Process Optimization of Composting Systems

Naoto Shimizu*

Field Science Center for Northern Biosphere, Research Faculty of Agriculture, Hokkaido University, Japan

Submission: August 05, 2018; Published: August 16, 2018

*Corresponding author: Naoto Shimizu, Field Science Center for Northern Biosphere, Research Faculty of Agriculture, Hokkaido University, Kita 9 Nishi 9, Kita-ku, Sapporo, Hokkaido, 060-8589, Japan, Tel: +81117063848; Email: shimizu@bpe.agr.hokudai.ac.jp

How to cite this article: Naoto Shimizu. Process Optimization of Composting Systems. Dairy and Vet Sci J. 2018; 7(3): 555712. DOI: 10.19080/JDVS.2018.07.555712

Abstract

This mini-review summarizes composting procedures using an aerated, packed-bed-type reactor and the types and effectiveness of different types of aeration during composting. Cattle manure was composted using an 18.8-L reactor with three different amounts of total air supplied (1080, 3240, and 10800 L/kg dry mass). The composting process was 360 h long and had continuous or on/off (20 min/h) aeration (intermittent aeration) and three turning patterns (no turning, full turning, and turning with position change). The degradation of organic matter in the three-stage system (the compost was turned every 120 h during the 360-h period) was significantly affected by total air supply volume and was more efficient with on/off (intermittent) aeration than with continuous aeration. The change in moisture content was more strongly affected by turning than by the aeration mode. The optimal composting conditions for organic matter degradation (maximum of 37.7%) were as follows: aeration rate, 0.45 L/min.kg dm; aeration mode, on/off; and full turning. The total accumulated weight losses and heat generated during composting indicated significant effects of the total air supplied and were largest in the continuous composting process.

Keywords:Composting; Cattle manure; On/off aeration; Turning; Heat generated; Degradation; Power consumption; Microorganisms; Oxygen; Nutrients; Carbon; Nitrogen; Moisture content; Porosity; Temperature

Introduction

Food supply is a primary issue for people around the world, and an increasing demand for various foodstuffs is anticipated in the future. Now and in the future, there is a need to utilize cattle manure sustainably and to use this resource without causing adverse environmental effects. Composting is the aerobic (oxygen-requiring) decomposition of organic materials by microorganisms under controlled conditions. During composting, microorganisms consume oxygen (O2) while feeding on organic matter. Active composting generates considerable heat and releases large quantities of carbon dioxide (CO2) and water vapor into the air. Composting reduces both the volume and mass of the raw materials while transforming biomass into a valuable soil conditioner. Factors affecting the composting process include oxygen, aeration, nutrients (carbon: nitrogen (C: N) ratio), moisture content, porosity, structure, texture, particle size, pH, and temperature.

There are several aeration control strategies that have been used in practice, although some laboratory studies have not described the aeration control strategy in adequate detail. Some previous studies have applied continuous aeration methods in composting experiments [1-6] and have presented a kinetic analysis of forced aeration [7,8]. In other studies, a model for fermentation and drying during composting satisfactorily predicted dry matter degradation [9,10]. Experiments using a small-scale reactor demonstrated that a relatively high ventilation rate and the specific combination of intermittent aeration (ventilation/resting ratio applied using an on/off method) could provide more effective composting than continuous ventilation [11]. A comparison of models for continuous and on/off aeration has not yet been undertaken. The mechanisms of the composting process during intermittent aeration are still unclear.

Many studies have addressed the basic requirements for composting. Composting system technologies are required to support agricultural production ecosystems. However, the main problem is the practical application of these technologies. We begin by introducing the different types of aeration in a packed-bed type reactor, the relationship between aeration and organic matter degradation, and the effectiveness of intermittent aeration.

Aeration

There are many variations in aeration, but it generally takes place either passively or by forced air movement. Turning charges materials with fresh air, and the air introduced by turning is quickly consumed by the composting process [12-14]. Passive aeration, often called natural aeration, takes place by diffusion and natural air movement. Forced aeration relies on fans to move air through the mass of composting materials. Continuous aeration can reduce the required air flow rate. It also reduces the fluctuation in temperature and O2 levels [15]. In a previous study, experiments comparing various aeration conditions were performed using an adiabatic-type reactor [11].

