Exploring Learning Factory Transformations in Industry 5.0

Yanchao Tana, Xingyu Lia and Ragu Athinarayanana*

School of Engineering Technology, Purdue University, West Lafayette, USA

Submission:November 23, 2023; Published:December 08, 2023

*Corresponding author: Ragu Athinarayanana, School of Engineering Technology, Purdue University, West Lafayette, USA

How to cite this article: Yanchao T, Xingyu L, Ragu A. Exploring Learning Factory Transformations in Industry 5.0. Robot Autom Eng J. 2023; 5(5): 555671. DOI: 10.19080/RAEJ.2023.05.555671

Abstract

Industry 5.0, an evolution beyond the technological advancements of Industry 4.0, emphasizes a human-centricity, sustainable, and resilient manufacturing paradigm. This shift necessitates addressing multifaceted challenges, including environmental sustainability, workforce skill gaps, human well-being, and implementation costs. Learning factories, conceived as a solution, bridge the gap between theory and practice by offering hands-on, experiential learning opportunities. However, current learning factories predominantly cater to Industry 4.0, lacking a focus on the human-centricity and sustainability crucial for Industry 5.0. This study explores the on-going transformations in learning factories and their potentials to address Industry 5.0 challenges.

Keywords: Learning factory; Industry 5.0; Human-Robot collaboration; Sustainability & Resiliency

Introduction

Industry 4.0 integrates physical assets with cutting-edge technologies such as cyber-physical systems, AI, and cloud computing. Despite its decade-long strides in enhancing efficiency and productivity, there has been a tendency to overlook human values and social needs [1]. Positioned as an extended paradigm to Industry 4.0, Industry 5.0 is characterized by an innovation focus aimed at facilitating the transition toward a sustainable, human-centric, and resilient industry, thereby contributing to societal well-being [2,3,4]. Industry 5.0 places core human needs and interests at the forefront of the production process, emphasizing ethical considerations, inclusivity, and societal well-being [5]. This marks a shift from a technology-driven progress approach to a value-driven futuristic manufacturing paradigm. In this context, industrial workers are encouraged to engage in continuous upskilling and reskilling to enhance career opportunities and achieve an improved work-life balance [2,4,6]. Moreover, this transition involves the establishment of circular processes that prioritize the reuse, repurposing, and recycling of natural resources, thereby minimizing waste and environmental impact [5].

The challenges associated with the implementation of Industry 5.0 are multifaceted. One of the challenges is balancing technological advancements with environmental sustainability, minimizing energy consumption, reducing waste, and establishing eco-friendly manufacturing processes [7]. Concurrently, future job roles will become even more knowledge- and skill-intensive [8], necessitating a workforce equipped with advanced digital skills for collaborating with robots in a variety of manufacturing tasks [5]. Bridging the workforce skills gap requires a comprehensive strategy for providing targeted training programs. Moreover, Industry 5.0 emphasizes human well-being, particularly worker safety and health. Based on the data from the US private manufacturing industry, there were 373,300 total cases of injuries and illnesses [9]. Addressing this issue requires real-time insights for enhanced potential hazard identification and timely intervention [10]. Additionally, the cost of implementation associated with the integration of cutting-edge manufacturing technologies essential for driving Industry 5.0 stands as a considerable challenge, which strain budgets, necessitating meticulous resource allocation and financial planning [11].

The learning factory serves as a perspective solution for addressing challenges in implementing Industry 5.0. The term 'learning factory' was first coined and patented in 1994 in a consortium of Penn State University [12]. Over the last decade, numerous learning factories have extensively been built in academia and industry [13]. As discussed in [14], traditional teaching methodologies prove inadequate in cultivating employee competencies requisite for current and future manufacturing environments. In contrast, learning factories are designed to bridge the gap between theory and practice. They provide hands-on, experiential learning opportunities, simulating real-world manufacturing scenarios. People can engage with state-of-the-art manufacturing technologies to gain practical skills directly applicable to industry needs. For instance, the MTA SZTAKI learning factory in Győr offers students hands-on education in design and operation to support human-robot collaborative assembly [15].

