Abstract

One of the most important properties in packaging paper are water and oil water repellent. Sizing and coating of packaging papers can enhance the barrier properties. Researchers use different material to improve these properties. In this research, the effect of using alum-rosin as internal sizing and zein as surface sizing to improve the barrier properties of kraft paper was investigated. The papers treated by using rosin at 4 levels of 0, 0.5, 1 and 1.5% on the basis of dry fibers. Then, corn zein sized on the surface of the paper at 3 levels of 0, 30 and 45 g/L of 90% ethanol. The properties of sized papers were investigated via different methods. Elevation of the zein content caused a decreased water and oil absorption. As well as, increased tensile and burst index, and a reduced tear index. The R1.5N2Z45 sample had the highest tensile and burst index. The FTIR result verified the presence of the rosin and zein in the papers. The broad peaks near 1469 and 1614 cm-1 correspond to the bending N–H and stretching C-N groups of the corn zein protein. Moreover, The FTIR of the rosin showed peaks that related to the stretching vibrations of C-H, C-H3, and C-H2 bending, doublet methyl group, C-O stretching, C-H stretching vibrations of alkene group, and C-H stretching vibrations of alkene group, respectively.

Keywords:Water absorption; Oil repellent; Zein; Packaging; Rosin

Abbreviations:AKD: Alkyl Ketone Dimer; ASA: Alkyl Succinic Acid; FTIR: Fourier-Transform Infrared Spectroscopy; CPAM: Cationic Polyacrylamide; HSD: Honest Significant Difference

Introduction

One of the most important materials with a widespread use in the world is paper and paper products. Paper plays an important role in human life. Therefore, researchers have made different changes in paper and its products with different methods and materials to reach to many functions of these products. There are different categories of papers such as antibacterial and antifungal papers, packaging, conductivity, industrial, insulation, membranes, and water and oil repellent papers [1]. The necessity of using papers feel in a wide range of human life, due to their properties such as diversity of application, cheap raw materials, availability and renewability, recyclability, and compatibility [2]. One of the most widely used paper is food packaging papers [3]. The use of high-quality papers is one of the most important parameters to improve the quality of packaging. In addition, the use of chemical additives and renewable natural compounds plays a decisive role in enhancing the physical and mechanical properties of packaging papers and ultimately the quality of packaging [4]. The presence of appropriate barrier properties in food packaging papers is important. These barrier properties include preventing the absorption of water, water vapor, and oil, which preserves the quality of the product before consumption by the end user.

The inherent hydrophilic nature of cellulose, due to hydrophilic groups in their structure, greatly increases the tendency of the papers to absorb water [5]. Although this property is important and essential in some grades of paper, such as tissue and sanitary papers, in many cases, papers must be resistant to the absorption or penetration of water molecules [6]. For example, packaging papers and paperboards require to resist on the rapid penetration of water and other liquids in some applications [7]. In this condition, the use of different sizing agents can be an effective approach to create and develop these properties. Sizing and coating are the most common methods for improving the properties of paper and paperboard. The sizing process is typically carried out in two ways: internal sizing and external (surface) sizing. The surface (external) sizing process is carried out at the dry end of the paper machine. As a result, the pores and voids of the surface of the papers are covered in a thin layer. In internal sizing, hydrophobic materials such as rosin, Alkyl ketone dimer (AKD), and Alkyl succinic acid (ASA) are added to the fiber’s suspension at the wet end of the paper machine, depending on the acidic or alkaline conditions, and as these materials stabilize on the fibers, they create a water repellent in the paper [8,9]. Rosin and its derivatives use as internal sizing agents in the papermaking industry. Generally, rosin derivatives are inexpensive, environmentally friendly and human friendly. They have a high tolerance to other additives in the papermaking. They also have a much longer shelf life than other sizing agents such as AKD [6]. Rosin-based materials are usually used with alum as a stabilizer.

