Synthesis of Calophyllum inophyllum Esters as Biofuel Feed stock

Vandana V 1*, Kodanda Rama Rao CH2, Somnath G1 and Babia L2

1Department of Chemistry, GITAM University, India

2Department of Mechanical engineering, GITAM University, India

Submission: May 11, 2017; Published: June 29, 2017

*Corresponding author: Vandana V, Department of Chemistry, Central Research Laboratory, GITAM University, India, Tel: +91-9160835464; Email: taarush@gmail.com/ghoshmnth@gmail.com

How to cite this article: Vandana V , Kodanda R R CH, Somnath G, Babia L. Synthesis of Calophyllum inophyllum Esters as Biofuel Feed stock. JOJ Material Sci. 2017; 2(2): 555583. DOI:10.19080/JOJMS.2017.02.555583

Abstract

Degrading fossil fuel resources have thrown world into chaos, besides various pollutions and greenhouse gases are a major concern. The fossil fuel shortage in near future is inevitable. This situation triggered the awareness to find alternative and sustainable energy resources. Biofuels are renewable fuel resources developed to replace conventional petroleum based fuels for transportation sector without altering the engines. In the present work, Biofuel is produced from Tamanu seeds (Calophyllum) which is available plenty in GITAM University. The fatty acid rich oil is converted to various esters using methanol, ethanol, 1-propanol, 2-propanol, 1-butanol. These esters were characterized by IR, JHNMR. The Physico- Chemical properties reveal that these esters can be one of the alternatives for the existing fossil fuel.

Keywords: Calophyllum inophyllum oil; Fatty acids; Esters; Bio fuel.

Introduction

Ever increasing petroleum products prices and uncertainties concerning their availability have increased the importance of vegetable oil based biofuel tremendously. The type of vegetable oils used for biofuel production is the parameter that contributes to the cost of the fuel preparation. In USA, mainly soybean oil is used as it is produced in surplus to the edible consumption. On the other hand, in Europe rapeseed oil or sunflower oil or used frying oils are utilized. In Asian countries like Malaysia and Indonesia, palm oil based biofuel are prepared as they have huge surplus of palm oil. India, being one of the major importers of vegetable oils every year, cannot afford to use any edible oil for the preparation of biofuel as almost half of its edible oil consumption depends on imports (9 million tons of edible oil). However, India, due to its tropical climatic conditions and vast terrain region has more than 100 types of trees yielding oil which are yet to be explored. The tree borne oils can be exploited for the preparation of biofuel. Calophyllum inophyllum is a species of family Guttifereae (Clusiaceae), it is a broad leaved evergreen tree widely planted throughout the tropics and easily grown along the coastal area. The tree is valued for its hardiness and beauty as an ornamental tree. Oil from the nuts has been traditionally used for medicine and cosmetics. Annual yield of Calophyllum is around 20-100kg/tree of whole fruits. Trees begin to bear sinificantly after 4-5 years. The nut kernel contains 50- 70% oil. Adeyeye et al. [1], Chavan et al. [2] has reported that the Calophyllum oil exhibited good physico chemical properties and could be used as a biodiesel feedstock and as an industrial application.

Atabani et al. [3] has reported that the efficiency of engines has increased when fatty acid blends of Calophyllum biodiesel were used. Sanjid et al. [4], has reported that the Impact of palm, mustard, waste cooking oil and Calophyllum Inophyllum biofuels on performance and emission of CI engines. Krishnaji et al. [5] has reported that the CI engine performance is improved with significant reduction in emissions for the Calophyllum inophyllum Biodiesel without any engine modification. Ravi et al. [6] has studied Performance, Combustion and Emission Characteristics on Single Cylinder Diesel Engine using Calophyllum inophyllum Oil. Sanjay et al. [7] has reported that the tamanu seed crush is directly converted into biodiesel with in-situ trans esterification of fatty acid to methyl and ethyl esters. These components of biodiesel were analyzed by GCMS technique. Mohan et al. [8] has reported that the tamanu oil is a promising alternative fuel for direct-injection in four-stroke VCR engine. Atabani et al. [9], has studied the Fuel Properties of Croton megalo carpus, Calophyllum inophyllum, and Cocos nucifera (coconut) Methyl Esters and their Performance in a Multi cylinder Diesel Engine. Calophyllum is widely grown in GITAM University Figure 1 and in this study we report the synthesis of different ester derivatives of Calophyllum fatty acid from Calophyllum oil to study the effect of chain length on the biofuel properties of the products.

