Evaluating Global Ecological Risk and Sustainable Development: A Study on Post-Blasted Explosive on the Ecosystem in Akamkpa Local Government Area of Cross River State, Nigeria

Ubong Ime Udoakpan1* and Ubong Okon Timothy2

1Department of Forestry and Natural Environmental Management, Faculty of Agriculture, University of Uyo, Nigeria

2Department of Theology, Edem Inyang Eshiet Theological Seminary, University of Uyo, Nigeria

Submission: March 21, 2023; Published: April 03, 2023

*Corresponding author: Ubong Ime Udoakpan, Department of Forestry and Natural Environmental Management, Faculty of Agriculture, University of Uyo, Nigeria

How to cite this article: Ubong Ime Udoakpan and Ubong Okon Timothy. Evaluating Global Ecological Risk and Sustainable Development: A Study on Post-Blasted Explosive on the Ecosystem in Akamkpa Local Government Area of Cross River State, Nigeria. JOJ scin. 2023; 3(2): 555608. DOI: 10.19080/JOJS.2023.03.555608

Abstract

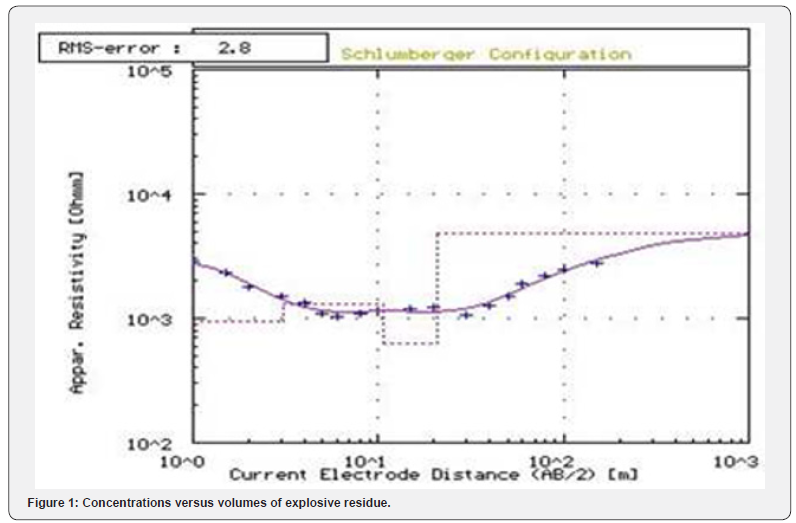

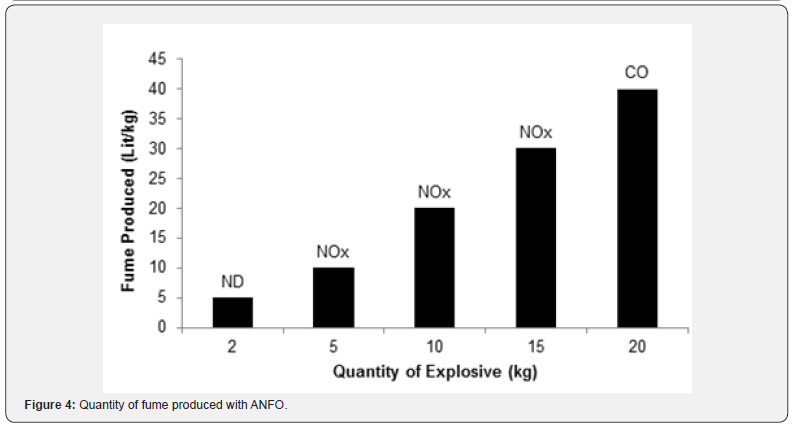

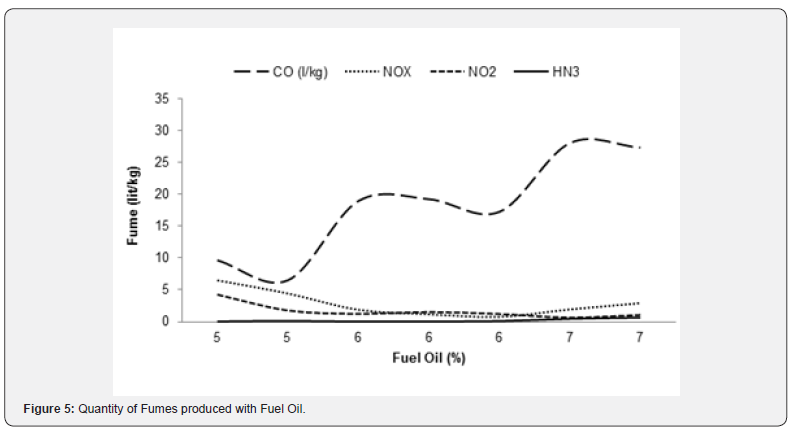

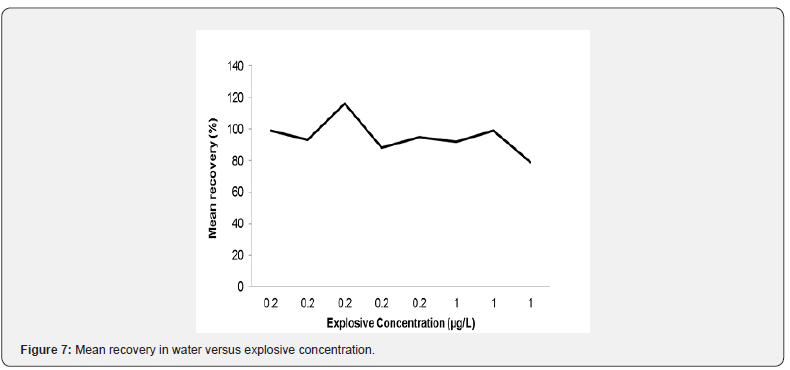

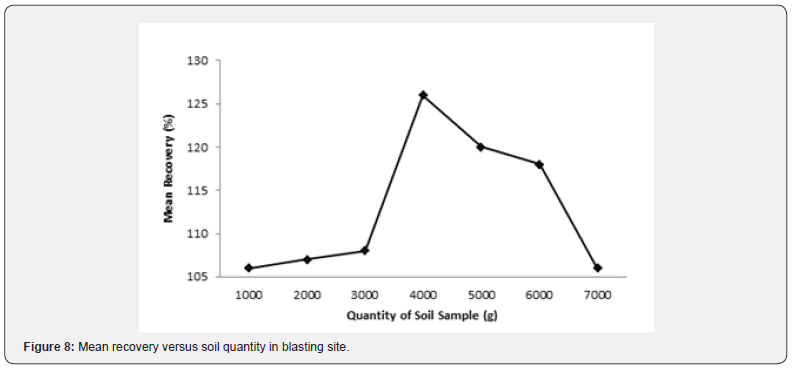

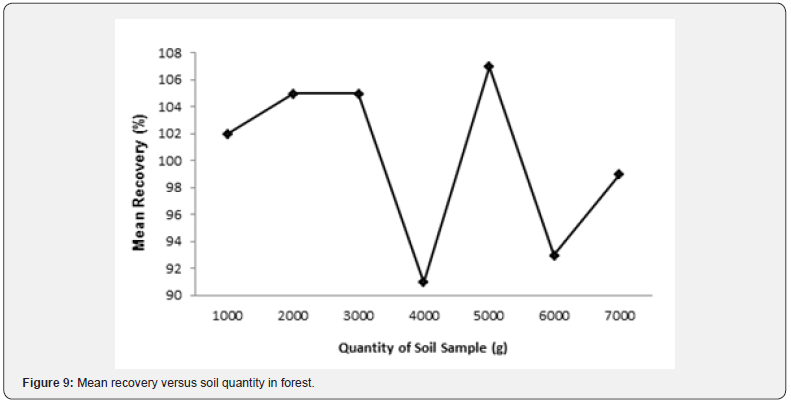

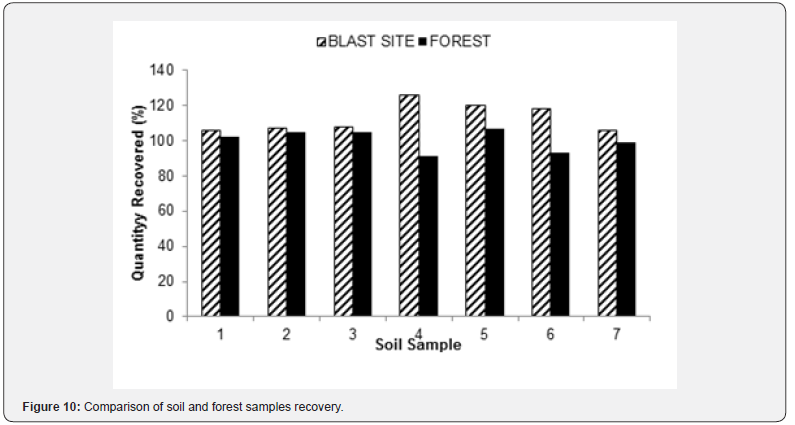

The study investigated the effects of post-blast explosive residues on ecosystems around Prodeco Quarry industry in Calabar Nigeria by collecting explosives residues and air/fumes samples. The variation between the intensity and temperature of explosive dissolution in the mine environment shows that trinitrotoluene (TNT) appears at the lowest temperature of 100°C and Pentaerythritol Tetranitrate (PETN) reflected at about 350°C and nitroglycerin (NG) shows almost at 580°C. Consequently, 5-15 kg of ammonia nitrate fuel oil (ANFO) produced 10-30 lit/kg of nitrogen oxide compound (NOx) fumes while 20 kg ammonia nitrate fuel oil (ANFO) produced 40 lit/kg of carbon monoxide fume. Also, 0.2 μg/L concentration of explosive in water recorded the highest mean recovery of 116.0% while 1.0 μg/L recorded the highest values of 99.0%. The mean recovery in soil sample is range between 105.0-126.0% while that of forest is range between 91.0-107.0% with the 50.0μg/L concentration of explosive. The study concluded that the contaminating effects of the explosives residues have direct and indirect influences