A Novel method for Nano‐Polishing TEM Samples Out of a Ni‐Ti Endodontic File

Licheng Hua Abayomi Omolewu, Nicholas Broadbent, Charles Z DengJanine L Conde, Mourad Benamara, Z Ryan Tian*

1Institute of Nanoscience⁄Engineering, University of Arkansas, Fayetteville, Arkansas

2Department of Chemistry and Biochemistry, University of Arkansas, Arkansas

3Department of Microelectronics‐Photonics, University of Arkansas, Arkansas

4Department of Mechanical Engineering, University of Arkansas, Arkansas

5Dentsply Sirona Endodontics, Tulsa, USA

6Dentsply Sirona Endodontics, Ballaigues, Switzerland

Submission: June 15, 2017; Published: June 23, 2017

*Corresponding author: Ryan Tian, Institute of Nanoscience/Engineering, University of Arkansas, Fayetteville, Arkansas, Email: rtian@uark.edu

How to cite this article: Licheng H A O, Nicholas B, Charles Z D, Janine L C, Mourad B, Z Ryan T.Ryan.et al. A Novel Method Fornano-Polishing TEM Samples Out of a Ni-Ti Endodontic File. JOJ Material Sci. 2017; 2(1): 555576. DOI:10.19080/JOJMS.2017.02.555576

Abstract

Specimen preparation of transmission electron microscopy (TEM) typically requires the use of focused ion beam (FIB) or ion milling. However, this FIB technology is too expensive, difficult to learn and operate, and time‐consuming even for the users with extensive training and experience. Here we demonstrate a user‐friendly mechanical method by simply using a tripod polisher for preparing TEM samples on alloyed oxide layer surface. Using this nano‐polishing method, TEM specimen of endodontic files of nickel‐titanium (Ni‐Ti) alloy we repolished successfully.

Keywords: Tripod polisher; Nickel‐titanium endodontic file; Angular adjustment

Opinion

Transmission electron microscopy (TEM) provides critical analyses of nano‐scale structures [1,2] in especially nanomaterials science. To obtain reliable results from the TEM analysis, the samples must be thinned to electron transparency. This can be achieved conventionally by a combination of mechanical polishing and focused ion beam (FIB) [3] or ion milling [4]. The FIB is common equipment usually attached to a high‐end scanning electron microscope (SEM) for TEM specimen preparation with its advantages and disadvantages [7]. For example, arte facts can be introduced during the sample preparation which may jeopardize the interpretation of the TEM data [8]. Besides the trouble in maintaining and using the expensive FIB‐SEM, the techniques require special skills, and are time‐consuming [8]. In particular, the regular mechanical polishing and FIB are both not good to analyze the different hue‐color of oxides on the surface of the Ni‐Tialloy endodontic file, since during the processes the oxide‐layer's structure and composition can be altered. Thus, finding a user‐friendly alternative for preparing especially the Ni‐Tialloy sample with the much reduced cost and time can greatly benefit the users with the limited budget and time.

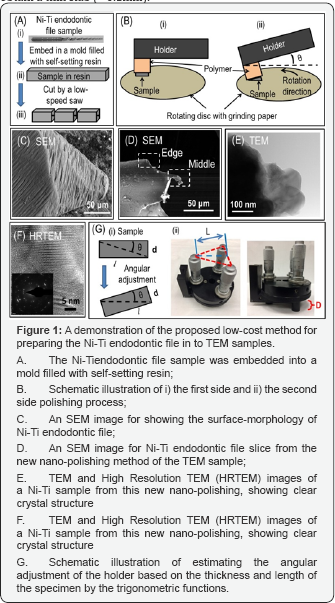

In this opinion, we demonstrated a new nano‐polishing method for preparing the Ni‐Tiendodontic file for TEM analysis by employing a low‐cost mechanical polisher called Tripod Polisher (Model 590, South Bay Technology).In particular, the thin Ni‐Tiendodontic file has aspiral (twisted) and tapered sharp tip see Figure 1A at which the TEM‐sample's preparation is quite difficult.