Packed – Bed Type Reactor

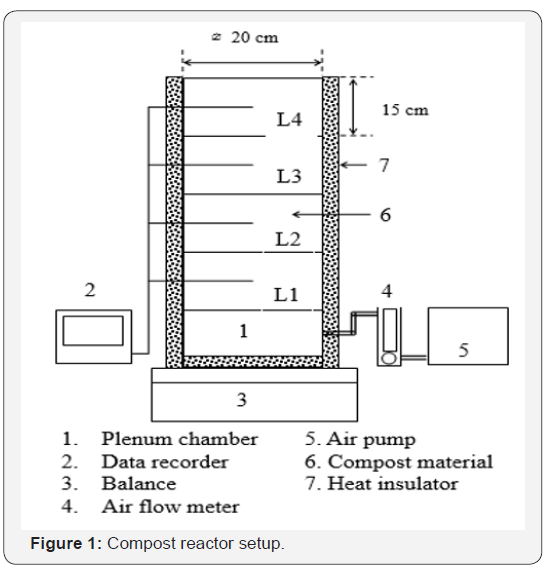

In our previous study, we tested various strategies for composting cattle manure with forced aeration. The composting of cattle manure was conducted using a contained (closed) system [16] comprising an 18.8-L reactor (Figure 1) with three different amounts of total air supplied (1080, 3240, and 10800 L/kg dry mass). The composting process was 360 h long and had two aeration methods (continuous and an on/off sequence at 20 min/h) and three turning patterns (no turning, A; full turning, B; and turning with position change, C) [17]. The runs were codified as follows, run 0.15Bc; where the number refers to the aeration rate (L/min.kg-DM), the capital letter denotes the turning type (A, B or C, as above) and the small letters denote continuous (c) or intermittent (i) aeration. The degradation of organic matter in the three-stage system (compost was turned every 120 h over the 360h period) was significantly affected by total air supply volume and was most efficient with on/off aeration. The change in moisture content was more strongly affected by turning than by the aeration mode.

Discussion

Temperature

When aeration is supplied throughout the composting period, lower aeration after the peak temperature can enhance the composting process [13]. Lowering the aeration rate after the peak temperature is reached may reduce heat loss by aeration. However, when the temperature exceeds 60 °C, the optimum for most thermophiles is reached, and the high temperatures start to limit the composting system [18]. The compost matrix needs to be turned to release heat from the inner portion, resulting in temporary cooling.

Organic Matter

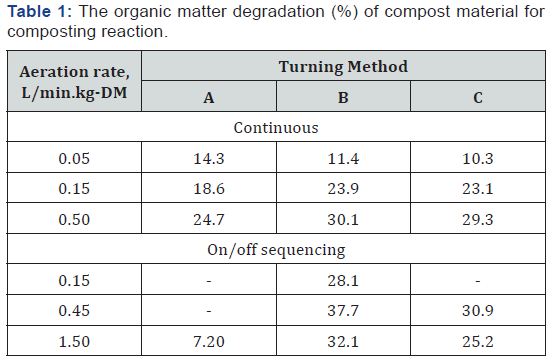

In the active composting phase, easily decomposable and putrescible compounds are broken down and pathogens are eliminated [12]. The effect of the aeration method and turning on organic matter degradation is shown in Table 1. Using the continuous method, increasing aeration within the range of 0.05 to 0.50L/min.kg-DM enhanced the organic matter degradation from 10.3% to 30.1%. For the intermittent method, increasing aeration from 0.15 to 0.45L/min.kg-DM increased the organic matter degradation from 28.1% to 37.7%, but further increasing aeration from 0.45 to 1.50 L/min.kg-DM reduced the organic matter degradation to 32.1%.

Intermittent aeration allows microbes to use oxygen efficiently. Another effect of intermittent aeration is that heat removal by aeration can be stopped or reduced, and that high temperature in the composting system facilitates extensive decomposition of organic matter. Appropriate turning and aeration results in the rapid decomposition of organic matter. The highest organic matter degradation was obtained in a composting system with an intermittent aeration rate of 0.45 L/ min.kg-DM and with full turning (type B) [17]. The pattern of moisture change was more strongly affected by turning than by aeration modes. The total accumulated weight losses and heat generated during composting indicated significant effects of the amount of air supplied. The largest effects were obtained using the continuous process.

Effect of aeration

With the same total aeration (3.24m3/kg-DM), the organic matter degradation for run 0.45Bi (37.7%) was higher than that for run 0.15Bc (23.9%). For continuous aeration, the highest organic matter degradation was obtained in run 0.50Bc (30.1%). To achieve the same organic matter degradation, power consumption for aeration could be reduced by 66.7% by applying intermittent aeration. In other words, intermittent aeration after turning enhanced organic matter degradation and reduced the energy requirements by two-thirds compared with continuous aeration [17].

