Influence of Using a Blend of Rennet Casein and Whey Protein Concentrate as Protein Source on the Quality of Mozzarella Cheese Analogue

Padhiyar Dhanraj, Jana AH*, Modha Hiral and Aparnathi KD

Department of Dairy Technology, Anand Agricultural University, India

Submission: August 18, 2016; Published: January 03, 2017

*Corresponding author: Atanu Jana, Professor & Head, Department of Dairy Technology, SMC College of Dairy Science, Anand Agricultural University, Anand - 388 110, Gujarat, India

How to cite this article: Padhiyar D, Jana AH, Modha H, Aparnathi KD. Influence of Using a Blend of Rennet Casein and Whey Protein Concentrate as Protein Source on the Quality of Mozzarella Cheese Analogue. Dairy and Vet Sci J. 2016; 1(1): 555551. DOI: 10.19080/JDVS.2017.01.555551

Abstract

Cheese is deficient in whey proteins and whey protein has high nutritional significance in human diet. Hence it was decided to incorporate whey protein concentrate (WPC) in the formulation of Mozzarella cheese analogue (MCA), based on rennet casein (RC) and study its effect on the quality of resultant cheese analogue. The proportion of RC: WPC employed were 95:5, 90:10 and 85:15 w/w. The formulation of MCA comprised of 23.5% of protein blend, 15% vegetable fat, 2.75 % blend of trisodium citrate and disodium hydrogen phosphate (2.5:1, w/w), 0.07 % calcium chloride, 0.6% citric acid, 1.1% NaCl, 1.5% cheese flavoring, and rest, water. Varying the proportion of RC and WPC had a significant influence on the composition, textural properties, baking qualities and sensory quality of MCA judged as pizza topping. MCA made using protein blend (RC: WPC - 90:10 or 85:15) behaved satisfactorily during pizza baking trials. However, MCA made using RC:WPC (90:10)exhibited superiority with regard to shred quality and marginal upper hand in terms of the total sensory score of cheese judged as a pizza topping, compared to the one made using 85:15 blend. The MCA made using RC:WPC (90:10)protein blend conformed to the legal requirements for ‘Pizza cheese’ in India and had the requisite baking characteristics suitable for its end use application as pizza topping. Hence, it is recommended to use a blend of RC and WPC (90:10 w/w) as the protein source in the formulation of MCA to obtain nutritionally superior cheese product having desired functional properties.

Keywords: Mozzarella cheese analogue; Rennet casein; Whey protein concentrate; Composition; Texture; Baking quality; Pizza pie

Abbreviations: WPC: Whey Protein Concentrate; MCA: Mozzarella Cheese Analogue; RC: Rennet Casein; NMC: Natural Mozzarella Cheese; PER: Protein Efficiency Ratio; NPU: Net Protein Utilization; BCAA: Branched Chain Amino Acids; CRD: Completely Randomized Design; FDM: Fat on Dry Matter; TSC: Trisodium Citrate

Introduction

Cheese analogues also referred to as cheese substitute or imitations, are the products that substitute or imitate cheese in part or whole. In such products, milk fat, milk protein or both may be partly or fully replaced by non-milk components, usually of vegetable origin [1]. Analogue cheese products are made utilizing processed cheese manufacturing technique, with the help of heat, mechanical shear and emulsifying salts. Analogue cheese products can be classified as (a) Dairy, (b) Partial dairy, or (c) Non-dairy analogues [2]. Cheese analogues are easy to prepare, require less time for manufacture (i.e. about 2 h for analogue vs. 5-7 h for natural Mozzarella cheese) and can be ‘tailor-made’ as per the specifications of the pizza retailer. Mozzarella cheese analogue (MCA) has been reported to be functionally more stable during refrigerated storage than natural mozzarella cheese (NMC).

Such stability makes analogues very attractive to the food processing and service industries [3]. Since there is variation in the quality of raw milk used for cheese making, it leads to variations in the functionality of cheese during its refrigerated storage. However, MCAs are prepared from dry ingredients (e.g. acid casein, rennet casein, etc. storable for a year at ambient conditions) which can be made from bulk milk and utilized in the commercial large scale manufacture of MCA. Hence, owing to the nearly constant quality of protein ingredient (i.e. casein/caseinates), the storage stability of MCAs is superior to that of natural Mozzarella cheese.

Cheese analogues are produced commercially in several countries, but the information relating to their formulation and method of manufacture are mostly patented. Cheese analogues are being produced and sold in USA, UK, Sweden, France, Germany, Belgium, Switzerland and Australia. The annual production of MCA was estimated at 80,000 metric tons, which exceeded 20% of the total quantity of Italian type cheese produced in the US. The market share of imitation cheese had stabilized at about 7% in the US and about 3% in Europe [4]. The cheese variety which has been imitated the most is Mozzarella cheese, due to the growing popularity of pizza world over. Cheese is the key ingredient in such pizza applications. The major application of cheese analogue is in compounded or formulated foods manufactured by catering or industrial establishments [5]. The manufacture of cheese analogue allows manufacturers greater scope in manipulating constituents toward nutritional, textural and economic ends.

The world cheese production reached 20.0 million MT in 2011 [6]. Mozzarella is America´s favorite cheese and accounts for nearly one-third of the cheese consumption. Analogue cheese is available in retail sector and accounted for 18,000 tonnes for supermarket sales in United States in 2005 (i.e. 7.0% of processed cheese sales) [7]. In the year 2000, the demand for Pizza cheese (low-moisture part-skim Mozzarella cheese) grew at 8.0% per year in Europe. Analogue cheese is sold into the industrial sector, and the most common variety sold has functional properties designed to mimic those of NMC [8].

