the access point [44]. Sensors on the trays ensure precise positioning. VLMs maximize vertical space utilization by leveraging warehouse height, allowing for high-density storage and efficient retrieval of items.

Automated Storage and Retrieval Machines (AS/RS)

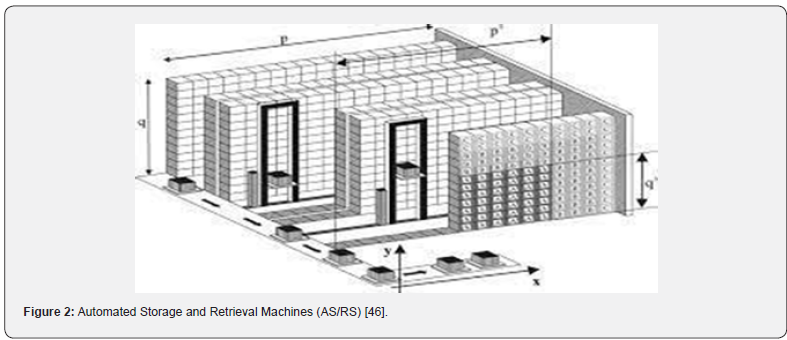

Automated Storage and Retrieval Machines encompass systems that use automated devices such as cranes, shuttles, or robotic arms to perform storage and retrieval tasks. AS/ RS generally function within aisles of racking structures [45]. They utilize computerized controls to navigate these aisles and access specific storage locations. Cranes or shuttles are used to move goods to and from the storage areas, while robotic arms handle tasks like picking, placing, and sorting. These systems are equipped with sensors and software algorithms to ensure accurate and efficient inventory management, as shown in Figure 2 [46]. AS/RS systems are versatile and capable of handling diverse load sizes, making them suitable for industries such as manufacturing, distribution, and retail.

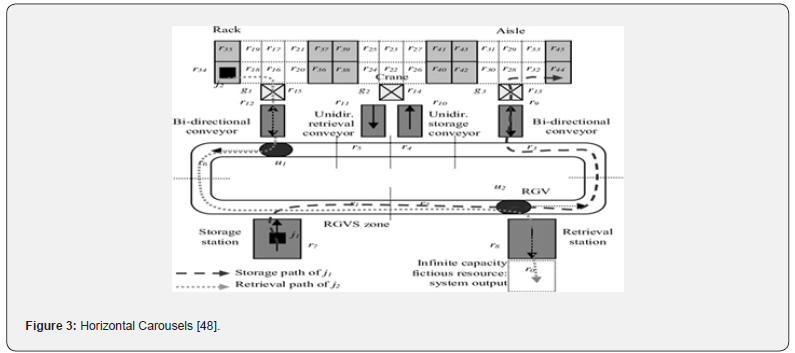

Horizontal Carousels

Horizontal Carousels are circular storage systems designed to rotate horizontally, bringing storage shelves or bins to a picking station [47]. These carousels consist of multiple shelves or bins mounted on a rotating track. When an item is needed, the carousel rotates to position the appropriate shelf at the access point. Computerized controls are used to track and manage the inventory stored on the shelves, as depicted in Figure 3 [48]. Operators can access items directly from the rotating shelves, increasing picking efficiency and reducing retrieval time. Horizontal carousels are particularly effective for smaller items or parts that have a high picking frequency.

Robotic Automated Storage and Retrieval Systems

Robotic AS/RS involve the use of robotic arms or autonomous vehicles to navigate storage environments and handle the storage and retrieval of items [49]. These systems incorporate advanced robotics and artificial intelligence to identify, pick, and transport items to designated locations [50]. Robotic AS/RS provide high flexibility and adaptability, efficiently managing a variety of load sizes and shapes, as illustrated in Figure 4 [51]. These systems rely on advanced sensors and vision technology to ensure precise identification and handling of items. Robotic AS/ RS are increasingly favored in industries requiring agility and customization in their storage and retrieval processes.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Comparative Analysis of Manual vs. Automated Storage Systems

