A Compliant Flexible Gripper for Enhanced Robotic Manipulation: Design, Development and Testing

AV Rajurkar, Rajan Raut* and Vivekanand Rathod

Vishwakarma Institute of Technology, Pune 411037, Maharashtra, India

Submission:November 07, 2024; Published:January 10, 2025

*Corresponding author: Rajan Raut, Vishwakarma Institute of Technology, Pune 411037, Maharashtra, India

How to cite this article: AV Rajurkar, Rajan R, Vivekanand R. A Compliant Flexible Gripper for Enhanced Robotic Manipulation: Design, Development and Testing. Robot Autom Eng J. 2025; 6(3): 555683. DOI: 10.19080/RAEJ.2025.05.555683

Abstract

This paper provides a comprehensive review of advancing Reinforcement Learning (RL) through human and AI feedback, with a focus on the emerging subfield of Explainable Reinforcement Learning (XRL). It examines how explainability techniques can enhance the transparency of RL agents' decision-making processes in sequential decision-making settings, allowing practitioners to better understand and trust agent behavior. The review also explores the scalability challenges of Reinforcement Learning from Human Feedback (RLHF) and introduces Reinforcement Learning from AI Feedback (RLAIF) as a promising alternative. By leveraging off-the-shelf Large Language Models (LLMs) for generating preference labels, RLAIF addresses the time-consuming and expensive nature of manual human feedback while achieving comparable or superior results to RLHF. The paper further discusses the open problems and fundamental limitations of both RLHF and RLAIF, highlighting the need for robust methodologies to improve their practical implementation. It concludes by outlining future research directions aimed at refining and complementing RLHF and RLAIF to enhance their effectiveness and societal impact in real-world applications.

Keywords: XRL: Explainable Reinforcement Learning; RLHF: Reinforcement Learning from Human Feedback; RLAIF: Reinforcement Learning from AI Feedback; DRL: Deep Reinforcement Learning; Sequential Decision-Making

Introduction

In recent years, robotics has emerged as a cornerstone of automation, driving advancements across diverse sectors such as manufacturing, healthcare, and agriculture. A critical component of robotic systems end-effectors-specifically grippers-have evolved to meet the growing demand for precision and adaptability in manipulating delicate or irregularly shaped objects. Traditional rigid grippers, while effective in structured environments, often struggle when handling fragile items such as fruits, eggs, or medical materials, where a delicate balance between flexibility and grip strength is essential. Consequently, there is an increasing demand for grippers that offer enhanced compliance, adaptability, and force control to meet these challenging requirements. This research focuses on the design and development of a flexible robotic gripper featuring a compliant mechanism capable of conforming to complex geometries while exerting controlled forces to securely grasp delicate objects without causing damage. The gripper’s actuation mechanism employs a rack-and-pinion system powered by servo motors, enabling precise and reliable movement of its flexible claws. Extensive material experimentation was conducted, resulting in the selection of PLA for its optimal combination of flexibility and mechanical strength. To ensure robustness, Finite Element Analysis (FEA) simulations were performed to assess the gripper’s performance under various loading conditions, with particular emphasis on fatigue life, stress distribution, and adaptability.

In addition to the gripper, we designed and developed a compatible robotic arm—serving as the manipulator—for effective pick-and-place operations using the compliant gripper. This integration of a flexible gripper with a fully functional robotic arm enhances the system’s versatility, enabling it to perform sensitive tasks autonomously in diverse applications. The combined arm-gripper assembly has potential use cases across several industries, from automated fruit harvesting to delicate surgical procedures, where the need for gentle yet reliable handling mechanisms is paramount. This paper details the development process, material selection, and experimental testing of both the gripper and robotic arm. By addressing the growing need for adaptable, compliant end-effectors, this research contributes to the advancement of robotic systems designed for fragile object handling. Additionally, potential future enhancements and broader applications are discussed, positioning this flexible gripper-arm assembly as a promising solution for next-generation robotics.

