Graphical Matching Design for Suspension Systems Considering Multiple Conditions and Indexes in the Time-Frequency Domain

Wu Jianwei, Wei Hai, Lao Zhenhai, Liang Guobao and Lin Bo*

Institute of new Technology, Guangxi Liugong Machinery Co., Ltd., Liuzhou 545007, China

Submission:December 16, 2024;Published:January 08, 2025

*Corresponding author:Lin Bo, Institute of new Technology, Guangxi Liugong Machinery Co., Ltd., Liuzhou 545007, China Email Address: linbo@liugong.com

How to cite this article: Wu J, Wei Hai, Lao Z, Liang G, Lin B. Graphical Matching Design for Suspension Systems Considering Multiple Conditions and Indexes in the Time-Frequency Domain. Robot Autom Eng J. 2025; 6(3): 555682.DOI: 10.19080/RAEJ.2025.06.555682

Abstract

In the vehicle suspension systems and dynamics, suspension parameters play a crucial role in determining ride comfort and handling stability. The effectiveness of suspension matching requires a comprehensive analysis of multiple performance indexes across various operating conditions. For suspension designs with significant load variations between empty and full loads, it is essential to develop a balanced design process that accounts for sprung mass vibration, suspension travel, suspension frequency, road conditions, driving speed, and tire dynamic load. Such a comprehensive approach is necessary to meet all performance indexes and minimize the extensive parameter tuning and experimental validation typically needed beyond traditional frequency-domain selection methods. This paper addresses these challenges by developing a multi-condition Simulink parametric simulation model specifically for suspension systems with substantial load variation. The model incorporates diverse road conditions and driving speeds and defines multiple performance indicators for suspension matching. Furthermore, it integrates an iterative process that transitions from frequency-domain preliminary selection to time-domain optimized adjustment. This approach results in a generalized, graphical methodology for suspension system matching. Building on this foundation, the paper presents a detailed matching process along with case studies to illustrate the application of the proposed methodology. This work provides a systematic framework and selection basis for the design and optimization of vehicle suspension systems, offering valuable guidance for achieving optimal suspension performance.

Keywords: Suspension system; Parameter matching; Empty and full loads; Damping coefficients for tension and compression; Graphical matching design

Introduction

In the realm of vehicle dynamics and suspension systems engineering, the suspension system, composed of tires, springs, dampers, and linkages, serves as the pivotal interface mediating the vehicle’s interaction with the road. Its design is critical, profoundly affecting ride comfort, handling, road possibility, and fatigue durability, thereby making it an indispensable component of vehicular systems [1-2]. Crafting a robust suspension design necessitates a meticulous balance among several factors, including dynamic vehicle response, road surface irregularities, vehicle load variations, driving speed fluctuations, tire dynamic loads, and suspension travel requirements. The task presents itself as a complex multi-objective optimization challenge, where enhancing ride comfort may compromise handling, and vice versa. Thus, achieving an equilibrium among these diverse conditions and performance indexes remains a considerable challenge in suspension design.

With the evolution of computational technologies and simulation methodologies, Computer-Aided Design (CAD) and vehicle dynamics modeling have advanced significantly. These innovations allow for the exploration of nonlinear suspension characteristics across varied road conditions, speeds, and parameters, facilitating comprehensive performance evaluations during the design phase. This technological leverage not only boosts design efficiency but also enhances performance compatibility [3]. For instance, David Mantilla et al. [4] employed a parameter-driven ANSYS APDL with multibody dynamics to ascertain optimal suspension stiffness and damping under various loads. Lu et al. [5] developed a multibody dynamics model for a leaf-spring suspension system, optimizing ride comfort through time-domain road profile reconstruction, and derived ideal suspension parameters. Chen et al. [6] proposed a modeling method integrating nonlinear mathematical models with traditional vibration models, utilizing a coupling of nonlinear dynamics and hierarchical optimization to improve suspension accuracy and effectiveness. Shen et al. [7] introduced an innovative Inerter-Spring-Damper (ISD) suspension structure, integrating an inerter with a conventional dynamic damper, with simulations confirming its enhanced performance. Zhao et al. [8] optimized front suspension parameters for large mining dump trucks, exploring the vehicle’s handling and ride comfort. Xiong Ke et al. [9] devised a nine-degree-of-freedom model for heavy-duty vehicles to optimize ride comfort, identifying optimal stiffness and damping parameters. Pazooki et al. [10] proposed the use of nonlinear dampers designed with the Energy Balance Method (EBM), further elevating vehicle ride performance. Fernandes et al. [11] demonstrated that asymmetric damping and geometric nonlinearity in suspension models improve ride comfort. Song Yong et al. [12] introduced a bionic suspension structure to enhance the ride smoothness of commercial vehicles with significant changes in sprung mass.

