Localization of Maximum Depth for Steel Cracks using Machine Learning

Hesham M Shehata*

Department of Mechanical Engineering, Alexandria University, Egypt

Submission: March 20, 2019; Published: April 02, 2019

*Corresponding author:Hesham M Shehata, Department of Mechanical Engineering, Faculty of Engineering, Alexandria University, Egypt

How to cite this article: Hesham M S. Localization of Maximum Depth for Steel Cracks using Machine Learning. Eng Technol Open Acc. 2019; 2(5): 555600. DOI: 10.19080/ETOAJ.2019.02.555600

Abstract

Autonomous localization of maximum depth for steel cracks is needed in order to automate the inspection process. In this study, an automatic localization of maximum crack depth is intended to be structured using machine learning. Steel micro cracking segments are captured and magnified by 10x using laser scanning microscope Keyence (VX-X100). The generated 3D profile of the cracks helps to localize the maximum depth per each segment. One hundred and fife segments of cracks are investigated. 80% of segments are intended to be used for learning and 20% segments for testing. The learning technique is expected to autonomously localize the maximum depth of crack effectively.

Keywords: Crack inspection; Machine learning; Localization of maximum depth; Computer vision

Introduction

Localization of maximum depth for cracks is considered to be a not easy task due to the irregularity of cracks profiles. The process to locate the maximum depth per each profile consumes time and cost. This process can be automated through learning techniques. In addition, it is required also to detect cracks and measure their characteristics like crack depth, length and width which is very important for maintenance. Inspection by cameras only can fasten and automate the inspection process.

Related Work

A system for crack detection on steel surfaces was described in [1,2] where experiments were made to detect cracks and measure both width and depth of the cracks. In addition, the crack depth was estimated through image processing techniques using updated Make 3D toolbox. In this work, the location of the maximum depth along the crack profile is intended to be investigated. Each crack segment is captured (2D image) along with the depth profile which helps to locate the maximum depth easily. Learning approaches in general require distinct patterns to detect reliably and unfortunately, cracks are not distinct enough. However, some features can be learnt during the process but with careful considerations. Cracks on concrete structures were detected using CNN in [3] where they use a classier with 5 classes. A vision-based method was proposed in [4] using a deep architecture of Convolutional Neural Networks, CNN, for detecting concrete cracks. The proposed CNN showed a robust performance compared to the traditional, well-known edge detection methods such as Canny and Sobel at detecting thin cracks under lighting conditions that is problematic for traditional methods. However in their work, crack features such as width and depth were not estimated. An automatic crack detection method was proposed in [5] based on trained supervised deep CNN to classify each image patch in a collected images. However, it remains a challenging task due to the intensity in-homogeneity of cracks, complexity of the background and lack of crack distinctive features.

Experiments

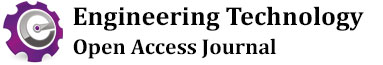

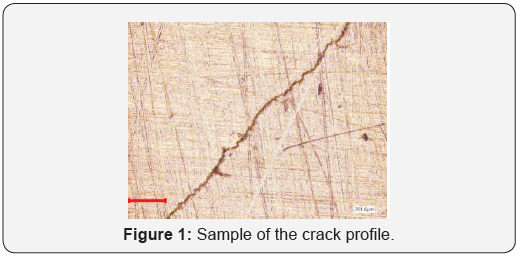

In earlier work, measurements are done on segmented cracks for steel specimens. Cracks characteristics measurement were performed using laser scanning microscope KEYENCE (VK-X100) [1]. The total number of cracks segments is 105. Figure 1 shows a sample crack profile while Figure 2 shows a sample of the depth profile in color. Blue areas represent the region of interest for maximum depth.

Learning Strategy

The proposed learning strategy depends on automatic or manual extract for region of interest (maximum depth) followed by focusing on their characteristics. Artificial neural network can be a good choice since the location of maximum depth area is predefined. In addition, automatic learning process can be followed and tested using new automatic learning functions based on labelling the regions of interest.