Biodegradable materials such as starch, polylactic acid, corn zein, and cellulose derivatives are commonly used as coating and sizing materials to improve barrier properties [10]. Zein is a corn protein and it produces in the starch and oil production of corn [11]. Zein is soluble in organic alcohol such as ethanol [12,13]. The corn protein including 45 – 50% zein. Zein is in a class of prolamin-based products with high hydrophobic and barrier properties. Zein offers different advantages such as low toxicity, cost-effectiveness, hardness, gloss, covering, oil and water barrier, antimicrobial. Zein has a variety of applications, including use in fibers, adhesives, coatings, ceramics, inks, cosmetics, textiles, chewing gum, and biodegradable plastics [14-16]. Zein as a natural product is biodegradable and renewable source and it has a great interest to study because of environmental issues [17]. To address the problem associated with the water and oil penetration in cellulosic sheets, surface sizing of papers with a solution based on zein is useful. In this study, the water and oil repellent packaging paper was produced using sizing agents, and the effect of the sizing process was evaluated. Barrier packaging papers were produced based on rosin, nano clay, and zein. The zein protein were coated on the surface of paper. The effect of the sizing was investigated relative to the barrier capacity of the papers. The results of the sizing process were characterized by Fourier-transform infrared spectroscopy (FTIR), oil and water absorption, and strengths properties of the sizing papers.

Materials and Methods Materials

Hardwood kraft fibers was provided from the wood and paper industry (Mazandaran Co., Sari, Iran). Zein was purchased from Acros Organics (Geel, Belgium). Nano clay – Montmorillonite (H2Al2O6Si) with a molecular weight of 18.01 (g/mol) and density 2.4g/cm3 was purchased from Sigma-Aldrich (St. Louis, MO), cationic polyacrylamide (CPAM) with a high molecular weight (500,000 to 20,000,000 Da), Ethanol (90.0%), aluminum sulphate (alum) (Al2(SO4)3), Isophorone diisocyanate (C12H18N2O2, 99.0%), rosin solution (35.0%) with a density 1.04g/cm3 were purchased from Merck (Kenilworth, NJ).

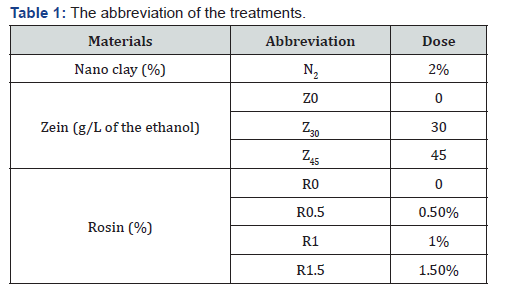

Preparation of the fibers and hand sheet

The kraft fibers sheets were soaked in deionized water for 24h. The kraft pulp was treated mechanically using a laboratory refiner (PFI mill – IDM test, Austria) to a freeness level of 300CSF. Alum was added to the fibers to pH 4.5, then nano clay (2% in the dry basis of the fibers) and cationic polyacrylamide 1% (on the dry basis of the fibers) were added to the fibers. Then rosin was added to the fiber’s suspension at different doses (0, 0.5, 1, and 1.5% on the dry basis of the fibers). The KF hand sheet had a basis weight of 60g/cm2 and was synthesized according to the TAPPI standard T205 (2002) [18]. The abbreviations of the treatments show in Table 1.

Sizing method

For coating the papers, the zein were immersed in 1000mL of ethanol (90.0%) at 70°C and for 30 minutes. 0.2% isophorone diisocyanate (on the basis of the zein) added to zein solution. The different doses of the zein in the sizing suspension (0, 30, and 45% in the dry basis of the paper) was spread on the surface of the papers with a metal roller. The sized papers were placed on oven at 30°C and pressurized in plastic frames for 24h.

Determination of the mechanical paper properties

The tensile, tear, and burst strength, air resistance, water absorption, and oil absorbency properties of the papers were measured according to the TAPPI standards T494 (2001), T414 (2004), T403 (2002), T460 (2006), T220 (2001), and T559 (2012), respectively [19-24]. The tests of mechanical properties of papers were carried out three times for each sample.