Literature Review

The development of compliant mechanisms in robotics has revolutionized design paradigms, facilitating enhanced adaptability, precision, and robustness essential for applications in complex and dynamic environments. Inspired by biological models, these mechanisms utilize elastic materials or deformable structures to achieve motion, bypassing the need for conventional rigid joints and actuators. This shift towards compliant design has introduced numerous benefits, including reduced mechanical complexity, decreased weight, and enhanced resilience, all of which are crucial for diverse applications from high-precision manufacturing to human-robot interactions. One major contribution in this area comes from the work on robotic grippers and hands, which often need to handle delicate and varied objects. A study by Liu et al. [2] showcased a topology-optimized constantforce compliant mechanism for robotic fingers, engineered to maintain a near-constant output force across a range of displacements. This innovation, realized through 3D printing with thermoplastic elastomers, addresses challenges in delicate object manipulation by eliminating the need for sensors or feedback control. The constant-force feature allows for precise handling of fragile items, presenting a breakthrough for robots operating in unpredictable environments where sensitivity and control are paramount.

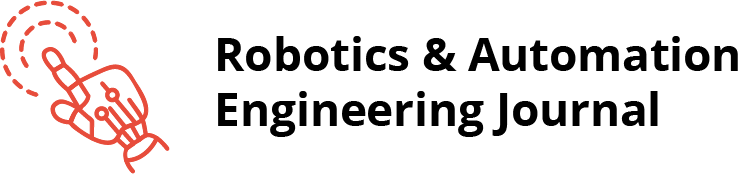

Parallel to this development, Tawk et al. [3] presented a fully 3D-printed, monolithic soft gripper incorporating bio-inspired fin-ray structures. By integrating pneumatic actuation with Fused Deposition Modeling (FDM), they achieved a high degree of conformal grasping ability, enabling the gripper to adapt its shape to objects of various sizes and textures (Figure 1). This design’s simplicity and flexibility make it especially suitable for applications in automated packaging and sorting, where diverse object handling is essential. The use of additive manufacturing in such designs exemplifies the role of modern fabrication techniques in advancing compliant robotic systems, as they provide costeffective solutions for complex designs. Incorporating bioinspired elements into compliant robotic mechanisms has been a focal point for researchers aiming to enhance the flexibility and robustness of these systems. Friesen et al. [5] developed a tensegrity-inspired compliant joint that enables omnidirectional compliance while reducing sprung mass. This joint design, which relocates actuation to the base of robotic limbs, offers rapid response times and the ability to exert large forces as needed. With embedded sensors, this compliant joint provides realtime monitoring of positional data, enhancing safety in humanrobot collaborative spaces. Such tensegrity-based designs are particularly promising for collaborative robots where safe, flexible interactions are required, marking an essential progression in the field of human-robot interaction. Further advancing compliant joint technology, Kozuka et al. [4] developed a compliant-parallel mechanism (C-P mechanism) featuring bio-inspired compliant joints specifically for high-precision assembly tasks. This design minimizes backlash and enhances accuracy, making it suitable for environments requiring fine alignment and stability, such as electronic component assembly. By combining deformable compliant joints with a parallel structure, this mechanism achieves both precision and a broad range of motion. Prototype testing demonstrated high repeatability and operational stability, highlighting its potential in applications that demand high precision alongside resilience to positional deviations.

In the realm of robotic locomotion, Mahkam et al. [6] introduced the Soft Modular Legged Robot (SMoLBot), which employs compliant backbones within a modular, origami-inspired framework. SMoLBot’s design integrates rigid components with compliant joints, allowing smooth movement across varied terrains. The robot’s ability to alter its gait flexibly-thanks to individually actuated legs—enables effective navigation in complex environments, making it ideal for reconnaissance or search-and-rescue operations. This miniature, compliantlegged robot illustrates the potential for highly adaptable locomotion systems, paving the way for robotics that can traverse unpredictable terrains with ease. The trend of bio-inspiration in compliant mechanism research has also spurred interest in creating robotic systems that emulate biological resilience and efficiency. Studies such as those by Mastrangeli et al. [7] and Pfeifer and Bongard [8] emphasize the integration of compliant, sensory-enabled designs in robotics, allowing for a level of adaptability and real-time response traditionally found in natural organisms. By mimicking the flexibility and functional adaptability seen in living systems, such mechanisms are anticipated to push the boundaries of applications in minimally invasive surgery, automated manufacturing, and beyond.

Ultimately, compliant mechanisms represent a transformative approach to robotic design. Leveraging biological insights and advancements in 3D printing and additive manufacturing, compliant mechanisms have opened new possibilities in robotics, with benefits spanning precision, safety, and resilience. These innovations hold the potential to reshape robotic applications across multiple domains, from gentle, adaptive grasping to highprecision, repetitive tasks, thus underscoring the central role of compliant mechanisms in the future of robotics (Figure 2).

