Rasgulla: A Review

Gurveer K and Goswami TK*

Agricultural and Food Engineering Department, IITKharagpur, India

Submission: March 14, 2017; Published: April 28, 2017

*Corresponding author: Goswami TK, Agricultural and Food Engineering Department, IIT Kharagpur 721302, India, Email: tkg@agfe.iitkgp.ernet.in

How to cite this article: Gurveer K and Goswami TK*. Rasgulla: A Review. Dairy and Vet Sci J. 2017; 2(3): 555589. DOI: 10.19080/JDVS.2017.02.555589

Abstract

Rasgulla is a popular sweetmeat prepared by chhana in South Asia. Rasgulla contains high amount of protein, fat, minerals and vitamins. Its quality depends on the method used to prepare chhana, quality of chhana and other process parameters. The present review discusses different unit operations followed to prepare rasgulla and basic parameters those give the textural and chemical quality to it.

Introduction

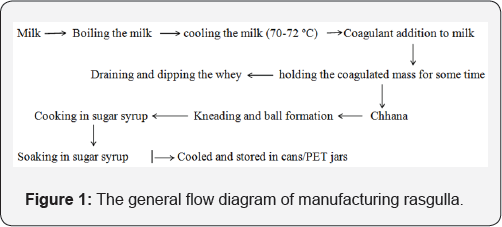

India accounts for nearly 18.6% of world milk production and is one of the largest milk producers. Moreover, according to an estimate 50-55% of the milk produced is converted to indigenous milk products such as yogurt, rasgulla, etc. Rasgulla (a sweet syrup cheese ball) most popular in the regions of South Asia, manufactured from Chhana (a precipitate obtained by heat and acid coagulation of milk) balls. Traditional Indian dairy products account for over 90% of all dairy products consumed in India [1]. It contains fat, high protein, minerals (mainly phosphorus and calcium) and vitamins (fat soluble - vitamin A and D) [2]. 100g of Rasgulla contains 186 calories and out of which carbohydrate, fat and protein provide 153, 17, and 16 calories, respectively. Rasgulla is defined as popular Indian sweetmeat with high textural values [3] and also common milk product [4]. Rasgulla is prepared in batch process by traditional and un-mechanized ways in local markets, but research have been done to mechanize the operation in preparing rasgullas by continuous process. The general flow diagram of manufacturing rasgulla is given below (Figure 1).

Chhana Preparation

Base material for preparing rasgulla is chhana. Texture and moisture content of chhanaare important parameters for quality of rasgulla and they depend majorly on type of milk and coagulant used, temperature, and pH of coagulation during preparation of chhana. It is reviewed that cow milk with fat content >3% is preferable to prepare chhana for manufacturing rasgulla because it gives soft and smooth textured chhana than buffalo milk [5-9]. Recommended a procedure for getting better quality chhana from buffalo milk in which they adjusted 4-5% fat in the milk.

Kundu & De [10] concluded that chhana obtained from buffalo milk was suitable for rasgulla preparation when milk with 5-6% fat was homogenized at 176kg/cm2. Recommended 5% and 4% fat in buffalo and cow milk respectively to get great quality of chhana for rasgulla [11]. Studies showed that use of soy milk in rasgulla preparation along with cow and buffalo milk to increase nutrition in the product [12,13], Bhargava et al. [14]. studied the influence of fat level in goat milk (1-6% fat) on chhana and rasgulla and obtained that 3-4% fat in goat milk gave the best results.

To prepare chhana milk is boiled and cooled down to temperature of 70 °C. Traditionally lemon juice and sour whey were used to coagulate the milk [15]. Different types and strength of coagulants or organic acid salts such as citric acid (1-2%), lactic acid (1-2%), calcium lactate, mixture of citric and lactic acid etc. are used to coagulate the milk [6,16-18], Adhikari et al. [19].

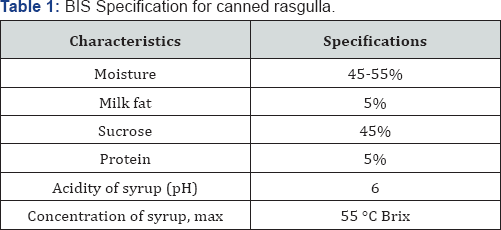

Many researchers optimized the pH of buffalo and cow milk to 5.7 and 5.4 to make chhana required for rasgulla preparation and it was also observed that for fresh milk, pH 5 was best suitable [6,11,16] and Soni et al. [20]. Generally, the optimum temperature of coagulation for making chhana from cow milk and buffalo milk is 70°C and 50°C respectively [10,21]. The Bureau of Indian Standards has laid down the specification for canned rasgulla as shown in (Table 1) (IS: 4079 (1967)).