Research has spawned numerous computer-simulated suspension design methods, innovative suspension architecture propositions, and explorations into nonlinear stiffness and damping. Nonetheless, many methodologies sidestep the vehicle’s design integration phase, zeroing in on performance optimization tasks such as developing multibody dynamic models. Traditional frequency-domain approaches can be overly simplistic, neglecting the nuanced matching process for different tensile and compressive damping coefficients. As a result, current suspension parameter matching during the design phase frequently depends on engineer experience and later-stage test calibrations based on empirical frequency-domain methodologies [13-15]. Despite these advances, empirical determinations often govern suspension design, particularly regarding the ratio of tension-compression damping. These values, although effective, lack a standardized comprehensive performance evaluation metric. Particularly in cases with marked load differences, a harmonized design process considering suspension travel, frequency, road conditions, speed, and tire dynamics is indispensable. Without such a process, fulfilling all suspension performance indexes proves daunting, often requiring extensive experimental validation. In mismatched parameters for suspension systems, subsequent improvements and adjustments demand considerable labor and costs.

To address these challenges, this paper proposes a parameterized Simulink simulation model tailored for suspension systems with significant load variations. The model considers various driving conditions and speeds and defines comprehensive suspension performance indexes. By adopting a systematic iterative process transitioning from empirical frequency-domain selections to time-domain optimizations for the parameter matching, we formulate a generalized, graphical methodology for suspension design matching. The efficacy of this approach with a detailed matching process and case study are illustrated for elucidating the variation patterns of suspension parameters, thereby providing a foundational selection framework for vehicle suspension design.

Suspension system

Quarter vehicle model

(Figure 1) shows a quarter vehicle model [16]. Considering the quarter vehicle model with different damping coefficients, the dynamic equations can be expressed as

where mu and ms denote the unsprung mass and sprung mass, respectively. zr,zu and zs are the vertical displacement of road surface, unsprung mass, and sprung mass, respectively. kt and ct are the stiffness and damping of tire, respectively. csc and cst represent the compression damping coefficient and tensile damping coefficient of the suspension, respectively. ks represents the stiffness of the suspension, and sign (·) is a symbolic function.

When the damping coefficients of tension and compression are equal (i.e. cs=cst=csc), the frequency domain analysis can be used, which can be linearized into the following dynamic equation

According to the complex modal theory of mechanical

vibration systems [17], the natural frequency and damping ratio

of a quarter of the vehicle model can be obtained. Here are a few

common terms for linear suspension systems:

• The partial frequency of the suspension refers to the

natural frequency of a single-degree-of-freedom vibrational

system when the unsprung mass is fixed. It can be calculated as

• The partial damping ratio of the suspension refers to the damping ratio of a single-degree-of-freedom vibrational system when the unsprung mass is fixed. It can be calculated as

• The suspension frequency and damping ratio refer to the counterpart concerning the natural frequency and damping ratio of the sprung mass, as calculated using the complex modal theory in equation (3).

Random road surface model

The nonlinear differential equations (1) and (2) typically use filtered white noise to construct random road surface excitations, with the following formulas [18-19]

where Gq(n0) is pavement unevenness coefficient, and the value of that of Chinese national standard C-grade pavement is 256×10-6 m3. f0 is the lower cut-off frequency and f0 = 0.0628 Hz. V is the velocity of vehicle with unit m/s. w(t) is white Gaussian noise with power spectrum 1. n0 is the frequency index, and n0 = 0.1 m-1.

By changing the driving speed and road level, random excitation inputs for different road surfaces can be obtained. To evaluate the comprehensive performance of various road suspension systems, common grades of road surfaces can be combined. (Figure 2) shows the simulated roughness curves of A-grade, B-grade, C-grade, and D-grade hybrid road surfaces at a vehicle speed of V=35 km/h, where 0~30 s, 30-60 s, 60-90 s, and 90-120 s are A-level road surface, B-class road surface, C-grade road surface, and D-grade road surface, respectively.