FTIR analysis

The infrared spectra of the samples were measured using a Cary 630 FTIR spectrometer (Agilent Technologies, Santa Clara, CA, USA). The spectra were measured with a spectral width ranging from 600 to 4000cm-1 at a resolution of 2cm-1

.Statistical analysis

Statistical analysis to identify any significant differences between the materials involved a one-way ANOVA followed by post Tukey’s honest significant difference (HSD) test with a significance level of p < 0.05.

Results and Discussion

FTIR of the samples

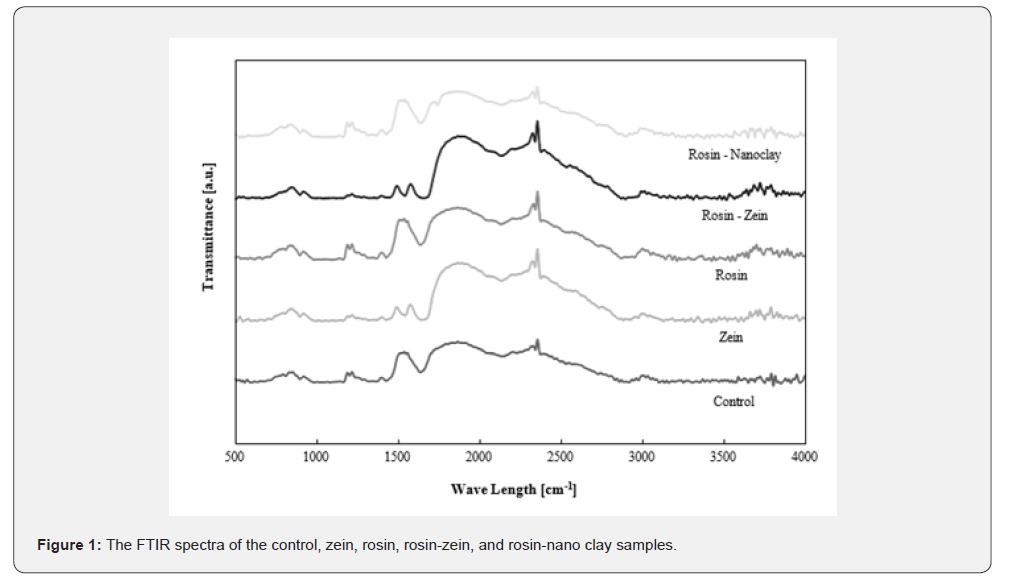

Figure 1 indicates the FTIR of the control (fibers), zein, rosin, rosin-zein with fibers, and rosin-nano clay with fibers samples. The broad peaks near 1469 and 1614cm-1 correspond to the bending N–H and stretching C-N groups of the corn zein protein [25]. As well as, the peak around 3200cm-1 appears the amide group corresponding to the stretching of the N–H and O–H bonds of the amino acids of the protein [26,27]. The peak around 2900c-1 is also observed, this peak corresponding with the C–H stretching groups. The paper with internal sizing by rosin and surface sizing by zein (rosin-zein) exhibited peaks in the same region, indicating that zein is present in the surface of the papers [28]. The peaks around 1637.49 – 1645.57c-1 in the samples are attributed to the type one amide group (stretching C=O). The peak at 1528 - 1531c-1 corresponding to the second amide group (N-H bending and C-N stretching) [25,27]. This confirms the linkage of the hydroxyl groups pf the fibers to amides groups of the proteins. The FTIR of the rosin showed peaks around 2931c-1, 1450c-1, 1400c-1, 1380c-1, 1108c-1, and 850c-1. The peaks are related to the stretching vibrations of C-H, C-H3, and C-H2 bending, doublet methyl group, C-O stretching, C-H stretching vibrations of alkene group, and C-H stretching vibrations of alkene group, respectively [28].