Casein or caseinates is the preferred protein source in the preparation of MCA [9,2]. Rennet casein is preferred over alternative protein sources (i.e. acid casein, caseinates) in the manufacture of MCA due to its desirable flavor and functional properties. Besides fat, protein is the major constituent affecting the quality of the cheese analogue. MCA has been prepared using casein or/caseinates at levels ranging from 23.0 to 28.5% [10- 12].

Besides casein, whey proteins are a good source of protein. Whey proteins are highly nutritious food ingredients [13]. Ultra-filtered Whey Protein Concentrates (WPC) is reported to possess higher protein efficiency ratio (PER) value while gelfiltered WPC has higher net protein utilization (NPU) value compared to those of casein [1]. Branched chain amino acids (BCAAs) refer to a group of essential amino acids, including leucine, isoleucine, and valine. Nearly 25% of all whey protein is made up of BCAAs. Researchers believe that BCAAs, specifically leucine, are responsible for regulating the protein synthesis which is important for tissue growth and repair. Whey proteins are also rich in sulphur containing amino acids like cysteine and methionine which enhance immune function through intracellular conversion to glutathione [14]. Whey protein helps to increase the serotonin activity and helps to promote restful sleep. Whey protein helps to reduce body fat and build the lean body mass and helps to improve the memory loss under stress [13].

Whey proteins have important functional properties in cheese systems such as the ability to act as emulsifiers (i.e. water and fat binding properties), attain gelation and impart foaming properties which makes them very versatile food ingredients [15-17]. Application of WPCs in the manufacture of cheese analogues can contribute to the essential savings of basic material (especially using low protein concentrates) and even help in improving the rheological properties of the resultant product [18].

In normal cheese making from milk, the valuable whey proteins are lost during separation of whey. In case of cheese analogues, incorporation of any value-added ingredient is possible; whey proteins are one such valued ingredient. Replacement of Kasseri cheese with WPC (24.0 % protein) used at levels of 9.0-39.0% (w/w) caused a decrease in the hardness of cheese analogues [19]. Whey proteins have been utilized as a partial substitute (≤3.75 g/100 g) for casein in the manufacture of MCA [20,21]. Replacement of RC with WPC (up to 3 g/100 g of RC) did not significantly affect the texture of cheese analogues; however, increasing casein replacement level to 15 g/100 g significantly decreased the meltability of cheese analogue. An increase in the amount of WPC in cheese analogue formulation from 1.25 to 11.25 g/100 g led to decrease in the hardness and meltability of cheese analogues.

A crumbly mouth feel was felt in cheese analogue containing mixture of RC and WPC, as against solely RC-based cheese analogue [20]. Contrary to the above findings, addition of WPC- 35 and WPC-65 (at the rate of 3.0% by weight) led to increase in the hardness of processed cheese analogues as compared to that made using acid casein alone [18,22]. A key aspect of cooking performance of Mozzarella cheese is its heat-induced functionality, including melting or flowability [23]. Incorporation of WPC to rennet casein based cheese analogue is bound to affect the sensory quality, protein content, rheology as well as the baking properties of resultant product. Hence, the study was planned to note the influence of incorporating WPC on the quality of MCA based on rennet casein.

Materials and Methods

Ingredients for cheese analogue]

Rennet casein (80.85% protein) and Whey Protein Concentrate (WPC-PROCON-3700 having 68.32% protein) were procured from M/s. Mahaan Protein Ltd., Kosikalan, UP, India. Specialty palm kernel oil (partly hydrogenated fat) based vegetable fat (Code No. DFR) was procured from M/s. Kamani Oil Industries Pvt. Ltd., Mumbai, India. The refined, bleached and deodorized palm kernel oil had an average meting point of 32°C. Anhydrous citric acid was obtained from M/s. Loba Chemie Pvt. Ltd., Mumbai, India. Calcium chloride, dihydrate was obtained from M/s. Merck Ltd., Mumbai, India.Tri-sodium citrate, dihydrate and di-sodium hydrogen orthophosphate, dihydrate were obtained from M/s. Qualigens Fine Chemicals, Mumbai, India. Tata brand vacuum-evaporated salt manufactured by M/s. Tata Chemicals Ltd., Mumbai, India was obtained from local market. Natural cheese flavoring (Mozzarella cheese bud - No. 34/1026) powder was obtained from M/s. Duke Thomson’s International through their representative at Indore, MP, India.

Preparation of Mozzarella cheese analogue

Mozzarella cheese analogue (MCA) was made as per the process standardized by Shah et al. [24] substituting plastic cream with palm kernel vegetable fat. A Hobart food processor (M/s. Hobart Corporation, Canada-Model No. N 50) operating at three different speeds (only two speeds operated; speed # 1 - 60 rpm, speed # 2 - 125 rpm) was used to blend the ingredients. A separate stainless steel vessel was used to heat the dough like mass prepared in the Hobart processor. During the experimentation, 500 g of MCA was prepared for each treatment under study. The experiment was replicated five times.

Chemical analyses

The MCAs were analyzed for total solids using Mojonnier Milk Tester [25], fat by Van Gaulik method [26], protein by micro- Kjeldahl method, pH and ash [27-29]. The salt content of cheese was determined by modified Volhard method [30]. Rennet casein was analyzed for total solids, fat, protein and ash content; the procedure for TS, protein and ash was same as adopted for cheese analogue. The fat content of rennet casein was carried out using Mojonnier fat extraction method [31]..