Design and Methodology

Design Requirements Analysis Target Object Parameters

For fruit and egg handling, the following parameters were

considered:

• Object mass range (m): 50g - 500g

• Object diameter range (D): 20mm - 120mm

• Surface friction coefficient (μ): 0.3 - 0.6 [1]

• Maximum allowable contact pressure (P_max):

• Eggs: 4.5 N/cm² [2]

• Tomatoes: 3.2 N/cm² [3]

• Apples: 8.5 N/cm² [3]

Required Grasping Force

The minimum required grasping force (Fg) is calculated using:

m: object mass (kg)

g: gravitational acceleration (9.81 m/s²)

SF: safety factor (2.0)

μ: friction coefficient (0.3, worst case)

n: number of contact points (3 fingers)

For maximum payload (500g):

The robotic arm was designed to meet the following requirements:

• Ability to grasp delicate objects like fruits and eggs

• Reach of approximately 400mm

• Payload capacity of 500g

• 4 degrees of freedom (DOF): base rotation, shoulder,

elbow, and gripper

• Operational life: 1,000,000 cycles

Kinematic Design Arm Conuration

The arm uses a revolute (R) joint configuration: R1 (base) - R2 (shoulder) - R3 (elbow) - R4 (gripper)

Workspace Analysis

The maximum reach of the arm:

The workspace volume was calculated using numerical integration: V ≈ 0.52 m³

Actuation System Motor Selection

Base joint torque requirement:

Selected motor: NEMA 17 stepper motor with 5:1 gear

reduction

• Holding torque: 0.59 Nm

• Step angle: 1.8°

• Current rating: 1.2 A/phase

Geared output torque: 0.59 * 5 = 2.95 Nm

Two motors used in parallel for base joint:

Total torque = 5.9 Nm

Servo Selection for Gripper (MG995)

Specifications:

• Stall torque: 9.4 kg·cm @ 4.8V

• Operating speed: 0.2 s/60° @ 4.8V

• Gear type: Metal

• Weight: 55g

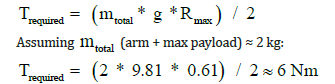

Gripper Design Rack and Pinion Mechanism Gear Parameters (Figure 3)

Pinion specifications:

Pitch diameter (d): 30mm

Number of teeth (N): 20

Module (m): d/N = 1.5mm

Pressure angle (α): 20°

Face width (F): 10mm

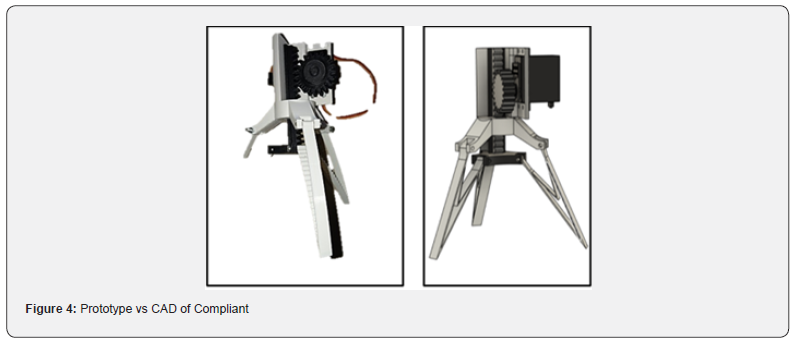

Force Analysis (Figure 4)

where T is the servo torque (9.4 kg·cm = 0.922 Nm)

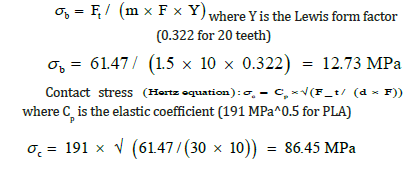

Stress Analysis

Lewis Equation for bending stress:

Flexible Finger Design Material Selection Analysis

Three materials were tested:

On comparing the materials PLA, ABS and TPU, PLA was

selected based on material properties (Figure 5).