Manual storage systems have historically been the predominant method for managing inventory and materials in warehouses [52]. However, the introduction of automated storage systems calls for a comparative analysis to evaluate their respective benefits and drawbacks, as summarized in (Table 1). Manual storage systems rely extensively on human labor for operations such as picking, sorting, and storing items, which often leads to inefficiencies and inaccuracies [53]. These systems are generally less effective in optimizing storage space and adapting efficiently to changing inventory requirements [54]. Additionally, manual systems are prone to human errors, which can adversely affect inventory accuracy and overall operational performance. Conversely, automated storage systems minimize the reliance on manual labor by utilizing advanced technologies such as robotics, sensors, and computerized controls to automate storage and retrieval processes [55]. This automation improves efficiency, accuracy, and speed in inventory management [56]. Furthermore, automated systems enhance space utilization by employing vertical storage solutions, making better use of available warehouse space [57]. In summary, the analysis highlights the considerable advantages of automated storage systems over manual ones in terms of efficiency, accuracy, and space optimization, as shown in (Table 1). While the initial investment in automated systems may be higher, the long-term benefits, including improved productivity, reduced labor costs, and enhanced inventory accuracy, outweigh the upfront expenses.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Automatic Storage and Retrieval Systems in Industry 4.0

Within the paradigm of Industry 4.0, Automatic Storage and Retrieval Systems (ASRS) serve as a fundamental component in revolutionizing warehouse management and logistics [58]. By integrating advanced technologies into manufacturing and industrial operations, Industry 4.0 positions ASRS as a critical enabler of efficient material handling, storage, and retrieval in smart warehouses and factories.

A key attribute of ASRS in the Industry 4.0 framework is its seamless integration with interconnected systems and the Industrial Internet of Things (IIOT) [59]. These systems are outfitted with sensors, RFID technology, and connectivity features, allowing for real-time data collection and interaction with other smart devices [60]. This interconnectedness enhances operational transparency and facilitates predictive maintenance, ensuring uninterrupted and optimized functionality of the storage systems [61,62]. In addition, ASRS supports the principles of automation and smart manufacturing inherent in Industry 4.0 by enabling autonomous operations. These systems utilize realtime data analysis to achieve self-optimization and adaptability [63]. Through the application of machine learning algorithms and AI-driven decision-making, ASRS can refine storage layouts, streamline retrieval processes, and enhance inventory management. This leads to improved operational efficiency and a reduction in overall costs.

The seamless integration of ASRS with advanced technologies, such as robotics and artificial intelligence, enhances its functionality in Industry 4.0 environments [64]. Robotic arms and Automated Guided Vehicles (AGVs) collaborate with ASRS, creating a more agile and efficient material handling system. This collaboration leads to higher throughput, fewer errors, and greater flexibility in responding to changing production demands. Additionally, ASRS plays a pivotal role in the development of “lights-out” warehouses, a key concept in Industry 4.0 [65]. These fully automated facilities operate with minimal or no human intervention, relying entirely on automated systems like ASRS for storage, retrieval, and distribution. Operating 24/7, lights-out facilities maximize productivity while reducing labor costs [66]. In conclusion, ASRS is a critical component of Industry 4.0, driving efficiency and transforming warehouse operations. Its integration with cutting-edge technologies and its ability to support autonomous, data-driven operations make it a cornerstone of modern smart manufacturing.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Design Guidelines

Designing Automated Storage and Retrieval Systems (AS/ RS) requires adherence to industry standards to ensure safety, reliability, and compliance [67]. The American Society of Mechanical Engineers (ASME) standard ASME 830.13-1991 outlines the construction, operation, inspection, and maintenance of AS/RS machines [68]. In addition, it refers to other key standards such as ANSI MH16.1-1974 for steel storage racks, ANSI/NFPA 70-1987 for electrical codes, and ANSI/NFPA 231C- 1986 for rack storage of materials.