Kneading and Ball Formation of Chhana

Kneading of channa is a process of mixing and folding the mass to smoothen it to give better and soft rheology to the product. Channa is kneaded traditionally by putting it on the hard surface [5]. Manual kneading is possible for batch production ; of rasgullas. After kneading chhana balls were made by rolling ( chhana (8-10g) in between palms.

Chhana kneading and ball formation process is mechanized by researchers to reduce manual efforts and time of producing rasgullas. Disc grinder was used to knead the chhana by Tarafdar [22,23]. Optimized the disc grinder speed to 0.89 m/s to knead ' chhana for preparing rasgulla. Chhana kneader cum ball former ' was designed based on mixing index of chhana Karunanithy et al. [24,25].

Cooking and Soaking of Chhana Balls

Strength and concentration of sugar syrup primarily depend on the desired sweetness and shelf-life of rasgulla. Many studies showed that strength of sugar syrup for cooking should be in the range of 50 to 55 °CBrix [7,10]. Ten hove & Das [23] studied the effect of cooking syrup strength on volume expansion of chhana balls. Optimized the cooking syrup concentration to 4°C Brix [26].

Kundu & De [10], Singh & Ray [16], De [11] and Soni et al. [20] recommended 40 °C Brix concentration of sugar syrup during soaking and kept the balls overnight in syrup. Goel and Agrawal [27] observed that 40% sugar concentration for 16 h under room temperature gave proper texture development to rasgulla. Mohanta & Shrivastava [26] optimized the concentration of soaking sugar syrup and time of soaking to 35°C Brix and 14.37 h respectively.

Texture of Rasgulla

Texture of rasgulla is an important parameter to acceptability and quality of rasgulla. Rasgulla should be soft and spongy according to consumer preference and rasgulla with spongy texture is valuable according to market price. Adhikari et al. [19] showed that rasgulla prepared from buffalo milk had higher values of textural parameters than that from cow milk. Goel & Agrawal [27] studied the effect of cooking temperature on texture of rasgulla and found that lower temperature of cooking gave spongy texture to rasgulla while higher temperature led to harder rasgulla. Karunanithy et al. [28] observed that rasgulla prepared by machine gave better textural results than that of commercial rasgulla.

Chemical Composition of Rasgulla

Specification of chhana for rasgulla preparation should be in the range as mentioned in IS: 5162 (1969).

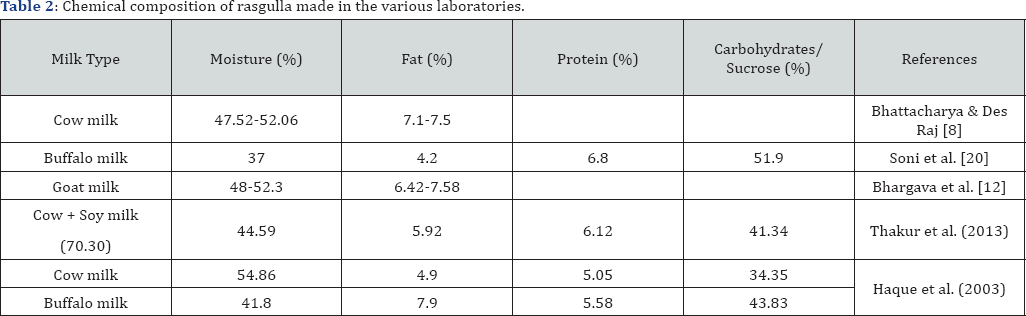

The chemical composition of rasgullas estimated by various researchers is shown in (Table 2).

Conclusion

Rasgulla, a soft and spongy syrupy dessert famous in Indian subcontinent and South Asia is made from chhana by cooking and soaking in sugar syrup. Wide range of chemical and physical composition was observed by many researchers due to usage of varieties of milk and ingredients to prepare the product and optimization parameters of processing. Good quality of rasgulla was obtained from chhana (3-4% fat in cow milk, 1-2% citric acid as coagulant and coagulation temperature of 72 °C) by kneading it properly with binding starch and then cooking the chhana balls in sugar syrup of 50°C Brix followed by soaking the balls in 40°C Brix sugar syrup. Hygienic practices during manufacturing of rasgulla at small scale and unorganized sector should be enforced for adequate shelf life of the product and to ensure public health safety.

References

- Aneja RP, Mathur BN, Chandan RC, Banerjee AK (2002) Technology of Indian milk products. In Dairy India publication, Delhi, India.