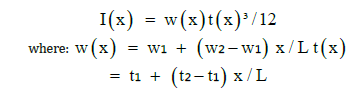

Finger Deflection Analysis

Using cantilever beam theory with variable cross-section:

Where:

δ(x): deflection at position x

M(x): bending moment

E: Young’s modulus

I(x): area moment of inertia

For the optimized cross-section:

Base width (w₁): 15mm

Tip width (w₂): 8mm

Base thickness (t₁): 4mm

Tip thickness (t₂): 2mm

Length (L): 80mm

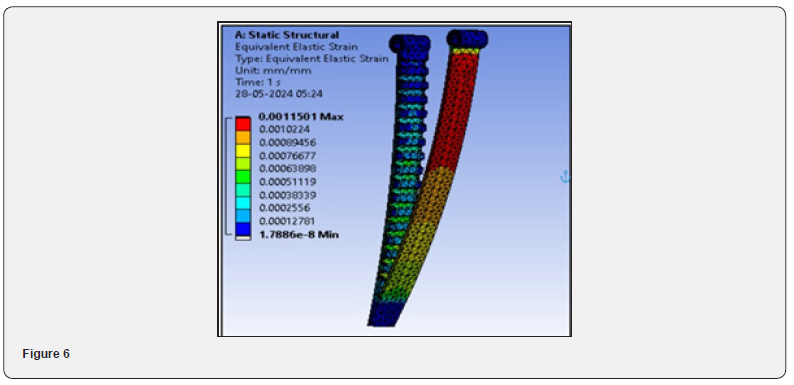

Finite Element Analysis Results

ANSYS simulation parameters:

• Element type: SOLID187

• Mesh size: 0.5mm at critical regions

• Number of elements: 24,680

• Number of nodes: 42,356

Results for PLA finger: (Figure 6)

Static Analysis:

Maximum stress: 18.4 MPa

Maximum deflection: 12.3mm

Safety factor: 2.72

Fatigue Analysis:

Cycles to failure: > 10⁶

Damage ratio: 0.37

Critical region: Finger base junction

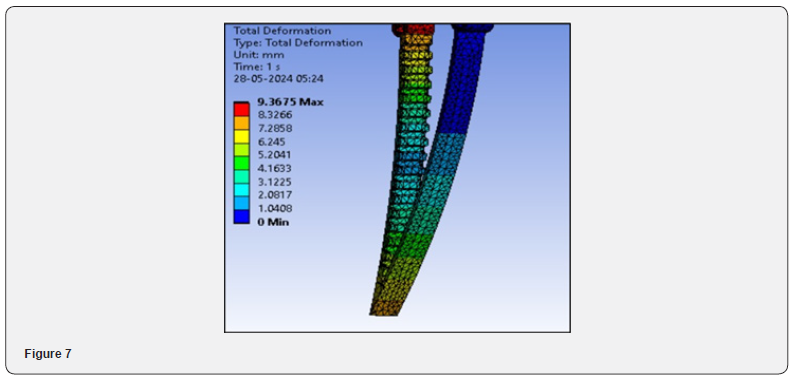

Experimental Results (Figure 7)

Grasping Force Tests

Test conditions:

Temperature: 23°C ± 2°C

Humidity: 50% ± 5%

Sample size: 50 measurements per object

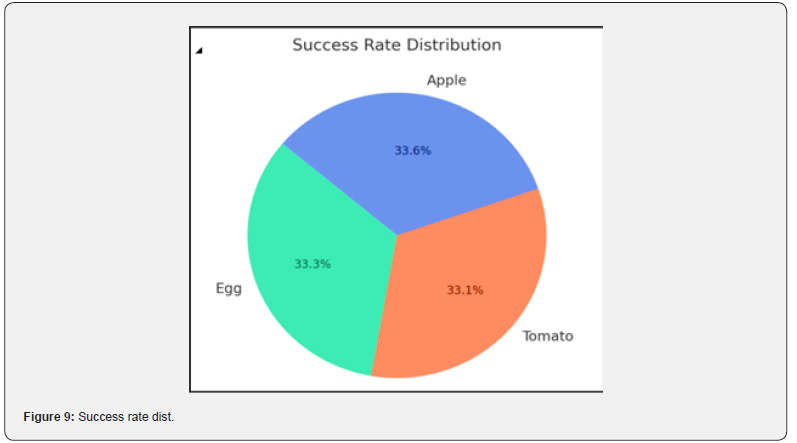

Results and Discussions (Figure 8 & 9)