In laboratory settings, however, full compliance with these standards may not always be feasible due to the project’s scale and flexibility. With smaller sizes and lighter loads in this specific application, adhering to every detailed code may be impractical [69]. While the ASME standard and university safety protocols were strictly followed, meeting all referenced standards may not have been possible [70]. Instead, the focus was placed on fulfilling essential safety measures and electrical code requirements relevant to the laboratory context. This ensured that the AS/ RS design maintained safety and functionality, tailored to the laboratory’s specific needs.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Design Approach

Several design approaches were considered for this Automated Storage and Retrieval System (AS/RS) to ensure efficiency and functionality.

Economic Design Models in ASRS

Economic design models focus on optimizing costeffectiveness in ASRS. These models aim to balance system performance with overall costs, taking into account factors like initial investment, operational expenses, maintenance, and the system’s lifespan [71]. By evaluating trade-offs among various design options, economic models help identify the most costefficient ASRS design that meets operational needs without exceeding budget constraints.

Engineering Design Approach for ASRS

The engineering design approach for ASRS follows a systematic methodology, emphasizing the application of engineering principles, technical specifications, and industry standards [72]. This approach focuses on functionality, reliability, and scalability while ensuring structural integrity, load-bearing capacities, and material selection meet safety regulations [73]. It aims to create ASRS designs that effectively meet operational demands while maintaining safety and robustness.

Concurrent Approach to Design in ASRS

The concurrent design approach involves a collaborative and simultaneous development process, integrating various disciplines such as engineering, technology, and user feedback. This approach fosters communication and parallel task execution, allowing for quicker design iterations and problem-solving [74]. In ASRS design, it enables seamless integration of mechanical, electrical, and software components from the start, speeding up the development and implementation process.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Safety and Efficiency Considerations

Safety and efficiency are crucial considerations in the design and operation of Automatic Storage and Retrieval Systems (ASRS). Ensuring the safety of both the system and personnel is essential for the success and sustainability of these automated systems in industrial environments [75]. Safety protocols within ASRS include various measures, starting with comprehensive risk assessments during the design phase [76]. ASRS must adhere to strict safety standards and regulations to prevent accidents. Protective barriers, emergency stop mechanisms, and sensors that detect obstructions are incorporated to mitigate potential hazards [77]. Additionally, regular maintenance and inspections are critical to identify and address safety concerns promptly. Efficiency in ASRS is achieved through careful system design and optimization. An efficient ASRS is characterized by streamlined workflows, minimal downtime, and maximized throughput [78]. This efficiency is achieved through strategic layout design, which minimizes travel distances for storage and retrieval operations. Optimization algorithms are used to enhance picking strategies and inventory allocation, reducing processing times and improving overall system productivity [79]. Balancing safety and efficiency require careful attention. Improving efficiency should never compromise safety standards [80].

Measures to boost efficiency, such as optimizing travel paths or increasing operational speed, must be implemented without compromising the safety of personnel or the integrity of the system. Furthermore, training programs are essential for personnel operating within ASRS environments. Employees must be well-versed in safety protocols and emergency procedures to respond effectively to unforeseen incidents [81]. Continuous training ensures that individuals stay updated on safety measures and can operate ASRS equipment proficiently. Regular safety audits and risk assessments are vital for maintaining a safe and efficient working environment [82]. These evaluations help identify potential hazards or inefficiencies, supporting continuous improvement and ensuring that ASRS operates optimally while adhering to safety standards [83]. In conclusion, achieving a balance between safety and efficiency is vital in the implementation and operation of ASRS [84]. By integrating robust safety measures without compromising operational efficiency, these systems can enhance productivity, reduce risks, and provide a safe working environment conducive to optimal performance within industrial settings.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Conclusion

In conclusion, the transition from manual to automated storage systems has become essential in modern warehouses and industries due to the growing need for efficiency, accuracy, and optimized space utilization. Manual systems, which have been traditionally relied upon, are increasingly being replaced by Automated Storage and Retrieval Systems (ASRS) due to their ability to streamline operations and significantly reduce human error. Through the integration of advanced technologies like robotics, sensors, and AI, ASRS systems offer a level of precision and speed that traditional manual systems simply cannot match. The ability to manage inventory and perform storage and retrieval tasks autonomously is transforming how warehouses operate, resulting in increased throughput, improved accuracy, and optimized storage capacity. The integration of ASRS within the framework of Industry 4.0 has further elevated their value in modern industrial settings. By incorporating technologies such as the Industrial Internet of Things (IIoT), ASRS systems can collect real-time data, enhancing operational transparency and enabling predictive maintenance. This interconnectedness facilitates continuous optimization of storage operations, leading to reduced downtime and increased overall efficiency.