However, existing learning factories predominantly cater to Industry 4.0, focusing on skills pertinent to digitalization, process automation, and analysis [16]. The imperative challenge lies in leveraging the initiatives of Industry 5.0 to achieve societal objectives, emphasizing human values in environments, and cultivating skills for effective collaboration with machines—elements crucial but presently absent in the existing learning factory. In this study, we aim to delineate the evolving learning factory paradigm that incorporates considerations for Industry 5.0 initiatives and to explore the broader opportunities for leveraging learning factories in the context of Industry 5.0.

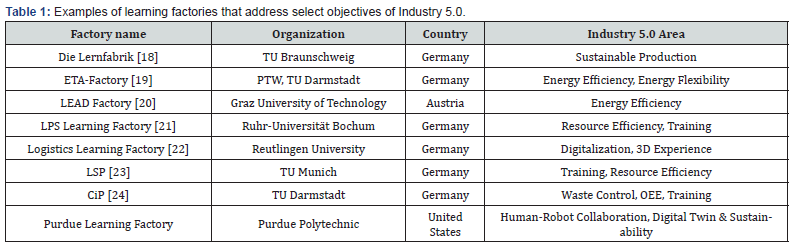

In alignment with the tripartite objectives of Industry 5.0—namely sustainability, human-centricity, and resilience—we conducted a comprehensive review and comparative analysis of learning factories in both academic and industrial domains relevant to the industry 5.0 goals [17]. Several learning factories have come to the forefront, identified for their potential alignment with specific facets of Industry 5.0 objectives, which are summarized in Table 1.

Discussion

The integration of Industry 5.0 principles into learning factories has the transformative potential to not only enhance traditional learning experiences but also extend their utility by incorporating a human-centric and sustainable approach, aligning with the objectives of Industry 5.0. To underscore the knowledge- and skill-intensive nature of future job roles, learning factories play a pivotal role in meeting the evolving demands of industries. These environments furnish hands-on educational experiences that delve into the seamless integration of human workers and robots within a unified workforce. Offering an optimal setting for comprehensive training in human-robot collaboration in various manufacturing scenarios. Learning factories can help discern potential hazards, formulate tailored safety protocols, and devise ergonomic guidelines to safeguard workers and enhance their well-being within collaborative work settings. Through this approach, workers not only gain insights into interacting with robots and understanding their functionalities but also cultivate the essential skills for effective and safe collaboration.

Furthermore, learning factories can function as testbeds to underscore the implementation costs associated with Industry 5.0. These facilities offer an experimental space for evaluating various human-robot collaboration technologies, enabling experimentation with robot programming, sensing technologies, communication protocols, and interfaces that facilitate seamless interaction between humans and robots. The controlled and experimental nature of learning factories provides a platform for refining resource allocation strategies and identifying opportunities to streamline processes, ultimately contributing to the reduction of implementation costs in the broader context of Industry 5.0 adoption.

Lastly, hands-on training and simulation of real-world manufacturing scenarios enable workers to develop skills in sustainable practices, fostering a workforce capable of implementing and advancing environmentally conscious strategies in the broader manufacturing industry. Additionally, they facilitate the development and implementation of circular economy strategies, promoting resource reuse, waste reduction, and a holistic approach to environmental responsibility in various manufacturing processes. In summary, the learning factory aligns with the broader goal of fostering a safe and sustainable work environment within the realm of Industry 5.0.

Conclusion

In this study, we unveil the learning factories as instrumental catalysts in fostering sustainable, resilient, and human-centric manufacturing environments essential for realizing the objectives of Moreover, Industry 5.0 is shown to effectuate a transformation in learning factories, imbuing them with environmentally friendly and socially responsible practice. Future efforts should focus on aligning learning factories with the evolving requirements of Industry 5.0, ensuring a seamless integration of technology, human values, and sustainability.

References

- Longo F, Padovano A, Umbrello S (2020) Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Applied Sciences 10(12): 4182.

- Xu X, Lu Y, Vogel-Heuser B, Wang L (2021) Industry 4.0 and Industry 5.0-Inception, conception and perception. Journal of Manufacturing Systems 61: 530-535.

- Adel A (2022) Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. Journal of Cloud Computing 11(1): 1-15.