Materials and Methods

Calophyllum seeds were collected from GITAM University, Visakhapatnam. Hydrochloric acid, 1-propanol were purchased from MERK life science pvt Ltd., Mumbai. Methanol was purchased from Himedia laboratories pvt. Ltd., Dombivli. Ethyl acetate, Hexane and basic alumina from Finar chemicals Ltd, Ahmadabad. Sodium sulphate, Sodium hydrogen carbonate, Sodium hydroxide was purchased from Fisher scientific pvt Ltd Mumbai. Ethanol was purchased from Changshu Hongsheng fine chemicals from Changshu city Jiangsu Province. pTSA (Para toluene sulphonic acid) was purchased from avra labs, Hyderabad, India.

Methods

Analytical methods: The GC analysis was performed with an Agilent 6890 N series Gas Chromatography equipped with a flame ionization detector. 1HNMR spectra were recorded on Avance 300MHz in CDCl3. Chemical shift values relative to TMS as internal standards were given 5 values in ppm. IR spectra were obtained on a 1600 FT-IR Perkin-Elmer spectrometer (Norwalk, CT) with a liquid flim between the NaCl. Physicochemical properties namely Free Fatty Acid, density, moisture content, viscosity, flash and fire, cloud and pour and copper strip corrosion were determined using standard AOCS and ASTM methods.

A typical procedure for the extraction of Calophyllum oil: The seeds were dried and the kernels were finely powdered and the powder was soxhlet extracted using hexane as a solvent. The hexane was removed under vacuum and the crude oil (40%) was dried under reduced pressure. The crude oil is used without further purification.

A typical procedure for the preparation of Calophyllum fatty acid: Calophyllum oil (200gm) and aqueous NaOH solution (36gm dissolved in 450ml distilled water) were stirred mechanically The reaction was monitored by TLC using the solvent system hexane/ethyl acetate (90:10v/v). The reaction was continued until the disappearance of Triglyceride in TLC. After completion of the reaction, the reaction mixture was cooled to 50 °C and acidified with concentrated HCl. The product was extracted with ethyl acetate and washed with water to remove excess HCl. The organic layer was dried over anhydrous Na2SO4 and concentrated under vacuum to obtain 180gm of product (78% yields). The fatty acid thus obtained is semi solid.

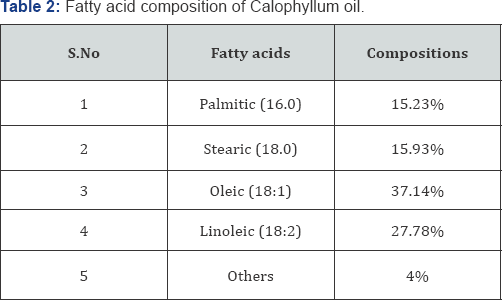

Fatty acid composition of the Calophyllum oil: Fatty acid methyl esters of the Calophyllum oil were prepared by refluxing crude oil with 2% H2SO4 in methanol for 4h. The esters were extracted with ethyl acetate, passed over anhydrous Na2SO4 and concentrated under vacuum. The obtained methyl ester was analyzed for its fatty acid composition by gas chromatography. The fatty acid composition of Calophyllum oil was tabulated in Table 2.