on the growth and development of the ecosystems. The study also recommend that quarry operators should ensure appropriate and proper selection, application and detonation of explosives during quarry operations. In the early twenty-first century, the earth supports a human population that, in general, is more numerous, healthier and wealthier than ever before. At the same time, there is an unprecedented awareness of the risks that face people, and what they value, throughout the world. Some of this concern is associated with the death and destruction caused by ‘natural’ hazards such as earthquakes and floods. Other anxieties focus on threats that are perceived as ‘man-made’, including industrial explosions, major transport accidents and other failures of technology..

Keywords: Global; Ecological Risk; Sustainable Development; Earthquakes; Floods

Abbreviations: TNT: trinitrotoluene; PETN: Pentaerythritol Tetranitrate; NG: Nitroglycerin; ANFO: Ammonia Nitrate Fuel Oil; SPE: Solid Phase Extraction; HPLC: High-Performance Liquid Chromatography; UV: ultraviolet; PTFE: Polytetrafluorethylene; PTV: Programmed Temperature Vaporizing; SIM: Selected Ion Monitoring; MSHA: Mine Safety and Health Administration; VOD: Velocity of Detonation

Introduction

The interpretation and understanding of Global Ecological Risks and Sustainable Development has changed significantly through history. A concern for earthquake and famine has existed since the earliest times [1]. In the past, these great catastrophes were seen as ‘Acts of God’. This perspective suggests that damaging events are a divine punishment for moral misbehaviour, rather than a consequence of human use of the earth. It encouraged a general acceptance of disasters as external, inevitable events. [2] saw that natural hazards are not physical phenomena outside of society but are linked to countless individual decisions to settle and develop risks-prone land. His contribution was to introduce a social perspective (human ecology) into hazard mitigation and to question whether truly ‘natural’ hazards really exist at all. A new field of environmental risks research began to emerge and soon exposed differences in approach. Whilst earth scientists geologists, meteorologists, hydrologists and civil engineers worked to predict extreme natural events and construct defensive control works, geographers and others explored a wider programme of loss mitigation through human adjustments, such as disaster aid and better land planning.