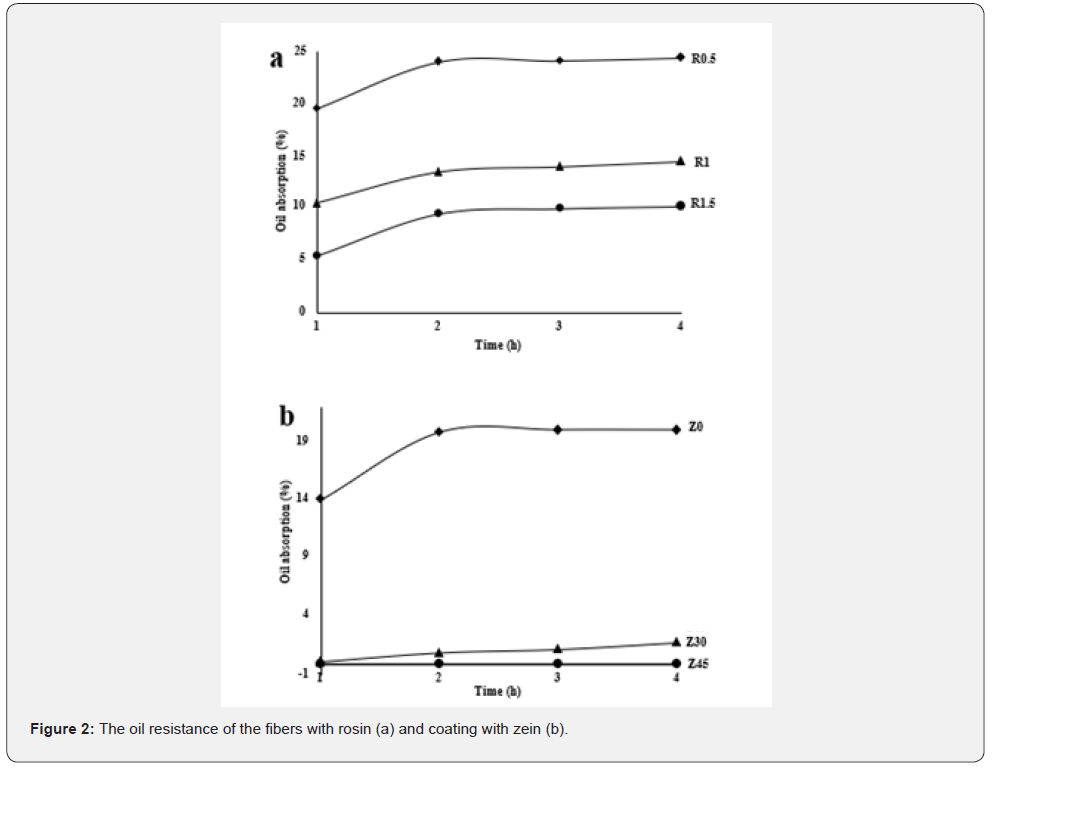

Oil absorption

The oil resistance of the fibers with rosin and nano clay (a) and coating with zein (b) can be seen in Figure 2a. Oil absorption increased with increasing the retention time. The papers without zein sizing, absorbed all of the oil and the sample was permeable completely. The R0N0Z45 sample had the highest oil resistance content, and the oil resistance content of the samples diminished as the zein content decreased. Moreover, oil resistance increased with increasing the rosin dose Figure 2b. The deposition of the sizing solution that contained zein onto the cellulose substrate of the papers augmented the thickness. Moreover, the former layer on the surface of the fibers coats the pores and empty space between fibers. Thus, the resistance of oil increased by increasing zein in the solution.

