Bearing Design Science in Technologically of Different Materials for Textiles Industry

Elsayed Ahmed Elnashar*

Professor, Textiles & Apparel, Home Economics Department, Kaferelsheikh University, Egypt

Submission: December 15, 2022; Published: February 16, 2023

*Corresponding author: Elsayed Ahmed ElNashar, Professor, Textiles & Apparel, Home Economics Department, Kaferelsheikh University, Egypt

How to cite this article: Elsayed Ahmed Elnashar. Bearing Design Science in Technologically of Different Materials for Textiles Industry. Eng Technol Open Acc. 2023; 4(5): 555648. DOI: 10.19080/ETOAJ.2023.04.555648

Abstract

Design science of textile applications in technologically successful applications bearing the science of bearing design science according to the ancient Egyptians using various materials included pedal mechanisms, linear actuators, practical valve stems, trunnions, axles, reciprocating mechanisms, automobile joints and ball joints, office equipment, healthcare equipment, production equipment, agricultural machinery and design science of mechatronics of textile machinery and aircraft accessories. Design science of textile applications of in technologically using various materials tin bronze cloth reinforced exhibit a particularly long wear life at a high load because the interlayer reinforcing fabric is itself a bearing material. design science of textile and testing applications in technologically have included static loads of up to 50,000 psi and dynamic loads of 35,000 psi at moderately low revs. Design science of the bearing still works, and the coefficient of friction remains low even when worn to the point of exposing the bronze texture. The shaft is mainly based on the use of various materials placed in the pockets of the cloth, and the contact of the shaft with the bronze in the cloth is acceptable, a balance of some kind results. Design science the reinforced metallic fabric also helps dissipate heat. Design science in highly corrosive applications, the texture of stainless steel adds protection against unwanted chemical reactions if corrosion exposes the metal.

Keywords: Bearing Design; Ancient Egyptian; Different Materials

Introduction

Design science of mechatronics in textile applications in technologically; when it comes to choosing the right plastic bearing for your application, the options are virtually limitless. Design science between unique composite fittings, specialized bushings and custom manufacturing, there are literally thousands of bearing design science options available to meet your application requirements. But how do you choose the exact materials to meet your specific requirements? What qualities should you look for? What options are available so far? We have prepared this guide as the ultimate plastic bearing selection guide for your transmission supplier to reveal the correct bearing shape, with the specific characteristics you need to optimize the performance of your industrial applications in technologically. Join us as we explore the art of choosing plastic bearings.

Design science of textile applications in technologically when it comes to choosing the right plastic bearing for your application, the options is virtually limitless. Design science between unique composite fittings, design science specialized bushings and custom manufacturing, there are literally thousands of bearing design science options available to meet your application requirements. But how do you choose the exact materials to meet your specific requirements? What qualities should you look for? What options are available so far?

We have prepared this guide as the ultimate plastic bearing selection guide for your transmission supplier to reveal the correct bearing shape, with the specific characteristics you need to optimize the performance of your industrial applications in technologically. Join us as we explore the art of choosing plastic bearings.

Brief History of Bearings

What is the purpose of the bearing? Definition of a bearing is a supporting structure, designed to “bear” or withstand stress or load in a bearing design science application. Just as the skeleton supports your body or shape, it is your joints or “bearings” design science that allow the freedom of movement or function of each individual part.

Bearings design science reduces friction levels at the intersection of two meeting points. It is available in two basic forms; contact linear and rotary motion and non-contact (liquid films and magnetic bearings). This article will focus on shapes design science, functions, and selection of contact bearings. Original bearing designs date back to 2200 B.C., When the ancient Egyptians used a form of rotating bearing design science to move huge stones to build the pyramids. applications in technology of textiles from primitive pyramid construction to present-day industrial use, both the shape and function of bearings design science has evolved greatly. Early bearing designs were made of wood and later versions of sintered bronze and various metals, until the breakthrough of plastic composites in the 1950s. From this point on, plastic composite bearings design science revolutionized engineering bearing design science in nearly all industries. Bearing jobs range from flat bearings, rolling element, and thrust bearings, to specialized bearings design science. In technologically Mechatronics in applications include nearly every conceivable industrial application, from rugged railroads and construction to highly sanitary food and medical environments. Regardless of the application, for best success, bearings design science must have the correct shape to allow for proper function.

