Nitrogen and Carbon Characteristics of Sludges from Formic Acid and Sodium Hydroxide Pulping of Kenaf Stem

Chukwudebelu JA1* and Agunwamba JC2

1Department of Chemical, Fibre and Environmental Technology, Federal Institute of Industrial Research, Nigeria

2Department of Civil Engineering, University of Nigeria, Nigeria

Submission: November 24, 2020;Published: January 04, 2021

*Corresponding author: Chukwudebelu JA, Department of Chemical, Fibre and Environmental Technology, Federal Institute of Industrial Research, Oshodi, Nigeria

How to cite this article: Chukwudebelu J, Agunwamba J. Nitrogen and Carbon Characteristics of Sludges from Formic Acid and Sodium Hydroxide Pulping of Kenaf Stem. Int J Environ Sci Nat Res. 2021; 26(5): 556196. DOI:10.19080/IJESNR.2021.26.556196

Abstract

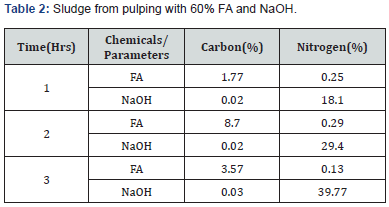

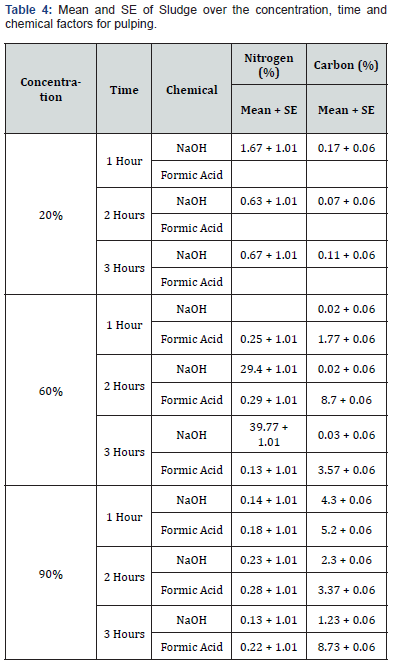

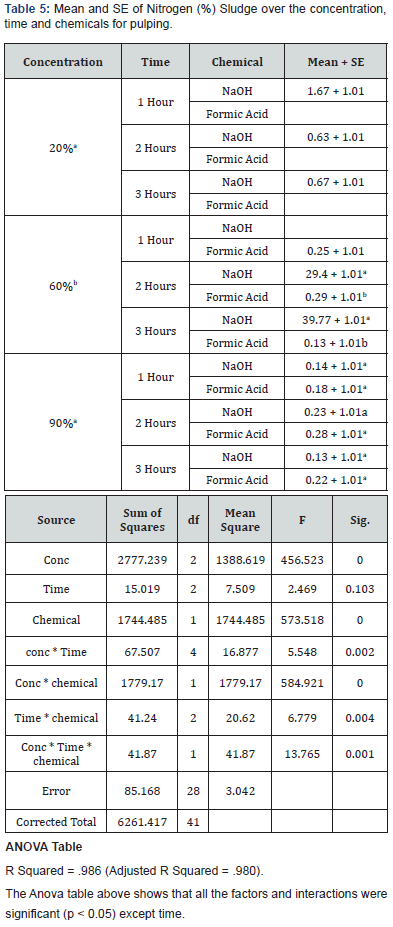

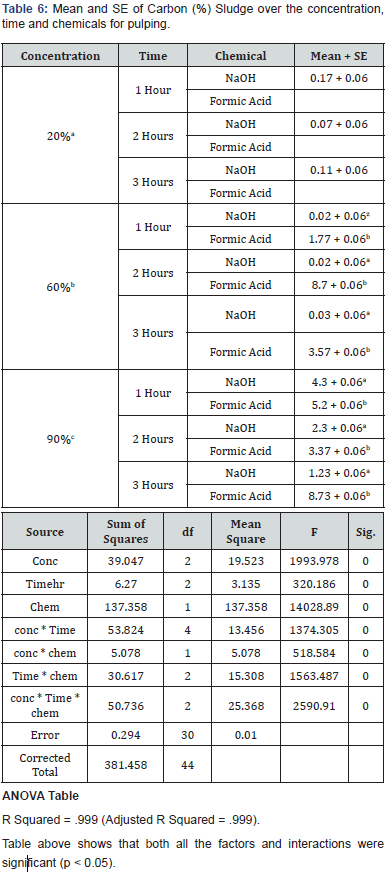

Sludge is produced during paper manufacturing. In this study, kenaf stem was pulped with formic acid and sodium hydroxide at 20%, 60% and 90% concentrations for a cooking period of 1,2 and 3h at 96oC under atmospheric pressure. The effluent from the pulping processes was filtered to get the sludge. The sludge was analysed for carbon and nitrogen. The sludge content from 20% pulping has nitrogen and carbon from sodium hydroxide, sludge from 60% pulping has carbon and nitrogen from both chemicals with more nitrogen while 90% pulping has more carbon. Considering the pulped stem, it showed under pulped, normal and over pulped with respect to 20%, 60% and 90%. Therefore, looking at the normal pulp at 60% concentration with the two chemicals, formic acid has moderate values of carbon and nitrogen compare to sodium hydroxide that showed high nitrogen content. Formic acid pulping is considered here because it can easily be recovered after pulping and the sludge used as manure.

Keywords: Kenaf; Sludge; Formic acid; Sodium hydroxide; Nitrogen; Carbon; Pulp

Introduction

The paper mill and pulp industry produce enormous quantities of paper and pulp products each year. It is the sixth largest polluting industry after the oil, cement, leather, textile, and steel industries, and many environmental contaminants are associated with the discharge of paper and pulp mill sludge [1]. Paper manufacturing is a complex industry involving multiple