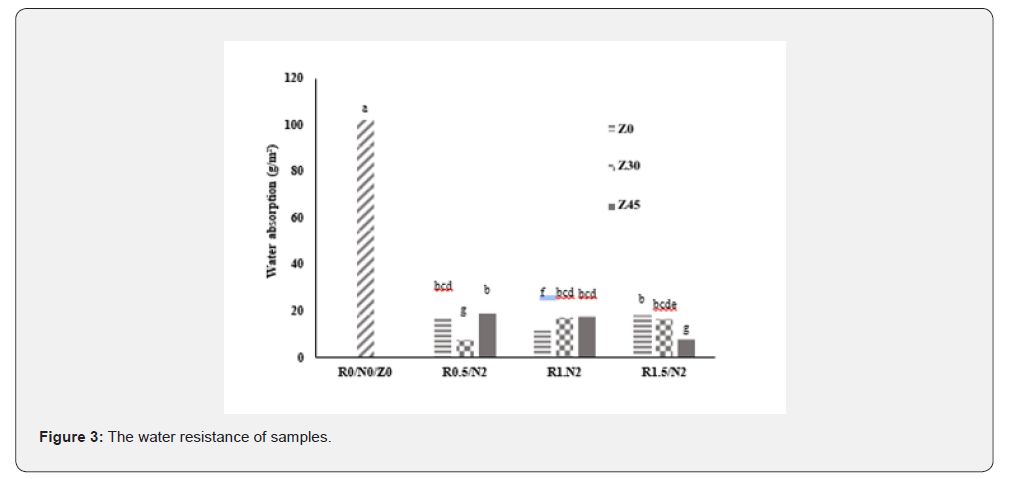

Water absorption

The water absorption of the fibers with rosin and nano clay, and coating with zein can be seen in Fig. 3. According to Figure 3 all dosages of alum-rosin and zein could decrease water absorption of the papers completely. One of the disadvantages of paper is its low water resistance, which may interfere with some of its applications, such as in insulating papers and oil absorption in printing. As a result, it is essential to control the water absorption of paper [29]. According to the results, the highest and lowest water absorption values were related to the untreated sample (control) and the R1N2Z45 sample, respectively. In a paper network, water molecules are absorbed by the fibers as well as the inter-fiber empty space. Surface sizing of zein impregnate the paper structure and fill the pores to form a layer on the surface of the paper. According to the results the effect of rosin and zein on the water absorption of the papers was significant. The water absorption increased with increasing the rosin dose and zein concentration. The sizing paper with 0.5% rosin had the higher water absorption rate than 1% and 1.5%. The reaction process between alum and rosin increases the linkage and enhances the reactivity between the fibers and the alum-rosin composite. This process also boosts the bonding, thereby reducing the reactive points that can react with the water molecules. Water molecules bond with hydroxyl groups and reduce the water absorption capacity.