Conclusion

This mini review compares aeration rates, aeration methods, and turning methods to determine the optimal composting conditions for cattle manure. Air was supplied at three different rates with continuous or intermittent aeration resulting in distinct patterns of moisture content, organic matter degradation, and total weight loss in each treatment. The range of aeration rates covered very low to excessive aeration. Intermittent aeration after turning enhanced organic matter degradation and reduced the energy requirements by two-thirds compared with continuous aeration. The composting and drying model showed satisfactory results for continuous and intermittent aeration. Further research is necessary to obtain experimental data for greenhouse gas emissions and the efficiency of the process to fully assess these methods as operational activities.

Conflict of Interest

This manuscript was prepared and reviewed with the participation of all the authors, who declare that they have no conflict of interest that compromise the validity of the results.

References

- Doshu N (2003) Composting facility using natural energy (in Japanese). Animal Husband 57(2): 267-271.

- Elwell DL, Keener HM, Wiles MC, Borger DC, Willett LB (2001) Odorous emissions and odor control in composting swine manure/sawdust mixes using continuous and intermittent aeration. Trans ASAE 44(5): 1307-1316.

- Guardia AD, Petiot C, Benoist JC, Druihe C (2012) Characterization and modelling of the heat transfers in a pilot-scale reactor during composting under forced aeration. Waste Manag 32(6): 1091-1105.

- Karyadi WNJ, Harano M, Shimizu N, Takigawa T, Kimura T (2007) Degradation of organic matter in cattle manure composting by aeration and turning in a packed-bed reactor. J Jap Soc Agric Machinery 69(4): 71-78.

- Lau AK, Lo KV, Liao PH, Yu JC (1992) Aeration experiment for swine waste composting. Bioresour Technol 41: 145-152.

- Robertsson M (2002) Effect of interrupted air supply on the composting process-composition of volatile organic acids. In: Insam H, Riddech N, Klammer S (Eds.), Microbiology of Composting. Springer, Japan, pp. 189-201.

- Bari QH, Koenig A, Guihe T (2000) Kinetic analysis of forced aeration composting-I Reaction rates and temperature. Waste Manag Res 18: 303-312.

- Bari QH, Koenig A (2000) Kinetic analysis of forced aeration composting-II. Application of multilayer analysis for prediction of biological degradation. Waste Manag Res 18: 313-31

- Bach PD, Nakasaki K, Shoda M, Kubota H (1987) Thermal balance in composting operations. J Ferment Technol 65(2): 199-209.

- Shimizu H, Wu X, Sato K, Nishiyama Y, Kimura T (1989) Heat and mass transfer in the aerobic fermentation and drying process of organic material in packed bed. J of the Soc Agric Struc 20(2): 169-176.

- Kimura T, Shimizu N, Kayadi WNJ, Sato K (2007) Effect of intermittent ventilation on composting of cattle manure with a small-scale reactor (in Japanese). J Jap Soc Agric. Machinery 69(5): 78-87.

- Epstein E (1997) Basic Concepts (Chapter 2). In: The science of composting, CRC Press LLC, Boca Raton, Florida, USA p. 19-51.

- Haug RT (1993) The practical handbook of compost engineering. CRC Press LLC, Boca Raton, Florida, USA.

- Michel FC, Forney LJ, J-F Huang, Drew S, Czuprenski M, et al. (1996) Effects of turning frequency, leaves to grass ratio, and windrow vs. pile configuration on the composting of yard trimmings. Compost Sci Util 4(1): 26-43.

- Puyuelo B, Gea T, Sánchez A (2010) A new control strategy for the composting process based on the oxygen uptake ratio. Chem Eng J 165: 161-169.

- Rynk R, Richard TL (2001) Commercial Compost Production Systems. In: Stoffella PJ, Kahn BA (Eds.), Compost Utilization in Horticultural Cropping Systems. CRC LLC, New York, USA, pp. 51-120.

- Shimizu N, Karyadi WNJ, Harano M, Iwabuchi K, Kimura T (2018) Cattle manure composting in a pack-bed reactor with forced aeration strategy. Engi Agric Environ. Food 11: 65-73.

- McKenley VL, Vestal JR (1984) Biokinetic analyses of adaption and succession: microbial activity in composting municipal sewage sludge. Appl Environ Technol 47: 933-941.