What is the purpose of the bearing? Simply put, a bearing is a supporting structure, designed to “bear” or withstand stress or load in a bearing design science of application. Just as the skeleton supports your body or shape, it is your joints or “bearings” that allow freedom of movement or function for each individual part. Bearings design science reduces friction levels at the intersection of two meeting points. It is available in two basic forms; contact with linear, rotary, and non-contact motion (liquid films and magnetic bearings). This article will focus on shapes, functions, and selection of contact bearings. Original bearing designs date back to 2200 B.C., when the ancient Egyptians used a form of rotating bearing to move huge stones to build the pyramids. Textile applications in technologically from the primitive construction of the pyramid to today’s industrial use, both the form and function of bearings have evolved greatly. Early carrying designs were made of wood and later versions of sintered bronze and various metals, until the penetration of plastic composites in the 1950s. From this point on, plastic composite bearings design science revolutionized engineering bearing design science in nearly all industries. Bearing jobs range from flat bearings, rolling element, and thrust bearings, to specialized bearings. Applications in technologically include nearly every conceivable industrial application, from rugged railroads and construction to medical environments and ultra- healthy foods. Regardless of the application, for best success, bearings design science must have the correct shape to allow for proper function.

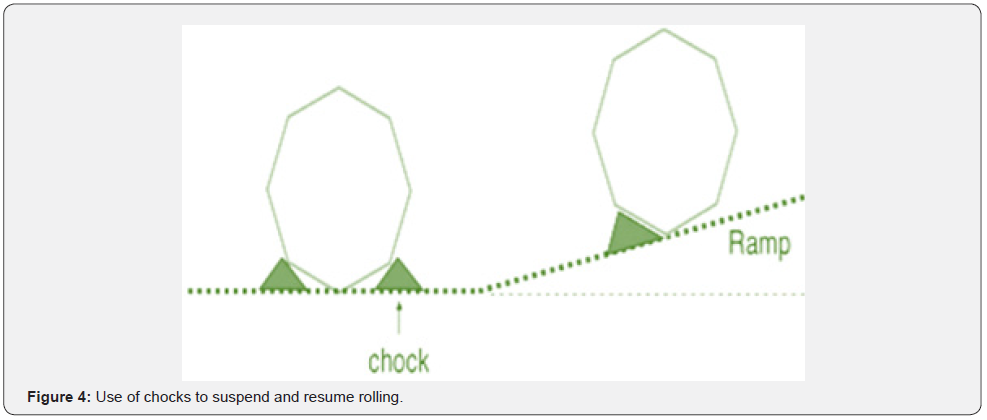

Assumption: the entire construction of the Egyptian pyramids was led by a vertical well with the central axis of the bearings design science as a serial transmission. This is a huge energy savings compared to drag which needs a continuous application of power, and it consumes a lot of energy. we may conclude, in practice, that it is better to have aid at first with a lever at first to tilt the stone a little so that only several men can begin to roll, and when we are attached to rolling the stone, it is better to use pegs to catch it. Like figure 4 that make it easy to resume rolling (Figures 1-4).

Nowadays, design science of mechatronics in applications in technologically of textiles roller chains drive a myriad of power transmission and conveyor applications technologically. However, maintenance of roller chains is vital to maximizing their life and effectiveness, especially in construction and mining applications in technologically that tend to be high-profile and subject to strict safety guidelines. to better understand today’s bearings design science, let’s start first with a brief history: 2200 B.C., the ancient Egyptians used some form of roller bearing to help move massive bricks while building the pyramids. When we choose the right plastic bearing design science for your application, the options are virtually unlimited. Between unique composite fittings, specialized bushings and custom manufacturing, there are literally thousands of bearing design science options available to meet your application requirements:

i. Design science with the specific features you need to improve the performance of your industrial mechatronics in applications technologically.

ii. But how do you select the exact materials to meet your specific requirements?

iii. Throw design science what qualities should you look for?

iv. Throw design science what options are available today?

Bearings

Applications of textiles a brief history what is the purpose of a bearing design science? Simply put, a bearing is a supporting structure, designed to “bear” or withstand stress or load in a bearing design science of application. Just as the skeleton supports your body or shape, it is your joints or “bearings” that allow the freedom of movement (or function) of each individual part. Bearings design science reduces friction levels at the intersection of two meeting points. It is available in two basic forms; contact linear and rotary motion and non-contact. This article will focus on design science shapes, functions, and contact bearing selection. Original bearing design science date back to 2200 B.C., when the ancient Egyptian’s used a form of rotating bearing to move huge stones to build the pyramids. From primitive hierarchical construction to today’s industrial use, both the form and function of bearings design science have evolved greatly. Early bearing designs were made of wood and later versions of sintered bronze and various metals, until the breakthrough of plastic composites in the 1950s. From this point on, plastic composite bearings revolutionized engineering bearing design science in nearly all industries. Bearing design science jobs range from flat bearings, rolling element, and thrust bearings design science, to specialized bearings. Applications in technologically include nearly every conceivable industrial application, from rugged railroads and construction to medical environments and ultra-healthy foods. Regardless of the application, for best success, bearings design science must have the correct shape to allow for proper function.