Parametric simulation model with multi-conditions

(Figure 3) shows the parametric simulation model with multi-conditions based on Simulink. This model consists of four modules: road surface module, dynamics module, display module, and performance index module. Among them, the road surface module contains five pavement models, namely random road, single pulse pavement, sine pavement, continuous pulse pavement, hybrid random and pulse road, and hybrid random road. Dynamics model of the suspension can be constructed by (Equations 1-2).

Performance evaluation indexes

Usually, the main performance indexes for evaluating suspension systems include sprung mass acceleration, tire dynamic load and suspension dynamic stroke [16]. However, for vehicle systems with significant changes in empty and full loads, the suspension stroke varies greatly. To meet the comprehensive requirements of maneuverability and comfort, shock absorbers with different damping coefficients for tension and compression are usually designed, which makes these traditional indexes unable to meet the practical design requirements. In response to this, the performance indexes of the maximum and minimum deformations are added, and the traditional indexes under empty and full loads are distinguished.

Sprung mass acceleration

When significant variations between empty and fully loads exist in the vehicle system, sprung acceleration is divided into unloaded sprung mass acceleration and fully loaded sprung acceleration. They are denoted by asE and asF, respectively. For random road surfaces, the performance indexes are primarily evaluated using the Root Mean Square (RMS) value, defined as Index1 and Index2:

where asE(t) and asF (t) denote the accelerations of the unsprung mass under the empty and full loads, respectively. The smaller the RMS value of the sprung mass acceleration, the less vibration is transmitted to the vehicle body.

Tire dynamic load coefficient

Tire dynamic load coefficient denotes the ratio of the tire dynamic load to the static load. For random road surfaces, it is evaluated using its RMS value to assess the suspension’s ground performance. In practice, the tire dynamic load coefficient is often higher for unloaded conditions than for fully loaded conditions. The tire dynamic load coefficient under the empty load is thus defined as Index3:

where zuE(t) and Δt denote the displacement of the unsprung mass and the static deformation of the tire under the empty load, respectively. When the tire load coefficient exceeds 1, the tire will lose contact with the ground. Hence, a smaller index is preferable, indicating lower tire dynamic load and less road damage.

Minimum and maximum suspension deformations

Considering the static equilibrium position, the relative displacement between the sprung and unsprung masses represents the absolute deformation of the suspension. The maximum relative displacement indicates the minimum suspension deformation, which typically occurs under unloaded conditions; the minimum relative displacement indicates maximum suspension deformation, usually occurring under fully loaded conditions. Therefore, the minimum and maximum deformations can be expressed as

where zsE(t) and zsE(t) represent the displacements of the sprung mass under the empty and full loads, zuF(t) denote the displacements of the unsprung mass under full load, and e Δ and f Δ represent the static deformations of the suspension under the empty and full loads, respectively.

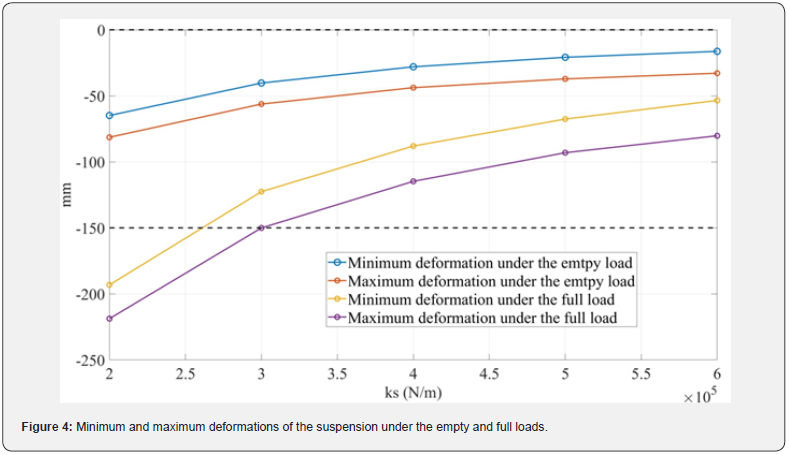

It can be seen that if the minimum deformation is greater than 0, the suspension experiences an extension effect, losing its support function. Similarly, if the maximum suspension deformation exceeds the allowable structural limit, the stop block will be impacted in the suspension system, severely affecting ride comfort and durability. Therefore, Index4 needs to be less than 0, and Index5 needs to be greater than the negative maximum suspension deformation. (Figure 4) shows the deformation curves of a vehicle suspension system with suspension stiffness.

