Abstract

Here in in this article an attempt has been made to study various types of microscopes in detail. In this review paper we have discussed various types of microscopes which are classified as electron microscopes, x-ray microscope and probe microscopes. Also, the various subtypes of each of these microscopes have been presented in this paper. This paper focuses on the historical developments, Principles of operation, instrumentation, advantages and limitations of the various types and subtypes of the microscopes. The properties of the materials at nanoscale depend upon their size, shape and nature. As nanomaterials are invisible, we require various advanced characterization techniques to reveal their morphology. The various advanced characterization techniques required for the analysis of nanomaterials are thoroughly discussed in this paper.

Keywords: Electron microscope; Probe microscope; X-Ray microscope; Fluorescence microscope

Electron Microscope

This type of microscope uses beams of accelerated electrons as a source of illumination. The wavelength of an electron is 100,000 times shorter than the visible photons. Consequently, electron microscopes are having higher resolving power than optical microscopes. The electron microscope can be further sub classified into different types such as SEM and TEM based upon their construction and type of action and information we get. Another advanced type of electron microscope is Combined SEM and TEM where two types of electron microscopes are combined together.

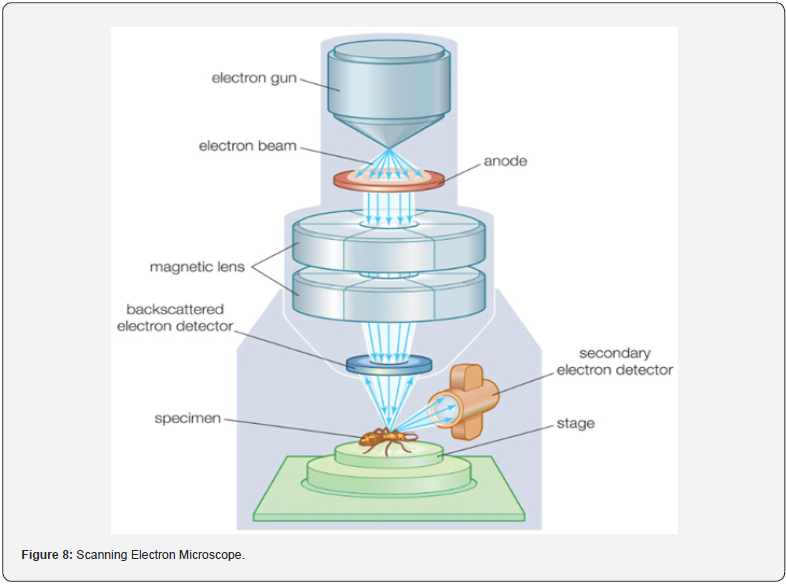

Scanning Electron Microscope:

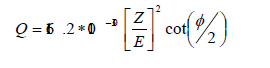

Scientists and engineers have been striving to achieve high magnification and resolution of microscopic and nanoscale entities. Numerous researchers have made efforts in this field, with a notable and successful contribution by German physicist Ernest Ruska and German electrical engineer Max Knoll in 1931. The scanning electron microscope (SEM) is a type of electron microscope that creates images by scanning a surface with a focused beam of electrons. These electrons interact with the atoms in the sample, generating various signals that provide information about the sample’s surface topography and composition. The electron beam scans in a raster pattern, and the beam’s position is combined with the intensity of the detected signal to form an image. SEM is used to observe specimen surfaces, where a fine electron beam causes the emission of secondary electrons from the surface. The surface topography can be observed in two dimensions. When the specimen is struck by an incident electron beam, it emits X-rays and three types of electrons: primary backscattered electrons, secondary electrons, and Auger electrons. SEM devices primarily utilize primary backscattered electrons [1-7].

Instrumentation and Working of SEM:

The essential components of an SEM include the electron

source (gun), electron lenses, sample stage, detectors for all

relevant signals, display/data output device, power supply,

vacuum system, cooling system, infrastructure requirements,

vibration-free flooring, and a room free from ambient magnetic

and electric fields.

a) Electron Gun: An electron gun generates electron

beams, which can be emitted either by heating a filament

(thermionic emission) or by applying a high potential difference

(field emission). Electron microscopes typically use magnetic

lenses. To create a strong magnetic lens, the density of magnetic

lines must be increased, achieved through a precisely fabricated

pole piece with a narrow gap. A key characteristic of a magnetic

lens is that changing the current passing through the coil alters the

lens’s strength, a feature not possible with optical microscopes.

b) Condenser lens and objective lens: When a lens is

positioned below the electron gun, it allows for the adjustment

of the electron beam diameter. SEM requires a finely focused

electron beam (probe), achieved by using a two-stage lens system

that combines the condenser and objective lenses. Consequently,

the electron beam from the electron gun is focused by these two

lenses, producing a small electron probe.

c) Specimen stage: In an electron microscope, specimens

are observed at high magnification and resolution. The SEM

specimen stage is designed to allow various movements, including:

(a) horizontal movement, (b) vertical movement, (c) specimen

tilting, and (d) rotation. The X and Y movements are used to select

the field of view, while the Z movement adjusts image resolution

and depth of focus.

d) Secondary Electron Detector: When a specimen in an

electron microscope is bombarded by electrons from an electron

gun, it emits secondary electrons. A secondary electron detector,

with a scintillator coated on its tip and a high potential difference

applied, detects these secondary electrons. The emitted electrons

are attracted to the high voltage, generating light. When the

electron beam strikes the sample, some incident electrons interact

with the nucleus of atoms. These negatively charged electrons are

attracted to the positively charged nucleus, encircle it, and then

exit the sample without losing speed, becoming backscattered

electrons. Secondary electrons originate from surface regions,

while backscattered electrons re-emerge from the sample.

Backscattered and secondary electrons provide different types

of information. Backscattered electrons are highly sensitive to

atomic numbers, with brighter regions indicating atoms with

higher atomic numbers and darker regions indicating atoms

with lower atomic numbers. Secondary electrons offer surface

information about the sample.

e) Secondary Electrons: Secondary electrons originate

from the surface of the sample being studied, generated through

inelastic interactions between the primary electron beam and the

sample. These electrons have lower energy compared to primary

or backscattered electrons and are essential for determining the

topography of the sample (Figure 1).

Principle of SEM

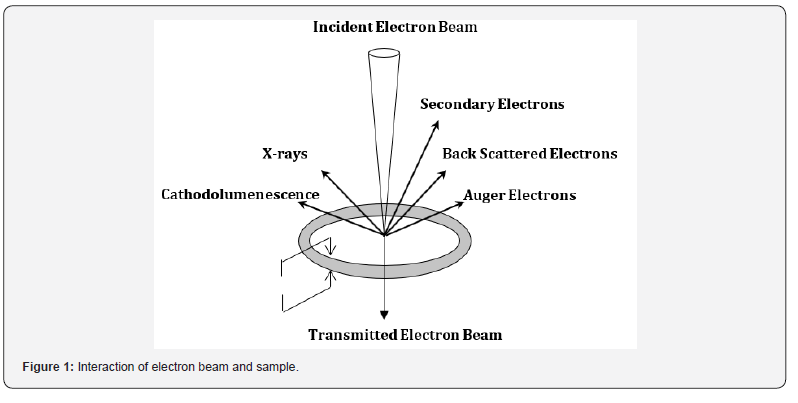

A monochromatic beam directed at a solid substrate surface generates various signals, contingent on the substrate’s composition and structure. In SEM imaging, backscattered or secondary electrons are commonly employed, with their intensity linked to the atomic number of the materials involved. Each backscattered electron can be captured, amplified, and utilized to modulate the brightness spot on a cathode ray tube (CRT). To acquire signals from an area, the electron beam scans over the specimen surface via two pairs of electromagnetic deflection coils, synchronized with the CRT beam. The signals are transferred point by point, generating a signal map of the scanned region displayed on a long-persistence phosphor CRT screen. Changes in brightness indicate variations in specific properties within the scanned area of the specimen (Figure 2).

The scattering cross section for back-scattered electrons is given as [2], where, Z is atomic number and E is electric field.

Here the cross-section is proportional to Z2. Hence, the backscattered electrons are used for the Z contrast or for compositional mapping.

Limitation of SEM:

a) Sample Preparation Requirements: SEM requires

samples to be conductive or coated with a conductive material

(e.g., gold, carbon) to prevent charging effects caused by the

electron beam. Sample preparation can be time-consuming and

may alter the sample’s natural properties.

b) Vacuum Environment: SEM operates under high

vacuum conditions, which can limit the analysis of certain samples,

especially those that are volatile, hydrated, or sensitive to vacuum

conditions. Some samples may require specialized sample holders

or environmental SEMs to maintain their integrity.

c) Limited Depth of Field: SEM has a shallow depth of

field, meaning that only the surface of the sample is in focus at any

given time. This can make it challenging to obtain clear images

of three-dimensional structures or samples with rough surfaces.

d) Resolution: While SEM offers high-resolution imaging

capabilities, the resolution is ultimately limited by factors such as

the electron beam energy, specimen characteristics, and detector

efficiency. Achieving sub-nanometer resolution often requires

sophisticated instrumentation and careful optimization.

e) Sample Damage: The high-energy electron beam used

in SEM can potentially damage the sample through processes

such as electron beam-induced deposition, sample heating, or

radiation damage. Minimizing beam exposure and optimizing

imaging conditions can help mitigate sample damage.

f) Limited Chemical Information: SEM provides

primarily morphological and topographical information about

samples. While energy-dispersive X-ray spectroscopy (EDS)

can be used for elemental analysis, it has limitations in terms

of sensitivity, spatial resolution, and quantification accuracy

compared to other analytical techniques like X-ray diffraction

(XRD) or X-ray photoelectron spectroscopy (XPS).

