Applications of Intelligent Monitoring in Deep Sea Culture Equipment

Yangze Dong*, Jun Yan, Yufeng Li, Xiaojie Lin and Liang Yang

Southern Marine Science and Engineering Guangdong Provincial Laboratory (Zhanjiang), China

Submission: March 26, 2021; Published: April 14, 2021

*Corresponding author: Yangze Dong, Southern Marine Science and Engineering Guangdong Laboratory (Zhanjiang), No 1 Wenti Road, Xiashan District, Zhanjiang, Guangdong Province, China

How to cite this article: Yangze D, Jun Y, Yufeng L, Xiaojie L, Liang Y. Applications of Intelligent Monitoring in Deep Sea Culture Equipment. Int J Environ Sci Nat Res. 2021; 27(5): 556223.DOI: 10.19080/IJESNR.2021.27.556223

Abstract

Deep sea culturing is one of the most important sources of fish for food. During the culturing procedure, there are several processes need be monitored. By giving the structure of the culture cage, its main tasks are analyzed. After that, the structure of the monitoring system is presented to meet the needs of normal and abnormal processing of the culture.

Keywords: Deep sea culture equipment; Intelligent monitoring; Acoustic-optic cooperation

Background

Ocean occupies over 70% of the earth surface, which is rich of valuable resources for human beings to take advantage. Fishing is one of the main food-obtaining means for mankind till the present. Due to overfishing, offshore fishery resources are decreasing distinctly. Therefore, offshore culture cages became a major way in fishery. With the rapid progress of offshore culturing, serious littoral environment pollution occurs, which results in reduction of outputs.

Aiming at this reality, culturing into far-deep sea is a better choice. Thinking of economy factors, the far-deep sea culturing system needs larger scales. And because it is far away from the land, autonomous operation and maintenance should be the necessary work style. Therefore, intelligent control and monitoring are its essential functions. Intelligent monitoring acts as information input for its recovery from failure and unexpected states by means of warning during its operation.

This paper would firstly give a structure of the intelligent monitoring system to meet the needs. An analysis would be presented focusing on the key technologies of the system in succession.

Intelligent Monitoring System in Deep Sea Culture Equipment

As stated above, in deep sea environment, the culture equipment is much larger than offshore ones. On one hand, it is then necessary for intelligent monitoring. On the other hand, the bigger scale supplies enough space for the monitoring system design.

This study focuses on the culture cage (besides, there are culture ship, ocean farm, etc.).

Structure of the culture cage

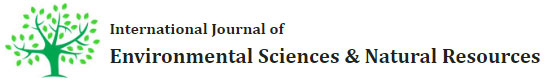

Figure 1 presents an illustration of typical culture cage.

There are four main parts within the equipment, which are Display & Control, Surface Operation, Culturing and Mooring subsystems from the above, respectively.

Main tasks of culturing

From fries to adult fish, it needs a certain period according to various species. Within the time, the fish would grow bigger under normal operations. In such circumstances, certain tasks must be accomplished. The tasks contain feeding and adults processing.

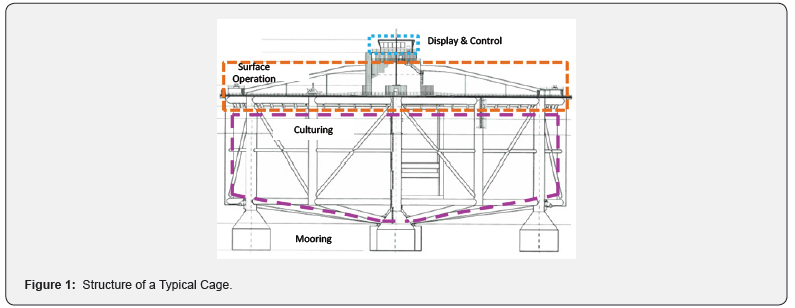

Unfortunately, thanks to the rather long time, unexpected cases might often happen. Such as equipment failure, fish illness, fish death, water pollution, etc. We call such circumstances as Abnormal Situation, which need to be dealt with as soon as possible. Figure 2 illustrates the main tasks of monitoring during the culture process, which it is divide into two categories: Normal and Abnormal.

It can be seen from above figure that the red blocks represent the situations need be monitoring daily, which would harm the harvest of culturing without immediately handling.

Ant

The Culturing Space is the principal part of the cage, where the fish live. Therefore, monitoring in this area is a significant task during the entire culturing procedure.

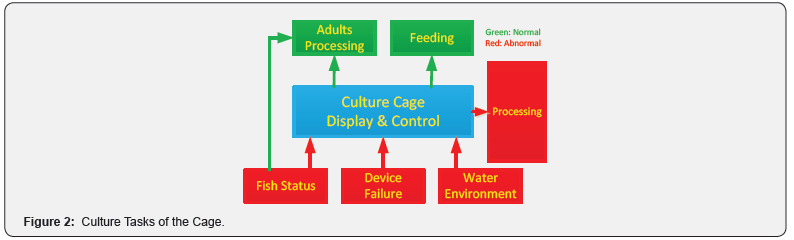

Corresponding to different needs of monitoring, different measures should be adopted. For example, for the monitoring of water environment, the most concentration is the water quality for culturing. Thus, task is carried out using specific sensors through chemistry testing. For the fish status, optical and acoustic measures are both utilized: for relative long range and to the fish group, acoustics shows a priority, while monitoring the near and individual fish, optics is the better choice. The same conclusion can be got as to the device failure detection such as the cage net. Figure 3 is the illustration of the monitoring system for the culture cage monitoring.

Key Challenges in Intelligent Monitoring System

As pointed out in Section 4.3, optics, acoustics and chemistry measures are all used in the monitoring. As we know, the basis of monitoring is sensing, which is the source of information. Combined with information storage and processing, the so-called conception of “Intelligent Sensing” occurs. Let us return to the cage monitoring, where there exist several key challenges.

Optic image generation and processing

Compared to the air environment, the water is not a good medium for transmission of light (and other electro-magnet waves), the optical camera cannot get high quality images necessary for successive processing.

On one hand, how to get better image needs investigate. For example, one can improve the quality by better light sources.

On the other hand, based on the current image, advanced image processing technologies should be studied to reach improvement.

Information fusion of heterogeneous sources

In the monitoring system, there are several kinds of sensors, which output raw data with different formats. Derived from there data, the necessary useful information should go to the D&C center, where decisions be made. Since the data are not the same source, representing different features, the fusion processing is much important.

Integration of the system

In the scope of the cage, the monitoring system cannot be omitted for better culture result. But above all, the interference to the normal activities of the fish and relevant devices should be reduced to the minimum.

This is a systematic problem which should be solved through integration of all of the parts.

Conclusion

During the culturing procedure, there are several processes need be monitored. By giving the structure of the culture cage, its main tasks are analyzed and the structure of the monitoring system is presented to meet the needs of normal and abnormal processing of the culture.