White’s approach was strengthened by the subsequent recognition of ‘man-made’ or technological hazards, notably environmental pollution, described as a ‘quasi-natural’ hazard [3] This hazards-based viewpoint, using a blend of structural and non-structural measures, became widely accepted and, during the 1970s, books from the North American research school inspired by White [2,3] consolidated what became known as the behavioural paradigm.

Ecological risk is defined as a process that evaluates the likelihood that adverse ecological effects may occur or are occurring as a result of exposure to one or more stressors. A risk does not exist unless [1] the stressor has the inherent ability to cause one or more adverse effects and [2] it occurs with or contacts an ecological component (i.e., organisms, populations, communities, or ecosystems) long enough and at a sufficient intensity to elicit the identified adverse effect. Ecological risk may evaluate one or many stressors and ecological components. Ecological risk may be expressed in a variety of ways. While some ecological risk assessments may provide true probabilistic estimates of both the adverse effect and exposure elements, others may be deterministic or even qualitative in nature. In these cases, the likelihood of adverse effects is expressed through a semi-quantitative or qualitative comparison of effects and exposure. Ecological risk can help identify environmental problems, establish priorities, and provide a scientific basis for regulatory actions. The process can identify existing risks or forecast the risks of stressors not yet present in the environment. However, while ecological risk assessments can play an important role in identifying and resolving environmental problems, risk assessments are not a solution for addressing all environmental problems, nor are they always a prerequisite for environmental management. Many environmental matters such as the protection of habitats and endangered species are compelling enough that there may not be enough time or data to do a risk assessment. In such cases, professional judgment and the mandates of a particular statute will be the driving forces in making decisions.