Basics of Bearing Design

applications in technologically of textiles evolution to better understand today’s trends, let’s first start with a brief history: 2600 BC - the ancient Egyptians used some form of roller bearing to help move massive bricks while building the pyramids. Nowadays plastic bearings excel in almost every conceivable industrial application, from durable railways and construction to high-sewage food and medical applications in technologically and aircraft. Bearing design science and applications: cost vs. performance. it is true that plastic materials can be more expensive than conventional metals. PBI polymers, for example, can run 25 or more times the price of cold-rolled steel. At these price points, it’s important to look beyond initial unit expenses, and instead calculate a lifetime performance cost. Properly designed components can achieve significant savings in the future due to longer wear rates, lower maintenance calls and superior service life. in technologically mechatronics in once you have selected a material based on the basic application requirements (environment, temperature, mating devices, etc.), we then recommend taking a look at the quality of the material. small bearings design science in motors and compressors piston-bolt bearings design science in crank presses, connecting rods in textile machinery, connecting rods in reciprocating wood saws torsion-less suspension (such as braided silk and other textiles for magnetometers fiber).

a. Bucket elevators, pulverizes, in textile machinery

b. Large excavators.

c. Textile machinery or band drives.

d. Machine tools where clutch is located in main driving pulley

Bearing Design in technologically

Design science and applications in technologically of textiles throw key criteria finally, all bearing design science challenges can be defined as material selection challenges. That is, simply put, to determine the feasibility of a plastic material, it is crucial to consider the following design criteria:

design science of Basic Plastic Features

i. Mechanical properties in technologically.

ii. Thermal and electrical

iii. Various considerations

iv. Characteristics of basic plastic materials

Design science and applications in technologically of textiles elastic behavior is related to stress and pressure on a plastic material. When stress levels reach a critical point, plastic production or deformation is directly affected. Design science and applications in technologically of textiles the impact strength of a polymer’s impact resistance is determined by the base resin of the material as well as any modifiers and strengthening agents added. Mechatronics in impact strength is usually measured by tensile strength load test, the higher the load measurement, the greater the impact strength. Thermal properties in technologically even a small change in temperature can have an effect on the strength and toughness of the plastic. to determine the thermal properties technologically, consider: continuous service temperature, the highest temperature at design science which a material retains its physical integrity. À maximum service temperature, the point at which temperatures will cause the plastic to stress and soften, as defined by ASTM. Design science and applications in technologically of textiles the dimensional stability of a material or expansion/ contraction rate is directly affected by exposure to temperature extremes, moisture levels and loads. In fact, levels of expansion in heat and levels of contraction (in cold) can be up to 10 times or more the rate for metals. For example, a plastic part made in a hot, dry desert warehouse is very likely to present dimensional challenges when installed in a cold, wet winter application if not parsed and cut properly.

Bearing applications in technologically in Mechatronics

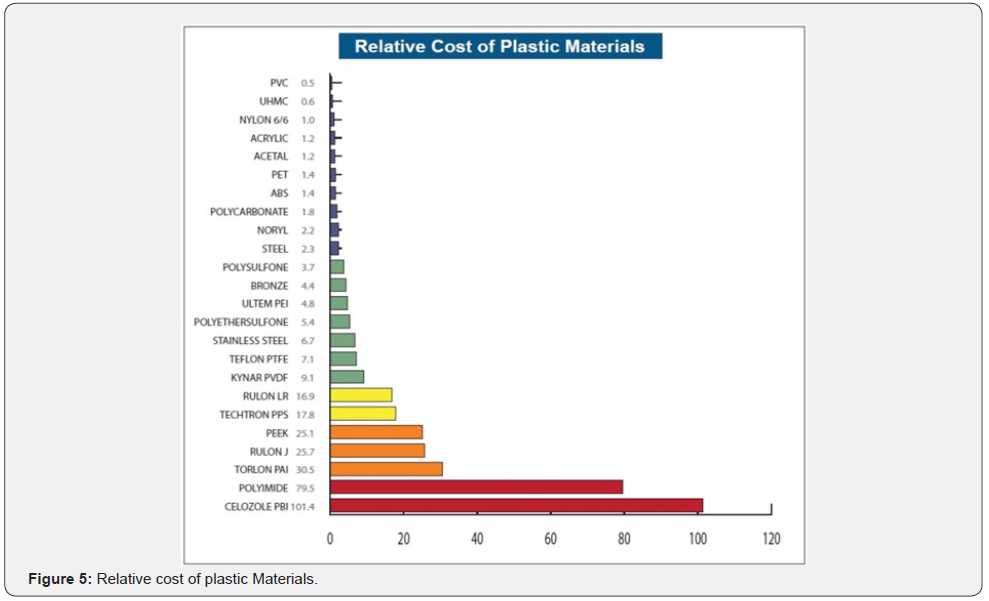

Design science and applications in technologically of textiles Cost vs. performance it is true that plastics can be more expensive than traditional metals. PBI polymers, for example, can run 25 or more times the price of cold-rolled steel. At these price points, it’s important to look beyond initial unit expenses, and instead calculate a lifetime performance cost. design science are Properly designed component that can generate significant savings down the line due to longer wear rates, fewer maintenance calls and superior service life. Once you have selected a material based on the basic design science and application requirements environment, temperature, mating devices, etc., we then recommend taking a look at the quality of the material (Figure 5).