Transmission Electron Microscope

Transmission Electron Microscope is a type of electron microscope that has three essential components viz. electron gun, image producing system, imaging recording system [8-15].

Instrumentation of TEM

a) Electron gun:

An electron gun is an essential component

that generates a precisely controlled electron beam in a TEM

(Transmission Electron Microscope). Positioned at the top of

the TEM, the electron gun emits electrons that travel through

the microscope›s vacuum tube. The key elements of an electron

gun include the electron emitter, the biasing cylinder (Wehnelt

cylinder), and the anode. The electron emitter is typically a

tungsten filament covered by a control grid (Wehnelt cylinder),

which has a central aperture aligned with the vacuum tube. The

cathode, located either above or below this aperture, and the

grid are negatively charged. The anode, typically disc-shaped

with an axial hole, is positioned to receive the emitted electrons.

As electrons are emitted from the cathode, they pass through

the central aperture of the Wehnelt cylinder and are accelerated

towards the anode at high voltage, maintaining a constant energy

level. This configuration effectively focuses the electron beam to

interact with the specimen and produce a well-defined image.

b) Image Producing System:

The imaging system of an

electron microscope includes an objective lens, a movable stage

for holding the specimen, and intermediate and projector lenses.

These components collaborate to focus electrons passing through

the specimen, resulting in a significantly magnified image. The

objective lens, typically with a short focal length of approximately

1-5 mm, first forms an intermediate image from the condenser.

This intermediate image is then transmitted to the projector

lenses for further magnification. There are two types of projector

lenses: the intermediate lens, which enables greater image

magnification, and the projector lens, which generally offers even

higher magnification than the intermediate lens.

c) Image Recording System:

The image recording system

includes a fluorescent screen used for viewing and focusing on the

image, along with digital cameras capable of effectively recording

and capturing it. To maintain optimal imaging conditions, a

vacuum system prevents electron collisions with air molecules

that could disrupt their movement and focusing ability. This

vacuum system comprises a pump, gauge, valves, and power

supply, ensuring electrons move directly to form the image

without interference. The resulting image is monochromatic,

typically appearing greyish or black, designed to be easily visible

to the human eye by passing through the fluorescent screen fixed

at the base of the microscope.

Working Principle:

Transmission electron microscopy (TEM) is a microscopic technique where an electron beam passes through an ultrathin specimen, interacting with it as it traverses. Its operational principle shares similarities with light microscopy, but differs fundamentally in the use of electrons instead of light rays to focus on and produce images of the specimen. Electrons have shorter wavelengths compared to light, enabling higher resolution capabilities in TEM. Unlike light microscopes where resolution increases with shorter wavelengths, TEM achieves resolution by increasing the energy of transmitted electrons.

In TEM analysis, a thin specimen is exposed to electrons to ensure uniform electron intensity across the illuminated area. As these electrons traverse the specimen, they either undergo scattering processes or pass through unaffected, leading to a nonuniform distribution of electrons emerging from the specimen’s surface. This distribution contains detailed structural and chemical information about the specimen.

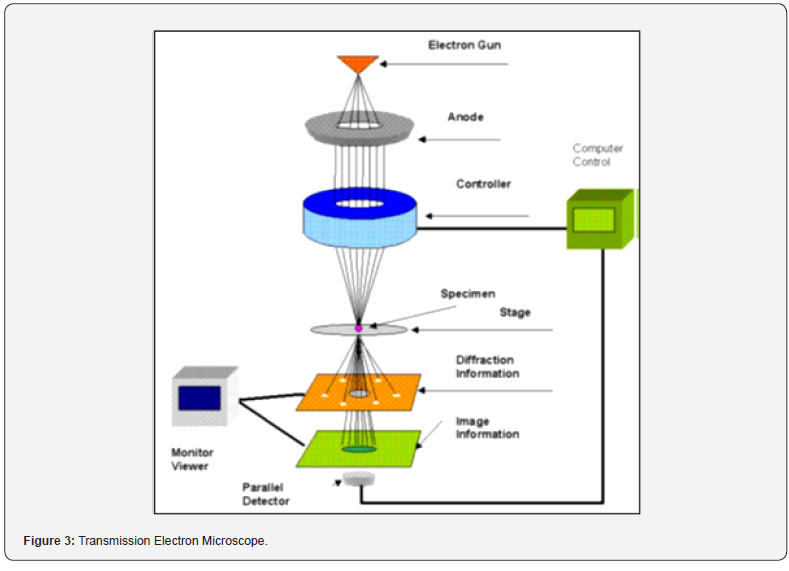

An electron microscope is designed to visualize this electron distribution in two main ways: the angular distribution of scattering, seen as diffraction patterns, and the spatial distribution of scattering, observed as contrast in specimen images. This setup enables direct observation of the specimen area that generates the diffraction pattern. The fundamental components of a transmission electron microscope are depicted in Figure 3.

Working principle of TEM:

a) The electron gun serves as a crucial source, generating a

stream of monochromatic electrons.

b) TEM operates using accelerated electron beams instead

of light, focusing them to create images.

c) The magnification capability exceeds that of a light

microscope by over 2 million times.

d) Condenser lenses 1 and 2 concentrate the stream into

a small, coherent beam. The first lens, adjustable via a spot size

knob, primarily determines the beam’s size, while the second lens,

controlled by an intensity or brightness knob, further adjusts the

spot size on the sample.

e) The condenser aperture limits the electron beam,

filtering out high-angle electrons.

f) The electron beam impacts the specimen, with a portion

of it passing through.

g) The transmitted portion is then focused by the objective

lens.

h) Optical objective and selected area metal apertures

further control the beam. The objective aperture enhances

contrast by blocking high-angle diffracted electrons, while the

selected area aperture enables examination of electron diffraction

patterns caused by the ordered arrangement of atoms in the

sample.

i) A photographic image is captured from the electrons

that have passed through the thin specimen under study. These

images strike a phosphorus image screen, generating light that

allows observation. Darker areas in the image indicate regions

where fewer electrons transmitted through the sample.

Limitation of TEM:

a) Sample Preparation: TEM requires samples to be

extremely thin (typically less than 100 nanometers) to allow

electrons to pass through. Preparing such thin samples can be

challenging and often involves techniques like ultramicrotomy

or ion milling, which can introduce artifacts. Potentially damage

sample or alter the sample’s structure.

b) Vacuum Environment: TEM operates under high

vacuum conditions, which can limit the analysis of certain samples,

especially those that are volatile or hydrated. Some samples may

require specialized sample holders or environmental TEMs to

maintain their integrity under vacuum.

c) Electron Beam Resolution: While TEM offers extremely

high resolution, the achievable resolution is ultimately limited by

factors such as the electron beam energy, specimen thickness,

and instrumental aberrations. Achieving atomic resolution often

requires sophisticated instrumentation and careful optimization.

d) Beam-sensitive Samples: Some samples are highly

sensitive to the electron beam and may undergo structural

changes or damage even at relatively low beam energies. Biological

specimens, organic materials, and certain nanomaterials are

particularly prone to beam damage.

e) Depth of Field: Similar to SEM, TEM has a limited depth

of field, meaning that only a thin section of the sample is in focus at

any given time. This can make it challenging to obtain clear images

of three-dimensional structures or samples with significant depth

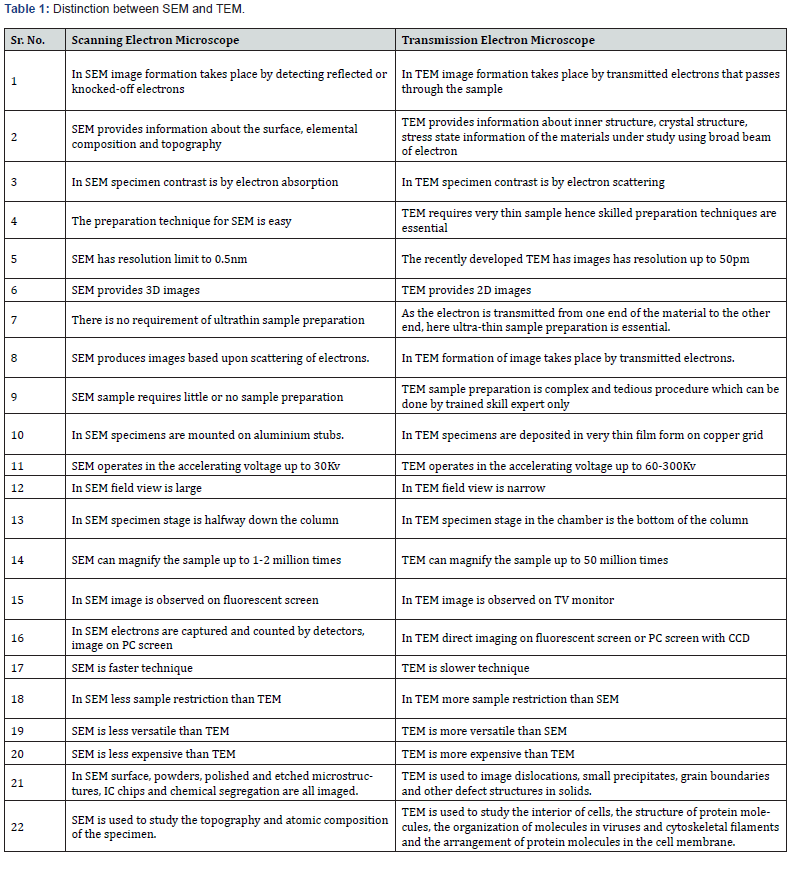

variations (Table 1).