The applications of explosive in exploration and exploitation of mineral through blasting operations have greatly contributed to the development of the utilization of numerous mineral resources. On the other hand, the fumes and others residues of the blasted explosives have caused a lot of biodegradation and hazardous impacts on ecosystem survival in a quarry environment [4]. Srivastava & Vellend [5] defined ecosystems as the network of interactions between organisms and their environment, which can be of any size but usually encompass specific, limited spaces. Meanwhile, Erick et al. (2013) described explosive as materials which are in a metastable state and are capable of undergoing a rapid chemical reaction without the participation of external reactants such as atmospheric oxygen. Katarzyna et al. [6] established the use of explosives in large scale by both the military and industries such as mining industries, high-energy metalwork industries, munitions manufacturing industries and civil engineering industries which have resulted in high levels of ecosystem contamination. According to Maurie & Priyadarshi [7] the most relevance field of applications of explosives among others is in the mining through blasting operations in both surface and underground mining activities.

The surface mining applications of explosives include quarrying and open pit mineral extraction for the production of granite aggregates, stone base and asphalt used in construction of building, bridges and roads; limestone, marble, shale for cement factories; metal productions coppers, gold, iron ore for steel companies [8]. Meanwhile, the underground mining applications of explosives include coal production, metal production, uranium and radioactive metals [9]. Explosives are made up of either a pure chemical compound or a mixture of several chemical compounds that react violently and vigorously to produce explosion spontaneously or on initiation [10,11]. Harold and Douglas [12] and Per-Aders Persson et al., (2009) classified explosives based on their physical/ chemical properties as: gelatin explosive (dynamites, barbarite and boosters); powder explosive (ammonite, methanite, carbonites charge for splitting rock and ANFO) and emulsion explosive (bulk emulsion explosive and cartridge emulsion explosives).

According to Winfield et al. [13] there has been presence of 2,4,6-trinitrotoluene (TNT), hexahydro-1,3,5-trinitro- 1,3,5-triazine (RDX, hexogen) and octahydro-1,3,5,7-tetranitro- 1,3,5,7-tetrazocine (HMX, Octogen) in soil, surface water and groundwater where these explosives are being used. Most of the blasted explosives are stable in soil due to their chemical structures and easily binding to the soil organic matter, which making soil remediation difficult [14]. Also, the high concentration of Trinitrotoluene, Hexogen and Octogen have resulted to decrease in terrestrial plant biomass, abnormality growth in terrestrial plants and decrease in biomass and fertility of earthworm [13-17] Domestic consumption of explosives and blasting agents during the year 2002 was about 5.53 billion pounds [18]. Out of this, about 3.79 billion pounds (68.5%) were used in coal mining, 1.17 billion pounds (21.1%) in metal and nonmetal mining, and 417 million pounds (7.5%) in construction blasting [18]. As a result of the frequent uses of explosive and explosive materials in Prodeco Quarry, this study, thereby assess environmental effects of post-blasted explosive on the ecosystem of Old Netim Village in Akamkpa Local Government Area of Cross River state, Nigeria.

Materials and Methods

Description of the Study Area

Prodeco Nig. Ltd is located at Old Netim Village in Akamkpa Local Government Area of Cross River state between latitude 5033’0”N to 6054’0”N and longitude 8018’0”E to 8039’30”E. The quarry site is located adjacent to thick forest and surrounded with water where both terrestrial and aquatic habitats reside. The quarry is near a community that their major occupation is farming. The major operation of the company is quarrying of granite deposit for construction purposes which include drilling and blasting using explosive and explosive materials for rock fragmentation and crushing of the blasted rock into aggregate uses for construction purposes. Akamkpa as a tropical rainforest. The natural forest has been exploited through cleaning and felling to meet demands for food, timber and fuel wood. Over the years this forest as witnessed intense human activities such as farming, lumbering and quarrying activities which has hampered regeneration.