Mechanical properties in technologically

Design science of Tensile strength Tensile strength measures the ability of a material to withstand a load under tension without failure. Also known as absolute strength, tensile strength is calculated in pounds per square inch (PSI). Design science of the higher the tensile strength. Mechatronics in design science and applications in technologically of textiles he better the bearing capacity of the material and its ability to resist cracking. Typical tensile strength of materials: Tensile elongation: The increase in length that occurs when a material is stretched, but before it breaks under tension. It is expressed as a percentage of the original length of the material. The high tensile strength and high elongation together contribute to the overall durability of the material. Design science and Mechatronics in Compressive Strength This measurement indicates a material’s resistance to fracture under stress. There is great variance in compressive strength between different grades of plastics. Flexural Bending strength translates into the material’s ability to resist bending under load, also known as the modulus of rupture or bending strength.

Design science of Hardness Plastics hardness measures the resistance of a material to an indentation, as measured by the Rockwell or Shore test methods. Rockwell method, generally used for stiffer plastics where polymer flexibility or creep is less likely to affect results nylon, polycarbonate, polystyrene, acetal. Shore/Durometer method, intended for softer materials such as urethane, PTFE and PVC. It is best to use hardness data to compare materials, and it is not correlated with other plastic properties in technologically or basic properties. Design science of the modulus covers the modulus of tensile, compression and bending and is defined as the ratio of stress or strength per unit area. Quoting from Young’s modulus of elasticity, the modulus can predict the reaction of a substance, as long as the stress is less than the product of the substance. [1], Nylon and acetal are commonly used in a variety of manufacturing design science and applications of in technologically. Since both materials are semi-crystalline thermoplastics, some of their properties overlap, such as fatigue resistance, chemical resistance, and corrosion resistance with a sharp melting point. In addition, both are a convenient choice of materials for creating small components such as washers, discs, and spacers. However, while there are some similarities in properties in technologically and use cases, the two materials remain distinctly different and are not entirely interchangeable technologically [2].

Results and Discussion

Differences between nylon and acetal

One obvious difference between nylon and acetal is aesthetics. Acetal is shiny, while nylon looks dull in comparison throw Mechatronics in design science and applications in technologically of Textiles [3]. They also differ with regard to performance:

i. Design science compared to acetal, nylon provides superior tensile strength and bending toughness. It can also handle high loads and high temperatures. However, in technologically it is subject to UV damage unless special additives are incorporated into its composition and reacts poorly to changes in humidity, causing it to swell and lose tensile strength.

ii. Design science compared to nylon, acetal offers higher impact resistance and cold resistance. It is suitable for moderate loads.

What is acetal plastic?

In technological design science of acetal, also known as polyoxymethylene (POM) is a synthetic polymer commonly used in precision engineering [4]. Similar to other semi-crystalline thermoplastics, it has good chemical resistance and fatigue resistance. It also demonstrates excellent tensile strength, mechatronics in good dimensional stability and machinability, low material weight and frictional properties technologically.

What is plastic nylon?

Design science of Nylon is also a synthetic polymer technologically, in addition to being one of the most widely used thermoplastics in industry [5,6]. It is highly durable, which indicates its resistance to damage from abrasion, chemicals (such as alcohol, oils, and solvents) and tearing. These qualities, along with the low cost of the material, make nylon a suitable choice for all types of industrial and commercial applications technologically.

Definitions of advantage of Acetal Plastic

In technologically as indicated above, acetal plastic is valued for its machinability of Mechatronics [7] in and many advantageous physical characteristics. Some of the key attributes of acetal include:

i. Design science of chemical resistance: excellent

ii. Design science of coefficient of friction: low

iii. Design science in dimensional stability: excellent

iv. Design science in electrical properties in technologically: good

v. Machinability: excellent

vi. Design science of porosity and moisture absorption: low

vii. Tensile strength and stiffness: excellent

viii. Wear resistance: excellent

ix. Availability in FDA and USDA-compliant grades in technologically: yes

Definitions of advantage of Acetal plastic

Design science of Mechatronics in noted acetal plastics are valued for their mechanical ability and many useful physical properties in technologically [8]. Some of the key attributes of acetal include:

i. Design science of chemical resistance: excellent

ii. Design science of coefficient of Friction: Low

iii. Design science of dimensional stability: Excellent

iv. Design science of electrical properties in technologically: good

v. Design science of machine capacity: excellent

vi. Design science of porosity and moisture absorption: low

vii. Design science of tensile strength and toughness: excellent

viii. Design science of corrosion resistance: excellent

ix. Availability in FDA and USDA compliant grades: Yes

Definitions of advantage of Nylon Plastics in technologically

The properties in technologically of nylon somewhat overlap with acetal, including regard to the following [9]