Strength properties of the samples

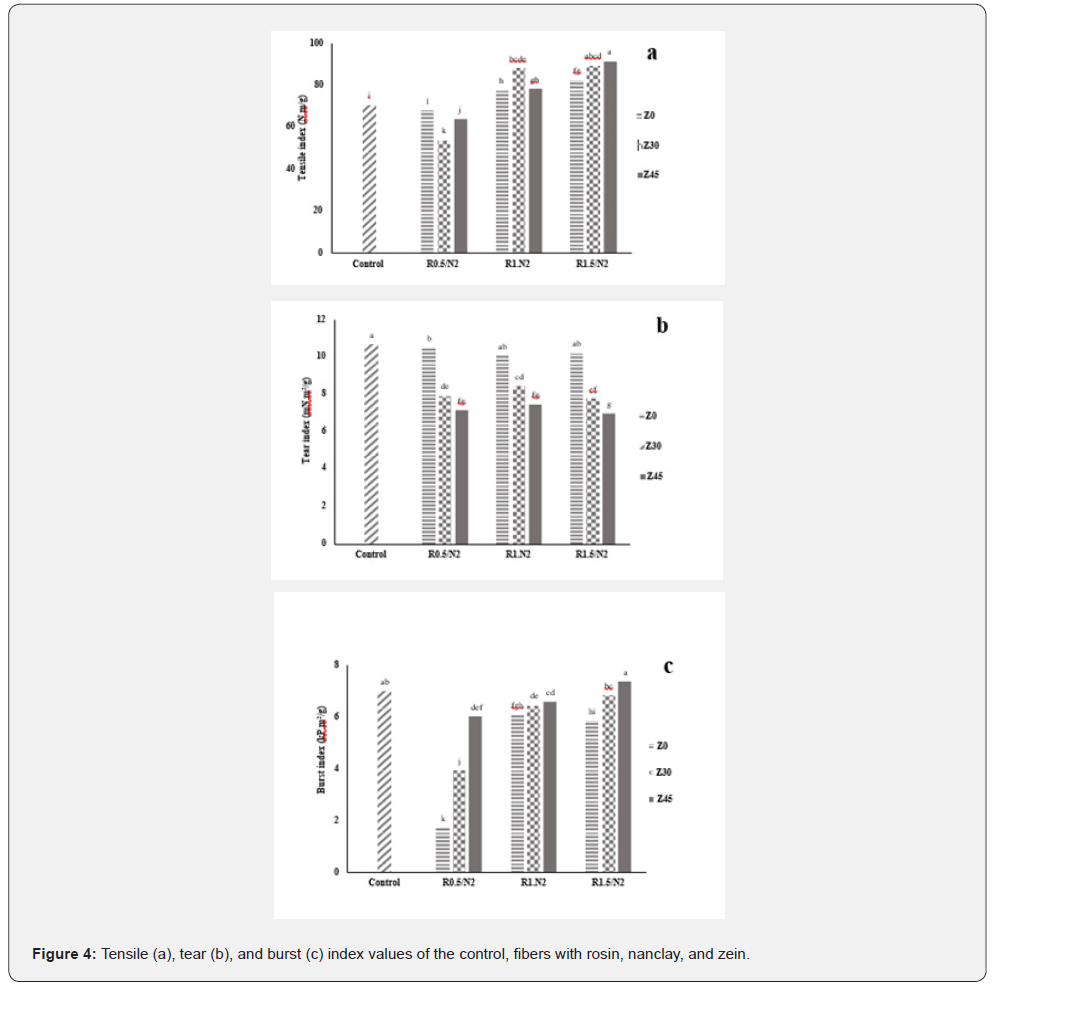

The tensile and tear strengths of the control (kraft paper), paper treated with rosin and nano clay, and coating papers were investigated. The diagrams of the tensile, tear, and burst index values can be seen in Figure 4a. The tensile and burst strength are influenced by several factors, e.g., the bonding between the fibers, bonding strength, number of bonds, paper sheet formation, and fiber bonded surface [30,31]. The bond type between the fibers in the paper was hydrogen bonding [32]. The tensile strength decreased for the papers with addition of nano clay in the production process of the fibers. The nano clay acts as a filler between the fibers and prevents bonding between the fibers, which as a result reduces the strength [33]. The highest tensile strength index was 93.1 Nm/g and it related to R1/5N0Z45 sample. The pH of the fiber’s suspension tends to acidic and more positive due to addition of alum. Thus, the negative ions in treated samples with 0.5% rosin disable to neutralize the positive charge of the system and diminished the bonding between fibers and tensile index decreased. Sizing by zein increased the tensile index in the samples. The improvement in tensile index is because of the formation of a coating layer on the fibers. The strength of the sized papers increased due to the interaction between the fibers and the layer of paper, as well as, increasing in the thickness [34]. The burst index of the samples demonstrated the same trend to tensile index. As Figure 4b shows, the R0.5N2Z0 had the highest tear index. The tear index decreased by increasing the rosin and zein consume in the samples Figure 4c.