The real-time data analysis allows for better decision-making, while also driving down operational costs by reducing human labor requirements and minimizing inventory inaccuracies. ASRS systems, with their adaptability and ability to function autonomously, have thus become crucial enablers of smarter, more cost-effective warehouse management in the context of Industry 4.0. The benefits of ASRS systems are undeniable, but their successful implementation requires careful consideration of system design, safety protocols, and continuous optimization. The development and maintenance of ASRS must prioritize safety and efficiency, ensuring that systems are not only effective but also secure for personnel. As industries move toward fully automated and interconnected systems, future research should focus on further refining ASRS technologies, incorporating even more advanced AI and machine learning algorithms, and exploring ways to improve energy efficiency and sustainability. With the continued evolution of automation technologies, ASRS systems are expected to play an even more pivotal role in reshaping the future of warehouse management, driving both operational excellence and long-term sustainability.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Acknowledgement

We extend our sincere gratitude to every person and department who supported us throughout the literature research.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Author Contributions

“Conceptualization, Zeenat Khan and Mohsin Bilal Ahmed; methodology, Zeenat Khan and Mohsin Bilal Ahmed; formal analysis, Zeenat Khan and Mohsin Bilal Ahmed, writing-original draft preparation, Mohsin Bilal Ahmed; writing-review and editing, Zeenat Khan; supervision, Zeenat Khan. All authors have read and agreed to the published version of the manuscript.”

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- Review Article

- Abstract

- Introduction

- Automation System

- Classifications of Automatic Storage and Retrieval System

- Comparative Analysis of Manual vs. Automated Storage Systems

- Automatic Storage and Retrieval Systems in Industry 4.0

- Design Guidelines

- Design Approach

- Safety and Efficiency Considerations

- Conclusion

- Acknowledgement

- Author Contributions

- Competing Interests

- References

References

- Roodbergen KJ, Vis IFA (2009) A survey of literature on automated storage and retrieval systems. European Journal of Operational Research 194(2): 343-362.

- Hameed HM, Al Amry KA, Rashid, AT (2019) The Automatic Storage and Retrieval System: An Overview 177(16): 36-43.

- Aisen AM, Broderick LS, Winer-Muram H, Brodley CE, Kak AC, et al. (2003) Automated storage and retrieval of thin-section CT images to assist diagnosis: System description and preliminary assessment. Radiology 228(1): 265-270.

- Wang H, Wei Y, Yan H (2023) Automatic single table storage structure selection for hybrid workload. Knowledge and Information Systems 65(3): 4713-4739.

- Mohammad Khasasi F, Abdul AM, Yusof ZM (2015) Development of an Automated Storage and Retrieval System in dynamic industrial environment. In: 2015 International Conference on BioSignal Analysis, Processing, and Systems (ICBAPS 2015), IEEE Inc 2015: 57-60.

- Eaglesham M, Deisenroth MP, Sarin SC (1995) Automated Storage and Retrieval System Design Report.

- Hanani F, Khasasi M, Yusof ZM, Zulkhairi MY, Aswadi M (2016) An approach to model the physical design of an automated storage and retrieval system.

- Özyurt R, Onyedi B, Elen A, Közkurt C (2023) Types of Robots Used in Automated Storage and Retrieval Systems.

- Sarkula J, Oinonen M (2023) Automated Storage and Retrieval System (AS/RS). Subject Automation Storage and Retrieval System (AS/RS).

- Lerher T, Ekren YB, Sari Z, Rosi B (2015) Simulation analysis of shuttle based storage and retrieval systems. International Journal of Simulation and Modeling 14(1): 48-59.

- Tamsir, Siswoyo Hadisantoso F (2020) Development of Automatic Storage Retrieval System for Variable Loads. Journal Sains, Teknologi dan Industri 18(1): 99-103.