processes where different products are produced and large quantities of waste of primary, biological or de–inking origin are generated, waste water treatment sludge, primary sludge, and secondary sludge among them [2,3]. Pulp and paper mill production is growing every year worldwide. As a consequence, the amount of generated waste is increasing, along with increasing concern [4].

Sludge is the final solid waste recovered from the wastewater treatment process in pulp and paper mills. Sludge discharged from paper mills is divided into four categories:

a)primary sludge (PS), which comes from the production of virgin wood fiber;

b)de-inking paper sludge (DPS), which comes from the process of removing inks from recycled paper;

c)secondary sludge (SS; activated sludge), which comes from the secondary wastewater treatment system; and

d)combined primary and secondary sludge [5].

The sludge composition generally comprises organic matter, nitrogen and phosphorus, which can be used as macronutrient fertilizers in agriculture [6]. Nitrogen is important for growth of plant, its food processing and creation of chlorophyll. Carbon is the main part of soil organic matter and it aids soil to have water-retention capacity, form and fertility.

The sources of solids in a treatment plant vary according to the type of plant and its method of operation [7,8]. The amount and chemical composition, as well as the geotechnical properties of paper mill sludge depend on the paper grade being manufactured, specific fresh water consumption, the wastewater cleaning technique applied and the type of raw materials (e.g. wood, fillers). Thus, the chemical composition of paper mill sludge produced by one mill is often significantly different from that of another [9,10].

Many parameters have been introduced and tests developed to measure specific properties of sludge in relation to particular methods of treatment. Conventional sludge characteristics can be grouped in physical, chemical and biological parameters. Physical parameters give general information on sludge processability and handlability. Chemical parameters are relevant to the presence of nutrients and toxic/dangerous compounds, so they become necessary in the case of utilization in agriculture. Biological parameters give information on microbial activity and organic matter/pathogens presence, thus allowing the safety of use to be evaluated [11].