i. Design science of chemical resistance: excellent

ii. Design science of coefficient of friction: low

iii. Design science of wear resistance: excellent

iv. Design science of availability in FDA and USDA-compliant grades: yes

Definitions of advantage of Acetal Plastic in technologically

Both nylon and acetal are suitable for use in applications in technologically that call for general-purpose engineering plastics [10]. However, there are a few reasons why you may choose acetal over nylon. For example:

i. When manufacturing parts of design science that require high dimensional stability

ii. When the finished part of design science or product will be regularly exposed to humidity or moisture

iii. When the chemical and wear resistance of the material is critical

Definitions of advantage of Nylon Plastic in technologically

Mechatronics in design science and applications in technologically of Textiles As a self-lubricating material [11], nylon is increasingly popular as a replacement for metal components that require external lubrication. Mechatronics in Compared to parts made from metal, parts made from nylon are also much lighter, produce less noise during operations, and have longer service lives [12]. Nylon also offers advantages over other design science of thermoplastics. For example:

i. Design science Compared to acetal, it has higher temperature resistance, tensile strength, and stiffness, as well as lower material cost.

ii. Design science compared to all other semi-crystalline thermoplastics; it offers the highest dielectric strength (in 6 cast formulas).

Design science of industry applications in technologically for acetal and nylon as both acetal and nylon are highly versatile, it would be difficult to list all possible industry applications for either material design science or applications in technologically of textiles [13]. Additionally, since both materials are semi-crystalline thermoplastics, their similar material properties in technologically make them suited for similar use cases.

Common Acetal Plastic Applications in Technologically

Acetal is used for design science of the manufacture of a wide range of parts and products, including the following:

i. Bearings

ii. Buckles

iii. Bushings

iv. Electrical parts and padding

v. Fasteners

vi. Fixtures

vii. Gears

viii. Jigs

ix. Manifolds

x. Rollers

xi. Valves

xii. Washers

xiii. Wear strips and padding

Mechatronics in design science in technologically, these components might end up in medical devices, conveyor systems, or other similarly complex assemblies.

Common Nylon Plastic Applications In Technologically

Nylon remains best known by the public for its uses as a sturdy and durable fabric [14]. However, beyond its use in clothing and other commercial goods, Mechatronics in design science and applications in technologically of Textiles it also finds application in many industrial parts and products. Similar to acetal, it is regularly used for the production of the following components:

i. Bearings

ii. Gaskets

iii. Gears

iv. Rollers

v. Seals

vi. Washers

vii. Wear Pads

Design science and applications in technologically of textiles as with acetal, these components are highly versatile and may be used in any number of industries. For example, nylon parts are often found in medical instruments, plumbing systems, and sprinkler systems. Design science also serves as alternatives to metal, wood, and rubber components in many engineering applications technologically. Nylon & acetal washers, although washers are often thought of as made exclusively from metal or rubber, thermoplastic washers have grown in popularity over the years. Mechatronics in the main function of washers is to distribute the pressure experienced by a fastener across a larger surface area while also protecting the fastener and attachment surface. In technologically design science they can also help disperse vibrations produced during operations to minimize the risk of the fasteners loosening over time [15]. Design science in new process fiber offers a selection of both nylon washers and acetal washers. Nylon washers are available in nylon 6, nylon 6/6, nylon MDS, or Nylatron ®, depending on the needs of the application. Design science and applications in technologically of textiles they are cost-effective, consistent, and customizable within lp-410 quality standards. Acetal washers are custom-made and come in a range of natural or pigmented resins.

Nylon and Acetal Products from New Process Fiber

Design science of Nylon and acetal are highly versatile materials used in the fabrication of a wide range of industrial parts and products. For all your non-metallic fabrication needs, turn to the experts at New Process Fiber. Mechatronics in design science and applications in technologically of Textiles at New Process Fiber, we are an experienced fabricator specializing in processing non-metallic materials [16]. We accommodate a broad selection of materials, including acetal, nylon, high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene homo and copolymer, and fire-retardant thermoplastics. In technologically Design science Equipped with over nine decades of industry experience and a 55,000 square foot fabrication facility, we have the knowledge and tools to serve the fabrication needs of customers from industries ranging from aerospace and automotive to construction and consumer goods to power tools and plumbing. Our full range of fabrication and finishing services includes:

i. Design science In-house tool and die making

ii. Sheet extrusion and slitting

iii. Slitting and shearing

iv. Non-metallic stamping

v. Custom embossing and screen printing

vi. Pressure-sensitive adhesive (PSA) design science and application in technologically.