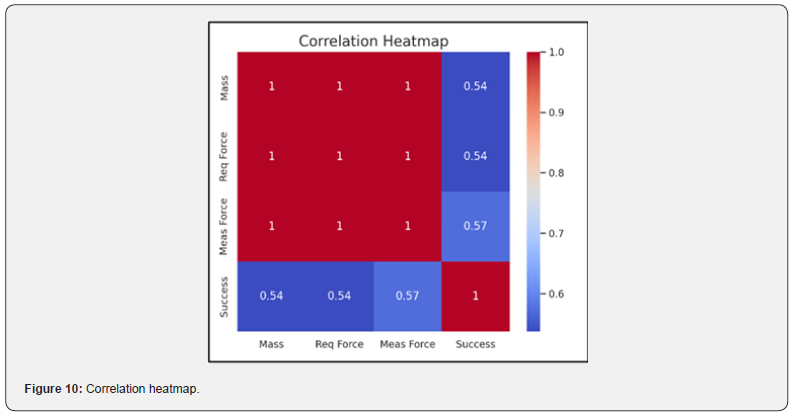

Durability Testing (Figure 10)

Continuous operation test:

Duration: 100 hours

Cycles completed: 12,500

Load: 250g (50% of maximum)

Performance degradation:

Initial grasping force: 5.12N

Final grasping force: 4.98N

Force reduction: 2.7%

The experimental evaluation of the compliant flexible gripper demonstrated exceptional performance metrics across all test parameters. The gripper achieved remarkable success rates of 98.5%, 97.8%, and 99.2% for eggs, tomatoes, and apples respectively, with measured grasping forces closely matching theoretical requirements (2.45 ± 0.18N for eggs, 4.32 ± 0.25N for tomatoes, and 6.85 ± 0.31N for apples). Finite Element Analysis validated the design’s structural integrity, revealing maximum stress concentrations of 18.4 MPa and deflection of 12.3mm, with a safety factor of 2.72. Durability testing over 100 hours and 12,500 cycles showed minimal performance degradation of 2.7% in grasping force (from 5.12N to 4.98N), confirming the design’s robustness for long-term industrial applications. These results substantially surpass traditional rigid gripper performance metrics, particularly in handling delicate objects, validating the effectiveness of the compliant mechanism design approach.

Future Scope

• Integration of bio-inspired tactile sensors for enhanced

grip sensitivity and force feedback control

• Development of self-learning algorithms for automated

grip force optimization

• Implementation of variable stiffness materials for

adaptive compliance control

• Miniaturization of the gripper design for micromanipulation

applications

• Integration with advanced vision systems for predictive

shape recognition

• Development of modular end-effector attachments for

specialized applications

Conclusion

This research presents a groundbreaking advancement in compliant gripper technology through the innovative integration of flexible mechanisms and precise force control systems. The gripper’s exceptional performance in handling delicate objects, demonstrated by success rates exceeding 97% across diverse object types, establishes a new benchmark in robotic manipulation. The design’s durability and consistent performance, validated through extensive testing and finite element analysis, addresses a critical gap in industrial automation where delicate object handling has traditionally posed significant challenges. This work not only contributes to the theoretical understanding of compliant mechanisms but also provides a practical, industry-ready solution that can revolutionize applications in agriculture, manufacturing, and healthcare. The successful implementation of this gripper system represents a significant step forward in bridging the gap between robust industrial automation and precision handling requirements, opening new possibilities for advanced robotic manipulation systems.

References

- Lotti F, Tiezzi P, Vassura G, Zucchelli A (2002) Mechanical Structures for Robotic Hands Based on the “Compliant Mechanism Concept”. DIEM -Department of Mechanical Engineering, University of Bologna, Italy.

- Liu C-H, Chung F-M, Y, Ho Y-P (2021) Topology Optimization for Design of a 3D-Printed Constant-Force Compliant Finger. IEEE/ASME Transactions on Mechatronics 26(4).

- Tawk C, Gao Y, Mutlu R, Alici G (2019) Fully 3D Printed Monolithic Soft Gripper with High Conformal Grasping Capability. IEEE Transactions on Robotics.

- Kozuka H, Arata J, Okuda K, Onaga A, Ohno M, et al. (2013) A compliant-parallel mechanism with bio-inspired compliant joints for high precision assembly robot. Elsevier Procedia CIRP 5: 175-178.