Texture profile analysis of cheese analogues

Compression (70% compression) testing of tempered(23 ± 1°C), cubical (1 cm3) cheese analogue samples was carried out using M/s. Lloyd Instrument (Model 1000, Lloyd Ltd, LRX, England; Sr. No. 160374) using 5 Kilo Newton (KN) load cell at cross-head speed of 20 mm/min. The textural characteristics of the cheese samples were directly displayed on the monitor of the computer as graph (Load (N) vs. time (s)) as well as derived values in tabular form. The gumminess and chewiness of cheese analogue samples was interpreted from their force-distance compression curve [32]. Five cubic cheese samples were used for each treatment under study and the average of these readings was reported.

Sensory evaluation of cheese analogue judged as a pizza topping

Freshly prepared pizza base (~15 cm diameter, 1.5 cm thick) was procured from a local bakery from Anand, Gujarat, India. A fixed quantity (70 g) of freshly shredded cheese was topped on each pizza base. Vegetable topping was deliberately avoided to permit flavor perception from cheese used as pizza topping. The pizza base topped with cheese were transferred to a forced draft hot air oven (M/s. Narang Scientific Works, New Delhi, Model-143) maintained at 2500C and kept there (about 3.0 min) until the cheese shreds melted completely. The segmented triangular pieces of pizza, obtained with the help of a pizza cutter, were served to each judge in hot condition (within 2 min. of removing from oven) for sensory evaluation. The cheese analogue, as pizza topping, was assessed on the basis of sensory quality by a panel of ten judges (2 females, 8 males; aged between 35 to 50 years) who were well aware of the desired characteristics of Pizza cheese. The judges were selected based on ‘Duo-trio’ and ‘Triangle’ tests. Maximum score of 10.0 was used for five sensory attributes viz., appearance (including fat leakage, browning), flavor, melting, stringiness and chewiness. The total sensory score for each cheese analogue was given out of 50.0.

Baking properties

MCA was analyzed subjectively for shreddability using a manual stainless steel shredder (pore size of opening - 3 mm diameter). Meltability was assessed by Schrieber test [33], stretchability using Fork test [34] and fat leakage by the method of Breene et al. [35].

Statistical analysis

Five replicate values of each attribute were subjected to statistical analysis using Completely Randomized Design (CRD) with equal number of observations [36].

Results and Discussion

Formulation of MCA

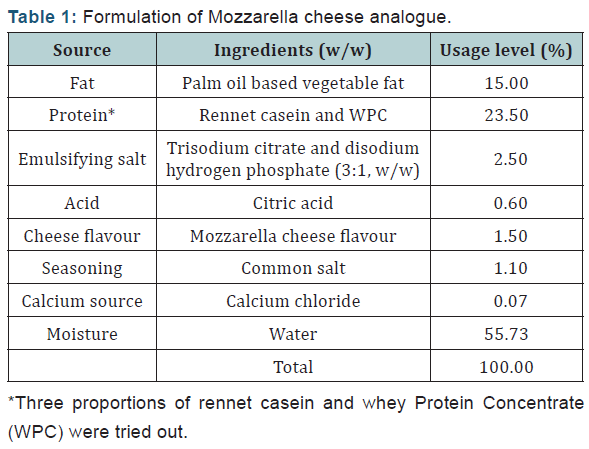

Mozzarella cheese analogue (MCA) was made using varying proportions (i.e. 95:5, 90:10, and 85:15 w/w) of Rennet casein (RC) and Whey Protein Concentrate (WPC) in the formulation, keeping the rate of addition of protein powder blend at a fixed rate of 23.5% by weight (Table 1). Since incorporation of WPC at higher levels is reported to exert some detrimental effects on the hardness and meltability of cheese [19-21], the level of substitution of RC with WPC was restricted to maximum of 15.0 % level only. Rest of the ingredients (i.e. vegetable fat, cheese flavoring, acid, emulsifying salt, common salt and water) and their levels were kept constant. The manufacturing protocol adopted was the same as standardized by Shah et al. [24] adopting the formulation shown in (Table 1). The photographs of MCAs made utilizing three proportions of RC and WPC (i.e. 95:5, 90:10, and 85:15) as the protein source is shown in (Figure 1).