Conclusion

Packaging papers have an important role in food safety. These papers can create barrier properties against bacteria, water and oil penetration. The effects of alum-rosin as internal sizing in wetend of papermaking and zein emulsion for surface sizing on the water and oil resistance properties of papers were investigated in this work. The papers treated by using rosin at 4 levels of 0, 0.5, 1 and 1.5% on the basis of dry fibers. Then, corn zein sized on the surface of the paper at 3 levels of 0, 30 and 45g/L of 90% ethanol. Compared to the untreated handsheets, the water and oil absorption values for the paper treated with zein emulsion were decreased. The tensile and burst index of the papers increased by increasing internal and surface sizing. However, the tear index shows different trend. The FTIR result verified the presence of the rosin and zein in the papers. The results of the research approved the corn zein is the proper sizing agent for packaging papers and it can enhance the barrier properties of the papers. However, further research is required to study the more dosage of zein emulsion and use different sizing and strengths additives agents to improve other properties of the packaging papers such as antibacterial property.

Author Contribution

Noureddin Nazarnezhad was involved in supervision, project administration, review and editing. Investigation, and data curation were done by Zakaria Taheri. Seyed Majid Zabihzadeh took part in editing and supervision and writing and formal analysis was performed by Shaghayegh Rezanezhad.

Declaration

Conflict of interest: The authors declare that there is no

conflict of interest.

Ethical approval: Not applicable.

References

- Rashid M, Abdul Ghafur M, Sharafat KM, Minami H, Miah MJ, et al. (2017) Biocompatible microcrystalline cellulose particles from cotton wool and magnetization via a simple in situ co-precipitation method. Carbohydr Polym 170: 72-79.

- Kaco H, Waznah Kh, Jaafar N, Gan YS (2017) Preparation and characterization of Fe3O4 / Regenerated cellulose membrane. Sains Malays 46(4): 623- 628.

- Netramai S, Kijchavengkul T, Kittipinyovath P (2016) Use of Paper in Food Packaging Applications. In book: Reference Module in Food Sciences Edition: 1st Publisher: Elsevier, p. 796.

- Honnold V (2009) Developments in the sourcing of raw materials for the production of paper. United States international trade commission. J Int Commer USA Trade Commission, p. 26.

- Zou Y, Hsieh JS, Wang TS, Mehnert E, Kokoszka J (2004) The mechanism of premixing rosin sizes for neutral- alkaline papermaking. Tappi J 3(9): 16-18.

- Hubbe MA (2006) Paper’s resistance to wetting - A review of internal sizing chemicals and their effects. BioRes 2(1):106-145.

- Elyasi-Bakhtyari S, Jalali-Torshizi H, Resalati H (2016) Alkyl ketene dimer (AKD) sizing of recycled-virgin cardboard with engineered heterogeneous layers under neutral and alkaline condition. Journal of Wood & Forest Science and Technology (In Persian) 23(1): 1-20.

- Ahmad S, Sharma R, Raj K, Mediratta R, Prasad K, et al. (2007) Alkaline sizing (AKD) with GCC filler: our experience. Tappi J 19(4): 123-127.

- Lindstrom T, Eklund D (1991) Water Penetration and Internal Sizing. Chapter VIII in Paper Chemistry: an Introduction. DT Paper Science Publication 305: 192-222.

- Bedane AH, Huang Q, Xiao H, Ei M (2012) Mass transfer of water vapor, carbon dioxide and oxygen on modified cellulose fiber-based materials. NPPRJ 27(2): 409.

- Luo Y, Wang T (2016) Chapter 9-Pharmaceutical and Cosmetic Applications of Protein By-Products. In: G Singh Dhillon (), Protein Byproducts, pp. 147-160.

- Lawton JW (2002) Zein: A History of Processing and Use. Cereal Chem 79(1): 1-18.

- Arcan I, Boyacı D, Yemenicioglu A (2017) The Use of Zein and Its Edible Films for the Development of Food Packaging Materials. Reference Module in Food Sciences, pp. 1-11.

- Shukla R, Cheryan M (2001) Zein: the industrial protein from corn. Industrial Crops and Products 13(3): 171-192.