Suspension workspace

Suspension workspace refers to the displacement between the sprung and unsprung masses, disregarding the static equilibrium position of the suspension. For random road surfaces, the performance is primarily evaluated using the RMS value, represented by Index6 and Index7:

Design process of matching suspension

The optimal matching design of a suspension system is crucial for vehicle dynamics. Its objective is to obtain the minimum sprung mass acceleration under the requirements of suspension travel and tire dynamic load, when vehicles with various speeds diver on different road surfaces. The three most important parameters characterizing suspension performance are suspension stiffness, tension damping coefficient, and compression damping coefficient.

Initial selection of stiffness and damping

For truck front suspensions, the desired frequency under full load is generally between 1.5 and 2.1 Hz, while for rear suspensions, it is between 1.7 and 2.17 Hz; the damping ratio requirement is between 0.1748 and 0.4136, which lies within the range for optimal comfort and safety [20-21].

Considering the sprung mass msF under the full load, the initially selected stiffness and selected damping coefficient can be expressed as

where f and ζ are the partial frequency and damping ratio for the suspension system, respectively.

For vehicles with significant variation between empty and full load, an empirical value of 1.8 Hz and 0.4136 is used as the initial selection for fully loaded suspension frequency and damping ratio.

Optimization of the stiffness

Based on the initial stiffness selection, the parametric Simulink model of mixed road surfaces is used to analyze the variation patterns of different indexes under various stiffness conditions, optimizing for the best overall performance result. The obtained optimal stiffness is denoted as kopt . The set of stiffness variation coefficients is defined as

Optimization of the damping coefficient

Based on the optimal stiffness kopt,the parametric Simulink model of mixed road surfaces is used to analyze the variation patterns of different indexes under various damping coefficients, optimizing for the best overall performance result, denoted as copt. The values of the damping variation coefficients are defined as

Optimization of the ratio of tension-compression damping

Based on the optimal stiffness kopt, and damping copt, the parametric Simulink model of mixed road surfaces is used to analyze the variation patterns of indexes concerning the tensioncompression ratio. By combining graphical curve results, the optimal ratio achieving the best comprehensive performance is obtained, denoted as ropt. The values of the tension-compression damping ratio coefficients are defined as

Design case of matching suspension

Suspension system dynamics parameters

With reference to similar vehicle products and according to the tire testing parameters provided by the supplier, the suspension system dynamics parameters and design requirements shown in are given in (Table 1). The purpose of suspension matching is to obtain the optimal suspension stiffness and tension-compression damping coefficients under the requirements of suspension space, tire dynamic load and sprung mass acceleration.

Initial selection of stiffness and damping

According to the design process of matching suspension in section 3, the initial stiffness and damping coefficient can be obtained as follows: k=537 N/mm, c= 39.3N·s/mm.

Optimization of the stiffness

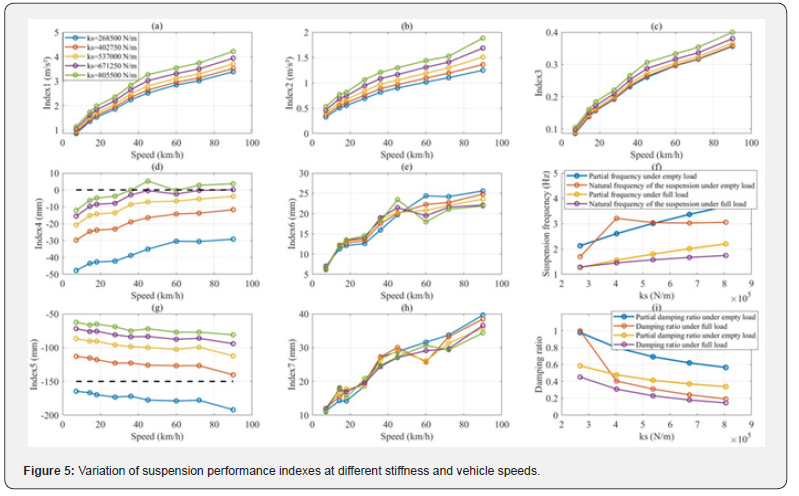

The initial stiffness value is multiplied by an element of the set given in Equation (16), yielding various curves of suspension performance indexes as stiffness varies by using the parametric Simulink model of mixed road surfaces, as shown in (Figure 5). Specifically, Figure 5 (a-e) and (g-h) display the curves of these indexes as stiffness changes, while Figure 5 (f) and (i) show the variations in suspension frequency and damping ratio with respect to stiffness.