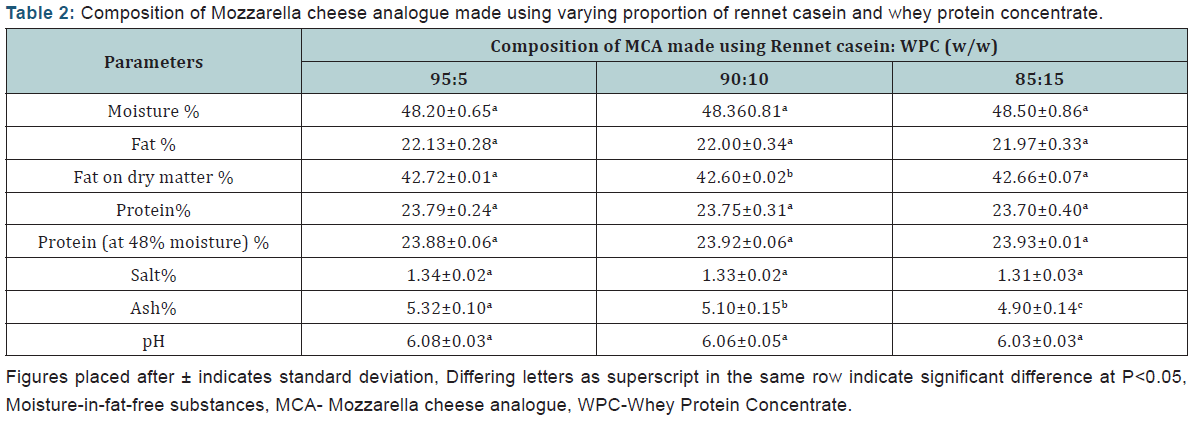

Composition of MCA

Legal standards dictate the compositional attributes of cheese and cheese analogues. The composition of cheese in turn influences the end use functionality of the resultant product. The data depicted in (Table 2) indicates that the only parameters that were significantly (P<0.05) affected by changing the proportion of RC and WPC in MCA formulation were fat on dry matter (FDM) and ash content of product. The FDM content of MCA made using RC: WPC (90:10) was the least (i.e. 42.60%) which differed significantly (P < 0.05) from the FDM of MCAs made using other two proportions i.e. 85:15 (i.e. 42.66% FDM) and 95:05 (i.e. 42.72% FDM).

The ash content of MCAs tended to decrease as the proportion of WPC increased in the protein powder blend. MCA made using protein powder in 95:5 (RC: WPC) had the highest ash content, which differed significantly (P<0.05) from the ash content of other two cheese analogues; the ash content of latter two cheese analogues also differed significantly (P<0.05) from each other. Since MCA made using RC: WPC (95:5) had slightly higher fat content and had the least moisture content, it obviously had highest FDM content (Table 2). Since the ash content of rennet casein (i.e. 8.32%) was greater than that of WPC (i.e. 4.19%), increasing the proportion of WPC in the protein mixture led to resultant MCA having decreased ash content.

Based on the Food Safety and Standards Act (FSSA) [37], requirement for moisture (maximum 54.0%) and FDM (minimum 35.0%) content for natural Mozzarella cheese (Pizza cheese variant) in India, all the three MCAs complied with such requirement. The standards for cheese analogues are nonexistent in India. The essential factors influencing the quality of MCA in the present study was the type of protein involved in the blend (i.e. RC and WPC), the total protein content, pH of system and the degree of emulsification achieved during cheese processing.

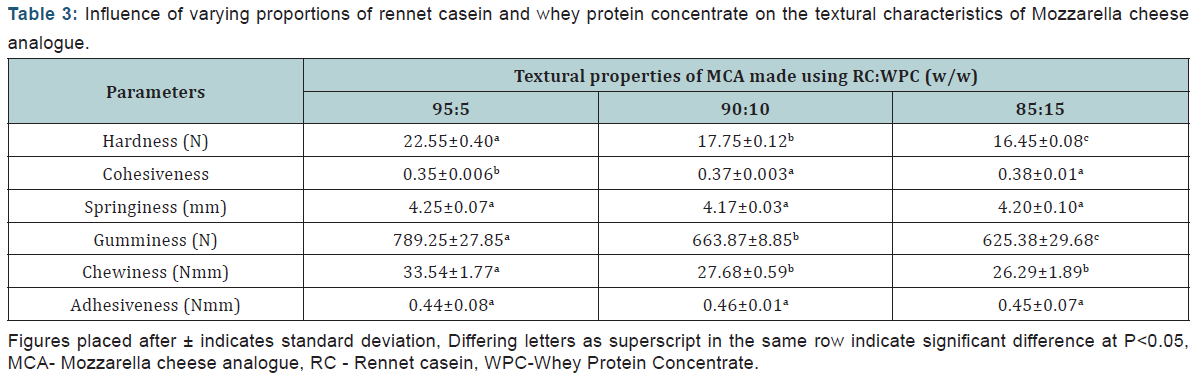

Textural characteristics of MCA

The textural characteristics of MCAs are an important parameter that has to be controlled so that the end use functionality of cheese product remains fairly constant. Some of the textural properties of cheese product dictate the functionality (i.e. shredding, stretch, meltability) of the resultant product. The results depicted in (Table 3) clearly shows that varying the proportion of the two protein sources (i.e. RC, WPC) had a significant influence on most of the textural parameters of MCAs, exception being for springiness and adhesiveness. The hardness of MCA tended to decrease with increasing proportion of WPC in the protein blend. The maximum hardness of MCA made using RC: WPC (95:5) differed significantly (P < 0.05) from the values of hardness associated with other two MCAs; the latter two cheese analogues also differed significantly (P < 0.05) from each other. The cohesiveness of MCAs made using RC: WPC in 90:10 and 85:15 proportions were at par with each other; such cohesiveness values were significantly (P<0.05) greater than the value associated with MCA made using 95:5 proportion (Table 3).

Gumminess and chewiness is basically the product of basic textural parameters and hence were affected significantly by the change in the proportion of RC and WPC in the protein blend. The values of gumminess and chewiness of MCAs tended to decrease as the proportion of WPC increased in the protein blend; such effect was found to be significant (P<0.05) for gumminess when all the three MCAs were compared with each other (Table 3).

With respect to chewiness, MCA made using RC: WPC of 95:5 blend had the maximum value which differed significantly (P<0.05) from the values of other two MCAS; the other two MCAs were at par with each other in this regard. Springiness which is somewhat related to stringiness (stretch) of cheese analogue (springiness is assessed at 2300C temperature while stringiness is assessed at pizza baking temperature) remained unaffected by the presence of WPC in the protein powder blend (Table 3).