- Sahu JK, Tiwari A (2008) Constraints and solutions for mechanization of dairy products manufacturing in North Eastern India. Indian Dairyman 60(6): 17-29.

- Despite AD, Datto SC (1993) Preparation of chhana for rasgulla manufacture. Ind J Dairy Sci 46: 95-96.

- Varadaraj MC, Ranganathan B (1984) Effect of chhana and rasgulla preparation on performed staphylococcal enter toxins and thermo stable decoxribonuclease in milk. Ind J Dairy Sci 36: 120-124.

- De S, Ray SC (1954) Studies on the indigenous method of chhana making. Part 1.The influence of the conditions of coagulation and the type of milk on the production of chhana. Indian J Dairy Sci 7: 113-125.

- Rao BVR (1971) Effect of different concentrations of citric acid coagulant and fat levels of milk from crossbred cows on yield of chhana, fat losses in whey, moisture retained in chhana and quality chhana, Allahabad University, Allahabad.

- Bhattacharya DC, Raj D (1980a) Studies on the production of Rasgulla I Traditional method. Indian J Dairy Sci 33(2): 237-243.

- Bhattacharya DC, Raj D (1980b) Studies on the production of Rasgulla II. Pressure cooker method. Indian J Dairy Sci 33(4): 479-483.

- Date WB, Lewis YS, Johar DS, Bhatia DS (1958) Studies on the preservation and preparation of rasogollas. J Ed Sci Tech Ind 7: 217220.

- Kundu SS, De S (1972) Chhana production from buffalo milk. Ind J Dairy Sci 25(3): 159-163.

- De S (1980) Outlines of dairy technology. Oxford University Press, Delhi, India.

- Katara RV, Bhargava VN (1990) Production of Rasgulla from cow milk containing different levels of soymilk. Asian J Dairy Res 9: 175-180.

- Chanda T (1999) Manufacture of Rasgulla from cow-milk chhana with addition of different level of soy-milk chhana, Department of Dairy Science Bangladesh Agricultural University, Mymensingh, Bnagladesh.

- Bhargava VN, Dubey RD, Katara RV (1992) Influence of fat level on production of chhana and rasgulla from goat milk. Small Ruminant Research 8: 55-65.

- Aneja VP, Rajorhia GS, Makker SK (1982) An improved process for continuous production of chhana. Asian J of Dairy Res 1(1): 41-44.

- Singh GP, Ray TK (1977) Effect of milk coagulants on the quality of chhana and chhana whey J Food Sci Technol 14: 205-267.

- Iyer M (1978) Physico chemical studies on chhana from cow's and buffalo's milk. M Sc Dissertation, Kurukshetra University, Kuruskhetra, India.

- Rajorhia GS, Sen DC (1988) Technology of chhana- A review. Indian J Dairy Sci 41: 141-148.

- Adhikari AK, Sahai D, Mathur ON (1990) Technology of Rasgulla manufacture from cow milk. Canada 2: 385-388.

- Soni K, Bandyopadhyay AK, Ganguli NC (1980) Manufacture of rasgulla from buf- falo milk. Ind J Dairy Sci 33: 357-365.

- Gajendran KL (1976) Effect of different concentrations of citric acid coagulant on yield and quality of chhana from homogenized buffalo milk. Allahabad University, Allahabad, India.

- Tarafdar HN, Das H, Prasad S (1988) Mechanical kneading of chhana and quality of rasogolla. Journal of Food Science and Technology 25(4): 223-227.

- Ten Hove K, Das H (1995) Evaluation of yield, texture and cooking time of Rosogolla. J Food Sci Technol 32: 109-114.

- Karunanithy C, Varadharaju N, Kailappan R (2007) Studies on development of kneader and ball former for Chhana in Raso- golla production. Part I: Performance evaluation of Chhana kneader. J Food Eng 81: 298-305.

- Karunanithy C, Varadharaju N, Kailappan R (2007) Studies on development of kneader and ball former for chhana in rasogolla production Part II: Development of chhana ball former and its evaluation. J Food Eng 80: 966-971.

- Mohanta B, Shrivastava SL (2014) Optimization of process parameters for preparation of rasogolla-an indian dairy product at atmospheric pressure. Asia Pacific Journal of Research 1(11): 47-56.

- Goel BK, Agrawal AK (1994) Optimization of processing parameters for continuous rasgulla manufacturing. Indian Dairyman 46(11): 697-699.

- Karunanithy C, Varadharaju N, Thangavel K (2006) A comparative study on quality and textural parameters of commercial and machine prepared Rasgulla. J Food Sci Technol 43: 93-95.