Effect of Polymer Dope Concentration on the Morphology and Performance of PES/PDMS Hollow Fiber Composite Membrane for Gas Separation

Xiangbao Liu, Huan Liu and Pei Li*

College of Materials Science and Engineering, Beijing University of Chemical Technology, China

Submission: April 27, 2017; Published: June 19, 2017

*Corresponding author: Pei li, college of Materials Science and Engineering, Beijing University of Chemical Technology, Beijing, 100029, China, E-mail: lipei@mail.buct.edu.cn

How to cite this article: Xiangbao Liu, Huan Liu, Pei Li. Effect of Polymer Dope Concentration on the Morphology and Performance of PES/PDMS Hollow Fiber Composite Membrane for Gas Separation. JOJ Material Sci. 2017; 1(5): 555573. DOI:10.19080/JOJMS.2017.01.555573

Abstract

In this research, we studied the effects of poly ether sulfone (PES) dope concentration varied from 22 to 28 wt. % on the morphologies and mean surface pore sizes of the PES hollow fiber substrates. In addition, the relations between the mean surfaces pore sizes of the PES substrate to the gas separation performances of the poly ether sulfone/poly dimethyl siloxane (PES/PDMS) hollow fiber composite membranes were explored. Results showed that as the PES concentration in the dope solution increased, both the mean pore size of the PES substrate and the gas permeance of PES/PDMS composite membrane decreased. SEM pictures showed that the dense layer of the PES substrate became apparently thicker and denser with the increase in PES dope concentration.

Keywords: Hollow fiber composite membrane; PES; PDMS; Gas separation

Abbreviations: PES: Poly Ether Sulfone; PDMS: Poly Dimethyl Siloxane; NMP: N-Methyl-2-Pyrrolidone

Introduction

In the past 20 years, gas separation becomes more and more important in membrane technologies. Hollow fiber composite membranes are one of the major membrane types for gas separation which are prepared from two or more kinds of materials through special techniques. A typical composite membrane combines a porous hollow fiber membrane as a substrate and a dense coating layer as the separation layer [1]. Therefore, the performance of composite membranes for gas separation depends on top layer material. However, the structure of the substrate is also important to reduce the gas transport resistance. The sub layer porosity should be as high as possible to avoid additional mass transfer resistance against the permeating compounds. Poly ether sulfone (PES) is one of the promising polymeric materials due to its excellent chemical and physical properties such as robust mechanical strength, good thermal stability, and superior chemical resistance [2]. It is a good candidate to be used as the support in composite membrane. Poly dimethyl siloxane (PDMS) has both good permeability and excellent adhesion property to the support that has been proven to be an excellent coating material [3-6].

The asymmetric polymeric membranes are mainly prepared using the immersion phase inversion method [7]. It is well known that the polymer concentration plays an essential role in membrane formation. Polymer concentration has a strong correlation to viscosity and gives a big influent to the membrane performance [8-11]. The viscosity of a polymer solution increases by increasing polymer concentration. Eventually, a critical concentration is reached where the entanglement of the polymer chains are inevitable [12]. Generally, a concept of critical polymer concentration is often employed as a guideline for a proper selection of polymer content in dope solutions. It has been hypothesized by Chung et al. that at or above the critical concentration, the polymer exhibits significant chain entanglement, which aids the formation of dense skin with minimal defects on the hollow fibers [13].

In the present paper, we report the preparation of PES/ PDMS hollow fiber composite membranes for gas separation. The main object of the present work is to investigate the effect of PES concentration in the dope solution on the hollow fiber membranes structure and performance of the PES/PDMS composite membrane.

Experimental

Materials

Poly ether sulfone (PES) [Ultra son® E1010; Mw=72,000, Mw/Mn=3.54], obtained from BASF (Germany). N-methyl- 2-pyrrolidone (NMP, >99%) was purchased from Tianjin Da maoChemical Reagent Factory, was use as solvent. (PDMS, Sylgard 184) was supplied by Dow Chemicals.

Viscosity measurement

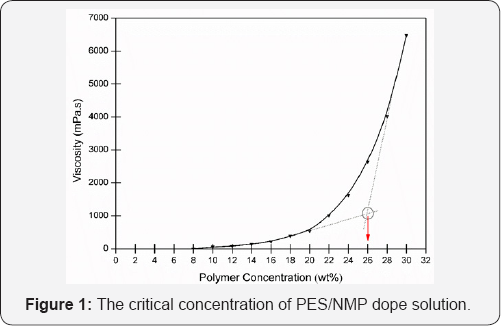

The critical polymer concentration can be determined from the correlation of viscosity versus polymer concentration. Figure 1 shows the viscosities corresponding to different polymer concentration at the spinning temperature of 25 °C. It can be seen that the critical polymer concentration is about 26 wt. %. In order to investigate the effect of PES concentration which were near the critical polymer concentration on the PES HF structures, PES dope concentrations of 22, 24, 26 and 28 wt. % were chosen in this study.