- Breque M, De Nul L, Petridis A (2021) Industry 5.0: towards a sustainable, human-centric and resilient European industry. Luxembourg, LU: European Commission, Directorate-General for Research and Innovation.

- Li X, Nassehi A, Wang B, Hu S J, Epureanu BI, et al. (2023) Human-centric manufacturing for human-system coevolution in Industry 5.0. CIRP Annals 72(1): 393-396.

- Huang S, Wang B, Li X, Zheng P, Mourtzis D, et al. (2022) Industry 5.0 and Society 5.0-Comparison, complementation and co-evolution. Journal of manufacturing systems 64: 424-428.

- Ghobakhloo M, Iranmanesh M, Mubarak MF, Mubarik M, Rejeb A, et al. (2022) Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values. Sustainable Production and Consumption 33: 716-737.

- Zizic MC, Mladineo M, Gjeldum N, Celent L (2022) From industry 4.0 towards industry 5.0: A review and analysis of paradigm shift for the people, organization and technology. Energies 15(14): 5221.

- Brown TM (2020) Injuries, illnesses and fatalities in manufacturing. Bureau of Labor Statistics.

- CEDEFOP S (2010) supply and demand in Europe Medium-term forecast up to 2010. Luxembourg: Publications Office 41.

- Donmezer S, Demircioglu P, Bogrekci I, Bas G, Durakbasa MN, et al. (2023) Revolutionizing the Garment Industry 5.0: Embracing Closed-Loop Design, E-Libraries, and Digital Twins. Sustainability 15(22): 15839.

- Abele E, Chryssolouris G, Sihn W, Metternich J, ElMaraghy H, et al. (2017) Learning factories for future oriented research and education in manufacturing. CIRP annals 66(2): 803-826.

- Cachay J, Wennemer J, Abele E, Tenberg R (2012) Study on action-oriented learning with a Learning Factory approach. Procedia-Social and Behavioral Sciences 55: 1144-1153.

- Abele E, Metternich J, Tisch M, Chryssolouris G, Sihn W, et al. (2015) Learning factories for research, education, and training. Procedia CiRp 32: 1-6.

- Kemény Z, Beregi R, Nacsa J, Kardos C, Horváth D (2018) Human–robot collaboration in the MTA SZTAKI learning factory facility at Győ Procedia Manufacturing 23: 105-110.

- Kamble SS, Gunasekaran A, Gawankar SA (2018) Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process safety and environmental protection 117: 408-425.

- Abele E, Metternich J, Tisch M (2019) Learning factories. Concepts, Guidelines, Best-Practice Examples.

- Sangwan KS, Herrmann C, Soni MS, Jakhar S, Posselt G, et al. (2018) Comparative analysis for solar energy based learning factory: case study for TU Braunschweig and BITS Pilani. Procedia CIRP 69: 407-411.

- Abele E, Bauerdick CJ, Strobel N, Panten N (2016) ETA learning factory: A holistic concept for teaching energy efficiency in production. Procedia CIRP 54: 83-88.

- Karre H, Hammer M, Ramsauer C (2018) Learn how to cope with volatility in operations at Graz University of Technology’s LEAD Factory. Procedia Manufacturing 23: 5-20.

- Bender B, Kreimeier D, Herzog M, Wienbruch T (2015) Learning factory 2.0–integrated view of product development and production. Procedia CIRP 32: 98-103.

- Brenner B, Hummel V (2017) Digital twin as enabler for an innovative digital shopfloor management system in the ESB Logistics Learning Factory at Reutlingen-University. Procedia Manufacturing 9: 198-205.

- Dillinger F, Kagerer M, Brandl F J, Bauer H, Tropschuh B, et al. (2021) Managing the Systemic Transition from a Learning Factory for Lean Production (LSP) to an Innovation Lab for Smart & Lean Processes at iwb (TUM). In Proceedings of the Conference on Learning Factories (CLF).

- Simons S, Abé P, Neser S (2017) Learning in the AutFab–the fully automated Industrie 4.0 learning factory of the University of Applied Sciences Darmstadt. Procedia Manufacturing 9: 81-88.