A Typical procedure for the preparation of Calophyllum Fatty alkyl esters: Calophyllum fatty acids (50gm, 0.178mol), 1-butanol (26.45gm, 0.356mol), p-TSA (0.5gm based on 1% weight of fatty acid) and 50ml of toluene were collected in three necked round bottomed flask equipped with a thermometer, condenser and Dean stark apparatus. The reaction mixture was stirred at 130-140 °C. The reaction was monitored by checking TLC using hexane: ethyl acetate (90:10v/v). After the disappearance of fatty acid and the theoretical amount of water was collected. The reaction mixture was cooled to room temperature. The crude was concentrated under vacuum to remove alcohol and toluene. The resultant product was dissolved in hexane, washed with NaHCO3 solution, passed over anhydrous Na2SO4 and dried under vacuum to afford alkyl esters of Calophyllum fatty acids. The unreacted fatty acid was removed by passing the crude over basic alumina. The ester product was analyzed for acid value. The esters were characterized by IR, 1HNMR Spectral studies.

Butyl ester of Calophyllum fatty acid

IR (neat, cm-1): 3007(-C=C-H); 1740(-C=0); 1172(C-O).

1HNMR (CDCl3, δ-ppm): 0.85-0.92(t, CH3), 1.2-1.38 & 1.56- 1.67(m, -CH2), 2.0-2.1 (m, CH2CH=CH2), 2.29-2.31 (t, CH2C=O), 3.93-4.01 (t, CH2O), 5.45 (m, -CH=CH).

The above procedure was followed to prepare various alkyl esters using different alcohols (methanol, ethanol, 1 & 2-propanol) with Calophyllum fatty acids. And those esters were characterized by IR & 1HNMR studies.

Methyl ester of Calophyllum fatty acid

IR (neat, cm-1): 3007(-C=C-H); 1742(-C=O); 1118(C-O).

1HNMR (CDCl3, δ-ppm): 0.90(t, CH3), 1.2-1.38 & 1.52- 1.65(m, -CH2), 2.0-2.1 (m, CH2CH=CH2), 2.29-2.31 (t, CH2C=O), 3.68 (t, CH2O), 5.38(m, -CH=CH).

Ethyl ester of Calophyllum fatty acid

1HNMR (CDC13, δ-ppm): 0.89(t, CH3), 1.28-1.37(m, -CH2), 1.65-1.7 (m, CH2CH=CH2), 2.25-2.35 (t, C H2C=O), 3.7 (t, CH2O), 4.15 & 4.30, 5.4(m, -CH=CH).

1-propyl ester of Calophyllum fatty acid

1H NMR (CDCl3, 5-ppm): 0.82-0.90(t, CH3), 1.2-1.4 & 1.601.72 (m, -CH2), 2.0-2.1 (m, CH2CH=CH2), 2.30-2.35 (t, CH2C=O), 3.68 (t, CH2O), 4.15 & 4.26, 5.35 (m, -CH=CH).

Physico-chemical properties: various physic-chemical properties studied are

a. Kinematic viscosity determination by ASTM D445:

b. Biofuel, the most important physico chemical property is kinematic viscosity. Since it affects the operation of fuel injection equipment. Results show that there is change in viscosity from the oil into the various esters.

c. Flash point: It is the lowest temperature at which a liquid forms an ignitable mixture in air near the surface of the liquid. Flash point is measured by ASTM D93 method. The results are in agreement with ASTM D93, which requires that flash point to be minimum 93oC of the synthesized esters.

d. Pour point: The pour point indicates the ability of the liquid to flow at lower temperatures. The pour points were determined by ASTM D97 method using pour point apparatus manufactured by Cultures Instruments India LLP, Bangalore, India. All the samples were run in duplicates.

e. Cloud point: The cloud point is indicates the ability of the liquid to start clouding at which temperature. The cloud point was determined by ASTM D2 500 using cloud point apparatus manufactured by Cultures Instruments India LLP, Bangalore, India.