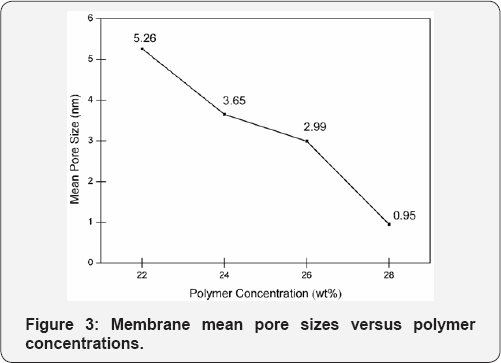

Preparation of the PES/PDMS hollow fiber composite membrane

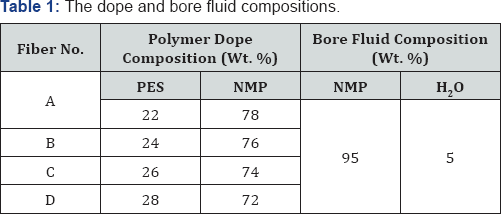

The PES hollow fibers were fabricated by a dry-jet wet- spinning process. The detailed experimental procedures can be found elsewhere [14]. In this study, the dope and bore fluid flow rates were kept constant during spinning. Some spinning parameters are shown in Table 1. The as-spun fibers were immersed in water for 3 days to remove the residual solvent. The procedure of solvent exchange was to immerse these fibers into methanol for 30min each time by three times and then n-hexane for 30min each time with three times. After the n-hexane wetted HF was air-dried, the dry fibers were dip-coated with 3 wt. % silicone rubber solution.

Determination of the membrane morphology and gas permeation properties

The morphologies of membranes were examined using scanning electron microscopy on a JEOL JSM-7800F. The gas flow rates were measured using a bubble flow meter with pure nitrogen (99.99%), oxygen (99.99%) and carbon dioxide (99.99%). The permeance, P/L, was calculated by the following equation:

P/L=Q/AΔP=Q/nDlΔPπ (1)

Where P is the permeability of separating layer (Barrer), L the thickness of the apparent dense-selective layer (cm), Q the pure gas flux (cm3/s), n the number of fibers in one testing module, D the outer diameter of the testing fibers (cm), l the effective length of the modules (cm), and AP the gas pressure difference cross the membrane (cmHg). We use GPU as the unit of permeance (1GPU=1*10-6cm3 (STP)/cm2 s cmHg).

The ideal separation factor can be determined from the following equation:

Results and Discussion

Membrane morphologies

Figure 2 shows the cross-section and outer surface morphologies of PES hollow fiber membranes spun from various PES/NMP dope concentrations. For all dope compositions the fibers have a typical asymmetric structure, which is composed of a sponge-like section and a finger-like porous structure. A large long finger-like macro voids are clearly seen in Figure 2a for low polymer concentration, whereas a much smaller macro voids in Figure 2b for high concentration. This is attributed to the changes of viscosity at different polymer concentration. Viscosity has a significant effect on the membrane morphologies. The greater viscosity at higher polymer concentration will remarkably delay the exchange rate between the solvent and water during the polymer precipitation process, leading to a higher polymer concentration at the interface between the polymer solution and the non-solvent (water) and results in development of a less porous morphology [15]. Polymers in a solution of high viscosity exhibit significant chain entanglement, which is one of the requirements to prepare a membrane with minimum defects [12]. As can be seen, small pores and defects were observed on the surface layer of membrane when the PES concentration at 22 wt. %. A similar observation was also reported elsewhere [16-18].

Membrane mean pore size

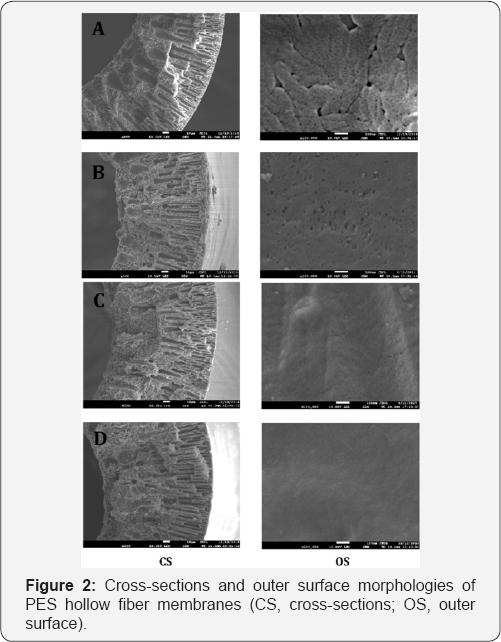

The effect of PES concentration on the membrane pore size is shown in Figure 3. Gas permeation tests were used to measure the average pore size. By increasing the polymer concentration, it was observed that the mean pore size decreased. As can be seen from the Figure 3, the mean pore size decreased from 5.26nm to 0.95nm. The low polymer concentration accelerates the solvent- non solvent exchange rate across the interface, leading to a more rapid precipitation. Consequently, the pores on the outer surface of membrane become larger. This is in accordance with the SEM observation (Figure 1).

