Application of Extended Cohesive Damage Model in Predicting Novel Sandwich Composites with Graded Layered Core

Surya Ghimire and Jiye Chen*

School of Civil Engineering and Surveying, University of Portsmouth, UK

Submission: June 06, 2018; Published: June 26, 2018

*Corresponding author: Jiye Chen, School of Civil Engineering and Surveying, University of Portsmouth, Portland Street, Portsmouth PO1 3AH, UK, Email: jiye.chen@port.acuk

How to cite this article: Surya Ghimire, Jiye Chen. Application of Extended Cohesive Damage Model in Predicting Novel Sandwich Composites with Graded Layered Core. JOJ scin. 2018; 1(3): 555565. DOI: 10.19080/JOJS.2018.01.555565

Introduction

This paper presents a highly efficient approach in predicting Novel Sandwich Composites with Graded Layered Core (NSCGLC) using the extended cohesive damage model (ECDM). Graded sandwich composites have drawn extensive attention from academics and engineers in the composite society in the last twenty years. In traditional sandwich structures, the core between the top and the bottom fibre laminates is single foam material with homogeneous property. This sandwich construction has two interfaces between core and the top and the bottom laminates respectively. At the interfaces miss matched materials may bring interfacial fractures e.g. delamination thus sandwich structures lose loading capacity.

In this investigation, the foam core is proposed to be graded material mimicked from bio-tube composites to have good behavior in failure mechanism. To achieve the best mechanical behavior, the ECDM was used to predict the failure mechanism with multiple delaminations in the NSCGLC. An example given in this investigation show that the detailed failure mechanism of graded sandwich composites was studied well by the ECDM, and an excellent outcome was achieved through the modeling prediction, which shows the loading capacity of the proposed sandwich composite with graded multiplayer foam core is increased by 45% compared to traditional sandwich composites with single or normal foam core.

The Formulations of the ECDM

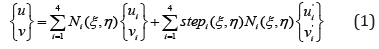

A brief description of the ECDM formulations is given in this section. Its detailed theory can be referred to the [1,2]. The Displacement Approximation Within A Specified Cracked Element Can Be Expressed By Eq. (1):

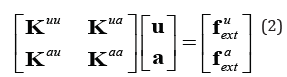

In which u and v are the displacement along x axis and y axis in 2D domain, respectively. In Eq. 1 the H is standard Heaviside step function. Using the weak form of equilibrium equation from Bubnov-Galerkin method, the discrete form of equilibrium equation for static analysis can be written as shown in Eq. (2).

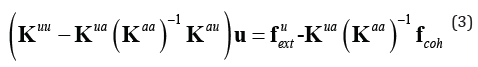

Where, Kuu and Kaa are the stiffness matrices associated with the standard FE approximation and the enriched approximation, respectively; Kua and Kau account for the coupling between the standard FE approximation and the enriched approximation; uextfand aextfare the equivalent nodal force vectors for standard FEM DoFs and enriched DoFs, respectively; u denotes the standard DoFs while a denotes the enriched DoFs. In a fully condensed equilibrium system, the additional enrichment term as is eliminated, thus the equilibrium equation with the standard FEM unknown quantities can be consequently obtained as shown in Eq. 3:

Where, the internal nodal force vector fcoh due to cohesive traction on the crack surface crackÃelement can be expressed as:

in which t is the traction between the two crack surfaces within the specified failure element.

Graded Layered Sandwich Composites

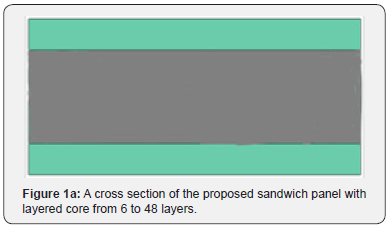

Figure 1a shows a cross section view of proposed novel sandwich panel. Its core is a graded layered foam material. The top and the bottom laminates are normal glass fibre laminates with 0°/90° lay-up. The basic foam material has Young’s modulus 89MPs. The core was designed as a multilayered in terms of bio-mimicked construction [3]. Multilayered cases with 6, 12, 16, 18, 24, 48 layers in the core were investigated. The Yang’s modulus at each layer is varied by either increased or decreased grade. At the two interfaces, the material gap was much reduced thus materials miss matched problem was mitigated.

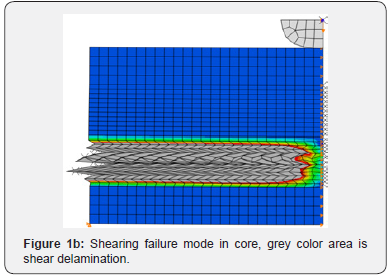

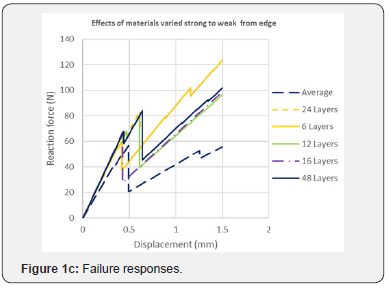

The ECDM technique was used to investigate the fracture behavior of the graded layered sandwich panel. Figure 1b shows a half model with shearing failure mode in the core predicted by the ECMD. The shearing failure started from the interface between the core and the bottom laminates then propagated toward the middle of the core. The shearing fracture initiated at the edge and moved to the centre of the panel. The failure responses can be seen from Figure 1c in which 5 layered core cases are presented and compared to the case of normal core case. It can be seen from Figure 1c that all graded layered core cases have higher loading capacity compared to the normal core case. It should be noted that the core with 6, 12 and 16 graded layers have a macro crack at the displacement of 0.5mm, while, the core with 24 and 48 layers have a micro crack at the same displacement, their corresponding macro crack occurs at the displacement of 0.7mm. Compared the loads at the macro crack state, the case with 48 graded layers increases loading capacity by 45% from the one of normal core case presented by dash line with label of average in Figure 1c.

Conclusion

The proposed sandwich composites with graded layered core were successfully investigated using the ECDM model. The investigation shows a very promising outcome in increasing loading capacity. In the future, this proposed sandwich panel can be manufactured using additive manufacture technology to conduct proposed graded layered core. This would be a costeffective approach for the next generation of sandwich composites.

References

- X Li, J Chen (2016) An extended cohesive damage model for simulating multi crack propagation in fibre composites. Composite Structures 143: 1-8.

- J Chen (2002) Predicting progressive delamination of stiffened fibrecomposite panel and repaired sandwich panel by decohesion mode. Journal of Thermoplastic Composite Materials 15(5): 429-442.

- J Chen (2013) Improvement of damage resilience of composites Bio-Based Composites for High-Performance Materials: From Strategy to Industrial Application. CRC press, Taylor and Francis, UK, England.