Combing SEM and TEM Together:

This instrument is called scanning transmission electron microscopy. This instrument can be applied to a TEM tool. Most modern TEM can be switched to STEM mode. In STEM mode, the beam is finally focused and scans the sample area while the image is generated by the transmitted electron. Combining Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) into a single instrument, often referred to as a “dual-beam” or “dual-mode” microscope, offers several advantages for comprehensive material characterization. Although such instruments are not commonplace, they offer significant benefits in terms of sample preparation, imaging, and analysis [16-21].

Instrument Configuration:

The instrument would likely consist of a platform that

integrates both SEM and TEM capabilities. The SEM component

would typically be used for initial sample inspection, navigation,

and coarse imaging due to its relatively large depth of field

and ease of use. The TEM component would allow for higherresolution

imaging and detailed analysis of thin sections of the

sample.

a) Sample Preparation: The combined instrument

would streamline sample preparation, as the same sample

could be examined using both SEM and TEM without the need

for additional sample handling. Initial sample inspection and

rough characterization could be performed using SEM, guiding

subsequent TEM analysis of specific regions of interest.

b) Imaging and Analysis: SEM imaging would provide

detailed surface morphology and topography information at

relatively low magnifications. TEM imaging would offer higherresolution

imaging of internal structures and thin sections of the

sample, providing atomic-scale details of crystal structure, defects,

and interfaces. Combined SEM and TEM analysis would allow for

comprehensive material characterization, including investigation

of microstructure, phase identification, chemical composition,

and elemental mapping.

Applications:

a) Material Science: Such instruments would be

invaluable for characterizing nanomaterials, nanoparticles, and

nanostructures, providing insights into their morphology, size

distribution, and crystalline structure. Biological Sciences: In

biology and life sciences, combined SEM/TEM capabilities could

facilitate the study of biological specimens, such as cells, tissues,

and biomaterials, offering detailed imaging of ultrastructure and

subcellular organelles.

b) Research and Development: Combined SEM/TEM

instruments would be essential tools for research laboratories

and industrial R&D facilities.

Limitations of combined SEM and TEM:

a) Instrument Complexity: Integrated SEM-TEM systems

are complex and require sophisticated engineering to combine

two distinct imaging modalities into a single instrument. This

complexity can lead to maintenance challenges, and longer

training times for operators.

b) Sample Preparation Challenges: Samples for combined

SEM and TEM analysis often require extensive preparation

to meet the requirements of both techniques. Achieving the

necessary thinness for TEM while maintaining conductivity or

surface topography for SEM can be challenging and may introduce

artifacts or limitations.

c) Limited Field of View: While SEM provides a wide field

of view, TEM offers higher resolution but a much narrower field of

view. Combined systems typically sacrifice some of the SEM’s field

of view to accommodate the TEM column, leading to limitations in

imaging large areas at high resolution.

d) Sequential Imaging: In most combined SEM-TEM

systems, imaging modes are sequential rather than simultaneous.

This means that switching between SEM and TEM imaging

requires physical adjustments of the sample and optics, leading to

longer analysis times and potential disruptions to sample stability.

e) Complexity of Data Interpretation: Combined SEMTEM

datasets can be complex to interpret, as they provide

complementary information from two different imaging

modalities. Integrating and correlating data from SEM and TEM

images may require advanced software tools and expertise,

especially for quantitative analysis or multi-modal imaging.

f) Limited TEM Performance: In some integrated systems,

the TEM functionality may be limited compared to standalone

TEM instruments. This can include constraints on achievable

resolution, imaging modes, or analytical capabilities, depending

on the design and specifications of the combined system.

X-Ray Microscope:

An X-ray microscope is an imaging instrument that uses X-rays instead of visible light to create high-resolution images of objects, typically on the nanometer scale [22-27].

Instrumentation of X-Ray Microscopy

a) X-ray Source: X-ray microscopes require a source of

X-ray radiation to illuminate the sample. Common X-ray sources

include X –ray tubes and Synchrotron radiations:

b) X-ray tubes: Produce X-rays by accelerating electrons to

high velocities and colliding them with a metal target.

c) Synchrotron radiation: Highly intense and tunable

X-rays are generated by accelerating charged particles (electrons

or protons) to nearly the speed of light in a synchrotron facility.

d) X-ray Optics: X-ray optics are used to focus and

manipulate the X-ray beam before it interacts with the sample.

Unlike optical microscopes, X-ray microscopes cannot use

conventional lenses due to the high energy and short wavelengths

of X-rays. Instead, X-ray optics contains Fresnel zone plate,

Multilayer mirrors, capillary optics.

e) Sample Stage: The sample stage holds the specimen and

allows for precise positioning and manipulation during imaging.

It may include mechanisms for translation, rotation, and tilt to

adjust the orientation of the sample relative to the X-ray beam.

f) Detector: X-ray detectors capture the X-rays transmitted

through or scattered by the sample to create an image.

g) X-ray CCD (charge-coupled device) cameras: Capture

X-ray photons and convert them into electronic signals for image

formation.

h) X-ray sensitive films: Traditional photographic films

that react to X-ray exposure. X-ray-sensitive scintillators coupled

with photodetectors: Convert X-ray photons into visible light,

which is then detected by photodetectors.

i) Data Acquisition System: A data acquisition system

processes and records the signals from the X-ray detector

to generate digital images. It may include analog-to-digital

converters, data storage devices, and software for image

processing and analysis.

j) Environmental Control: X-ray microscopes may operate

in controlled environments to minimize sample degradation and

maintain stable imaging conditions. This may include temperature

control, humidity control, and the elimination of vibration and

electromagnetic interference.

k) Safety Measures: Due to the ionizing nature of X-rays,

safety measures such as radiation shielding, interlocks, and safety

protocols are essential to protect operators and ensure regulatory

compliance.

l) Synchrotron Facility (for synchrotron-based X-ray

microscopy): Synchrotron-based X-ray microscopes require

access to a synchrotron radiation facility equipped with a dedicated

beamline optimized for X-ray microscopy. These facilities provide

intense and tunable X-ray beams for high-resolution imaging

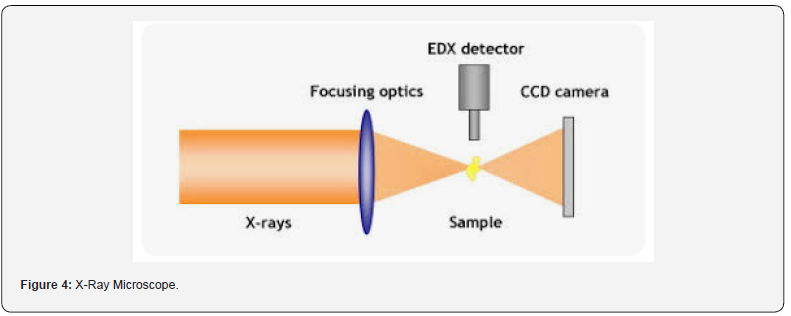

experiments (Figure 4).

Key Components of X-Ray Microscopy

a) X-ray Source: X-ray microscopes typically use a

synchrotron radiation source or an X-ray tube as the source of

X-rays. Synchrotron radiation sources produce highly intense and

focused X-ray beams by accelerating electrons to nearly the speed

of light and directing them through a magnetic field. X-ray tubes

generate X-rays by accelerating electrons and bombarding a

metal target.

b) Focusing Optics: X-ray microscopes utilize various

types of focusing optics to concentrate the X-ray beam onto the

specimen. These may include mirrors, lenses, or diffractive

optics designed to bend and focus X-rays to achieve high spatial

resolution.

c) Sample Stage: The sample stage is a platform on which

the specimen is mounted for imaging. It may be equipped with

precise positioning controls to manipulate the specimen and

adjust its orientation for imaging from different angles.

d) Detector: X-ray microscopes employ specialized X-ray

detectors to capture the X-rays that interact with the specimen

and produce images. These detectors may include charge-coupled

devices (CCDs), complementary metal-oxide-semiconductor

(CMOS) sensors, or X-ray film, depending on the imaging

requirements and desired resolution.

e) Image Reconstruction Software: X-ray microscopy

generates 2D and 3D images of the specimen based on the detected

X-ray signals. Sophisticated image reconstruction algorithms and

software are used to process the raw data and reconstruct the

images with high resolution and contrast.

Advantages of X-Ray Microscopy

a) High Resolution: X-rays have shorter wavelengths

than visible light, allowing X-ray microscopes to achieve higher

resolution and visualize biological structures on the nanometer

scale.

b) Non-destructive Imaging: X-ray microscopy is nondestructive

and can image samples in their native state without

the need for staining or fixation.

c) Elemental Contrast: X-ray microscopes can provide

elemental contrast by detecting differences in the absorption or

fluorescence of X-rays by different elements within the specimen.

d) 3D Imaging: X-ray microscopes can generate threedimensional

images of specimens by acquiring multiple 2D image

slices at different depths and reconstructing them into a 3D

volume. This enables the visualization of internal structures and

complex morphologies in three dimensions.