Gas Permeability and Selectivity

The pressure-normalized fluxes of N2, O2 and CO2 for noncoated and silicone-coated hollow fiber membranes were measured at 25 °C at a pressure difference of 2bar and 5bar, respectively. The idea selectivity of O2/N2 and CO2/N2 was then calculated using Eq. (2). Uncoated and coated membranes were tested at 2bar and 5 bar, respectively. All experiments were carried out at 25 °C.

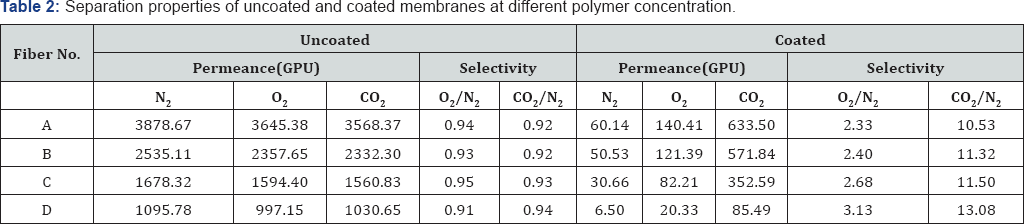

Table 2 summaries the separation properties of both uncoated and PMDA coated membranes. It can be seen that the gas flux increases with the decrease in PES dope concentration. The reason is that the decrease in polymer concentration in the spinning dope favors the formation of a less dense top layer [19-23]. The extremely high permeation fluxes of these gases through the uncoated hollow fiber membranes indicate that the gas transport through these membranes were predominantly determined by a combined Knudsen flow and Poiseuille flow mechanism [14]. All the uncoated membrane exhibited poor selectivity. This is due to the existent of defects at the surface layer.

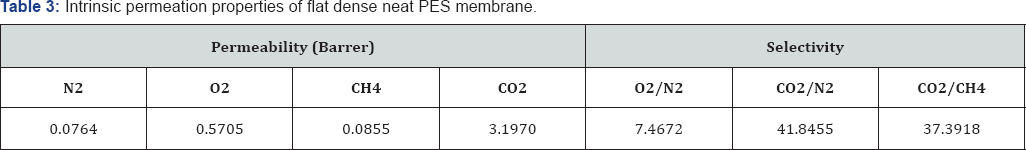

Table 3 Intrinsic permeation properties of flat dense neat PES membrane. Dense membranes were tested at 35 °C and 10.1325x105Pa (10atm).

After PDMS coating, the permeance of all membranes have been substantially reduced and the selectivity greatly enhanced. The function of silicone coating is caulk the pinholes or defects on the membrane outer dense layer. The membrane spun from the high polymer concentration present low pressure-normalized flux, but high selectivities. Compared with the intrinsic gas separation properties of PES dense film Table 3, all the samples show relatively low selectivity. Note that, the ideal selectivities of CO2/N2 and O2/N2 are 10-13 and 2-3 respectively, which match the intrinsic selectivity of PDMS polymer. Therefore, the PDMS coating layers dominate the gas transport performance.

In summary, fiber A with a PES concentration of 22 wt. % is the best substrate for preparing PES/PDMS composite gas separation membrane, since it shows the highest CO2 permeance of 633.5 GPU with a similar CO2/N2 selectivity of 10.5.

Conclusion

Polymer dope concentration is an important factor which influences the resultant morphology and performance of PES/ PDMS hollow fiber composite membranes. It is observed that increasing PES concentration in the spinning dope decreases the mean pore size of the PES hollow fiber substrate. On the other hand, with similar gas selectivities to the intrinsic PDMS polymer, it is preferred to increase the mean pore size of the PES substrate as much as possible. Our results show that the best gas separation performance can be obtained by reducing the PES concentration to 22 wt. % in the dope solution.

References

- Vankelecom IFJ, Moermans B, Verschueren G, Jacobs PA (1999) Intrusion of PDMS top layers in porous supports. Journal of Membrane Science 158(1): 289-297.

- Kesting RE, Fritzsche AK (1993) Polymeric gas separation membranes. Wiley.

