Can Laser Ablation Studies Predict Coating Degradation on Substrates?

Stephen S*

Department of Chemistry, Khalifa University of Science and Technology, UAE

Submission: November 29, 2017; Published: December 14, 2017

*Corresponding author: Sasi Stephen, Department of Chemistry, Khalifa University of Science and Technology, The Petroleum Institute, Abu Dhabi, P.O. Box 2533, UAE.

How to cite this article: Stephen S. Can Laser Ablation Studies Predict Coating Degradation on Substrates?. JOJ Material Sci. 2017; 3(3): 555616. DOI:10.19080/JOJMS.2017.03.555616

Opinion

Protective coatings on metal substrates undergo degradation due to various conditions such as intense solar irradiation, wind, rain, moisture, sand storm etc. Degradation of coatings is a serious problem, generally, and is a severe problem in the petroleum industry [1,2]. Structures and pipe lines are susceptible to damage due to coating deterioration. The loss suffered by the industry due to such damages is huge. If there is a mechanism to predict the damage or to monitor the progress pattern of the damage, essential safeguards can be put in place. One such suggested mechanism is to study a cross section or slice of the coated material and to assess the damage inflicted on the substrate using a Laser Ablation system hooked up to a mass spectrometer [3,4]. Several studies indicate that the progress of the damage can be reasonably assessed and that should provide an early warning to take counter measures to slow down or to arrest the damage process.

An earlier study has used samples which were treated steel substrates protected with a uniform layer of acrylic based coating [5,6]. The coating was ensured to be of uniform thickness. The control samples were maintained indoors at ambient conditions while the experimental samples were subjected to harsh environmental conditions outdoors and on roof tops. The deterioration or damage to the coating was assessed, at pre-determined intervals by subjecting the coating to laser ablation and monitoring the damage using a mass spectrometer connected to the laser unit. The study had simulated the situation of coating degradation under real conditions of the environment. The reported results have unequivocally proved that the study was useful in assessing the coating degradation.

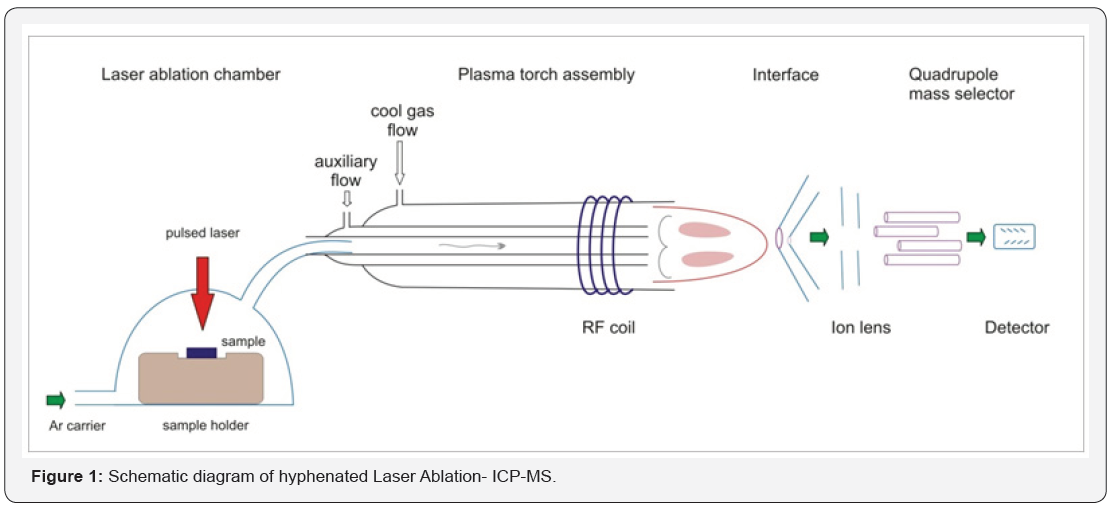

The technique mostly depends on the efficient and synchronous use of two instruments–the Laser Ablation unit and the ICP Mass Spectrometer (Figure 1). The sophistication of the laser units have grown to such levels that a fine tuned laser beam can be pre-programmed to drill through virtually any material or medium [7,8] . As newer models of laser units have emerged with shorter wavelengths carrying higher energy, any sample from soft materials like biological samples to hard geological or heavy metals can be dealt with by the laser ablation units [9-11]. Several parameters of the laser beam can be controlled and fine-tuned by computer controlled firmware. The diameter of the beam itself can decide the crater size. The beam energy can be fine-tuned in accordance with the hardness of the subjected sample. An inert gas sweep across the sample chamber will ensure the smooth transport of the ablated sample into the mass spectrometer. A well balanced combination of beam diameter and beam energy, coupled with the right gas flows will ensure drilling the sample through pre-determined depths without much accumulation of debris in the crater. In addition to drilling through the sample, drilling across the surface along a grid is equally feasible. The recent innovations in the field of laser ablation have catapulted the technique to the fore front of depth profiling studies. All these point to the fact that a well programmed laser ablation unit can be made use of to study the coating degradation. The technology has proved itself to be reliable and reproducible [12,13].

It is equally important to have the hyphenated mass spectrometer well-tuned and well synchronized to the laser unit. Every hit of the laser pulse generates a stream of atomized elements which are swept into the plasma, where they are ionized and enter the evacuated mass spectrometer region. Unlike the liquid sampling mode, which delivers a continuous stream of samples into the mass spectrometer, until several sweeps across the spectrum of selected masses are completed, the laser ablation provides only short term pulses. The pulses may stay only for a few milli-seconds, some times. Hence the mass spectrometer has to be sensitive enough to capture the extremely short pulses which are time restrained as well as are of low intensity. However taking into consideration of the present class of instruments, and the highly sensitive electron multiplier detectors, it can be stated with almost certainty that the technique is fool proof [14,15]. Signals of very short duration and those of low intensity can be registered by present day mass spectrometers. Modern electron multiplier tubes are capable of amplifying the signal with acceptable signal to noise ratios.