The hardness of cheese/cheese analogue system depends on the type of protein involved, protein content, pH of system, moisture content, etc [5]. Casein is the predominant protein in rennet based cheese system wherein calcium associated with casein also confers rigidity (firmness) to the cheese matrix. Application of WPC in cheese system has been found to slightly interfere with casein cross-links, decreases the protein content of cheese (since WPC has lower protein content compared to RC) leading to decrease in the hardness of cheese analogues. As the proportion of whey protein in the protein mixture rose, it probably interfered with the protein matrix created predominantly by casein, resulting in decreased cheese hardness.

However, since the denatured whey proteins (due to processing treatment involved in cheese analogue manufacture) probably aided in better binding with casein, it led to cheese analogues having greater cohesiveness, when the proportion of whey protein was raised in the protein powder blend. Addition of denatured whey protein to the base mixture (i.e. 8.0 % butter fat, 40.0 % hard cheese, 2.0% soft curd, 3.0 % emulsifier) has been reported to decrease the firmness of the process cheese product. Solowiej et al. [38,39] noted an increase in the adhesiveness of processed cheese analogue upon incorporation of 1-3% of WPC- 80 in rennet casein based formulation.

Shredding

Shreddability and resistance to clumping after shredding are the major determinants of overall functional characteristics of cheese [44]. Nowadays, Mozzarella cheese producers are also catering ‘packaged shredded cheese’ to confer convenience to the end users of cheese. Hence shredding property is an important criterion for MCA. Upon shredding, if the cheese shreds with ease and the resultant shreds obtained are thin and long, without any tendency to mat with each other post shredding, the shreddability is considered to be ‘Very good’. If the cheese offers some resistance while shredding (not with ease) and the shreds obtained are short and thick, with some tendency to mat with each other post shredding, the shreddability is considered to be ‘Good’.

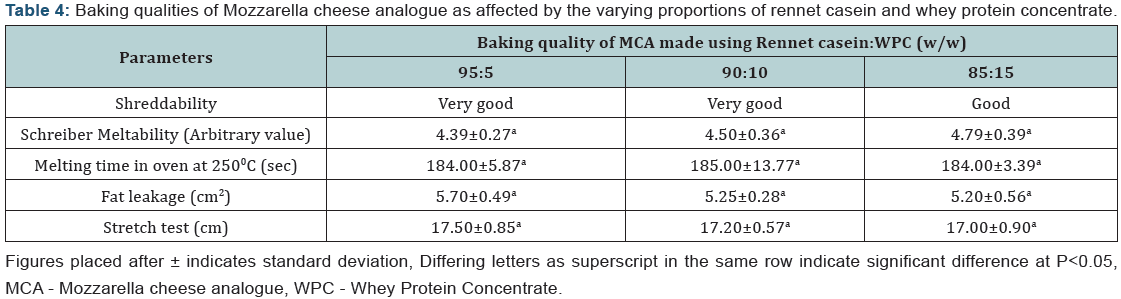

As is evident from (Table 4), the shredding characteristic of MCA made using RC: WPC of 95:5 and 90:10 was rated ‘Very good’; whereas MCA made using RC: WPC of 85:15 had ‘Good’ shred quality (Table 4). In case of 95:5 MCA, the shreds obtained were thick and somewhat long. In case of 90:10 cheese, the shreds obtained were short and had a tendency to mat with each other. In case of 85:15 cheese, the shreds were long but had greater tendency to mat with each other, post shredding.

Meltability

Meltability refers to the capacity of the cheese particles to coalesce to a uniform, continuous layer of melted cheese when placed in the baking oven [3,40]. Once the pizza base topped with shredded cheese is put in the baking oven, it is allowed to stay in the oven till the cheese shreds melts completely to form a uniform ‘circular sheet’ ready to be retrieved from the oven for consumption. Though non-significant, the meltability of MCA made using RC: WPC of 85:15 was somewhat superior to that of other two MCAs (Table 4). Cheese having greater meltability is desired in baked pizza. Likewise, the time required by all the three MCAs (i.e. 95:5, 90:10, 85: 15) to melt in the oven was almost the same (Table 4). Meltability of cheese analogue is based on the type of protein ingredient used in the formulation (i.e. casein/caseinates, whey proteins). WPC is known to possess emulsifying properties. An over-emulsified cheese tends to be non-melting, while the reverse is true for an under-emulsified cheese. The change in the emulsified state of fat (vegetable fat) in MCA as exerted by the level of WPC used in the formulation might be influencing the meltability of cheese analogue [45]. Soloweijet al. [39] reported a decrease in the meltability of processed cheese analogue in RC based product added with 1-3% of WPC-80, especially when the protein concentration in the cheese product was raised.

Fat leakage

Free oil formation is the tendency of oil (vegetable fat) to separate from the melted cheese and form oil pockets, upon baking. The high temperature of air in the baking oven deters the milk protein in maintaining vegetable fat in emulsion to some extent, consequently leading to release of few droplets of free oil at the surface of melted cheese. Some degree of free fat in baked melted cheese is desirable; excessive amount is derogatory to its appearance, palatability and crispness [35]. Though nonsignificant, the fat leakage was somewhat lower for MCA made using RC:WPC of 85:15, compared to their counterparts made using 95:5 and 90:10 proportion of protein mixture (Table 4).