The geology of the study area is Nnetim which is made up of basement complex rocks. Soil properties vary with topography and orientation of the hill-slope. The soils are generally sandy loam soil to lateritic clay soils. The climate of the area is humid tropical, characterized by double maxima rainfall, which starts from the month of April to October, reaching its climax in the month of June and September. The annual average is about 1500- 3000mm. temperature ranges from 21°C-23°C in the wet season and 24°C-27°C in the dry season. The area records a relative humidity between 80-100% and vapour pressure in air average 29 millibars throughout the year (NAN, Weather Reports, 2014, CRBDA report 2006).

Residues Samples of Explosive

The explosives residue samples were collected by swabbing the surface of the post-blast debris and skin with wet cotton ball. The cotton balls were wet as already been soaked in 0.50 mL (50:50 water: methanol). The samples collected by cotton swabs were kept inside polythene bag for laboratory analyses. In the laboratory, the captured explosives were extracted from the cotton ball into water. The cotton ball was placed at the bottom of a 10-mL plastic syringe; drawn 10 mL of water into the syringe, the syringe was allowed to stand for 15 minutes before releasing the water from the syringe into a collection tube. Then Solid Phase Extraction (SPE) was applied to the 10-mL extract to isolate the organic explosives. A 3-mL, Waters Oasis Sorbent, SPE tube was conditioned, loaded with extract, washed, and explosives escaped with methanol, followed by direct analysis of the resulting extract solution using high-performance liquid chromatography (HPLC) with ultraviolet (UV) detector. Analysis was performed on an octadecylsilane- based (C18) column using acetonitrile-water mixture (55:45) as mobile phase in accordance with [18-21]. The mobile phase was pumped at 1.0 mL/min and separation affected using an isocratic mode with the detection wavelength of 230 nm. The procedure was repeated with various volumes of extract using larger sizes of plastic syringe 20 mL, 30 mL, 40 mL, 50 mL, 60 mL, 70 mL, 80 mL, 90 mL, 100 mL and different concentration results of explosives (PETN) contents in water were obtained and recorded.

Water Samples

Water samples were collected from open pit mines sump, surface (hole) reservoir and nearby estuary to the blasting site. The water was sampled with washed and rinsed plastic containers in accordance with APHA (1998) standard methods before taken to laboratory for analysis. The 100 mL water samples were passing through a solid phase extraction (SPE) cartridge containing 500 mg of a divinylbenzene/vinylpyrrolidone copolymer and a 47 mm disk containing a reverse phase sulfonated polystyrene divinylbenzene phase in accordance to EPA 3535A standard method to detect the explosive and extracted. 4 ml of acetonitrile was used to elect extracted components of the sulfonated polystyrene divinylbenzene phase cartridge, followed by final dilution to exactly 5 ml with acetonitrile. A white precipitate formed by mixing the diluted extract was removed with a 0.45μm polytetrafluorethylene (PTFE) syringe filter.

The sample components were separated, identified, and measured by injecting an aliquot of the concentrated extract into a high resolution fused silica capillary column of a GC/MS system with a programmed temperature vaporizing (PTV) injector. Compounds eluting from the GC column were identified by comparing their measured mass spectra and retention times to reference spectra and retention times in a database. Analysis was performed using full scan and selected ion monitoring (SIM) mass spectrometry. Reference spectra and retention times for analyses were obtained by the measurement of calibration standards under the same conditions used for samples. The concentration of each identified component was measured by relating the MS response of the quantization ion(s) produced by that compound to the MS response of the quantization ion(s) produced by a compound that is used as an internal standard. The mean recovery from seven replicate 500 mL water samples extracted using solid phase extraction cartridge and with a final volume of 5 mL of acetonitrile was recorded.

Air Samples

Air samples were collected from the blasting chamber. A total volume of blasting chamber of 79.236ft3 (25.56 m3) was created in the mineral ore body (granite) at the Prodeco quarry, enclosed between two explosion proof bulkheads. The collection of the fumes was carried out by detonating explosive (primer) with blasting agent and confining the fumes. Following the shot, a fan mounted at one end of the chamber mixes the chamber atmosphere at 3,500 ft3 /min. The samples were taken to laboratory for analyses. The fumes collected were analyzed using bubblers or vacutainers to collect samples for analysis at the analytical chemistry lab according to Mine Safety and Health Administration (MSHA) and International Makers of explosives in Pittsburgh Research Center’s Experimental Mine. Measurements and test analyses of fumes produced by blasts enable the determination of fumes that were produced. The procedure was repeated with different quantity of ammonia nitrate fuel oil (ANFO) and the following fume production results were recorded.