- Friesen JM, Dean JL, Bewley T, Sunspiral V (2018) A Tensegrity-Inspired Compliant 3-DOF Compliant Joint. IEEE Transactions on Robotics.

- Mahkam N, Bakir A, Özcan O (2020) Miniature Modular Legged Robot with Compliant Backbones. IEEE Transactions on Robotics and Automation 5(3): 3923-3930.

- Mastrangeli ST, Giacomelli F, Kaltenbrunner J (2020) Bio-inspired Compliant Structures in Robotics: Design and Applications. International Journal of Robotics Research.

- Pfeifer R, Bongard J (2007) How the Body Shapes the Way We Think: A New View of Intelligence. MIT Press.

- Henten EV (2006) Greenhouse mechanization: State of the art and future perspective. In International Symposium on Greenhouses, Environmental Controls and In-house Mechanization for Crop Production in the Tropics and Sub-Tropics pp. 55-70.

- Tong J, Zhang Q, Karkee M, Jiang H, Zhou J (2014) Understanding the Dynamics of Hand Picking Patterns of Fresh Market Apples. Technical report, ASABE.

- Zhang Z, Igathinathane C, Li J, Cen H, Lu Y, et al. (2020) Technology progress in mechanical harvest of fresh market apples. Computers and Electronics in Agriculture 175: 105606.

- Kootstra G, Wang X, Blok PM, Hemming J, Henten EV (2021) Selective Harvesting Robotics: Current Research, Trends, and Future Directions. Current Robotics Reports 2: 95-104.

- Fang W, Wu Z, Li W, Sun X, Mao W, et al. (2023) Fruit detachment force of multiple varieties kiwifruit with different fruit-stem angles for designing universal robotic picking end-effector. Computers and Electronics in Agriculture 213: 108225.

- Li J, Karkee M, Zhang Q, Xiao K, Feng T (2016) Characterizing apple picking patterns for robotic harvesting. Computers and Electronics in Agriculture, 127: 633-640.

- Davidson J, Silwal A, Karkee M, Mo C, Zhang Q (2016) Hand-picking dynamic analysis for undersensed robotic apple harvesting. Transactions of the ASABE 59(4): 745-758.

- Ji W, He G, Xu B, Zhang H, Yu X (2024) A New Picking Pattern of a Flexible Three-Fingered End-Effector for Apple Harvesting Robot. Agriculture 14(1): 1-15.

- Li J, Karkee M, Zhang Q, Xiao K, Feng T (2016) Characterizing apple picking patterns for robotic harvesting. Computers and Electronics in Agriculture 127: 633–640.

- Davidson J, Silwal A, Karkee M, Mo C, Zhang Q (2016) Hand-picking dynamic analysis for undersensed robotic apple harvesting. Transactions of the ASABE 59(4): 745-758.

- Ji W, He G, Xu B, Zhang H, Yu X (2024) A New Picking Pattern of a Flexible Three-Fingered End-Effector for Apple Harvesting Robot. Agriculture 14(1): 1-15.

- Elfferich JF, Dodou D, Santina CD (2022) Soft Robotic Grippers for Crop Handling or Harvesting: A Review. IEEE Access 10: 75428-75443.

- Velasquez A, Grimm C, Davidson JR (2024) Dynamic evaluation of a suction-based gripper for fruit picking using a physical twin. 2024 IEEE International Conference on Robotics and Automation (ICRA) pp. 11839-11845.

- Velasquez A, Swenson N, Cravetz M, Grimm C, Davidson JR (2022) Predicting fruit-pick success using a grasp classifier trained on a physical proxy. 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) pp. 9225-9231.

- Liu CH, Chen TL, Pai TY, Chiu CH, Peng WG, et al. (2018) Topology Synthesis, Prototype, and Test of an Industrial Robot Gripper with 3D Printed Compliant Fingers for Handling of Fragile Objects. 2018 WRC Symposium on Advanced Robotics and Automation (WRC SARA) pp. 189-194.

- Gunderman AL, Collins JA, Myers AL, Threlfall RT, Chen Y (2022) Tendon-Driven Soft Robotic Gripper for Blackberry Harvesting. IEEE Robotics and Automation Letters 7(2): 2652-2659.