- Qiangxian W, Sakabe H, Isobe S (2003) Studies on the toughness and water resistance of zein-based polymers by modification. Polymer 44(14): 3901-3908.

- Shahidul Islam M, Tadele DT, Mekonnen TH (2025) Corn Zein Nanocarriers for Agrochemical Delivery and Smart Packaging. Adv Sustain Syst e00922.

- Song Z, Pan Y, Xiao H (2013) Effects of zein emulsion application on improving the water and water vapor barrier properties of paper. NPPRJ 28 (3): 381-385.

- TAPPI T205 (2002) Forming hand-sheets for physical tests of pulp, TAPPI Press, Atlanta, GA.

- TAPPI T494 (2001) Tensile properties of paper and paperboard (using constant rate of elongation apparatus), TAPPI Press, Atlanta, GA.

- TAPPI T414 (2004) Internal tearing resistance of paper (Elmendorf-type method), TAPPI Press, Atlanta, GA.

- TAPPI T403 (2002) Bursting strength of paper, TAPPI Press, Atlanta, GA.

- TAPPI T441 (2013) Water absorptiveness of sized (non-bibulous) paper, paperboard, and corrugated fiberboard (Cobb test), TAPPI Press, Atlanta, GA.

- TAPPI T220 (2001) Physical testing of pulp handsheets, TAPPI Press, Atlanta, GA.

- TAPPI T559 (2012) Grease resistance test for paper and paperboard, TAPPI Press, Atlanta, GA.

- LA Forato, R Bernardes-Filho, LA Colnago (1998) Protein Structure in KBr Pellets by Infrared Spectroscopy. Anal Biochem 259(1): 136-141.

- Lenzuni M, Suarato G, Miele D, Carzino R, Ruggeri M, et al. (2021) Development of biodegradable zein-based bilayer coatings for drug-eluting stents. RSC Advances 11(39): 24345.

- Corradini E, Curti PS, Meniqueti AB, Martins AF, Rubira AF, et al. (2014) Recent advances in food-packing, pharmaceutical and biomedical applications of zein and zein-based materials. Int J Mol Sci 15 (12): 22438-22470.

- Kansal D, Hamdani SS, Ping R, Sirinakbumrung N, Rabnawaz M (2020) Food-Safe Chitosan-Zein Dual- Layer Coating for Water- and Oil Repellent Paper Substrates. ACS Sustainable Chem Eng 8: 6887-6897.

- Rahmaninia M, Javid E, Varshoei A (2016) Process variables and the performance of cationic rosin as an internal sizing agent in recycled corrugated container pulp. BioRes 11(2): 5333-5342.

- Rezanezhad SH, Nazarnezhad N, Resalati H, Zabihzadeh SM (2022) Characterization of Magnetic Bio- Nanocomposites of Nanocrystalline Cellulose (NCC) Coated on Paper Surface. BioRes 17 (3): 4607-4622.

- Maurer HW, Kearney RL (1998) Opportunities and challenges for starch in the paper industry. Starch 50(9): 396-402.

- Zakaria S, Ong BH, Ahmad SH, Abdullah M, Yamauchi T (2005) Preparation of lumen-loaded kenaf pulp with magnetite (Fe3O4). Mater Chem Phys 89(2-3): 216-220.

- Rezanezhad SH, Nazarnezhad N, Resalati H, Zabihzadeh SM (2022) The Use of Gluconic Acid as an Additive in Magnetic Paper. BioRes 17(1): 342-354.

- Klungness JH, Klungness A, Ahmed N, Roos- Sutherland N, Abubakr S (2000) Lightweight high opacity paper by fiber loading: filler comparison. NPPRJ 15(5): 345-350.

- Gällstedt M, Brottman A, Hedenqvist MS (2005) Packaging-related Properties of Protein- and Chitosan-coated Paper. Packag. Technol Sci 18(4): 167-170.