In technological mechatronics in design science and applications in technologically of textiles using these services, we fabricate countless non-metallic components, including washers, spacers, gaskets, shims, and more. Whether you’re seeking assistance with nylon, acetal, or some other thermoplastic, we are well equipped to satisfy your fabrication needs [17]. rolling bearings by using textiles materials of nylon and acetal, design science of mechatronics in aircraft rolling bearings design science of nylon and acetal, the properties in technologically of typical dry rubbing bearing materials small-end bearings in engines and compressors, plunger-pin bearings in crank-operated presses, connecting rods in textile machinery, connecting rods in wood reciprocating saws torsion less suspensions (e.g. stranded silk and other textile for magnetometers) fibers)

Bucket Elevators, Pulverisers

In technologically design science of mechatronics in textile machinery large excavators, design science of textile machinery or band drives. Machine tools where clutch is located in main driving pulley Low viscosity oils e.g. below about 0.01 Ns/m2 at 60DC, suitable for the lubrication of high-speed bearings such as textile spindles. Slides and linear bearings on To reduce friction and wear at the Greases and solid lubricants are The sliding contact area should be protected from dirt by fitting scraper seals packaging machines, design science in textile machines, mechanical handling devices handled at each end if possible [18].

Plastic Bearings in Technologically

Design science and applications in technologically of Textiles Different types of plastics have properties in technologically which make them suitable for bearing applications, the most commonly used are phenolics, acetals, UHMWPE, and nylon. Although many different types of plastics have properties which make them suitable for bearing applications In Technologically, the most commonly used are phenolics, acetals, UHMWPE, and nylon. The major limitations involved in the use of plastics have to do with high temperatures and possible cold flow under heavy loads.

Phenolics: design science of Composite materials that consist of cotton fabric, or other fillers bonded with phenolic resin. The compatibility of the phenolics makes them easily lubricated by various fluids. They have replaced wood bearings and metals in such applications In Technologically as propeller and rubber-shaft bearings in ships and electrical switchgear, rolling-mill, and water-turbine bearings. In small instruments and clock motors, laminated phenolics serve as structural members as well as a bearing material [19]. In technologically they have excellent strength and shock resistance coupled with resistance to water, acid, and alkali solutions. Some precautions must be observed with phenolic bearings. Design science thermal conductivity is low, so heat generated by bearing friction cannot be readily transmitted through the bearing liner. Consequently, larger, heavily loaded bearings must have a generous feed of water or lubricating oil to carry away heat. Some swelling and warping of these bearings occurs in the larger sizes, so larger-than-normal shaft clearances are required in Mechatronics.

Nylon: Although the phenolics have predominated in heavy-duty applications technologically, they are frequently replaced by nylon, which has the widest use in bearings. Nylon bushings exhibit low friction and require no lubrication [20]. Nylon is quiet in operation, resists abrasion design science, wears at a low rate, and is easily molded, cast, or machined to close tolerances. Possible problems with cold flow at high loads can be minimized by using a thin liner of the material in a well-supported metal sleeve. Design science improvement in mechanical properties in technologically, rigidity, and wear resistance is obtained by adding fillers such as graphite and molybdenum disulfide to nylon. While the maximum recommended continuous service temperature for ordinary nylon is 170°F, and 250°F for heat-stabilized compositions, filled-nylon parts resist distortion at temperatures up to 300°F.

PTFE: Has an exceptionally low coefficient of friction and high self-lubricating characteristics, immunity to almost all types of chemical attack, and ability to operate over extremely wide temperature range (-330 to 360°F continuous, to 550°F short-term).

New reinforcing constructions, particularly tin bronze, and stainless-steel interlayer reinforcement (metal fabric), have raised PV ratings, minimized cold flow, and extended wear life substantially. These have outperformed properly applied metal sleeve bearings at PVs of 30,000 or more. Other reinforcing constructions include fabric, powder metal filler, and steel backing in various combinations.

Cost of PTFE bearing material is high relative to plain metal or other resins. But applications for PTFE center in low rpm, oscillatory or intermittent service or where reliable service without lubrication is vital. Load capacity depends on construction and reinforcing material. Many applications in technologically include exposure to weather, chemicals, or vapors which attack metals, lubricants, and some plastics. Others, such as sluice gates, involve the need to operate smoothly, reliably, and without sticking after prolonged idle periods.[1]

Nylon and acetal are commonly used in a wide range of design science and manufacturing applications technologically [21]. As both materials are a semi-crystalline thermoplastic, some of their characteristics overlap, such as their fatigue resistance, chemical resistance, and wear resistance with a sharp melting point. Additionally, design science both are appropriate material choices for the creation of small components such as washers, discs, and spacers in technologically. However, while there are some similarities in properties and use cases, the two materials remain distinctly different and are not entirely interchangeable. One of the most obvious differences between nylon and acetal lies is aesthetics; acetal is shiny, while nylon appears dull in comparison. They also vary in regard to performance. For example:

i. In technologically the Design science Compared to acetal, nylon offers superior tensile strength and bending stiffness. It can also handle higher loads and higher temperatures. However, it is susceptible to damage from UV radiation unless special additives are incorporated into its formula and reacts poorly to changes in humidity, which cause it to swell and lose tensile strength.

ii. Design science Compared to nylon, acetal provides higher impact resistance and cold resistance. It is suitable for moderate loads.