Soil Samples

Soil samples were collected from nearby forest around the quarry locations and other samples were collected around the blasting phase of the company. The soil samples were collected between the depths of 0 - 15cm with an auger and kept in a well labeled air tight polythene bag before transfer to the laboratory for analysis. A quantity of 1000 g was taken from each soil sample and mixed with methanolacetonitrile; shake for about 5 minutes using mechanical shaker, followed by extraction in an ultrasonic bath with the use of acetonitrile. The separation of explosives in liquid extracted samples was conducted with the use of Thermo Scientific, Hypersil Gold C18 250 × 4.6 mm chromatography column (filling granulation - 5 μm) proceeded with precolumn Hypersil Gold 10 × 4 mm (filling granulation - 5 μm). The detection of explosives was done by the method of high performance liquid chromatography. The procedure was repeated for different quantities of the various soil samples collected at mine and forest sites 2000g, 3000g, 4000g, 5000g, 6000g, 7000g. Explosives concentrations in the soil sample were measured in accordance with EPA Method 8095. The explosives contamination (accumulation) was measured in each soil sample and recorded.

Results and Discussion

Explosive Residue: Figure 1 shows that high accumulation of explosive residue in a blasting environment yield increase in concentration of contaminating the lives of terrestrial and aquatic habitats living in estuaries around the blasting area. The graph shows that concentration is directly and indirectly increasing as the volume of the analyte increases. Meaning that there is tendency of high adverse effects on the natural organic matters as the increase in volume is proportional to increase in concentration. Figure 2 shows the variation between the intensity and temperature of explosive dissolution in the mine environment. It was discovered that explosive contents were identified separately by the intensity of individual components as they appeared at different temperatures and compared to limit detection table whereby different explosive components signified at different temperature, such that TNT appears at the lowest temperature of approximately 100C and PETN reflected at about 350C and NG shows almost at 580C. Thus, explosive dissolution from the solid residue occurs in stages with temperature changes; thereby determines the level of contaminations in the blasting environment (topsoil and water) based on temperature difference. This implies that the potential for high intensity increases with increase in temperature which enhanced life deteriorations and gaseous emissions to the mine’s environment.

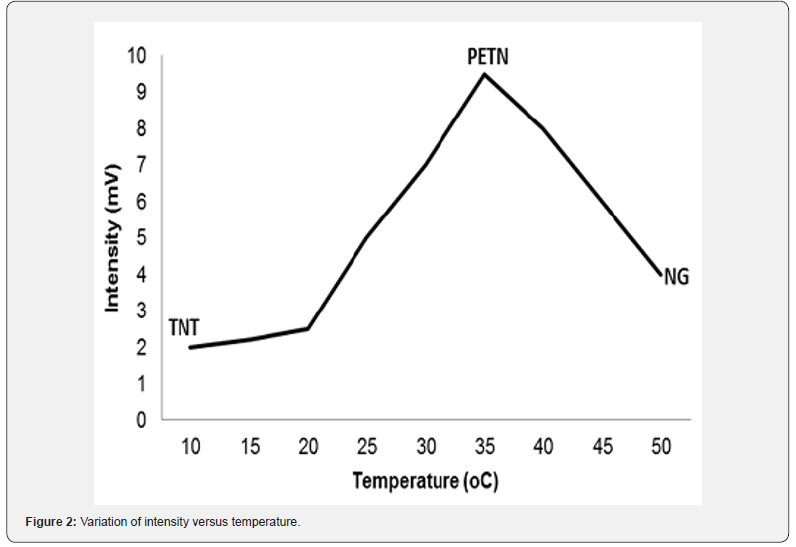

Moreso, Figure 3 shows that the intensity of analyte increases with time. This means that time (frequency) is the important factor that determines explosive impacts on the mine’s environment. As often as the residue is produced from holes charging and deflagration results, as much as contamination of the environment grows consequentially and diminishes as long as soil consumed the chemical components.

Air Sample: Figures 4 shows the levels of toxic fume produced with the quantity of the explosive detonated. The generation of the fume depends on the quantity of explosives and blasting agent being used. The graph shows that when 2 kg of ammonia nitrate fuel oil (ANFO) was used no fume was detected, but when 5 – 15 kg of ANFO was used, nitrogen oxide compound (NOx) was the major fume detected while carbon monoxide was the fume detected when above 15 kg of explosive was used. This revealed that the more the quantity of explosive used, the more poison fume produced. The nitrogen oxide compound and carbon monoxide released to the atmosphere from blast explosives contaminate both the ecosystems and the environment due to their poisonous nature. The long time exposure to these gases caused the various health hazards for ecosystem and quarry workers witness with the environment.