Stretch

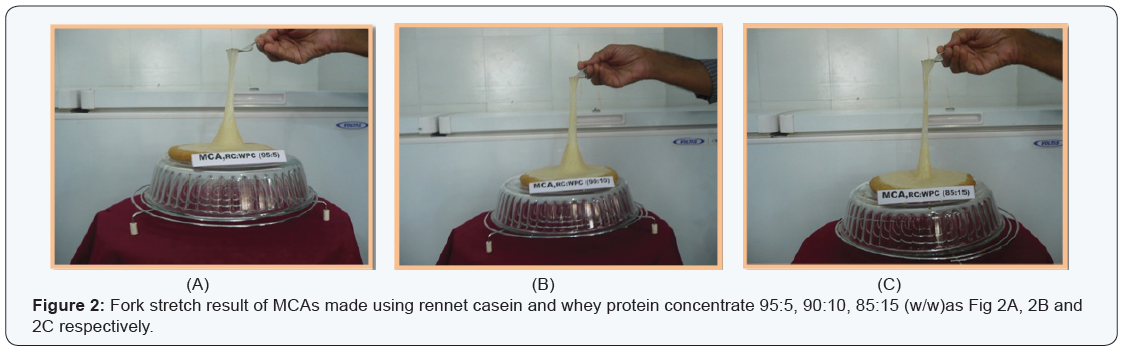

Stretchability is the ability of the melted cheese to form fibrous strands that elongate without breaking under tension [43]. The stretch of Mozzarella cheese should be minimum 7.5 cm measured from the surface of pizza [32]. Though non-significant, as the proportion of WPC increased (i.e. 95:5 to 85:15) in the MCA formulation, there was a slight reduction in the stretch value (Table 4). The photographs of melted cheese analogues subjected to stretch test is shown in Figure 2. The above findings reveal that the baking properties of MCA remained unaffected by the presence of WPC in admixture with RC at the three proportions studied.

Sensory characteristics of MCA as a pizza topping

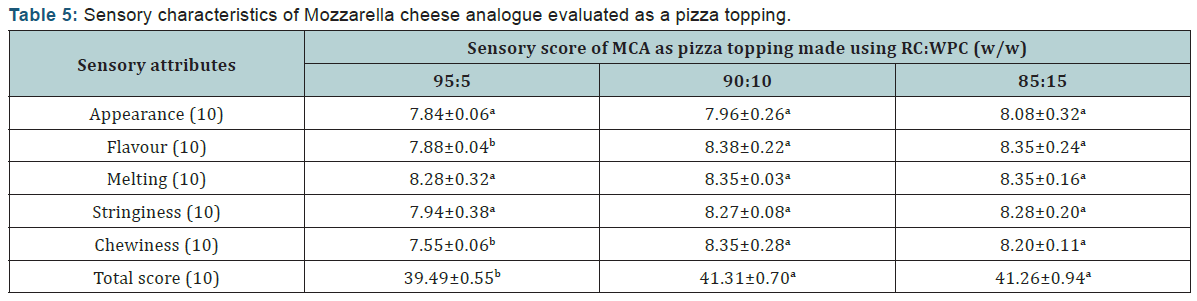

According to one survey, Mozzarella cheese manufacturers considered shreddability, meltability, stretchability, elasticity and stringiness to be equally important for consumer satisfaction. On the other hand, for pizza retailers, the most important attributes were flavor, shreddability and meltability [46]. The data furnished in Table 5 indicates that use of WPC in admixture with RC as the protein source had a significant (P<0.05) influence on the sensory flavor, chewiness and total sensory score of the resultant cheese analogues, when judged as pizza topping. The detailed description of each sensory attribute of cheese is given below.

The foot note has been pasted is the mail I sent

Appearance

All the MCAs appeared ‘dull white’ in appearance which might be due to inclusion of WPC in the protein blend. WPC powder was light brown in color, while rennet casein was a white powder. The fat leakage was moderate in case of MCAs made using protein blends 85:15 and 95:5 (RC:WPC), whereas it was least in case of MCA made using RC:WPC (90:10). Browning was not noticed in any of the cheese samples, when judged as a pizza topping.

Flavor

The flavor score of MCAs made using RC:WPC of 90:10 and 85:15 was significantly (P < 0.05) superior to that made using 95:5 protein blend; the former two MCAs were rated at par with each other in this respect (Table 5). This implied that use of relatively higher quantum of WPC in admixtures with RC in the preparation of MCA led to better perception of cheese flavor in the baked good. Such influence might be ascribed to the subdued flavor of RC in MCAs containing higher proportion of WPC in the protein blend.

Melting

All the three MCAs melted evenly throughout the circumference of the pizza base; all the three MCAs behaved identically in this respect (Table 5).

Stringiness

This pose is essentially known for its ability to regulate the working of the thyroid glands. These glands are responsible for the proper functioning of the entire body including the digestive, nervous, reproductive system, regulating metabolism and respiratory system. Apart from that, it nourishes the spine with a good supply of blood and oxygen, helping you beat nervous system disorders, and improving your all round health (Figure 5).Stringiness is the property of Mozzarella cheese that is prized by the consumers during consumption of pizza topped with cheese. All the three MCAs stretched equally well during consumption of the hot pizza containing cheese as topping and hence all the cheeses got stringiness rating that was at par with each other (Table 5). Such findings can be very well corroborated with the findings of Fort Stretch test (Table 4).

Chewiness

During mastication of the cheese during consumption of pizza, moderate degree of chewiness is preferred by the consumers. Out of the three MCAs, the one made using RC:WPC (95:5) had the highest chewiness (and hence scored lower for such attribute); the chewiness score of such MCA was significantly (P<0.05) lower than the scores allotted to other two cheese samples. The latter two MCAs had identical chewiness score (Table 5).