Artificial Neural Networks

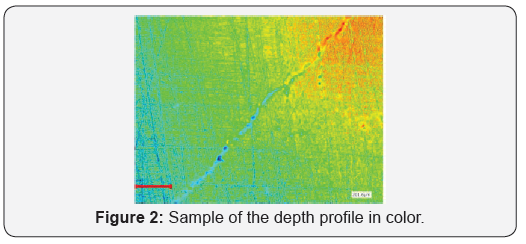

Artificial neural network can be trained and tested using the mentioned data set of images for automatic feature extraction of region of interest (maximum depth). This can be performed effectively using image processing algorithms since the maximum depth area is already predefined from actual measurements. The proposed characteristics include crack maximum depth area pixels intensities (values and location), number of pixels and width. Figure 3 shows a segment sample image highlighted with the maximum depth area.

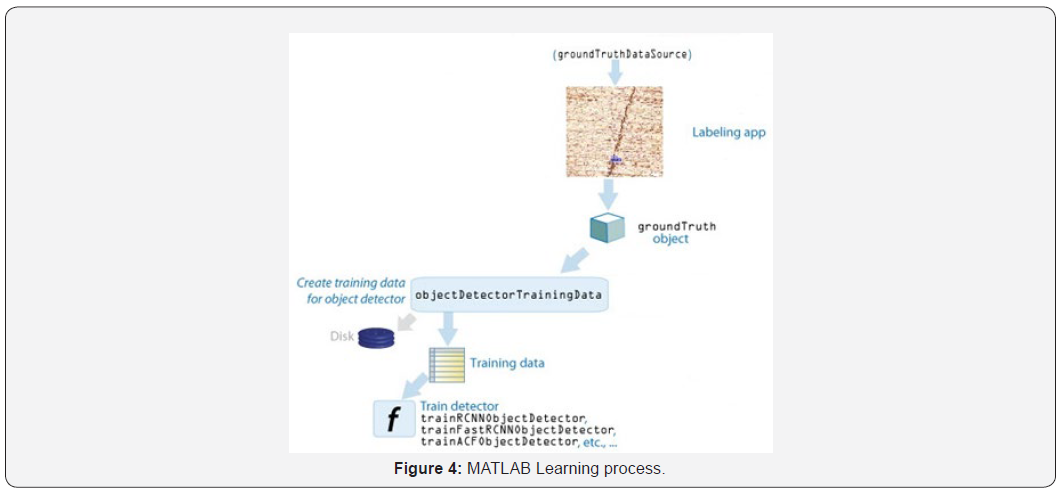

Object Detector Training Data Function

Using MATLAB, the Image Labeler app can be used to localize the ROI (Max. Depth Region). Then Ground Truth Data can be used to create automatic algorithm training data using the object Detector Training Data Function. Figure 4 shows the proposed learning process.

Expected Outcome

The learning technique is expected to autonomously localize the maximum depth of cracks based on captured 2D images only without the need of any additional measurements.

References

- Hesham SM, Yasser MS, Mohamed A, Taher HA (2018) Depth estimation of steel cracks using laser and image processing techniques. Alexandria Engineering Journal 57(4): 2713-2718.

- Hesham SM, Yasser SM, Mohamed A, Taher HA (2018) Crack Width Estimation Using Feed and Cascade Forward Back Propagation Artificial Neural Networks. Key Engineering, Materials Journal 786: 293-301.

- Suguru Y, Takashi M (2017) Development of an Automatic Detector of Cracks in Concrete Using Machine Learning. Procedia Engineering 171: 1250-1255.

- Young JC, Wooram C, Oral B(2017) Deep learning-based crack damage detection using convolutional neural networks. Computer Aided Civil and Infrastructure Engineering 32(5): 361-378.

- Zhang L, Yang F, Daniel ZY, Julie ZY (2016) Road crack detection using deep convolutional neural network. In Proceedings of IEEE Interna-tional Conference on Image Processing (ICIP).