In (Figure 5), Index1 and Index2 are the RMS values of unsprung mass acceleration under the empty and full loads, respectively; Index3 is the tire dynamic load coefficient under the empty load; Index4 and Index5 are the minimum and maximum suspension deformations, respectively; Index6 and Index7 are the RMS values of Suspension workspace under the empty and full loads, respectively.

According to (Figure 5), it can be observed that:

1. Index1, Index2 and Index3 increase with increasing

stiffness, as shown in Figure 5 (a-c). Therefore, for these indexes,

a lower suspension stiffness is favorable.

2. Index6 and Index7 decrease with increasing stiffness,

as shown in Figure 5 (e) and (h). It indicates that for these two

indexes, higher suspension stiffness is beneficial.

3. Considering the suspension travel design requirements,

the minimum deformation of the suspension should exceed -150

mm, and the maximum deformation of suspension should be less

than 0. According to Figure 5 (d) and (g), the permissible stiffness

range can be approximately determined as greater than 380 and

less than 660 N/mm.

To obtain the minimum Index1, Index2 and Index3, ks=400 N/mm is a better choice under the requirements of suspension travel design and dynamic deformation. It is determined from Figure 5 (f) and (i) that the partial frequencies of the suspension system under the empty and full loads are about 2.61 and 1.56 Hz, respectively; the partial damping ratio is approximately 0.478 and 0.799, respectively.

It is noted that the minimum and maximum deformations of the suspension at maximum vehicle speed are shown in Figure 5 (d) and (g), which are extreme values that typically do not occur.

Optimization of the damping coefficient

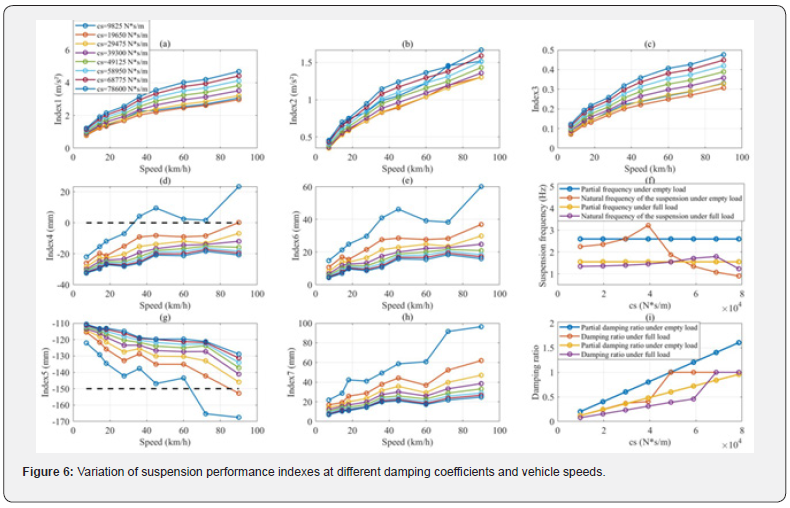

After determining ks=400 N/mm, the initial damping coefficient is multiplied by an element of the set given in given in Equation (17), yielding various curves of suspension performance indexes as damping coefficients varies by using the parametric Simulink model of mixed road surfaces, as shown in (Figure 6). Specifically, Figure 6 (a-e) and (g-h) display the curves of these indexes as damping coefficients, while Figure 6 (f) and (i) show the variations in suspension frequency and damping ratio with respect to damping coefficients.

According to (Figure 6), it can be observed that:

1) Index1, Index2 and Index3 increase with increasing

damping coefficient, as shown in Figure 6 (a-c). Therefore, a lower

suspension damping coefficient is favorable for these indexes.

2) Index6 and Index7 decrease with increasing damping

coefficient, as shown in Figure 6 (e) and (h). It indicates that

for these two indexes, higher suspension damping coefficient is

beneficial.

3) Considering the suspension travel design requirements,

the minimum deformation of the suspension should exceed -150

mm, and the maximum deformation of suspension should be less

than 0. According to Figure 6 (d) and (g), the permissible damping

range is determined to be greater than 19.65 N/mm.

