Soni-Laser, Welded Connections, with a Difference

Phil Carr*

Carrs’ Welding Technologies Ltd., UK

Submitted: October 16, 2023; Published: October 27, 2023

*Corresponding author: Phil Carr, Carrs’ Welding Technologies Ltd., UK

How to cite this article: Phil Carr*. Soni-Laser, Welded Connections, with a Difference. JOJ Material Sci. 2023; 8(2): 555733. DOI:10.19080/JOJMS.2023.08.555733

Abstract

Carrs are contract welders, we weld everything that can be welded and even the metals that don’t want to be welded, but need repairing, so they MUST be welded. Our motive for welding is always to find a solution to repair metal components. So, “cast iron”, “cast alloy”, “copper”, are all words, that signal trouble…. so, if you say we need copper welded to aluminium, we know it’s difficult, some say impossible, due to the Intermetallic compounds produced (IMCs).

Soni-Laser was a dream come true, Innovate UK said “Go away and try this Ultra-Sound excitation and see if you can weld copper to aluminium”, because in the battery world, they need copper and aluminium connections, and it must be good. So, we teamed up with Brunel University, and we set about seeing what the various frequencies and amplitudes and angles of attack, made the best battery connections.

Keywords: Aluminium; Fusion zone; Ultrasounds; Transducer

Aims

We already knew that Ultra-sound, PUVT, (or Power Ultra-sound Vibration Treatment) effects the metal, as the weld re-solidifies back to a solid. Essentially, we apply the vibrations to the metal that we are welding and we want to see the what happens. Crucially though, it forced the grain structure of the new material, (i.e. the fusion zone) to be more rounded and not so linear, i.e. it seems to stop the intermetallics lining up and making lines, which is where a hot crack initiates from… Cracks are bad for connections and mean the weld will fail!

a) Copper to aluminium produces hideous intermetallics, which are brittle and crack, so we use every trick we know in the book to stop it happening and then we add PUVT too, and blow me, using the oscillating head on the fibre laser, it gives us a result.

b) Aluminium to aluminium welds constitute most of the welds done in the battery world, so we set out to study this too, for better or for worse, is this a good marriage.

c) Weld strength and impedance, can we make the welds and hence the connections of your battery in your car, stronger and less lossy. A win-win, if we can make them stronger and with a lower impedance, and in the nightmare scenario and you crash your car; all those connections are forced to their limits.

d) Contactless transducer, we knew already that we can make PUVT make a difference, but unless we can vibrate the connection, ie the job through the air, we were on a hiding to nothing. Contactless vibration treatment was the only way ahead.

Results of the Soni-Laser

a) Contactless Transducers for PUVT work and work well. Brunel designed various different devices, as a lab style try-out; they were tested and proved to work. This is the major achievement for Soni-Laser as this means PUVT is possible in production. We have a project!!

b) Aluminium, to Aluminium welds with PUVT are more than 10% stronger and have improved extension prior to fracture, in cases up-to 64% improved extension prior to fracture. Proved on all the aluminium grades normally used in battery interconnection.

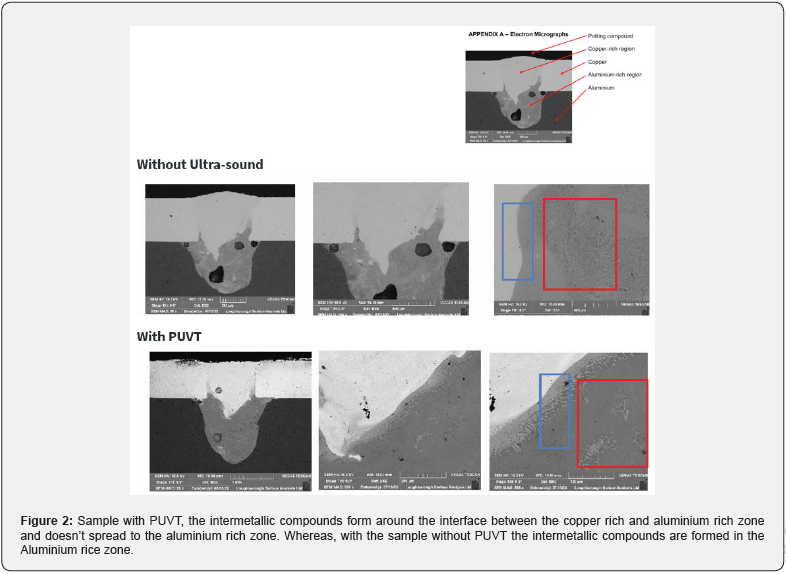

c) Copper to Aluminium welds are more than 10% on average stronger and up-to 22% stronger in cases, (Figure 1) PUVT improved the extension, but it is still not an advised weld for a battery/busbar connection. It’s too brittle and prone to fracture.

d) Connection Impedance showed a small benefit, where Aluminium is welded with PUVT, the connection showed a small reduction of impedance of typically 5%.

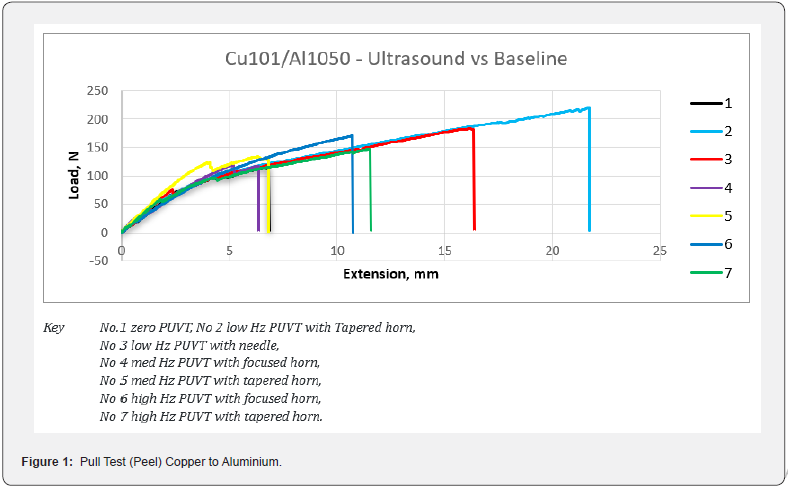

e) SEM analysis shows in the copper/aluminium weld a more uniform composition in the aluminium rich region when applying ultrasounds.

f) SEM analysis shows that the PUVT reduces the spread of the copper into the fusion zone, thus reducing the intermetallic compounds in the aluminium rich region.

The copper to aluminium peel tests showed that the PUVT made a big difference, especially at low frequency, with the tapered horn transducer.

SEM And EDX Analysis Results, for Low Frequency Tapered Horn only

Baseline Appendix, of macroscopy, which shows a crosssection of a weld at approximately 100x. Copper is light coloured material on top, the dark grey is the aluminium. Otherwise known as the fusion and heat affected zone.

The images below show that in the sample with PUVT, the intermetallic compounds form around the interface between the copper rich and aluminium rich zone and doesn’t spread to the aluminium rich zone. Whereas, with the sample without PUVT the intermetallic compounds are formed in the Aluminium rice zone (Figure 2).

Conclusion

PUVT should be added when welding battery connections, there are no negative consequences, aluminium connections are stronger and extend further before fracturing. Al/Cu connections are better and less IMCs are formed. QED. Soni-Laser Project - Ultrasonic assisted laser welding for high volume assembly of automotive battery packs.