- Jha P, Mason LW, Way JD (2006) Characterization of silicone rubber membrane materials at low temperature and low pressure conditions. Journal of Membrane Science 272(1-2): 125-136.

- Merkel TC, Gupta RP, Turk BS, Freeman BD (2001) Mixed-gas permeation of syngas components in poly (dimethylsiloxane) and poly(1-trimethylsilyl-1-propyne) at elevated temperatures. Journal of Membrane Science 191(1-2): 85-94.

- Li P, Chen HZ, Chung TS (2013) The effects of substrate characteristics and pre-wetting agents on PAN-PDMS composite hollow fiber membranes for CO2/N2 and O2/N2 separation. Journal of Membrane Science 434: 18-25.

- Chen HZ, Thong Z, Li P, Chung TS (2014) High performance composite hollow fiber membranes for CO2/H2 and CO2/N2 separation. International Journal of Hydrogen Energy 39: 5043-5053.

- Wang T, Zhao C, Li P, Li Y, Wang J (2015) Fabrication of novel poly (m-phenylene isophthalamide) hollow fiber nanofiltration membrane for effective removal of trace amount perfluorooctane sulfonate from water. Journal of Membrane Science 477: 74-85.

- Hal Wood J, Wang, Sourirajan S (1993) The effect of polyethersulfone concentration on flat and hollow fiber membrane performance. Separation Science and Technology 28(15-16): 2297-2317.

- Ismail AF, Lai PY (2003) Effects of phase inversion and rheological factors on formation of defect-free and ultrathin-skinned asymmetric polysulfone membranes for gas separation. Separation & Purification Technology 33(2): 127-143.

- Yamasaki A, Tyagi RK, Fouda AE, Jonasson MT (1999) Effect of Solvent Evaporation Condition on Gas Separation Performance for Asymmetric Membranes. Journal of Applied Polymer Science 71: 1367-1374.

- Kesting RE, Fritzsche AK, Cruse CA, Moore MD (1990) The second- generation polysulfone gas-separation membrane. ii. The relationship between sol properties, gel macrovoids, and fiber selectivity. Journal of Applied Polymer Science 40(9-10): 1575-1582.

- Hal Wood, J Wang, S Sourirajan (1993) The effect of polyethersulfone concentration on flat and hollow fiber membrane performance. Separation Science and Technology 28(15-16): 2297-2317.

- Tai SC, Teoh SK, Hu X (1997) Formation of ultrathin high-performance polyethersulfone hollow-fiber membranes. Journal of Membrane Science 133(2): 161-175.

- Wang D, Li K, Teo WK (1996) Polyethersulfone hollow fiber gas separation membranes prepared from nmp/alcohol solvent systems. Journal of Membrane Science 115(1): P85-108.

- CA Smolders, AJ Reuvers, RM Boom, IM Wienk (1992) Microstructures in phase-inversion membranes. part 1. formation of macrovoids. Journal of Membrane Science 73(2): 259-275.

- Sani NAA, Lau WJ (2014) Influence of polymer concentration in casting solution and solvent-solute-membrane interactions on performance of polyphenylsulfone (ppsu) nanofiltration membrane in alcohol solvents. Journal of Polymer Engineering 34(6): 489-500.

- Darvishmanesh S, Tasselli F, Jansen JC, Tocci E, Bazzarelli F, et al. (2011) Preparation of solvent stable polyphenylsulfone hollow fiber nanofiltration membranes. Journal of Membrane Science 384(1-2): 8996.

- Jansen JC, Darvishmanesh S, Tasselli F, Bazzarelli F, Bernardo P, et al. (2013) Influence of the blend composition on the properties and separation performance of novel solvent resistant polyphenylsulfone/ polyimide nanofiltration membranes. Journal of Membrane Science 447(22): 107-118.

- Mulder MHV, Hendrikman JO, Wijmans JG, Smolders CA (1985) A rationale for the preparation of asymmetric pervaporation membranes. Journal of Applied Polymer Science 30(7): 2805-2820.

- Koops GH, Nolten JAM, Mulder MHV, Smolders CA (1994) Integrally skinned polysulfone hollow fiber membranes for pervaporation. Journal of Applied Polymer Science 54(3): 385-404.

- Pesek SC, Koros WJ (1994) Aqueous quenched asymmetric polysulfone hollow fibers prepared by dry/wet phase separation. Journal of Membrane Science 81(1-2): 71-88.

- Lai J Y, Liu MJ, Lee KR (1994) Polycarbonate membrane prepared via a wet phase inversion method for oxygen enrichment from air. European Polymer Journal 50(86): 103-118.

- Chung TS, Kafchinski ER, Foley P (1992) Development of asymmetric hollow fibers from polyimides for air separation. Journal of Membrane Science 75(1): 181-195.