- Janilionis V, Bazaras Ž (2013) The design and investigation of two storage/retrieval mechanisms of the cylindrical automated storage and retrieval system. Transport 28(4): 352-360.

- Bargiotas D, Ktena A, Manasis C, Ladoukakis O (2009) A scalable low-cost automated storage & retrieval system. In: 2009 16th International Conference on Systems, Signals, and Image Processing (IWSSIP 2009): 5367724.

- Arnovick GN, Hies JA, Wood JS (2023) Information Storage and Retrieval-Analysis of the State of the Art.

- Ajay T, Vinoth A, Daniel Glad Stephen J (2020) Design optimization and development of an Automated Storage and Retrieval System. In: IOP Conference Series: Materials Science and Engineering, IOP Publishing Ltd: 032031.

- Xia Z, Yaohua W, Delong X, Yunxia C (2018) Dynamic modelling of an automated vehicle storage and retrieval system and a simulation analysis of its efficiency. International Journal of Engineering Modelling 31(4): 29-42.

- Maheswari MKU, Malathi S, Taruni M, Yuvapriya R, Chaarumathi M (2018) Automatic Ream Handling System (Automatic Storage and Retrieval System) by using PLC. GRD Journal for Engineering 3(4).

- Jantan D (2008) Development of a Computer-Controlled Automated Storage and Retrieval System.

- Braam RGL (2023) Increasing performance in an automated storage and retrieval system warehouse.

- Hanani F, Khasasi M, Yusof ZM, Alias MA, Adam I (2016) Development of Automated Storage and Retrieval System (ASRS) for Flexible Manufacturing System (FMS).

- AbdelGawad AF (2015) Multidisciplinary Engineering for the Utilization of Traditional Automated Storage and Retrieval System (ASRS) for Firefighting in Warehouses. American Journal of Energy Engineering 3(1): 1.

- Turner BA, Graves S, Seigel TJ, Herson M, Dean A, et al. (2020) Evaluation of Automated Storage and Retrieval in a Distribution Center.

- Pingale MS, Kulkarni HH (2019) Design and Development of Automated Storage and Retrieval System (ASRS) for Warehouse Using IOT and Wireless Communication. International Journal of Science and Technology Research 8(9).

- Oliveira JA, Ferreira J, Pereira GAB, Dias LS (2020) An improved Evolutionary Algorithm to sequence operations on an ASRS warehouse.

- Hameed H, Rashid A, Al Amry K (2020) Automatic Storage and Retrieval System using the Optimal Path Algorithm. Iraqi Journal of Electrical and Electronics Engineering 125-133.

- Lerher T, Sraml M, Potrc I, Tollazzi T (2010) Travel time models for double-deep automated storage and retrieval systems. International Journal of Production Research 48.

- Automated storage and retrieval system.

- Wenkai M, Yanyan W, Jinchang H, Yaohua W (2020) Optimizing replenishment based on order structure in crane & shuttle-based storage and retrieval system.

- Xue Y, Liu H (2012) Intelligent storage and retrieval systems based on RFID and vision in automated warehouse. Journal of Networks 7(2): 365-369.

- Zollinger H, Zollinger Associates (2020) AS/RS Application, Benefits, and Justification in Comparison to Other Storage Methods: A White Paper Replenishment System for Distribution Center.

- University of Florida Department of Electrical and Computer Engineering (2005) EEL 5666 Intelligent Machines Design Laboratory Spring 2005 Final Report Automated Storage & Retrieval System.

- Trost P, Kartnig G, Eder M (2022) Simulation of the maximum throughput of Autostore-storage systems. Logistics Journal.

- Totuk O (2023) Chapter 16 Boxed Medicine Robot Shelving Design Based on Dynamic Storage Allocation in AS/RS Systems.

- Sarker BR, Sobhan Babu P (1995) Travel time models in automated storage/retrieval systems: A critical review. International Journal of Production Economics 40(2-3): 173-184.

- Rosenblatt MJ, Eynan A (1989) Deriving the Optimal Boundaries for Class-Based Automatic Storage/Retrieval Systems. Management Science 35(12): 1519-1524.