To obtain the minimum Index1, Index2 and Index3, cs=27 N·s/mm is a better choice under the requirements of suspension travel design and dynamic deformation. It is determined from Figure 6 (f) and (i) that: the partial frequencies of the suspension system under the empty and full loads are about 2.60 and 1.55 Hz, respectively; the partial damping ratio is approximately 0.320 and 0.550, respectively.

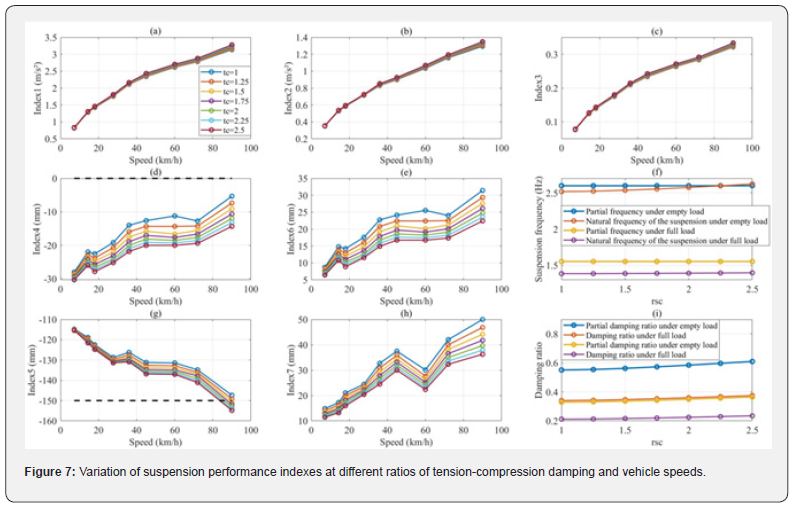

Optimization of the ratio of tension-compression damping

After determining ks=400 N/mm and cs=27 N·s/mm, the ratio can be changed by an element of the set given in Equation (18), yielding various curves of suspension performance indexes as ratio of tension-compression damping varies by using the parametric Simulink model of mixed road surfaces, as shown in (Figure 7). Specifically, Figure 7 (a-e) and (g-h) display the curves of these indexes as ratio of tension-compression damping, while Figure 7 (f) and (i) show the variations in suspension frequency and damping ratio with respect to ratio of tension-compression damping.

According to (Figure 7), it can be observed that:

1) Index1, Index2 and Index3 are little affected by the ratio

of the tension-compression damping, as shown in Figure 7 (a-c).

With the ratio of tension-compression damping, they increase

slightly.

2) Index6 and Index7 signally decrease with increasing the

ratio of the tension-compression damping, as shown in Figure 7

(e) and (h). It indicates that for these two indexes, the higher the

ratio of the tension-compression damping is beneficial.

3) Considering the suspension travel design requirements,

the minimum deformation of the suspension should be greater

than -150 mm, and the maximum deformation of suspension

should be less than 0. According to Figure 7 (d) and (g),the

permissible ratio range of the tension-compression damping is

determined to be less than 1.5.

To obtain the minimum Index1, Index2 and Index3, rtc=1.5 is a better choice under the requirements of suspension travel design and dynamic deformation. Therefore, the optimal tension and compression damping coefficients are 33.07 and 22.05 N·s/mm, respectively. At this point, it is determined from Figure 7 (f) and (i) that the partial frequencies of the suspension system under the empty and full loads are about 2.60 and 1.55 Hz, respectively; the partial damping ratio is approximately 0.33 and 0.56, respectively.

Conclusion

1. A graphical method for suspension performance

evaluation and parameter matching analysis is proposed. Based

on the initial empirical selection of stiffness and damping, a

parametric Simulink model for multi-criteria analysis with hybrid

road surfaces is established. By varying parameter coefficients,

simulation results of various suspension performance indexes

under different vehicle speeds and operating conditions are

obtained. This approach facilitates the graphical display of

performance indexes and suspension performance evaluation,

providing a comprehensive basis for matching suspension

parameters.

2. The method overcomes the limitations of matching

parameters in the empirical frequency-domain by developing

an iterative optimization strategy. It combines the advantages

of the qualitative selections in the frequency domain and the

quantitative evaluations in the time domain. An iterative matching

process is presented, progressing from initially selected stiffness

and damping coefficients to optimally refined stiffness, damping

coefficients, and further to the optimal ratio of the tensioncompression

damping, which achieves the optimal comprehensive

performance of suspension systems.