f. Copper strip corrosion: Determines the corrosiveness of the substance As per ASTM D 130 method. Copper strip corrosion was determined by using copper strip corrosion bath which was purchased from Cultures Instruments LLP, Bangalore, India. A polished copper strip in immersed in 30ml of sample being tested at 50 °C for 3h. After 3 h the Cu strip is removed, washed and the colour and tarnish level was assessed against the ASTM copper strip corrosion standard.

g. Density: Density is determined by Pycnometer. The density of Calophyllum esters were measured by ASTM D4052 method at 250 °C.

h. Moisture content: Moisture content was calculated by using ASTM D2974-87 method.

i. Acid number: Acid number indicates the amount of free acid present in sample. The acid number was calculated by using ASTM D974/01 with help of standard KOH solution.

Results and Discussion

The advantages of using non edible oils as fuel compared to diesel fuel are liquidity, ready availability, renewability, lower sulphur and aromatic content, biodegradability, higher cetane number These oils are extremely viscous converting these to biofuel decreases its viscosity. Blending of these oils and biofuel with some % of diesel fuel was a suitable method to reduce choking and for extended engine life.

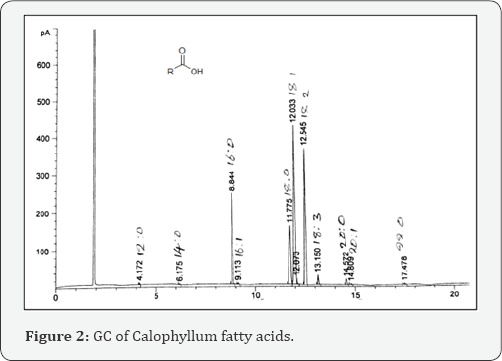

The present study is focused on the use of non-edible Calophyllum oil rich in free fatty acid and was widely grown in GITAM University and also along the coastal areas of India. The seeds of Calophyllum were collected dried and crushed. The oil was soxhlet extracted using hexane as a solvent. The extracted crude oil is greenish yellow and it gets darkened during the storage. The oil having disagreeable odour. The physico chemical properties of crude oil are tabulated in Table 1 and were carried out as per (ASTM) -6751. Extracted oil consisted of pure triglyceride and free fatty acids along with minor components. The crude oil was trans esterified using methanol to obtain Calophyllum fatty acid methyl esters and the methyl esters were determined for fatty acid composition using gas chromatography and the results were tabulated in Table 2, Figure 2.

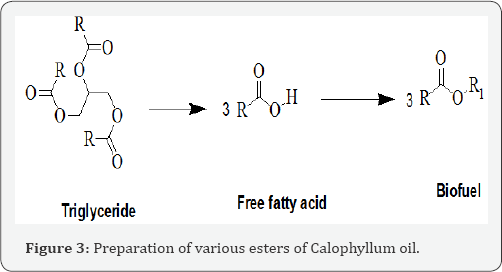

Calophyllum oil was esterified with different alcohols such as methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, using H2SO4 or p-TSA by two step process Figure 3. The first step involving the formation of free fatty acid by base hydrolysis. The fatty acid is a semi solid and the next step involving the esterification of free fatty acid with various alcohols, the ester thus obtained was liquid having a pleasant odour and the esters of Calophyllum fatty acids were characterized by NMR and IR spectral studies. The presence of peak in IR around 1740cm-1(- C=O) and 1174(C-O-C) and the presence of peaks in NMR around 2.29-2.31(2H, t, CH2C=O), 3.93-4.01(2H, t, CH2 the formation of ester was given below in Figure 4. (A-methyl, B-ethyl, C-1-propyl, and D-1-butyl)