Principle of X-Ray Microscope:

The principle of X-ray microscopy is based on the interaction

of X-rays with matter, which results in absorption, scattering, and

diffraction phenomena.

a) Sample Interaction: When the X-ray beam interacts

with the sample, it undergoes various interactions depending

on the sample’s composition and structure. These interactions

include absorption, scattering, fluorescence, and phase contrast.

b) Absorption: X-rays are absorbed by the atoms within

the sample, with the degree of absorption depending on the

atomic number and density of the material. Regions of higher

absorption appear darker in the X-ray image, providing contrast

between different materials or structures within the sample.

c) Scattering: X-rays can be scattered by the sample’s

microstructure, leading to changes in the direction and intensity

of the X-ray beam. Scattering phenomena, such as Compton

scattering and Rayleigh scattering, contribute to image contrast

and provide information about the sample’s density and

composition.

d) Fluorescence: Some materials exhibit fluorescence

when exposed to X-rays, emitting characteristic secondary X-rays

with wavelengths different from the incident X-rays. Fluorescence

imaging techniques can be used to map specific elements within

the sample based on their fluorescence spectra.

e) Phase Contrast: In addition to absorption-based

contrast, X-ray microscopy can utilize phase contrast techniques

to enhance image contrast by exploiting differences in the phase

of the X-ray wavefront as it passes through the sample. Phase

contrast imaging is particularly useful for visualizing low-contrast

features and soft tissues.

f) Detection and Imaging: After interacting with the

sample, the X-ray beam is collected by a detector, such as an X-raysensitive

CCD camera or a phosphor screen coupled to a chargecoupled

device (CCD).

g) Data Analysis and Reconstruction: Advanced image

processing and reconstruction techniques are often employed

to enhance the quality and resolution of X-ray microscopy

images. This may include tomographic reconstruction methods

for generating three-dimensional images from a series of twodimensional

projections.

Limitations of X-Ray Microscope:

a) Limited Depth of Penetration: X-rays have limited

penetration depth in most materials, particularly dense and thick

samples. This can restrict the imaging of samples with significant

thickness, requiring thinning or sectioning of the sample to obtain

clear images.

b) Radiation Damage: X-rays can cause radiation damage

to biological samples, leading to alterations in sample morphology,

chemistry, and viability. Prolonged exposure to X-rays can induce

DNA damage, protein denaturation, and other cellular changes,

affecting the integrity of the sample and limiting the duration of

observation.

c) Sample Preparation: Sample preparation for X-ray

microscopy often involves complex and time-consuming

procedures, such as embedding, sectioning, and staining.

d) Limited Contrast for Soft Materials: X-ray microscopy

is less sensitive to soft materials and low-contrast features

compared to techniques such as electron microscopy or optical

microscopy. This is challenging to visualize certain biological

tissues, polymers, and organic materials without the use of

contrast agents or specialized imaging techniques.

e) Resolution Limitations: Although X-ray microscopy

offers high-resolution imaging capabilities, achieving subnanometer

resolution is challenging due to limitations in X-ray

optics and detector technology.

f) Radiation Safety: X-ray microscopy involves the use of

ionizing radiation, which poses potential health risks to operators

and researchers. Proper radiation safety protocols, including

shielding, monitoring, and dosimetry, are essential to minimize

radiation exposure and ensure safe operation.

g) Data Analysis Complexity: Analyzing and interpreting

X-ray microscopy data can be complex and computationally

intensive, particularly for three-dimensional imaging and

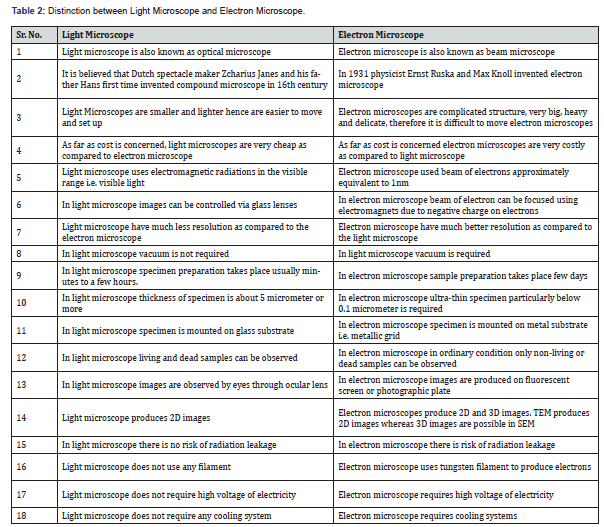

tomographic reconstruction (Table 2).

Probe Microscopy

The various types of microscopes under the category of probe microscopy are described below:

Scanning Probe Microscope:

Scanning Probe Microscopy (SPM) is a group of techniques used for imaging and analyzing surfaces at the nanometer scale. Unlike traditional optical or electron microscopy, which rely on lenses and electromagnetic fields to produce images, SPM operates by scanning a sharp probe over the surface of a sample to measure various surface properties with extremely high resolution SPM works by bringing a sharp probe tip into close proximity or contact with the surface of a sample. As the probe tip interacts with the surface, various physical properties are measured, such as forces, currents, or mechanical vibrations [28-35].

Instrumentation of Components of SPM:

a) Probe Tip: The heart of SPM is a sharp probe tip,

typically made of materials like silicon or silicon nitride, with a

radius of only a few nanometers.

b) Cantilever: The probe tip is mounted on a flexible

cantilever, which deflects in response to interactions with the

sample surface.

c) Scanner: A precise scanning mechanism moves the

probe tip laterally across the surface of the sample, allowing for

the acquisition of high-resolution images.

d) Detector: Various detection methods are used to

measure the interactions between the probe tip and the sample

surface. These can include mechanical deflection of the cantilever,

changes in tunneling current, or shifts in resonance frequency.

e) Feedback System: A feedback loop controls the distance

between the probe tip and the sample surface to maintain a

constant interaction force or tunneling current. This ensures

that the probe tip stays in close proximity to the surface during

scanning.

Main Techniques within SPM:

Atomic Force Microscopy (AFM): Measures surface

topography by scanning a sharp probe tip over the sample surface

and detecting the deflection of a cantilever.

a) Scanning Tunneling Microscopy (STM): Measures the

tunneling current between the probe tip and the sample surface,

providing atomic-scale resolution of conductive surfaces.

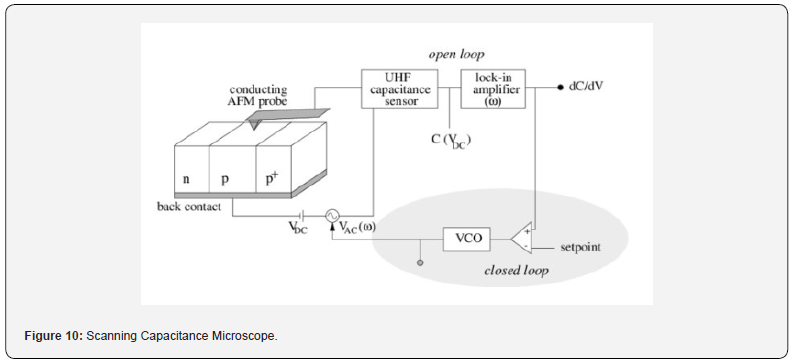

b) Scanning Kelvin Probe Microscopy (SKPM): Measures

variations in surface potential by detecting changes in the

electrostatic force between the probe tip and the sample surface.

c) Scanning Capacitance Microscopy (SCM): Maps

variations in the capacitance between the probe tip and the sample

surface, providing information about carrier concentrations in

semiconductors.

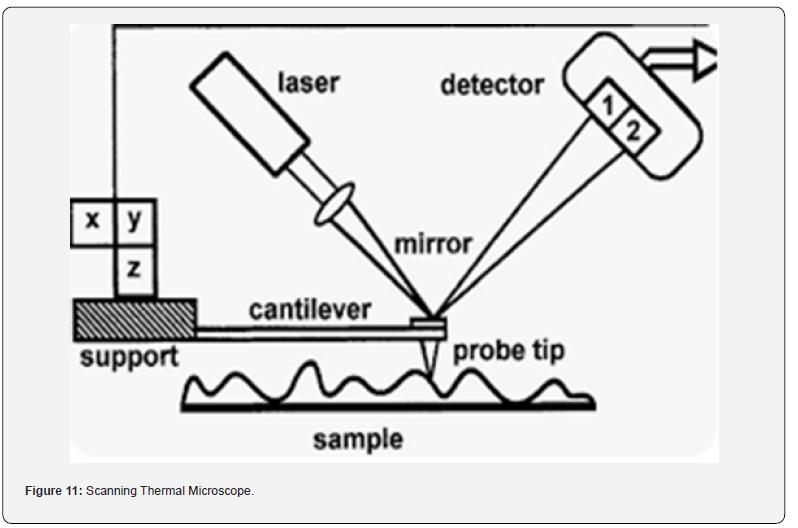

d) Scanning Thermal Microscopy (SThM): Measures

variations in temperature on the sample surface by detecting

changes in the thermal conductivity or expansion of the cantilever.

Applications of SPM:

SPM is used in a wide range of scientific and technological fields, including nanotechnology, materials science, biology, and semiconductor device characterization.

It can provide high-resolution images of surfaces, reveal atomic-scale details, measure mechanical properties, and map variations in surface potential or conductivity.

Applications include surface roughness analysis, nanoscale patterning, biological imaging, characterization of thin films, and investigation of surface chemistry.

Atomic Force Microscope:

The AFM can operate in several modes, primarily distinguished by how the tip interacts with the specimen surface. In contact mode, the tip maintains continuous contact with the specimen throughout scanning. In intermittent contact mode, the tip oscillates and intermittently touches the specimen surface. In non-contact mode, the tip does not touch the specimen at all during scanning [36-40].