Natural and anthropogenic environmental changes greatly influence the behaviour of metallic pollutants in sludge, as the form in which they occur may be change. Such external factors can include pH, temperature, the redox potential, organic matter decomposition, leaching, ion exchange processes and microbiological activity [12].

The pulp and paper industry consumes enormous amounts of water and natural resources and is also one of the largest effluents generators. Before the 1970s, wastewaters from the pulp and paper mills were normally discharged directly to the rivers or lakes, without any treatment or even a rough primary treatment. The high organic loads and solid content in the effluents affected the aquatic ecosystem in several ways such as localized damage to the benthic community, oxygen depletion in large areas and numerous changes in fish reproduction and physiology [13].

This study sets out to find out the effects of chemical, concentration and time interactions under laboratory conditions on the quality of sludge considering nitrogen and carbon from two chemical pulping processes.

Materials and Methods

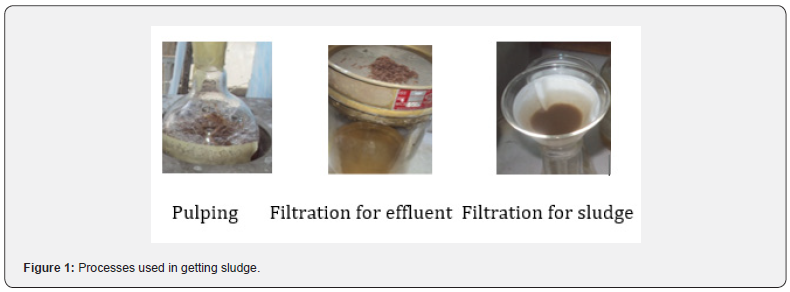

Kenaf stem was pulped with formic acid and sodium hydroxide at 20, 60 and 90% concentrations for a cooking time of 1, 2 and 3h at 95°C under atmospheric pressure. At the end of each period, the sample was filtered with a fine mesh sieve of size 0.027mm to get effluent and the effluent was filtered with a filter paper to get the sludge used in the analyses. The sludge samples were then air-dried and screened to remove other contaminating materials. The screened raw materials were ground and placed in an airtight container to balance the moisture content and then used for chemical analysis. The tests were carried out in triplicate and each value is an average of three samples.

Determination of nitrogen content

Nitrogen content of the sample was determined by using Kjedahl technique [14]. The method involves digestion of samples, distillation of digests and titration of distillate.

Where T = (sample titre – blank titre)

Determination of carbon content

Colorimetric method of [15] was used to calculate the total carbon (Figure 1).

Results and Discussion

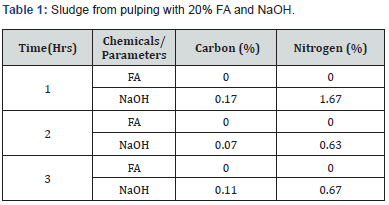

Table 1 presents the values of carbon and nitrogen from sludge obtained from pulping kenaf stem with 20% concentration of FA and NaOH. The sludge from formic acid pulping with 20% formic acid at three-hour intervals did not show any presence of carbon and nitrogen. Carbon and nitrogen were detected in the sludge from sodium hydroxide pulping at three-hour intervals in a decreasing concentration. The highest concentrations of carbon (0.17%) and nitrogen (1.67%) were obtained after 1-hour pulping while the lowest (0.07 & 0.63) were after two hours pulping. The increase of carbon content after three hours pulping may be as a result of esterification reaction as reported by [16].

Conclusion

The sludge content from 20% pulping has nitrogen and carbon from sodium hydroxide, sludge from 60% pulping has carbon and nitrogen from both chemicals with more nitrogen while 90% pulping has more carbon. Considering the pulped stem, it showed under pulped, normal and over pulped with respect to 20%, 60% and 90%. Therefore, looking at the normal pulp at 60% concentration with the two chemicals, formic acid has moderate values of carbon and nitrogen compare to sodium hydroxide that showed high nitrogen content. Formic acid pulping is considered here because it can easily be recovered after pulping and the sludge used as manure. However, further research is recommended with more focus on other sludge parameters.