The synthesized alkyl esters of Calophyllum fatty acids were evaluated for their physico chemical properties and fuel properties the results were tabulated in Table 3. The kinematics viscosity of the oil at 40 °C and 100 °C are 63.12cst and 10.67cst. While that of esters in the range of 6-22 and 2-9cst. It was found that the flash point of are in agreement with ASTM D93, The flash point of the oil is 185.2 °C. While that of esters are in range of 100-200 °C. The pour point of the oil is -9.8 °C. While that of esters in range of -30 to 0 0C. The cloud point was determined by ASTM D-2500 using cloud point apparatus manufactured by Cultures instruments LLP, Bangalore, India. The pour point of the oil is 90 °C. While that of esters in range of 0 0C to 20 0C. The color and tarnish of copper strip level was assessed against the ASTM copper strip corrosion standard and all the esters exhibited copper corrosion values of 1a.

Conclusion

There is a tremendous demand for non-edible based oils due to depletion of mineral resources and growing concerns for eco-friendly products. Calophyllum oil, widely grown in coastal area as well as in GITAM University can be used as a feedstock for bio-fuel production. In the present study methyl, ethyl, 1-propyl, 2-propyl, 1-butyl, esters were prepared from corresponding alcohols and are evaluated for fuel properties. The fuel properties were compared with literature and ASTM D6757 biodiesel standards. The study revealed that various esters of Calophyllum oil seem to be a satisfactory feed stock for future biodiesel production.

Acknowledgment

Authors sincerely thank the Departments of Mechanical engineering and Chemistry of GITAM University for giving an opportunity to carry out research and synthesis of bio fuels from Calophyllum. Also IICT, Department of Lipid Science and Technology, Hyderabad and Sionic pharmaceuticals, Visakhapatnam for NMR, GC and IR spectral data.

References

- Adeniyi A (1991) Studies on seed oils of Garcinia kola and Calophylluminophyllum. Journal of Science of food and Agriculture 57: 441-442.

- Chavan SB, Kumbhar RR, Deshmukh RB (2013) CallophyllumInophyllum Linn ("honne”) Oil, A source for Biodiesel Production. Research Journal of Chemical Sciences 3(11): 24-31.

- Atabani AE, Aldara da SC (2014) Calophylluminophyllum L. - A prospective non-edible biodiesel feedstock. Study of biodiesel production, properties, fatty acid composition, blending and engine performance. Renewable and Sustainable Energy Reviews 37: 644655.

- Sanjid A, Masjuki HH, Kalam MA, Ashrafur Rahman SM, Abedin MJ, et al. (2013) Impact of palm, mustard, waste cooking oil and Calophyllum inophyllum biofuels on performance and emission of CI engine. Renewable and Sustainable Energy Reviews 27: 664-682.

- Rahul Krishnaji B, Channapattana SV, Nilima Baliram G, Ingole SM (2014) Experimental Investigation of Performance Characteristics of CalophyllumInophyllum Biodiesel in CI Engine by Varying Compression Ratio. International Journal of Engineering and Advanced Technology (IJEAT). 3(5): 2249-8958.

- Ravi SD, Hotti SR, Hebbal OD (2014) Performance, Combustion and Emission Characteristics on Single Cylinder Diesel Engine using CalophyllumInophyllum (Surahonne) Oil. International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 3(9): 378-385.

- Sanjay kumar D, Swati S, Raghunath P (2012) Preparation of Biodiesel of Undi seed with In-situ Transesterification. Leonardo Electronic Journal of Practices and Technologies 20: 175-182.

- Mohan T Raj, Murugumohan Kumar, Kandasamy K (2012) Tamanu oil - an alternative fuel for variablecompression ratio engine.International Journal of Energy and Environmental Engineering 3:18.

- Atabani AE, Irfan Anjum B, Mahlia TMI, Masjuki HH, Mofijur M, et al. (2013) Fuel Properties of Croton megalocarpus, Calophylluminophyllum, and Cocosnucifera (coconut) Methyl Esters and their Performance in a Multi cylinder Diesel Engine. Energy Technol 1: 685-694.