Principle of Atomic Force Microscope:

The Atomic Force Microscope (AFM) is an advanced method

for imaging and analyzing the surface morphology and properties

of materials at the nanoscale. It operates on the principle of

detecting surface features through the interaction between a

sharp probe tip and the sample surface, offering high-resolution

visualization and characterization capabilities.

a) Cantilever Probe: At the core of an AFM lies a miniature

cantilever outfitted with a sharp probe tip at one end. This probe

tip, often composed of silicon or silicon nitride and typically a few

nanometers in radius, is crucial for interactions with the sample

surface. The cantilever itself, also typically made from silicon

or silicon nitride, functions as a delicate spring that bends in

response to forces exerted between the probe tip and the sample

surface.

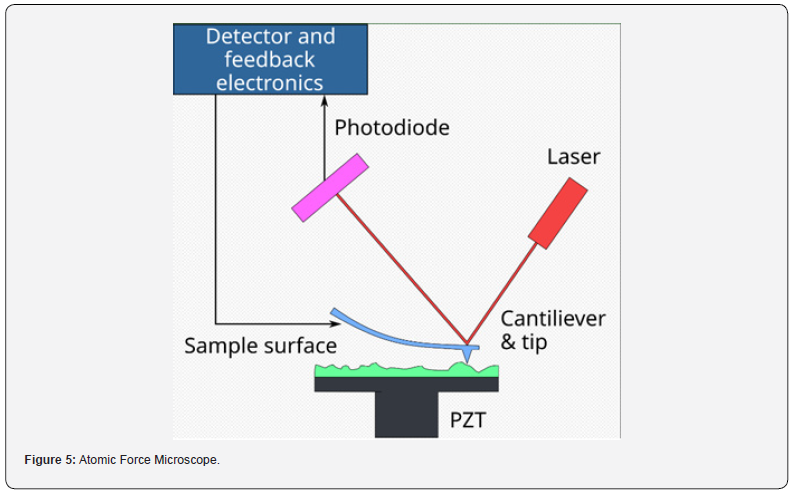

Instrumentation of Atomic Force Microscopy:

a) Cantilever Assembly: At the core of the AFM is the

cantilever assembly, comprising a sharp probe tip connected

to a flexible cantilever. The probe tip is commonly crafted from

silicon or silicon nitride and can take various shapes like conical,

pyramidal, or spherical. The cantilever functions as a responsive

spring that bends in reaction to forces exerted between the probe

tip and the sample surface.

b) Laser Deflection System: A laser beam is aimed at

the rear of the cantilever, and its reflected beam is captured

by a position-sensitive photodetector. As the cantilever bends

in response to interaction forces with the sample surface, the

position of the reflected beam on the photodetector shifts, offering

immediate feedback on the cantilever’s deflection.

c) Feedback Electronics: Feedback electronics are used

to regulate the vertical position of the cantilever, ensuring a

consistent force or distance between the probe tip and the sample

surface throughout the scanning process.

d) Piezoelectric Scanner: The sample stage is installed

on a piezoelectric scanner, providing accurate control over the

sample’s position in relation to the probe tip. This scanner can

move the sample with nanometer-scale precision along the x, y,

and z axes, facilitating raster scanning of the probe tip across the

sample surface to produce detailed, high-resolution images.

e) Control and Data Acquisition System: An AFM operates

with a control and data acquisition system to manage scanning

parameters, operate the instrument, and gather data from sensors

like the photodetector. This system usually integrates software for

image acquisition, processing, and analysis, alongside hardware

components such as analog-to-digital converters (ADCs) and

digital signal processors (DSPs).

f) Environmental Control: Some AFM systems are

equipped with environmental control features to minimize

vibration, temperature fluctuations, and humidity changes that

can affect imaging performance.

g) Optional Accessories: Depending on the specific

application, additional accessories may be incorporated into

the AFM setup. These can include liquid cells for imaging in

liquid environments, heating or cooling stages for temperaturedependent

studies, and specialized imaging modes such

as magnetic force microscopy (MFM) or electrostatic force

microscopy (EFM) (Figure 5).

Advantage of Atomic Force Microscope:

a) High Resolution: AFM can achieve atomic-scale

resolution, allowing researchers to study surface topography and

features with unprecedented detail. This makes it a valuable tool

for investigating nanoscale structures, including individual atoms

and molecules.

b) Versatility: AFM can operate in various modes, including

contact mode, tapping mode, and dynamic mode, allowing for a

wide range of imaging and measurement techniques. It can also

be used to study diverse sample types, including solid surfaces,

biomolecules, polymers, and thin films.

c) Non-destructive Imaging: Unlike some microscopy

techniques that require staining or labeling, AFM can image

samples in their native state without damaging or altering them.

This non-destructive nature makes it particularly useful for

studying delicate or sensitive samples.

d) 3D Imaging: AFM can generate three-dimensional

images of sample surfaces, providing valuable information about

surface morphology, roughness, and topography. This capability

is essential for understanding the spatial organization and

properties of nanoscale structures.

e) Measurement Capabilities: In addition to imaging,

AFM can perform various measurements, including force

spectroscopy, adhesion measurements, mechanical properties

mapping, and electrical characterization. These capabilities make

it a versatile tool for studying material properties and interactions

at the nanoscale.

f) Operational Flexibility: AFM can operate in different

environments, including air, liquid, and vacuum, allowing for the

study of samples under a wide range of conditions. This flexibility

enables researchers to investigate biological samples, polymers,

and other materials in their native environments.

g) High Sensitivity: AFM is highly sensitive to small forces,

making it suitable for detecting subtle interactions between

the tip and sample surface. This sensitivity enables the study of

weak forces such as van der Waals forces, chemical bonding, and

molecular interactions.

h) Real-Time Imaging and Manipulation: Some AFM

systems offer real-time imaging capabilities, allowing researchers

to observe dynamic processes as they unfold. Additionally, AFM

can be used for nano-manipulation tasks, such as pushing, pulling,

and positioning individual atoms or molecules on a surface.

Limitation of Atomic Force Microscope:

a) Limited Speed: AFM imaging typically operates at

relatively slow scan speeds compared to other microscopy

techniques such as scanning electron microscopy (SEM) or optical

microscopy. This limitation can be particularly significant when

studying dynamic processes or large sample areas.

b) Sample Constraints: AFM requires samples to be

relatively flat and stable to achieve high-resolution imaging.

Samples with rough surfaces or soft materials may present

challenges or require specialized techniques for imaging.

Additionally, AFM is primarily suited for studying solid or semisolid

materials and may not be suitable for analyzing liquids or

gases directly.

c) Sample Artifacts: Sample preparation for AFM can

introduce artifacts, especially when imaging soft or biological

samples. Sample drying, flattening, or surface modifications can

alter the sample’s native structure and properties, leading to

inaccurate or misleading results.

d) Tip Wear and Contamination: The AFM tip can wear

out or become contaminated over time, affecting imaging quality

and resolution. Tip degradation can lead to imaging artifacts

and require frequent tip replacement or cleaning, increasing

experimental costs and downtime.

e) Limited Imaging Modes: While AFM offers various

imaging modes (e.g., contact mode, tapping mode, dynamic mode),

each mode has its own limitations and trade-offs.

f) Environmental Sensitivity:AFM performance can

be sensitive to environmental conditions such as temperature,

humidity, and vibration. Maintaining stable experimental

conditions is crucial for obtaining reproducible and reliable

results, especially for long-term or high-resolution imaging

experiments.

g) Complex Data Analysis: AFM data analysis can be

complex, requiring specialized software and expertise to interpret

and quantify imaging results accurately. Extracting meaningful

information from AFM images often involves processing large

datasets, filtering noise, and performing advanced image analysis

algorithms.

Scanning Tunneling Microscope:

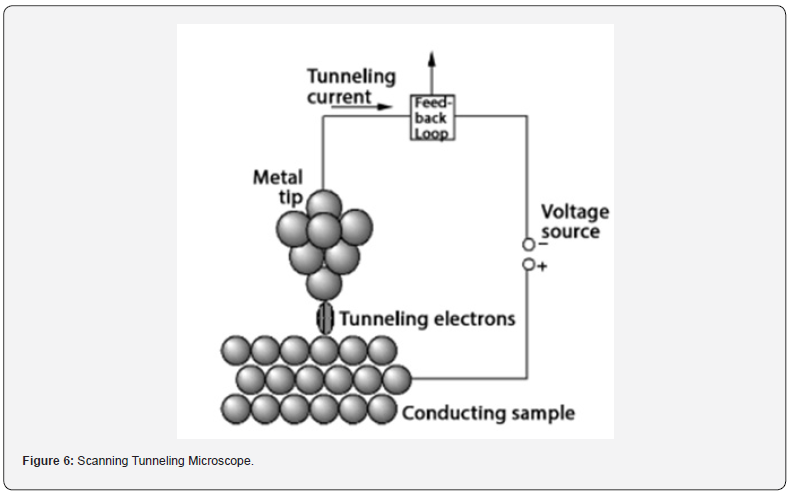

STM detects the flow of electrons through quantum tunneling between the tip and the sample, generating high-resolution images of surface topography with atomic-scale precision [41-42].