In experiment, this sample was first of all embedded in a mold filled with a self‐setting polymeric resin, as showed in Figure 1A. There is in‐molded sample was then cross‐sectioned using a low‐speed diamond saw. Next, the cross‐sectioned file was mounted onto the polymer stub of the tripod polisher Then, the stub was attached to the screw‐micrometer for being gradually lowered down until the sample touches the abrasive surface (Figure 1B).

On this basis, sandpapers of ascending grit‐sizes (400, 800, and 1200) were iteratively applied onto the specimen for grinding, which produced a smooth surface. Then, likewise using diamond‐polish paper with the grit‐size ranging from 6 to 0.1 microns, the surface of the sample was polished further. The final polishing step on the same side of the specimen was performed using a mechano‐chemical process with a water‐solution of colloidal silica. After finishing this side, the sample was flipped over for grinding and polishing, as described above, to finally obtain a thin slab (∼0.1mm).

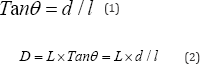

Thereafter, the angle of the holder was calculated (see equations below), and physically adjusted. Then, the thin‐slab (on the tripod‐polisher) was further polished by repeating the aforementioned steps (Figure 1B), until the tip was thinner than 100nm for the ease of electron transmission for the TEM analysis [9]. To avoid overheating and dehydrating the sample to induce unwanted reactions on the sample‐surface during the polishing, a water‐cooling was used all the time.

The results from the SEM (FEI XL‐30, Philips) and TEM study on the Ni‐Ti sample were outlined in Figure 1C‐1F. The SEM micrograph (Figure 1C) showed morphology of Ni‐Ti endodontic file, and that of Figure 1D showed a transparent edge from the middle of the Ni‐Ti sample slice. The images from the TEM analysis (FEI, TITAN 80‐300) (Figure 1E&1F) showed a clear crystal lattice‐structure of the Ni‐Ti endodontic file. These results implied that the use of the low‐cost tripod polisher for preparing the TEM sample out of the Ni‐Ti endodontic file's spiral tip was effective.

The angular adjustment of the holder can be calculated based on the thickness (d) and length (l) of the specimen (Figure 1G) via trigonometric function. The equations are shown in the (1) and (2) below, where, d=the specimen's thickness (measure by screw micrometer); l=the specimen's length (measure by rule); 0=angle between holder base and horizontal axis; D=the height the micrometer screw gauge need to lowered; L=the triangle's height from three screw micrometers see Figure 1G.

Summary

In summary, a user‐friendly and simple angular adjustment using the low‐cost tripod polisher enabled an effective and efficient method for preparing Ni‐Ti endodontic file TEM samples. This method has the proven versatility for reliably, reproducibly, and efficiently producing specimen of many types for TEM nano‐analysis, which is ideal for new users with limited funds and time.

References

- Buess G (1993) Review: transanal endoscopic microsurgery (TEM). J R Coll Surg Edinb 38(4): 239‐245.

- Kuwano S, Fujita T, Pan D, Wang K, Chen M (2008) TEM sample preparation for micro compressed nanocrystalline Ni. Mater Trans 49(9): 2091‐2095.

- Langford RM (2006) Focused ion beams techniques for nanomaterials characterization. Microsc Res Tech 69(7): 538-549.

- Dieterle L, Butz B, Müller E (2011) Optimized Ar(+)‐ion milling procedure for TEM cross‐section sample preparation. Ultramicroscopy 111(11): 1636‐1644.

- Giannuzzi LA, Stevie FA (1999) A review of focused ion beam milling techniques for TEM specimen preparation. Micron 30(3): 197‐204.

- Howitt DG (1984) Ion milling of materials science specimens for electron microscopy: A review. J Elec Micros Tech 1(4): 405-414.

- Mayer J, Giannuzzi LA, Kamino T, Michael J (2007) TEM sample preparation and FIB‐induced damage. MRS bull 32(05): 400‐407.

- Safran G, Szasz N, Safran E (2015) Two‐In‐one sample preparation for plan‐VIew TEM. Microsc Res Tech 78(7): 599‐602.

- Williams DB, Carter CB (2009) Transmission Electron Microscopy. (2nd edn), Springer, New York, USA.