Acknowledgement

The support from the Federal Institute of Industrial Research, Oshodi, Lagos, Nigeria and University of Nigeria, Nsukka, during this work is well appreciated.

references

- Ali M,Sreekrishnan TR (2001)Aquatic toxicity from pulp and paper mill effluents: A review. Adv Env Res 5(2): 175-196.

- Monte M, Fuente E, BlancoA, Negro C (2009) Waste Management from pulp and Paper Production in the European Union. Waste Manag29(1): 293-308.

- Bajpai P(2015) Management of pulp and Paper Mill Waste. Springer International Publishing. Switzerland.

- Simao L,Hotza D,RauppPereiraF,LabrinchaJA,Montedo ORK (2018) Wastes from pulp and paper mills - a review of generation and recycling alternatives.Cerâmica64(371): 443-453.

- Geng S, ZhangY, James D (2007) Characteristics of Paper Mill Sludge and its Utilization for the Manufacture of Medium Density Fiberboard. Wood and Fiber Science 39(2): 345-351.

- Ribeiro P, AlbuquerqueA, QuintaNova L,Cavaleiro V (2010) Recycling pulp mill sludge to improve soil fertility using GIS tools. ResourConservRecycl54: 1303-1311.

- Metcalf, Eddy (2003) Wastewater Engineering—Treatment and Reuse. In: Tchobanoglous G, Burton FL, Stensel HD (Eds.), (4th edn),McGrow Hill, New York, USA.

- Tay J, Yang P, Zhuang W, Tay S, Pan Z(2007)Reactor performance and membrane filtration in aerobic granular sludge membrane bioreactor. Journal of Membrane Science304(1-2): 24-32.

- Jackson M, Line M (1997) Organic composition of a pulp and paper mill sludge determined by FTIR, 13C CP MAS NMR, and chemical extraction techniques. J Agric Food Chem45(6): 2354-2358.

- Battaglia A,Calace N,Nardi E,Petronio B,Pietroletti M(2003) Paper mill sludge – soil mixture: kinetic and thermodynamic tests of cadmium and lead sorption capability. MicrochemJ 75(2): 97-102.

- YanS, Bala S, Tyagi, R,Surampalli R (2009)Wastewater Sludge CharacteristicsChapter 2.

- Kazi T, Jamali M, Kazi G, Arain M, Afridi H,et al. (2005) Evaluating the mobility of toxic metals in untreated industrial wastewater sludge using a BCR sequential extraction procedure and a leaching test. Anal BioanalChem 383(2): 297-304.

- María N(2017) Pulp Mill Wastewater: Characteristics and TreatmentUniversidad de la República, Engineering School, Chemical Engineering Institute, Forest.

- Pearson D (1976)The Chemical Analysis of Foods. (7thedn), Churchill Living stone, London.

- Nelson D, Sommers L (1996)Total carbon, organic carbon, and organic matter. 961-1010.In: DL Sparks et al. (Eds.), Methods of soil analysis. Part 3. Chemical Methods. SSSA Book Series No. 5, SSSA and ASA, Madison, WI.

- Oh S,Yoo D,ShinY,SeoG (2005)FTIR analysisofcellulosetreatedwithsodium hydroxideandcarbóCarbohydrate Research340(30): 417-428.

- GatenholmP,Gellerstedt F (1999)Surface properties oflignocellulosicfibersbearingcarboxylic groups. Cellulose6: 103-112.

- Gary M, Said A, Amy S (1995)Sludge Characteristics andDisposal Alternatives for the Pulp and Paper Industry.In: Proceedings of the 1995 International environmental conference; 1995 May 7-10; Atlanta, GA. Atlanta, GA: Tappi Press: pp. 269-279.