During mastication of the cheese during consumption of pizza, moderate degree of chewiness is preferred by the consumers. Out of the three MCAs, the one made using RC:WPC (95:5) had the highest chewiness (and hence scored lower for such attribute); the chewiness score of such MCA was significantly (P<0.05) lower than the scores allotted to other two cheese samples. The latter two MCAs had identical chewiness score (Table 5).quantum of WPC (i.e. 95:5), culminating in moderate degree of chewiness in the former two MCAs when judged on pizza pie (Table 5).

Total sensory score

The total sensory score of the MCA, judged as pizza topping, made using the protein blends was in decreasing order: 90:10 > 85:15 > 95:5. The former two MCAs had significantly (P < 0.05) superior total sensory score when compared to the one made using 95:5 (RC:WPC) protein blend. The total sensory score of the former two MCAs (i.e. made using RC:WPC of 90:10 and 85:15) was rated at par with each other (Table 5). The significantly lower score for flavor and chewiness associated with MCA made using RC:WPC (95:5) led to such cheese product having the least total sensory score.

MCA made using either of 90:10 or 85:15 protein blends (RC:WPC) behaved satisfactorily as a pizza topping. When the proportion of RC:WPC changed from 90:10 to 85:15, there was a decrease in the ash and FDM content; the hardness and gumminess of cheese decreased and slight inferior shreddability was noticed in MCA. However, looking to the superiority of MCA made using RC:WPC (90:10) with regard to shred quality and marginal superiority in terms of the total sensory score of cheese as pizza topping (i.e. vs. 85:15), such protein blend (i.e. RC:WPC, 90:10) is recommended for use in the formulation of MCA at suggested rate of addition of 23.5% by weight. Such protein powder blend (RC plus WPC) yielded an analogue having superior functional properties for use on pizza such as flavor, chewiness and fat leakage.

Conclusion

Application of blend of rennet casein and Whey Protein Concentrate (RC:WPC in 90:10 w/w) used at 23.5% by weight is recommended as the protein source in the formulation of MCA considering the objectively assessed baking qualities of cheese product and the sensory quality of MCA used as a pizza topping. Incorporation of WPC in MCA formulation helped in improving the nutritional profile (healthy product) of the cheese product, helped in better perception of cheese flavor and reduced the chewiness of product making the cheese more palatable when used as a pizza topping.

References

- Qureshi SA, Asad W, Sultana V (2009) the effect of Phyllantus emblica Linn. On type II diabetes, triglycerides and liver specific enzyme. Pak J Nutr 8(2): 125-128.Forsum E (1973) Nutritional evaluation of whey protein concentrates and their fractions. J Dairy Sci 27(6): 665-670.

- Chavan R, Jana A (2007) Cheese substitutes: an alternative to natural cheese - A review. Int J Food Sci Technol Nutr 2(2): 25-39.

- Kiely LJ, Mc Connell SL, Kindstedt PS (1991) Observation on the melting behavior of imitation Mozzarella cheese. J Dairy Sci 74(10): 3568-3572.

- Mc Carthy (1990) Imitation cheese products. Bulletin, International Dairy Federation, No. 249: 45-52.

- Bachmann Hans-Peter (2011) Cheese analogues: a review. Int Dairy J 11(4-7): 505-515.

- www.ameft.com/World_Cheese_Consumption.pdf

- Dairy Facts (2006) International Dairy Foods Association, Washington, DC, USA.

- www.en.wikipedia.org/wiki/Pizza_cheese

- Fox PF, Guinee TP, Cogan TM, Mc Sweeney PLH (2000) Processed cheese and substitute or imitation cheese products. Fundamentals of Cheese Science, An Aspen Publication, Gaithersburg, Maryland, USA, pp. 429-451.

- Lobato-Calleros C, Vernon-Carter EJ, Guerrero-Legaratta L, Soriano- Santos J, Escalona-Beundia H (1997) Use of fat blends in cheese analogues - influence on sensory and instrumental textural characteristics. J Text Studies 28(6): 619-632.

- O’ Malley AM, Mulvihill DM, Singh T (2000) Proteolysis in rennet casein-based cheese analogues. Int Dairy J 10(11): 743-753.

- Mounsey JS, O’ Riordan ED (2008a) Alteration of imitation cheese structure and melting behavior with wheat starch. Europ Food Res Technol 226(5): 1013-1019.

- Shankar JR, Bansal GK (2013) A study on health benefits of whey proteins. Int J Adv BioTechnol & Res 4(1): 15-19.

- Anon (2008) Whey protein. Alternative Medicine Rev 13(4): 341-347

- Mangino ME (1992) Properties of whey protein concentrates. In: Whey and Lactose Processing. Zadow JG (Ed.), Elsevier Appl. Sci., New York, USA, p. 231.

- Jayaprakasha HM, Brueckner H (l999) Whey protein concentrate: A potential functional ingredient for food industry. J Food Sci Technol 36(3): 189-204.

- Dees AL (2002) Effects of various ingredients on a model process cheese system. M.Sc. thesis, Graduate Faculty of North Carolina State University, Raleigh.

- Solowiej B, Gustaw W, Nastaj M (2008) Effect of the addition of whey protein concentrates on rheological properties of processed cheese analogues. ZywnoscNauka Technologia Jakosc, 15(5): 226-234.