Principle of Scanning Tunneling Microscope:

The Scanning Tunneling Microscope (STM) functions based on

quantum tunneling, a phenomenon in quantum mechanics where

a particle can pass through a potential energy barrier despite

lacking sufficient classical energy. In STM, a sharp conducting tip

is positioned very close to the sample surface. By applying a small

bias voltage between the tip and the sample, electrons can tunnel

through the vacuum gap separating them.

a) Tip and Sample Interaction: The STM comprises a

sharp metallic tip mounted on a piezoelectric scanner and a

conductive sample. The tip is positioned within an extremely

close distance, typically a few angstroms, from the sample surface.

b) Quantum Tunneling: When a small bias voltage

(usually ranging from a few millivolts to a few volts) is applied

between the tip and the sample in an STM, electrons have the

ability to tunnel through the vacuum gap separating them. The

likelihood of tunneling exponentially correlates with the width of

this gap.

c) Current Measurement: A feedback loop is employed

to sustain a constant current (typically ranging from a few

picoamperes) by adjusting the tip-sample distance during

scanning. Variations in the tunneling current are utilized to map

the surface topography with atomic-scale resolution.

d) Topographic Imaging: As the tip moves across the

sample surface, changes in the tunneling current occur because

of variations in the distance between the tip and sample surface

induced by surface features. These fluctuations are utilized to

create a topographic image of the sample surface.

e) Atomic Resolution: Since the tunneling current is

highly sensitive to the tip-sample distance, the STM can achieve

atomic resolution by precisely controlling this distance. This

allows researchers to visualize individual atoms and molecular

structures on the sample surface.

Instrumentation of Scanning Tunneling Microscope:

a) Probe Tip: The heart of the STM is a sharp metallic

probe tip, typically made of tungsten or platinum-iridium, with a

radius of a few atoms. The tip is mounted on a flexible cantilever

and brought into close proximity to the sample surface.

b) Piezoelectric Scanner: The sample stage is mounted

on a piezoelectric scanner, which allows for precise control of the

position of the sample relative to the probe tip. The scanner can

move the sample in the x, y, and z directions with nanometer-scale

precision, enabling raster scanning of the probe tip across the

sample surface to generate high-resolution images.

c) Feedback Control System: A feedback control system

is used to maintain a constant tunneling current between the

probe tip and the sample surface during scanning. This feedback

loop adjusts the vertical position of the probe tip by moving the

piezoelectric scanner up or down to keep the tunneling current

constant.

d) Electronics and Amplifiers: Electronics and amplifiers

are used to measure the tunneling current between the probe tip

and the sample surface. The tunneling current is typically in the

range of picoamperes to Nano amperes and requires sensitive

amplifiers to detect.

e) Voltage Source: A voltage source is used to apply a

bias voltage between the probe tip and the sample surface, which

controls the tunneling current. By adjusting the bias voltage,

researchers can change the height of the tunneling barrier and

thus the sensitivity of the STM to surface features.

f) Control and Data Acquisition System: A control

and data acquisition system is used to operate the STM, control

scanning parameters, and acquire data from the tunneling current

measurements. This system typically includes software for

image acquisition, processing, and analysis, as well as hardware

components such as analog-to-digital converters (ADCs) and

digital signal processors (DSPs).

g) Environmental Control: Some STM systems are

equipped with environmental control features to minimize

vibration, temperature fluctuations, and humidity changes that

can affect imaging performance. This may include vibration

isolation tables, temperature-controlled enclosures, and vacuum

chambers (Figure 6).

Advantage of Scanning Tunneling Microscope:

a) Atomic Resolution: The STM provides atomic-scale

resolution, allowing researchers to visualize individual atoms and

molecules on surfaces. This level of detail is essential for studying

surface structures, defects, and chemical bonding at the atomic

level.

b) Versatility: STM can be used to study a wide range of

materials, including metals, semiconductors, insulators, and

biological samples. It is particularly well-suited for analyzing

conducting or semiconducting surfaces due to its reliance on

tunneling current.

c) Non-destructive Imaging: STM imaging is nondestructive,

as it relies on the quantum mechanical tunneling

of electrons rather than physical interaction with the sample

surface. This allows researchers to image samples in their native

state without altering their structure or properties.

d) High Sensitivity: STM is highly sensitive to changes

in tip-sample distance, making it capable of detecting subtle

variations in surface topography and electronic properties. This

sensitivity enables the detection of atomic-scale features and

surface defects with high precision.

e) Real-time Imaging: STM can provide real-time imaging

of sample surfaces, allowing researchers to observe dynamic

processes as they occur. This capability is particularly valuable

for studying surface reactions, growth processes, and surface

diffusion phenomena.

f) Manipulation and Nanolithography: STM can be used

for precise manipulation of atoms and molecules on surfaces

through a technique known as scanning tunneling spectroscopy.

This enables researchers to create nanostructures, manipulate

individual atoms, and study the properties of nanoscale devices.

g) Operational Flexibility: STM can operate in various

environments, including ultra-high vacuum, ambient conditions,

and liquid environments. This flexibility allows researchers to

study samples under conditions relevant to specific applications,

such as catalysis, corrosion, and biological processes.

Quantitative Analysis: STM can provide quantitative

measurements of surface properties, including surface

roughness, height profiles, and electronic density of states. These

measurements are valuable for characterizing material properties

and understanding surface phenomena at the atomic scale.

Limitation of Scanning Tunneling Microscope:

a) Conducting Sample Requirement: STM requires the

sample to be conductive or semi-conductive. Insulating samples

cannot be imaged directly using STM unless they are coated with

a conductive layer, which can alter their properties or introduce

artifacts.

b) Sample Preparation: Sample preparation for STM

can be challenging and time-consuming. Samples must be clean,

flat, and stable to achieve high-quality imaging, and preparation

techniques such as cleaving, annealing, or deposition may be

required.

c) Limited Depth of Field: STM has a limited depth of

field, meaning that only surface features within a narrow range of

heights are in focus at any given time.

d) Tip Wear and Contamination: The STM tip can wear

out or become contaminated over time, affecting imaging quality

and resolution. Tip degradation can lead to imaging artifacts

and require frequent tip replacement or cleaning, increasing

experimental costs and downtime.

e) Vibration Sensitivity: STM is sensitive to mechanical

vibrations, which can degrade imaging quality and resolution.

f) Limited Scanning Area: The scanning area of STM is

relatively small compared to other microscopy techniques. Largearea

imaging require stitching together multiple scans, which is

time-consuming and introduce alignment errors.

g) Temperature Sensitivity: STM performance can be

affected by temperature variations, particularly at cryogenic

temperatures or in environments with temperature gradients.

Temperature stabilization measures may be required for accurate

and reproducible imaging.

h) Low Imaging Speed: STM imaging typically operates

at relatively slow scan speeds compared to other microscopy

techniques such as scanning electron microscopy (SEM) or atomic

force microscopy (AFM). This limitation can be particularly

significant when studying dynamic processes or large sample

areas.

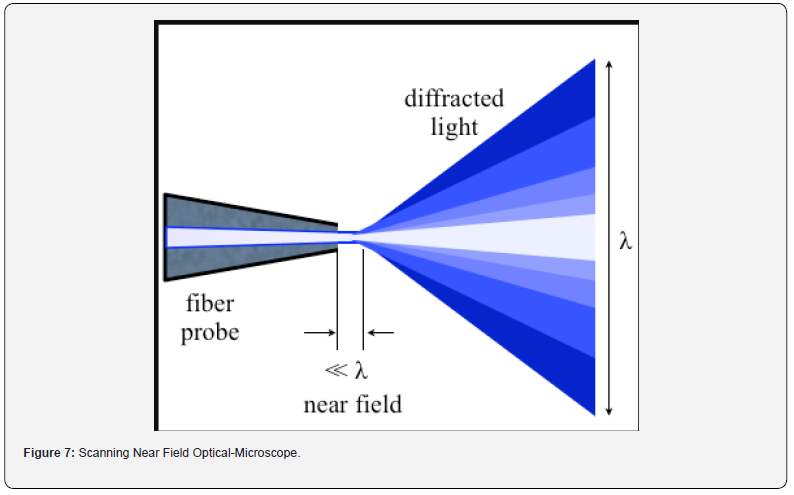

Scanning Near-field Optical Microscope (SNOM or NSOM): Principle of Scanning Near-field Optical Microscope:

The SNOM or NSOM operates on the principle of exploiting the near-field interaction between a sharp probe and a sample surface to achieve sub-diffraction-limited optical resolution. Unlike conventional optical microscopy, which is limited by the diffraction of light, SNOM utilizes the evanescent optical field that extends beyond the optical diffraction limit [43-46].

Sharp Probe Tip: SNOM employs a sharp probe tip, typically

tapered to a nanometer-scale aperture, that is scanned across the

sample surface. The probe tip acts as a nano-sized optical antenna,

interacting with the near-field optical signals emanating from the

sample.

a) Evanescent Near-field Interaction: When the probe

tip is positioned close to the sample surface (within a distance

on the order of the wavelength of light), it interacts with the

evanescent optical field that extends beyond the surface. This

interaction results in changes to the probe’s optical properties,

such as transmission, reflection, or scattering.

b) Detection of Optical Signals: The optical signals

modified by the near-field interaction are detected and analyzed

to generate images or spectroscopic data. Various detection

methods can be employed, including collection-mode SNOM

(measuring transmitted or reflected light) or illuminationmode

SNOM (illuminating the sample through the probe tip and

detecting scattered light).

c) Scanning Probe Operation: The probe tip is scanned

across the sample surface in a raster pattern using precise

positioning mechanisms. By recording the optical signals at each

position, a high-resolution optical image or map of the sample’s

optical properties is generated.

d) Sub-diffraction-limited Resolution: The spatial

resolution of SNOM is determined by the dimensions of the

probe tip and its proximity to the sample surface, rather than

the wavelength of light. This allows SNOM to achieve optical

resolution beyond the diffraction limit, with lateral resolutions

down to tens of nanometers or even below.