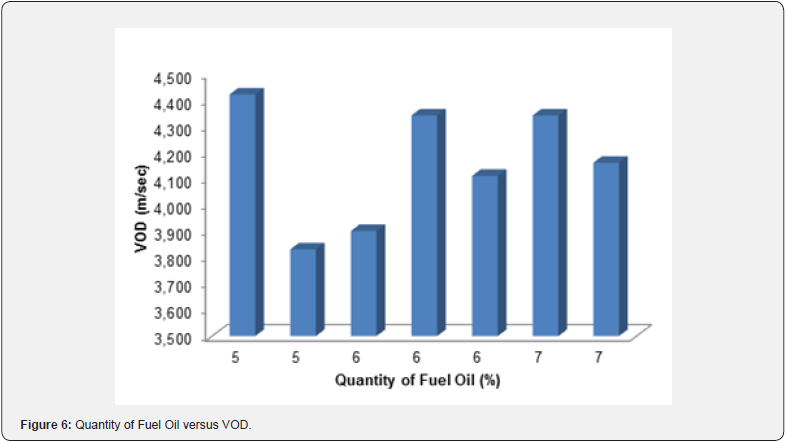

Also, Figure 5 shows the quantity of fuel oil being used when mixing ANFO. The higher the fuel quantity the higher the fumes produce and the higher its environmental contamination. The predominant fume that is normally produced when using higher fuel is carbon monoxide which is dangerous to both man and animal within the blasting environment. Other fumes that are produced are also dangerous as well despite the little quantity, but can easily be transformed to higher useful compounds. However, Figure 6 shows that variations of fuel oil affect velocity of detonation (VOD) which implies that low VOD results in fume production and in turns yield contamination of the environment.

Water Samples: Figure 7 shows that water samples have different explosive concentrations that caused environmental contaminations to both aquatic and terrestrial habitats. The highest mean recovery was recorded at 116.0 % when the concentration of explosive is 0.2 μg/L while 99.0 % was recorded when the explosive concentration is 1.0 μg/L. This implies that explosives contamination of water has toxic effect on the ecology and man who depend on the water source for survival. The ionic products of explosives that reacted with the water rendered the water toxic to health, and corrosive to the mining equipment while the purification expenditure of this contaminated water usually results to loss in mine economics. The infiltration and percolation process of water from the surface to the depth usually carries a trace ionic quantity of explosives to underground that influences the taste of underground water within the study area.

Soil Samples: Figure 8 illustrates that concentration of explosive contents in blasting site is very high as a result of immediate deposition of blast explosive residues causing cascading, karsts and geomorphic generation from repeated explosive chemical reactions that alter material properties of soil and rocks within the quarry environment.

Consequently, there was increased in explosive contamination within the blasting area until a stage whereby the residual accumulation was spread to immediate environments through erosion and denudation and diminishing in concentration was manifested.

Figure 9 shows continuous spreading of explosives residues and their variable concentration changes in the nearby forest. Consequently, the effect of explosives contamination on wildlife, microorganisms, plants, man and vegetation was manifested from growth and development retardation and hazardous health conditions due to their interrelated and interdependent in food chain and food web within an ecosystem or habitat. Figure 10 compares the mean recovery which shows higher distribution of explosive in blasting site than in the forest simply because of repeated explosion and direct residual deposition on the blasting site immediate environment; whereas the forest is indirectly contaminated through agents of erosion and denudation (wind, water, waves and gravity) with limited and uneven distribution of residual explosives. This has an impact on the natural habitat of living organisms within the reach of the explosives at the blasting site more than in the forest.

Conclusion

The contamination from blast explosives residues in quarry operations go beyond visible assessment as usually insinuated by the miners but it requires scientific and technological detection. The analyses demonstrated have confirmed the presence of explosives residues; carbon monoxide, nitrogen oxides, dust, smoke, undetonated and deflagrated explosive compounds as contaminants in quarry and its environments. The contaminant effects of the explosives residues have their direct and indirect influences on the growth and development of the ecosystems, the biodegradation, geomorphic, cascading, karsts and other topographic deformations which affect the quarry environments landslide and inhabitants. The direct contamination effects of residual explosive on living inhabitants of an ecosystem include eye irritation, health deterioration, air, water and land pollutions, and the indirect influences are on inanimate living creatures upon which man and animal depend. The plants and vegetation that are responsible for photosynthesis and oxygen production are suffering undergrowth and development which in return have effects on animate creatures that depend upon them.