- Kaminarides S, Stachtiaris S (2000) Production of processed cheese using Kasseri cheese and processed cheese analogues incorporating whey protein concentrate and soybean oil. Int J Dairy Technol 53(2): 69–74.

- Murphy KJ (1999) Properties of imitation cheese containing noncasein proteins. M.Agr.Sc. Thesis, University College Dublin, National University of Ireland, Dublin.

- Sołowiej B (2007) Effect of pH on rheological properties and meltability of processed cheese analogues with whey products. Polish J Food Nutr Sci 57(3): 125-128

- Solowiej B, Mleko S, Gustaw W, Udeh KO (2010) Effect of whey protein concentrates on texture, meltability and microstructure of acid casein processed cheese analogues. Milchwissenschaft 65(2): 169-172.

- O’ Riordan ED, Duggan E, O Sullivan M, Noronha N (2011) Production of analogue cheeses. In: Tamime AY (Ed.), Process Cheese and Analogues. (1st edn.), Wiley-Blackwell, West Sussex, England, pp. 219-239.

- Shah Rahul, Jana AH, Aparnathi KD, Prajapati PS (2010) Process standardization for rennet casein based Mozzarella cheese analogue. J Food Sci Technol 47(5): 574-578.

- Milk Industry Foundation (1959) Laboratory Manual. Methods of analysis of milk and its products, (3rd edn.), Washington, USA, p. 283.

- Bureau of Indian Standards (1979) Methods for determination of fat in cheese by Van Gaulik method, IS-9070, Bureau of Indian Standards (BIS), Manak Bhavan, New Delhi, India, p. 4.

- Patel GC, Vyas SH, Upadhyay KG (1986) Evaluation of Mozzarella cheese made from buffalo milk using direct acidification technique. Indian J Dairy Sci 39(4): 394-403.

- Bureau of Indian Standards (1961) Methods of test for dairy industry. Rapid examination of milk. Bureau of Indian Standards (BIS), IS-1479 (Part-I), Manak Bhavan, New Delhi, India, p. 1-57.

- Kosikowski FV (1982) Cheese and Fermented Milk Foods. (3rd edn), Edwards Brothers Inc, Am Arbor, Michigan, USA, pp. 153-167,178.

- International Dairy Federation (1987) Dried milk, dried whey, dried buttermilk and dried butter serum – Determination of fat content (Rose-Gottlieb Reference Method), International Standard 9C, International Dairy Federation, Brussels, Belgium.

- Voisey PW (1976) Engineering assessment and critique of instruments used for meat tenderness evaluation. J Text Studies 7(1): 11-48.

- Park J, Rosenau JR, Peleg M (1984) Comparison of four procedures of cheese meltability evaluation. J Food Sci 49(4): 1158-1170.

- USDA (1980) Specification for Mozzarella cheese. Agricultural Marketing Service, United States Department of Agriculture (USDA), Washington DC, USA.

- Breene WM, Price WV, Ernstrom CA (1964) Manufacture of Pizza cheese without starter. J Dairy Sci 47(11): 1173-1180.

- Steel RGD, Torrie JH (1980) Principles and procedure of statistics - A biometrical approach (2nd edn), Mc Graw Hill, Kogakusha Ltd, Tokyo, Japan pp. 137-167.

- FSSA (2011) Food Safety and Standards Act (FSSA).

- Salem SA, Salem AE, Gooda E (1987) Improvement of chemical, rheological and organoleptic properties for local-low fat processed cheese. Egyp J Dairy Sci 15(2): 263-270.

- Solowiej B, Cheung IWY, Li-Chan ECY (2014) Texture, rheology and meltability of processed cheese analogues prepared using rennet or acid casein with or without added whey proteins. Int Dairy J 37(2): 87- 94.

- Glenn TA, Daubert CR, Farkas BE, Stefanski LA (2003) A statistical analysis of creaming variables impacting process cheese melt quality. J Food Quality 26(4): 299-321.

- Ennis MP, O’Sullivan MM, Mulvihill DM (1998) The hydration behavior of rennet casein in calcium chelating salt solution as determined using a rheological approach. Food Hydrocolloids 12(4): 451-457.

- Ennis MP, Mulvihill DM (1999) Compositional characteristics of rennet caseins and hydration characteristics of the caseins in a model system as indicators of performance in Mozzarella cheese analogue manufacture. Food Hydrocolloids 13(4): 325-337.

- Jana A (2001) Mozzarella cheese and pizza – the compatible partners. Beverage & Food World, 28(10): 14-19.

- Apostolopoulos C, Marshall RJ (1994) A quantitative method for the determination of shreddability of cheese. J Food Quality 17(2): 115- 128.

- www.naturalproductsinsider.com/articles/2000/02/understandingprocess- cheeses.aspx

- Savage AA, Mullan WMA (1996) Quality perceptions and expectations of Mozzarella cheese producers and pizza manufacturers. Milchwissenschaft 51(12): 677-679.

- Hoffmann W, Hinrichs M, Johannsen N, Scheurer G, Maurer-Rothmann A (2005) Use of different acid caseins in analogue low-moisture Mozzarella. Milchwissenschaft 60(4): 395-398.

- Jana AH, Shah Rahul, Aparnathi KD, Padhiyar D (2015) Influence of rennet casein levels on the chemical, baking and sensory quality of Mozzarella cheese analogue. J Dairy Vety Anim Res 2(3): 39-45.

- Mounsey JS, O’ Riordan ED (2008b) Modification of imitation cheese structure and rheology using pre-gelatinized starches. Europ Food Res Technol 226(5): 1039-1046.