3. A method for the matching analysis of the tensioncompression

damping coefficients is presented. This study defines

the ratio of tension-compression damping and, in conjunction

with the optimized damping coefficient, investigates the

variation patterns of various performance indexes, establishing

a quantitative evaluation basis for different ratios of tensioncompression

damping.

References

- Editorial Board of China Transport (2017) Review on China's Automotive Engineering Research Progress:2017. China Journal of Highway and Transport 30(6): 1-197.

- Yu M, Evangelou SA, Dini D (2024) Advances in Active Suspension Systems for Road Vehicles. Engineering 33: 160-177.

- Qiangshun L, Guosheng W, Lu W, Yu C (2016) Great vibration analysis for mi l itary vehicle and parameters matching method for its suspension. Journal of PLA University of Science and Technology (Natural Science Edition) 17(6): 591-597.

- Mantilla D, Arzola N, Araque O (2022) Optimal design of leaf springs for vehicle suspensions under cyclic conditions. Ingeniare: Revista Chilena de Ingenieria 30(1): 23-36.

- Lu JW, Zeng FL (2008) Optimisation of suspension parameters based on simulation of ride comfort in vehicle development. International Journal of Vehicle Design 47(1-4): 37-50.

- Chen K, He S, Xu E, Tang R, Wang Y (2020) Research on ride comfort analysis and hierarchical optimization of heavy vehicles with coupled nonlinear dynamics of suspension. Measurement 165: 108142.

- Shen Y, Chen L, Yang X, Shi D, Yang J (2016) Improved design of dynamic vibration absorber by using the inverter and its application in vehicle suspension. Journal of Sound and Vibration 361: 148-158.

- Zhao J, Ren X, Dong Z, Liu T (2024) Optimization Design of Double Wishbone Front Suspension Parameters for Large Mining Dump Truck and Analysis of Ride Comfort. Applied Sciences (Switzerland) 14(5): 1812.

- Xiong Ke, Gan Nian-Fei, Liu Liang (2014) Optimization and Research on Vehicle's Ride Comfort. Computer Simulation 31(1): 185-189.

- Pazooki A, Goodarzi A, Khajepour A, Soltani A, Porlier C (2018) A novel approach for the design and analysis of nonlinear dampers for automotive suspensions. Journal of Vibration and Control 24(14): 3132-3147.

- Fernandes JCM, Goncalves PJP, Silveira M (2020) Interaction between asymmetrical damping and geometrical nonlinearity in vehicle suspension systems improves comfort. Nonlinear Dynamics 99(2): 1561-1576.

- Yong S, Hao L, Zhanlong L, Bijuan Y, Jie M et al. (2023) Constant partial frequency and constant height design of nonlinear commercial vehicle bionic suspensions. China Mechanical Engineering 34(01): 84-94.

- Kim BM, Kim JW, Moon ID, Oh CY (2014) Optimal combination of design parameters for improving the kinematics characteristics of a midsize truck through design of experiment. J Mech Sci Technol 28(3): 963-969.

- Shenmin X, Yun Z, Hongtao W (2027) Tuning Steps for Automotive Suspension. Beijing Automotive Engineering 4(3): 17-20.

- Hongliang Z, Zhimin L (2021) Tuning and Adjustment of Chassis Performance of a Light Bus. Automobile Technology 46(24): 47-51.

- Qidi F, Jianwei W, Chuanyun Y, Tao F, Ning Z, et al. (2023) Linear Quadratic Optimal Control with the Finite State for Suspension System. Machines 11(2): 127.

- Pan-Xu S, Hong Y, Qing-Lin L (2020) Complex mode superposition method of hybrid structure seismic responses based on dynamic characteristics. Engineering Mechanics 37(11): 69-82.

- Jun Y, Xinbo C, Lirin W, Liu Y (2017) Simulation method of road excitation in time domain using filtered white noise and dynamic analysis of suspension. Journal of Tongji University (Natural Science Edition) 45(3): 398-407.

- Wang G, Qu W, Chen C, Chen Z, Fang Y (2022) A road level identification method for all-terrain crane based on Support Vector Machine. Measurement 187: 110319.

- Zhisheng Y (2018) Automotive Theory. China Machine Press, Beijing.

- Changcheng Z (2011) Vehicle Suspension Design and Theory. Beijing: Peking University Press.