In the following technologically, we provide an overview of acetal and nylon outlining what they are, their properties, their key Definitions of advantage, and typical industry applications of design science to facilitate material selection.

What Is Acetal Plastic?

Acetal, also known as polyoxymethylene (POM), is a synthetic polymer commonly used in precision engineering. Similar to other semi-crystalline thermoplastics, it has good chemical resistance and fatigue resistance [22]. It also demonstrates excellent tensile strength, good dimensional stability, and design science of machinability in Mechatronics, and low material weight and frictional properties technologically. It is often used for the manufacture of stiff, dimensionally stable components that need low surface friction.

What Is Nylon Plastic?

Nylon is also a synthetic polymer, as well as one of the most commonly employed engineering thermoplastics in the design science of Mechatronics in applications in technologically of Textiles. It is highly durable, demonstrating resistance to damage from abrasion, chemicals (such as alcohols, oils, and solvents), and tearing. These qualities, combined with the material’s low cost, make nylon a suitable option for all manner of industrial and commercial applications in technologically.

Properties in technologically of Acetal Plastic

As indicated above, acetal plastic is valued for its machinability and many advantageous physical characteristics. Some of the key attributes of acetal include:

i. Design science of chemical resistance: excellent

ii. Coefficient of friction: low

iii. Dimensional stability: excellent

iv. Electrical properties in technologically: good

v. Machinability: excellent

vi. Porosity and moisture absorption: low

vii. Tensile strength and stiffness: excellent

viii. Wear resistance: excellent

ix. Availability in FDA and USDA-compliant grades: yes

x. Properties in technologically of Nylon Plastics

xi. The properties in technologically of nylon somewhat

overlap with acetal, including regard to the following:xii. Chemical resistance: excellent

xiii. Coefficient of friction: low

xiv. Wear resistance: excellent

xv. Availability in FDA and USDA-compliant grades: yes

However, design science of Mechatronics in design science of the material also offers better thermal resistance, durability, and performance for the given price point.

Definitions of advantage of Acetal Plastic

Both nylon and acetal are suitable for use in design science and applications in technologically that call for general-purpose engineering plastics [23]. However, there are a few reasons why you may choose acetal over nylon. For example:

i. When manufacturing parts that require high dimensional stability

ii. When the finished part or product will be regularly exposed to humidity or moisture

iii. When the chemical and wear resistance of the material is critical

iv. Definitions of advantage of Nylon Plastic

Design science of Mechatronics in a self-lubricating material, nylon is increasingly popular as a replacement for metal components that require external lubrication. design science are Compared to parts made from metal, parts made from nylon are also much lighter, produce less noise during operations, and have longer service lives.

Nylon also offers advantages over other thermoplastics. For example:

i. Design science is compared to acetal; it has higher temperature resistance, tensile strength, and stiffness, as well as lower material cost.

ii. Design science are compared to all other semi-crystalline thermoplastics, it offers the highest dielectric strength (in 6 cast formulas).

Design science throws Industry applications in technologically for acetal and nylon as both acetal and nylon are highly versatile, it would be difficult to list all possible industry applications in technologically for either material [24]. Additionally, since both materials are semi-crystalline thermoplastics, their similar material properties in technologically make them suited for similar use cases.

Common Acetal Plastic applications in technologically in Mechatronics

Acetal is used for the manufacture of a wide range of parts and products of design science, including the following:

i. Bearings

ii. Buckles

iii. Bushings

iv. Electrical parts and padding

v. Fasteners

vi. Fixtures

vii. Gears

viii. Jigs

ix. Manifolds

x. Rollers

xi. Valves

xii. Washers

xiii. Wear strips and padding

These components of design science might end up in medical devices, conveyor systems, or other similarly complex assemblies.

Common Nylon Plastic Applications in Technologically

Nylon remains best known by the public for its uses as a sturdy and durable fabric. However, beyond its use in clothing and other commercial goods, it also finds application in many design science of industrial parts and products. Similar to acetal, it is regularly used for the production of the following components:

i. Bearings

ii. Gaskets

iii. Gears

iv. Rollers

v. Seals

vi. Washers

vii. Wear Pads

As with acetal, these components are highly versatile and may be used in any number of design science industries. For example,nylon parts are often found in medical instruments, plumbing systems, and sprinkler systems. They also serve as alternatives to metal, wood, and rubber components in many engineering applications in technologically of design science.