Instrumentation of Scanning Near Field Optical-Microscope:

a) Optical Fiber Probe: The heart of the SNOM is a

tapered optical fiber probe, typically made of silica or other

dielectric materials. The probe tip is tapered to a sharp point with

dimensions on the order of the wavelength of light. The probe acts

as both an illumination source and a near-field detector for optical

signals.

b) Cantilever Assembly: The optical fiber probe is

mounted on a flexible cantilever, similar to those used in Atomic

Force Microscopy (AFM). The cantilever allows for precise

positioning of the probe tip relative to the sample surface and

enables scanning in the x, y, and z directions.

c) Piezoelectric Scanner: The sample stage is mounted

on a piezoelectric scanner, which allows for precise control of the

position of the sample relative to the probe tip. The scanner can

move the sample in the x, y, and z directions with nanometer-scale

precision, enabling raster scanning of the probe tip across the

sample surface to generate high-resolution images.

d) Feedback Control System: A feedback control system

is used to maintain a constant distance between the probe tip and

the sample surface during scanning. This feedback loop adjusts

the vertical position of the probe tip by moving the piezoelectric

scanner up or down to keep the near-field interaction constant.

e) Optical Source: An optical source, typically a laser, is

used to illuminate the sample surface through the optical fiber

probe. The laser light is coupled into the probe and focused to a

diffraction-limited spot at the probe tip, creating a highly localized

optical field near the sample surface.

f) Optical Detection System: Light scattered or emitted

from the sample surface is collected by the probe tip and guided

back through the optical fiber to a detector. The detector measures

the intensity, polarization, wavelength, or other optical properties

of the collected light, providing information about the sample’s

optical properties and surface features.

g) Control and Data Acquisition System: A control and

data acquisition system is used to operate the SNOM, control

scanning parameters, and acquire data from the detector.

This system typically includes software for image acquisition,

processing, and analysis, as well as hardware components such as

analog-to-digital converters (ADCs) and digital signal processors

(DSPs).

h) Environmental Control: Some SNOM systems are

equipped with environmental control features to minimize

vibration, temperature fluctuations, and humidity changes that

can affect imaging performance. This may include vibration

isolation tables, temperature-controlled enclosures, and vacuum

chambers (Figure 7).

Figure 4 shows the distribution of socio-economic impacts on forest-dependent communities, including displacement, poverty increase, and loss of cultural heritage [34].

Advantage of Scanning Near Field Optical-Microscope:

a) Sub-diffraction-limited Resolution: SNOM can achieve

optical resolution beyond the diffraction limit of light, allowing for

imaging and spectroscopy at the nanometer scale. This enables

researchers to study optical properties and structures with

unprecedented detail.

b) Nanoscale Optical Imaging: SNOM provides highresolution

optical imaging of nanoscale features, including surface

plasmon polarities, photonic nanostructures, and biological

samples.

c) Real-time Imaging: SNOM can provide real-time

imaging of dynamic processes at the nanoscale, allowing

researchers to observe rapid changes in optical properties or

sample morphology as they occur.

d) Surface Sensitivity: SNOM is highly sensitive to

changes in the local optical properties of the sample surface, such

as refractive index variations, absorption, and fluorescence. This

sensitivity enables the detection of subtle surface features and

optical phenomena that may not be observable with conventional

optical microscopy techniques.

e) Multimodal Imaging and Spectroscopy: SNOM can

be combined with other imaging and spectroscopy techniques,

such as atomic force microscopy (AFM), fluorescence microscopy,

and Raman spectroscopy, to provide complementary information

about sample properties.

f) Non-destructive Imaging: SNOM imaging is nondestructive,

as it does not require staining or labeling of samples.

g) Versatility: SNOM can be used to study a wide range of

materials and sample types, including semiconductors, metals,

polymers, Nano photonics, plasmonics, Biosensing and biological

samples.

Limitation of Scanning Near-field Optical Microscope:

a) Complex Probe Fabrication: SNOM probes require

precise fabrication to produce sharp tips with nanometer-scale

apertures. Fabrication methods such as electrochemical etching

or focused ion beam milling can be time-consuming and may

result in variability between probes, affecting imaging quality and

reproducibility.

b) Limited Signal Collection Efficiency: SNOM typically

collects only a small fraction of the total emitted or scattered light

from the sample surface. This limited collection efficiency can

result in low signal-to-noise ratios, especially for weakly emitting

or scattering samples, making it challenging to obtain high-quality

images or spectroscopic data.

c) Probe-sample Interaction: The interaction between

the SNOM probe tip and the sample surface can influence the

measured optical signals and introduce artifacts. Tip-sample

interactions, such as tip-induced sample deformation or surface

modification, may alter the sample’s optical properties and affect

imaging accuracy.

d) Tip Wear and Degradation: SNOM probe tips can wear

out or become contaminated during scanning, leading to changes

in probe geometry and optical properties. Tip degradation can

degrade imaging resolution and sensitivity, necessitating frequent

probe replacement or cleaning.

e) Sample Preparation Requirements: SNOM imaging

often requires samples to be flat, clean, and optically smooth to

achieve high-quality results. Sample preparation techniques, such

as surface polishing or coating, may alter the sample’s native

properties or introduce artifacts that affect imaging accuracy.

f) Limited Imaging Speed: SNOM imaging typically

operates at relatively slow scan speeds compared to other

microscopy techniques. This limitation can be particularly

significant for large-area imaging or time-resolved experiments,

where long acquisition times may be required.

g) Environmental Sensitivity: SNOM performance can

be sensitive to environmental conditions such as temperature,

humidity, and vibrations. Maintaining stable experimental

conditions is crucial for obtaining reproducible and reliable

imaging results.

Scanning Electron Microscope (SEM) with a Field Emission Gun (FEG):

The Scanning Electron Microscope (SEM) with a Field Emission Gun (FEG) represents a significant advancement in electron microscopy technology. The development of FEG-SEM traces back to the mid-20th century when field emission electron sources were first proposed and studied [47-49].

Principle of Scanning Electron Microscope with Field Emission Gun:

a) Field Emission Electron Source: The FEG utilizes a

sharp tungsten or other refractory metal tip with a nanometerscale

apex. Applying a high electric field to the tip causes electrons

to be emitted from its surface via the quantum mechanical

tunneling phenomenon known as field emission.

b) Highly Focused Electron Beam: The emitted electrons

form a highly collimated beam due to the small size of the emitter

tip and the strong electric field. This focused electron beam is then

accelerated and directed towards the sample surface.

c) Sample Interaction: When the electron beam interacts

with the atoms in the sample, various phenomena occur, including

elastic and inelastic scattering, secondary electron emission,

backscattered electron emission, and X-ray emission. These

interactions depend on the sample’s atomic number, density, and

composition.

d) Detection of Signals: Various detectors within the SEM

capture signals resulting from interactions between the electron

beam and the sample. Secondary electrons, backscattered

electrons, and X-rays are commonly detected and used for imaging

or compositional analysis of the sample.

e) Scanning and Imaging: The electron beam scans across

the sample surface in a raster pattern using electromagnetic or

scanning coils. At each position, the detected signals are processed

to generate an image of the sample surface. Precise control over

beam position and intensity enables high-resolution imaging of

sample morphology.

f) Resolution and Imaging Modes: FEG-SEM typically

achieves sub-nanometer resolution, facilitating detailed imaging

of surface features. Different imaging modes, such as secondary

electron imaging, backscattered electron imaging, and energydispersive

X-ray spectroscopy (EDS), provide complementary

information on sample composition, topography, and material

contrast (Figure 8).

Advantage of Scanning Electron Microscope with Field Emission Gun:/

a) Improved Resolution: FEG-SEM typically achieves

higher resolution than conventional SEMs due to the smaller

electron source size and higher beam brightness. This allows

for the visualization of finer surface features and the imaging of

nanoscale structures with sub-nanometer resolution.

b) Enhanced Beam Brightness: FEG-SEM produces a

highly focused and intense electron beam with a small source size,

resulting in increased beam brightness. This improved brightness

enables sharper imaging, higher signal-to-noise ratios, and better

sensitivity for detecting low-energy secondary electrons and

X-rays.

c) Higher Spatial Resolution at Low Beam Energies:

FEG-SEM can achieve high spatial resolution even at low beam

energies, making it suitable for imaging sensitive or beamsensitive

samples. This capability is particularly advantageous

for studying biological specimens, polymers, and nanomaterials

without causing sample damage or beam-induced artifacts.

d) Reduced Beam Damage: The high beam brightness

and small probe size of FEG-SEM result in reduced beam damage

to the sample compared to conventional SEMs. This allows for

longer imaging times and repeated imaging of the same area

without significant sample degradation, making FEG-SEM suitable

for long-term studies and in-situ experiments.

e) Improved Depth of Field: FEG-SEM exhibits improved

depth of field compared to conventional SEMs, allowing for

clearer imaging of samples with uneven or rough surfaces. This

enables the visualization of three-dimensional surface structures

and topographies with greater clarity and detail.

f) Versatility in Imaging Modes: FEG-SEM offers

versatile imaging modes, including secondary electron imaging,

backscattered electron imaging, and compositional analysis

using energy-dispersive X-ray spectroscopy (EDS). This flexibility

allows researchers to obtain complementary information about

sample morphology, composition, and material contrast in a

single instrument.

g) Increased Stability and Reliability: FEG-SEM systems

are often designed with advanced stability mechanisms and

vacuum systems, resulting in improved instrument reliability and

uptime. This ensures consistent performance and high-quality

imaging over extended periods of operation.