Recommendation

The study therefore suggested that quarry operators should ensure appropriate and proper selection, application and detonation of explosives during quarry operations. The proper selections of explosive usage will enhance total detonation and prevent deflagration which might yield residue generation while proper application will protect wastage that accumulate as contaminants which might hinder soil fertilities and fuel generation through chemical reactions that kill bio-organisms like bacteria, fungi, algae and others.

References

- Vincent T Covello, Jeryl L Mumpower, Pieter Stallen JM, Uppuluri VRR (1985) Environmental Impact Assessment, Technology Assessment, and Risk Analysis. Contributions from the Psychological and Decision Sciences (Nato ASI Subseries G:) Softcover 4.

- Macdonald N, Chester D, Heather Sangster, Todd B, Hooke J, et al. (1945) The significance of Gilbert F White’s 1945 paper ‘Human adjustment to floods’ in the development of risk and hazard management 36(1): 125-133.

- Burton, Katherine (1964) Bells on two rivers the history of the Sisters of the Visitation of Rock Island Illinois Milwaukee Bruce Pub Co pp: 118.

- Juhasz AL, Naidu R (2007) Explosives: fate, dynamics, and ecological impact in terrestrial and marine environments. Rev Environ Contam Toxicol 191: 163-215.

- Srivastava DS, Vellend M (2005) Biodiervsity ecosystem function research: is it relevant to conservation? Annual review of Ecology, Evolution and Systematics 36: 267-294.

- Katarzyna P, Korneliusz M, Tadeusz S (2013) Synergetic toxic effect of an explosive material mixture in soil. Bulletin of Environmental Contamination and Toxicology 91(5): 555-559.

- Maurie P, Priyadarshi H (2011) Blasting - Technology solutions for mining. Techno Mine.

- Meyer R, Köhler J, Homburg A (2007)Explosives, 6th, Compl. Weinheim: Wiley-VCH Verlag GmbH, Weinheim, Germany.

- Cooper Paul (1996) Explosives engineering. Wiley-VCH, Inc. United States of America. EPA Method 3535A: Solid-Phase Extraction (SPE). EPA site. EPA Method 8095: Explosives by Gas Chromatography. EPA site 20: 460.

- Porterfield WW (1993) Inorganic chemistry of explosive: A unified approach, 2nd ed., Academic Press, Inc., San Diego, pp: 479-480.

- Akhavan J (2011) The chemistry of explosives, 3rd Edition. Norfolk: Biddles Ltd., Kings Lynn, Norfolk, Virginia.

- Harold DM, Douglas KW (2009] A Guide to the safe storage of explosive materials. Occupational Safety and Health Division, NCDOL, Raleigh p: 7.

- Winfield LE, Rodgers JH, D Surney SJ (2004) The responses of selected terrestrial plants to short (<12 days) and long term (2, 4 and 6 weeks) hexahydro-1,3,5-trinitro-1,3,5-triazine (RDX) exposure Part I: growth and developmental effects. Ecotoxicol 13(4): 335-347.

- Rocheleau S, Lachance B, Kuperman RG, Hawari J, Thiboutot S, et al. (2011) Biodegradation and biotransformation of explosives. Curr Opin Biotechnol 22(3): 434-440.

- Best EPH, Geter KN, Tatem HE, Lane BK (2006) Effects, transfer, and fate of RDX from aged soil in plants and worms. Chemosphere 62(4): 616-25.

- Vila M, Lorber Pasca S, Laurent F (2007) Fate of RDX and TNT in agronomic plants. Environ Pollut148(1): 148-154.

- Krishnan G, Horst GL, Shea PJ (2000) Differential tolerance of cool- and warm-season grasses to TNTcontaminated soil. Int J Phytoremediation 2(4): 369-382.

- USGS [2003] Minerals Information. Explosive Web.

- Sunahara GI (2008) Toxicity and uptake of cyclic nitramine explosives in rye-grass Lolium perenne. Environ Pollut 156(1): 199-206.

- Lachance B, Renoux AY, Sarrazin M, Hawari J, Sunahara GI (2004) Toxicity and bioaccumulation of reduced TNT metabolites in the earthworm Eisenia andrei exposed to amended forest soil. Chemosphere 55(100): 1339-1348.

- Umi KA, Sumathy R, Syahidah AH (2008) Forensic analysis of explosive residues from hand swabs. The Malaysian Journal of Analytical Sciences 12(1): 25-31.