- Sari Z, Saygin C, Ghouali N (2005) Travel-time models for flow-rack automated storage and retrieval systems. International Journal of Advanced Manufacturing Technology 25: 979-987.

- Alonso-Ayuso G, Tirado G, Udías A (2013) On a selection and scheduling problem in automatic storage and retrieval warehouses. International Journal of Production Research 00: 1-22.

- Lee HF (1997) Performance analysis for automated storage and retrieval systems. IIE Transactions (1997) 29: 15-28.

- Vasili MR, Tang SH, Vasili M (2012) Automated storage and retrieval systems: A review on travel time models and control policies. In Springer 4, TUT Press: 159-209.

- Cinar ZM (2023) Configuration Design and Optimization of Circular Automated Storage and Retrieval System (C-AS/RS).

- Sarkula J, Oinonen M (2020) Automated Storage and Retrieval System (AS/RS). Subject Automation Storage and Retrieval System (AS/RS).

- Bin PM (2017) ASSE4311_106_1720: Learning Outcome Asse. III/ME_ Form: SDP02 Final Report Team2 Project title: Automated Storage and Retrieval System (ASRS) # Student Name.

- Gaouar Z, Sari N, Sari C, Saygin N (2006) Metaheuristic based control of a flow rack automated storage retrieval system. Journal of Intelligent Manufacturing 2010(4): 1157-1166.

- Chen L, Langevin A, Riopel D (2010) The storage location assignment and interleaving problem in an automated storage/retrieval system with shared storage. International Journal of Production Research 48: 991-1011.

- Manzini R, Gamberi M, Regattieri A (2006) Dead lock detection. International Journal of Advanced Manufacturing Technology 28: 766-774.

- Dotoli M, Fanti MP (2007) Deadlock detection and avoidance strategies for automated storage and retrieval systems. IEEE Transactions on Systems, Man, and Cybernetics, Part C 37: 541-552.

- Salton G (2006) Document on automatic storage and retrieval.

- Design and Fabrication of automated guided vehicle with automatic storage and retrieval system.

- Arnovick GN, Hies JA, Wood JS (2020) Information Storage and Retrieval-Analysis of the State of the Art.

- Kanet JJ, Ramirez RG (1986) Optimal Stock Picking Decisions in Automatic Storage and Retrieval Systems.

- Lehmann T, Hußmann J, Author C (2020) Travel time model for multi-deep automated storage and retrieval system with a homogeneous allocation structure. Logistics Research 14: 5.

- Gong Y, de Ko RBM, Chen W, de Koster RBM (2020) Performance estimation of a passing-crane automated storage and retrieval system. International Journal of Production Research 1-22.

- Nelson RH, Otten TH, Nelson RH (2020) Publisher International Foundation for Telemetering Journal International Telemetering Conference Proceedings Rights.

- Dassisti M, Dotoli M, Epicoco N, Falagario M (2012) Internal logistics integration by automated storage and retrieval systems: A reengineering case study. In Lecture Notes in Computer Science, Springer 78-82.

- Sarawale RK, Domale A, Deokar S, Kardile S (2015) Retrieval System with Automatic Storage Using SCAD. International Engineering Research Journal 2: 151-153.

- Eaglesham M, Deisenroth MP, Sarin SC (1995) Automated Storage and Retrieval System Design Report.

- Koç YZ (2023) Automatic Storage and Retrieval System (AS/RS) Design for Manufacturing System. International Journal of Computational and Experimental Science and Engineering 9(2): 102-104.

- Borovinšek M, Ekren BY, Burinskienė A, Lerher T (2017) Multi-objective optimisation model of shuttle-based storage and retrieval system. Transport 32(2): 120-137.

- Yu YB, de Koster R (2020) Designing an Optimal Turnover-based Storage Rack for a 3D Compact AS/RS.

- Sari Z, Ghomri L, Ekren BY, Lerher T (2014) Experimental Validation of Travel Time Models for Shuttle-based Automated Storage and Retrieval System.