Limitation of Scanning Electron Microscope with Field Emission Gun:

a) Complexity: FEG-SEM systems are more complex

in design and operation compared to conventional SEMs.

The integration of a field emission electron source requires

sophisticated engineering and control systems, leading to

increased complexity in instrument setup, maintenance, and

troubleshooting.

b) High Vacuum Requirement: FEG-SEM systems operate

under high vacuum conditions to maintain electron beam stability

and minimize electron scattering. Achieving and maintaining high

vacuum levels can be challenging and may require specialized

vacuum pumps and stringent cleanliness protocols.

c) Beam Instability: Despite their improved beam

brightness, FEG-SEM systems may still experience beam instability

due to factors such as electronic noise, thermal fluctuations, or

mechanical vibrations. Beam instability can result in image drift,

reduced imaging resolution, and decreased data quality.

d) Sample Charging: FEG-SEM imaging can be susceptible

to sample charging effects, particularly when imaging insulating

materials or non-conductive samples. Sample charging can lead to

image distortions, artifacts, and difficulties in obtaining accurate

surface topography.

e) Beam-induced Damage: While FEG-SEM systems

produce a highly focused electron beam, prolonged exposure to

the beam can still cause sample damage, particularly for beamsensitive

materials. Beam-induced heating, radiation damage, and

surface contamination can affect sample integrity and introduce

artifacts in imaging.

f) Limited Depth of Field: FEG-SEM imaging typically

exhibits a limited depth of field, particularly at high magnifications

and low beam energies. This can make it challenging to obtain

clear images of samples with complex topographies or large

height variations.

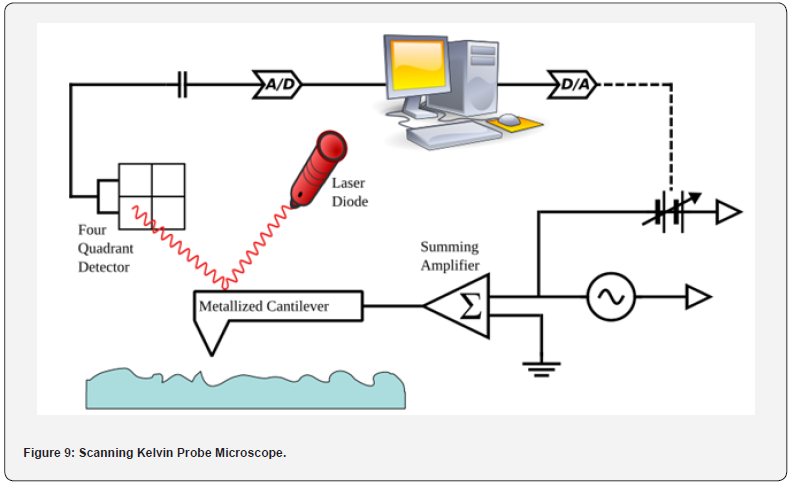

Scanning Kelvin Probe Microscope (SKPM):

The Scanning Kelvin Probe Microscope (SKPM) has its roots in the Kelvin probe technique, which was first developed in the 19th century by Lord Kelvin to measure the work function of metals.

Principle of Scanning Kelvin Probe Microscope:

The Scanning Kelvin Probe Microscope (SKPM) measures the

surface potential of a sample by scanning a conductive probe tip

at a constant height above the sample surface, applying a small

alternating current (AC) bias voltage in the process table.

Conductive Probe Tip: The SKPM probe tip is typically made

of a conductive material such as metal-coated silicon or conducting

diamond. It is brought into close proximity to the sample surface,

maintaining a constant height during scanning.

a) Small AC Bias Voltage: A small AC bias voltage, typically

in the millivolt range, is applied between the probe tip and the

sample surface. This voltage creates an electric field between the

probe and the sample, leading to charge redistribution on the

sample surface.

b) Detection of Electrostatic Force: As the probe scans

over the sample surface, fluctuations in the surface potential

cause variations in the electrostatic force between the probe tip

and the sample. These force changes are observed by monitoring

the deflection of the probe or measuring the capacitance between

the probe and the sample.

c) Feedback Control: A feedback loop is used to sustain

a consistent force or capacitance between the probe tip and the

sample surface by modifying the DC bias voltage applied to the

probe. The amount of DC bias voltage needed to maintain this

constancy is directly related to the surface potential of the sample

at each location.

d) Surface Potential Mapping: By documenting the DC

bias voltage at each position while the probe scans the sample

surface, a surface potential map is created. This map offers insights

into variations in surface charge distribution, work function, and

electrical characteristics of the sample on a nanometer scale.

Instrumentation of Scanning Kelvin Probe Microscope:

a) Probe Tip Assembly: The key component of the SKPM

is the probe tip assembly, which typically consists of a sharp

metallic tip attached to a cantilever. The probe tip is made of a

conductive material such as gold or platinum and is brought into

close proximity to the sample surface during imaging.

b) Cantilever and Scanner: The probe tip assembly is

mounted on a flexible cantilever, similar to those used in Atomic

Force Microscopy (AFM). The cantilever allows for precise

positioning of the probe tip relative to the sample surface and

enables scanning in the x, y, and z directions. A piezoelectric

scanner controls the movement of the sample stage to facilitate

raster scanning of the probe tip across the sample surface.

c) Feedback Control System: A feedback control system

is used to maintain a constant distance between the probe tip and

the sample surface during scanning. This feedback loop adjusts

the vertical position of the probe tip by moving the piezoelectric

scanner up or down to keep the force between the tip and the

sample constant.

d) Kelvin Probe: The Kelvin probe is used to measure the

contact potential difference (CPD) between the probe tip and the

sample surface. The Kelvin probe typically consists of a reference

electrode and a sample electrode, with the CPD being proportional

to the difference in work function between the two electrodes.

e) AC Biasing System: The SKPM applies an AC bias

voltage between the probe tip and the sample surface to measure

variations in surface potential.

f) Lock-In Amplifier: A lock-in amplifier is used to detect

and measure the AC component of the current flowing between

the probe tip and the sample surface. The lock-in amplifier

synchronizes with the AC bias voltage to selectively measure the

signal at the modulation frequency, providing a highly sensitive

measurement of the CPD.

g) Control and Data Acquisition System: A control and

data acquisition system is used to operate the SKPM, control

scanning parameters, and acquire data from the lock-in amplifier.

This system typically includes software for image acquisition,

processing, and analysis, as well as hardware components such as

analog-to-digital converters (ADCs) and digital signal processors

(DSPs).

h) Environmental Control: Some SKPM systems are

equipped with environmental control features to minimize

vibration, temperature fluctuations, and humidity changes that

can affect imaging performance. This may include vibration

isolation tables, temperature-controlled enclosures, and vacuum

chambers (Figure 9).

Advantage of Scanning Kelvin Probe Microscope:

a) Surface Potential Mapping: SKPM provides highresolution

mapping of surface potential variations on a sample

surface. This capability allows researchers to visualize and

quantify surface charge distribution, work function differences,

and electrical properties with nanometer-scale spatial resolution.

b) Non-destructive Measurement: SKPM measurements

are non-destructive and non-invasive, as they do not require

physical contact with the sample surface. This allows for the

characterization of delicate or sensitive materials without altering

their properties or inducing damage.

c) Quantitative Analysis: SKPM enables quantitative

measurement of surface potential values, providing precise

information about the electrical properties of materials. This

quantitative analysis is valuable for studying charge transport

mechanisms, surface reactivity, and device performance.

d) High Sensitivity: SKPM is highly sensitive to changes in

surface potential, making it capable of detecting subtle variations

in charge distribution and work function. This sensitivity allows

for the detection of surface defects, dopant concentrations, and

interface properties at the nanoscale.

e) Multi-modal Imaging: SKPM can be combined with

other scanning probe microscopy techniques, such as atomic force

microscopy (AFM), to provide complementary information about

sample morphology, mechanical properties, and surface potential

simultaneously. This multimodal imaging approach enhances the

understanding of structure-property relationships in materials.

f) Versatility: SKPM can be applied to a wide range of

materials, including semiconductors, metals, polymers, and

biological samples.

g) In-situ and Operando Studies: SKPM can be used for

in-situ and operando studies, allowing researchers to investigate

dynamic processes, such as surface reactions, charge transfer,

and device operation, in real-time. This capability is valuable

for understanding the kinetics and mechanisms of surface

phenomena [50-52].

Limitation of Kelvin Probe Microscope:

a) Surface Sensitivity: SKPM measurements are sensitive

to surface contamination, roughness, and non-uniformities,

which can affect the accuracy and reliability of surface potential

mapping. Surface preparation and cleanliness are critical for

obtaining meaningful results.

b) Sample Conductivity Requirement: SKPM requires

samples to be at least semi-conductive or electrically grounded

to obtain accurate surface potential measurements. Insulating

samples may exhibit charge accumulation or surface charging

effects, leading to inaccurate results or image artifacts.

c) Complexity of Interpretation: Interpreting SKPM data

and extracting meaningful information about sample properties

can be challenging, particularly for heterogeneous or complex

materials. Calibration procedures, data analysis algorithms,

and model assumptions may introduce uncertainties in surface

potential measurements.

d) Limited Depth Sensitivity: SKPM is inherently a

surface-sensitive technique, with limited depth penetration into

the sample. It provides information about the surface potential

but does not provide depth-resolved measurements of subsurface

layers or buried interfaces.

e) Topography Coupling: Surface topography variations

can affect SKPM measurements by modulating the probe-sample

distance and influencing the electrostatic force between the