Nylon & Acetal Washers

Although washers are often thought of as made exclusively made from metal or rubber, thermoplastic washers have grown in popularity over the years. The main function of washers is to distribute the pressure experienced by a fastener across a larger surface area while also protecting the fastener and attachment surface. They can also help disperse vibrations produced during operations to minimize the risk of the fasteners loosening over time. Design science as New Process Fiber offers a selection of both nylon washers and acetal washers. Nylon washers are available in Nylon 6, Nylon 6/6, Nylon MDS, or Nylatron®, depending on the needs of the application. They are cost-effective, consistent, and customizable within LP-410 quality standards. Acetal washers are custom-made and come in a range of natural or pigmented resins.

Conclusion

Design science and applications in technologically of Textiles at New Process Fiber, we are an experienced fabricator specializing in processing non-metallic materials. We accommodate a broad selection of materials, including acetal, nylon, high-density polyethylene (HDPE), low-density polyethylene (LDPE), polypropylene homo and copolymer, and fire-retardant thermoplastics. Equipped with over nine decades of industry experience and a 55,000 square foot fabrication facility, we have the knowledge and tools to serve the design science for fabrication needs of customers from industries ranging from aerospace and automotive to construction and consumer goods to power tools and plumbing.

Our full range of fabrication and finishing services includes:

i. In-house tool and die making

ii. Sheet extrusion and slitting

iii. Slitting and shearing

iv. Non-metallic stamping

v. Custom embossing and screen printing

vi. Pressure-sensitive adhesive (PSA) application

Design science and applications in technologically of Textiles Using these services, we fabricate countless non-metallic components, including washers, spacers, gaskets, shims, and more. Whether you’re seeking assistance with nylon, acetal, or some other thermoplastic, we are well equipped to satisfy your fabrication needs.

References

- Acetal Plastic vs. Nylon Plastic (2020) New process fibre company.

- ElSayed A ElNashar (2022) Parameters characterizing the human figure: anthropometric principles of shaping work areas, Course: Safework and Ergonomics, Lodz University of Technology, Poland.

- Bard Kathryn A, Shubert Steven Blake (2014) Encyclopedia of the Archaeology of Ancient Egypt.

- Guran Ardéshir Rand, Richard H (1997) Nonlinear dynamics. World Scientific: 178, ISBN 978-981-02-2982-5

- ElSayed A ElNashar (2022) Digital Transformation of Healthcare by Artificial Intelligence in Sectors of Textile Industries in Egypt, Digital Health 4th International Conference.

- Bearing Industry Timeline. Archived from the original on 28 December 2014. Retrieved 21 October 2012.

- Philip Vaughan (2013) Double- Row Angular Contact Ball Bearings.

- David Mozer (2013) Bicycle History, Chronology of the Growth of Bicycling and the Development of Bicycle Technology.

- Stribeck R (1901) Kugellager für beliebige Belastungen. Zeitschrift des Vereines Deutscher Ingenieure 3(45): 73-79.

- ElSayed A ElNashar, Dmitry Pirogov (2022) Properties of torsion rod in “Sulzer” projectiles loom. Journal of Textile Engineering & Fashion Technology 8(1).

- ElSayed A. ElNashar, Dmitry Pirogov (2021) Properties of Torsion Rod in "Sulzer” Projectiles Loom. 3rd International Webinar Advanced Materials, International Conference on Advanced Materials, Materials Science and Nanomedicine.

- Machine Design (2007), Did You Know: Bud Wisecarver (PDF), Machine Design, pp. 1

- ElSayed A ElNashar (2021) Sustainable Textiles Industries in Brand Technology Between Technologies of Brands. 3rd International Webinar Advanced Materials. International Conference on Advanced Materials, Materials Science and Nanomedicine.

- Schwack F, Stammler M, Pol G, Reuter A (2016) Comparison of Life Calculations for Oscillating Bearings Considering Individual Pitch Control in Wind Turbines. Journal of Physics: Conference Series 753(11).

- Luiz Otavio Amaraol Affonso (2006) Antifriction Bearings - an overview | ScienceDirect Topics.

- Budynas Richard, Nisbett J Keith (2014). Shigley's Mechanical Engineering Design. Mc Graw Hill, USA, pp. 597.

- Schwack Fabian, Bader Norbert, Leckner Johan, Demaille Claire, Poll Gerhard (2020) A study of grease lubricants under wind turbine pitch bearing conditions. Wear pp. 454–455.

- White John H (1985). The American Railroad Passenger Car Baltimore, Maryland: Johns Hopkins University Press 2, 518.

- Gebhardt, George Frederick (1917). Steam Power Plant Engineering. John Wiley & sons: 791.

- Hobbs, George William, Elliott Ben George, Consoliver Earl Lester (1919) The gasoline automobile. McGraw-Hill, USA, pp. 111–114.

- Dumas, Paul (1922) Pressure Lubricating Characteristics. Motor Age, Class Journal 42.

- Gobain Saint (2012) Saint-Gobain and Norco Get Celebrity Thumbs-Up.

- https://en.wikipedia.org/wiki/Bearing_(mechanical)

- Hazards of Inappropriate Working Clearance of Spherical Roller Bearings (2020) Roller Bearings Suppliers.