There are several other technologies currently available to study coating thicknesses. But then why is laser ablation technology superior to them? Most of the surface analysis techniques and instrumentation are expensive. Most of them require careful pre-treatment of the section of the samples. Atomic Force Microscopes, Scanning Electron Microscopes or X-ray Photo-electron Spectroscopy etc. are extremely expensive and sample preparation is cumbersome. The cost of ICP mass spectrometers and laser units are affordable. There is virtually no sample preparation for laser irradiation studies. All one has to do is to cut a section of the sample into a suitable size like 4x4 cm so that the sample fits itself in the laser chamber. The laser is very versatile so that it can deal with any sample from soft tissues to hard rocky deposits. Once a section of the sample is inside the laser chamber, a pre-cursor of the results appear in minutes.

However, when it comes to coating degradation studies, one major hurdle often encountered is the absence of validated standards. This is a major handicap faced by laser investigators. NIST glass standards are often used to standardize laser beams. But they don’t qualify to be used in coating studies. Hence the best means to study coating degradation is to compare the degraded coating to carefully maintain coated controls. The controls can be maintained in ideal environmental conditions, which can serve as yard sticks to ascertain the level of degradation that had taken place in the real samples.

Conclusion

The tandem technique of Laser Ablation-ICP-MS serves as a reliable tool to study the coating degradation when coated materials are subjected to environmental conditions. The technique is relatively less expensive compared to other sophisticated techniques. The technique does not demand time consuming sample preparations apart from cutting and chopping the material to fit into the sample chamber. Laser measurements are highly sensitive so that differences of a few microns in the coating thickness can be determined. If used properly, the technique can be gainfully employed to study coating degradation and thereby minimize heavy losses in several industries.

References

- Yang XF, Vang C, Tallman D, Bierwagen E, Croll G P, et al. (2001) Weathering degradation of a polyurethane coating. Polymer Degradation and Stability 74(2): 341-351.

- Hare CH (1992) The Degradation of Coatings by Ultraviolet Light and Electromagnetic Radiation Anatomy of Paint. Journal of Protective Coatings & Linings.

- Balzer H, Hoehne M, Sturm V, Noll R (2005) Online coating thickness measurement and depth profiling of zinc coated sheet steel by laserinduced breakdown spectroscopy. Spectrochimica Acta Part B: Atomic Spectroscopy 60(7-8): 1172-1178.

- Pisonero J, Koch J, Wälle M, Hartung W, Spencer ND, et al. (2007) Capabilities of Femtosecond Laser Ablation Inductively Coupled Plasma Mass Spectrometry for Depth Profiling of Thin Metal Coatings. Analytical Chemistry 79(6): 2325-2333.

- Fok S, Pillay AE, Stephen S, Abd-Elhameed A (2011) Rapid evaluation of the extent in micro-degradation of protective coatings using laserablation inductively coupled plasma mass spectrometry (LA-ICP-MS). International Journal of Instrumentation Technology 1(1): 34-43.

- Pillay AE, Fok S, Stephen S, Abd-Elhameed A (2009) Monitoring Interfacial Degradation in Metal Coatings using Laser Ablation Technology (ICP-MS). Candian Journal of Pure & Applied Sciences 3(2): 821-825.

- Pillay AE, Vukusic S, Stephen S, Abd-Elhameed A (2010) Rapid Ablative Laser Technique (ICP-MS) for Monitoring Material Homogeneity in Polypropylene. Chemical Sciences Journal p. 1-9.

- Pillay AE, Elhameed AA, Nunn R, Stephen S (2016) Deep-UV Laser Ablation Technology [213nm] Coupled with Plasma Quadrupole Mass Spectrometry for Rapid Determination of Nickel/ Vanadium Ratios in Asphaltenes. Mass Spectrometry & Purification Techniques 2(1): 1-5.

- Nemes P, Barton AA, Li Y, Vertes A (2008) Ambient Molecular Imaging and Depth Profiling of Live Tissue by Infrared Laser Ablation Electrospray Ionization Mass Spectrometry. Analytical Chemistry 80(12): 4575-4582.

- Halbhuber KJ, König K (2003) Modern laser scanning microscopy in biology, biotechnology and medicine. Annals of Anatomy - Anatomischer Anzeiger 185(1): 1-20.

- Gunther D, Frischknecht R, Heinrich CA, Kahlert HJ (1997) Capabilities of an Argon Fluoride 193 nm Excimer Laser for Laser Ablation Inductively Coupled Plasma Mass Spectometry Microanalysis of Geological Materials. Journal of Analytical Atomic Spectrometry 12: 939-944.

- Chichkov BN, Momma C, Nolte S, von Alvensleben F, Tünnermann A, et al. (1996) Femtosecond, picosecond and nanosecond laser ablation of solids. Applied Physics A 63(2): 109-115.

- Russo RE, Mao X, Mao SS (2002) Peer Reviewed: The Physics of Laser Ablation in Microchemical Analysis. Analytical Chemistry 74(3): 70A-77A.

- Ammann AA (2007) Inductively coupled plasma mass spectrometry (ICP MS): a versatile tool. Journal of Mass Spectrometry 42(4): 419- 427.

- Pröfrock D, Prange A (2012) Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) for Quantitative Analysis in Environmental and Life Sciences A Review of Challenges Solutions and Trends. Applied Spectroscopy 66(8): 843-868.