- Gharehgozli AH, Yu Y, Zhang X, de Koster R (2017) Polynomial time algorithms to minimize total travel time in a two-depot automated storage/retrieval system. Transportation Science 51(1): 19-33.

- Abrams M, Haigh P, Comfort J (1988) Proceedings of the 1988 Winter Simulation Conference.

- Dotoli M, Fanti MP (2007) A Coloured Petri Net Model for Automated Storage and Retrieval Systems Serviced by Rail-Guided Vehicles: A Control Perspective.

- Lewczuk K (2021) The study on the automated storage and retrieval system dependability. Eksploatacja i Niezawodnosc, 23(4): 709-718.

- Storage Systems. By MIT Institute.

- Guezzen AH, Sari Z, Castagna P, Cardin O (2013) Travel Time Modeling and Simulation of a Mobile Racks Automated Storage/Retrieval System. International Journal of Engineering and Technology 5(3): 420-423.

- Hsieh S, Tsai KC (2001) A BOM Oriented Class-Based Storage Assignment in an Automated Storage/Retrieval System.

- Hu YH, et al. (2005) Travel time analysis of a new automated storage and retrieval system. Computers & Operations Research 32: 1515-1544.

- Torchio F (2023) "Survey on automated systems for smart warehouses." PhD diss, Politecnico di Torino.

- Bahurdin MM, Othman J, Dir TMAT, Othman J (2020) Developments shuttle-based storage and retrieval system current and future. International Journal of Advanced Science and Technology 29: 4430-4437.

- Fujisawa H (2002) A survey of advancements in document recognition and document retrieval technologies. In: DLM-Forum.

- Chong ZH, Luxman R, Pang WC, Yi Z, Meixuan R, et al. (2018) An innovative robotics stowing strategy for inventory replenishment in automated storage and retrieval system. In: 15th International Conference on Control, Automation, Robotics, and Vision (ICARCV) pp: 305-310.

- Sodiya EO, Umoga UJ, Amoo OO, Atadoga A (2024) AI-driven warehouse automation: A comprehensive review of systems. GSC Advanced Research Review 18(02): 272-282.

- Marchet M, Melacini S, Perotti S, Tappia E (2013) Development of a framework for the design of autonomous vehicle storage and retrieval systems. International Journal of Production Research 51: 4365-4387.

- Ko M, Park SC, Chang M (2013) Control level simulation of an automatic storage and retrieval system in the automotive industry. Concurrent Engineering 21(1): 13-25.

- Cassettari L, Currò F, Mosca M, Mosca R, Revetria R, et al. (2021) A 4.0 automated warehouse storage and picking system for order fulfillment. In: Lecture Notes in Engineering and Computer Science, World Congress on Engineering 7-9.

- Odeyinka OF, Omoegun OG (2023) Warehouse Operations: An Examination of Traditional and Automated Approaches in Supply Chain Management.

- Yarlagadda VK (2024) Cutting-edge developments in Robotics for Smart Warehousing and Logistics Optimization. Robotics Xplore: USA Automation Digest 1: 61-79.

- Ekren BY, Akpunar A (2021) An open queuing network-based tool for performance estimations in a shuttle-based storage and retrieval system. Applied Mathematical Modelling 89: 1678-1695.

- Eldemir F, Graves RJ, Malmborg CJ (2004) New cycle time and space estimation models for automated storage and retrieval system conceptualization. International Journal of Production Research 42(22): 4767-4783.

- Mora X, Wu M, Panori A (2020) Mind the gap: Developments in autonomous driving research and the sustainability challenge. Journal of Cleaner Production 275: 124087.

- Pulat BM, Pulat PS (1988) Performance analysis of automatic storage and retrieval systems- A comparative approach. In: Proceedings of the 20th Conference on Winter Simulation 591-596.

- Gharehgozli AH, Yu Y, Zhang X, de Koster R (2017) Polynomial time algorithms to minimize total travel time in a two-depot automated storage/retrieval system. Transportation Science 51(1): 19-33.

- Mandala S, Sowjanya G (2020) Recent Advancement and Role of Search Engines in Information Retrieval System. AIJREAS 6(4).